吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (1): 163-171.doi: 10.13229/j.cnki.jdxbgxb20190968

• 材料科学与工程 • 上一篇

矩形截面型材三维多点拉弯成形减薄率

梁继才1,2( ),廖雁飞1,2,滕菲3(

),廖雁飞1,2,滕菲3( ),梁策1,4,李义1,4

),梁策1,4,李义1,4

- 1.吉林大学 材料科学与工程学院,长春 130022

2.吉林大学 辊锻工艺研究所,长春 130022

3.长春大学 机械与车辆工程学院,长春 130012

4.吉林大学 汽车材料教育部重点实验室,长春 130022

Rectangular section profile thinning rate of three-dimensional multi-point stretch bending process

Ji-cai LIANG1,2( ),Yan-fei LIAO1,2,Fei TENG3(

),Yan-fei LIAO1,2,Fei TENG3( ),Ce LIANG1,4,Yi LI1,4

),Ce LIANG1,4,Yi LI1,4

- 1.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

2.Roll Forging Institute,Jilin University,Changchun 130022,China

3.School of Mechanical and Vehicle Engineering,Changchun University,Changchun 130012,China

4.Key Laboratory of Automobile Materials,Ministry of Education,Jilin University,Changchun 130022,China

摘要:

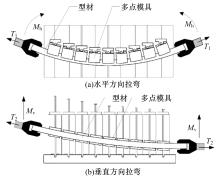

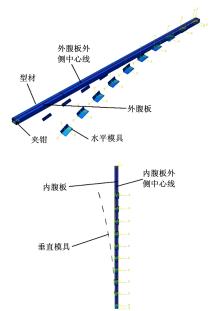

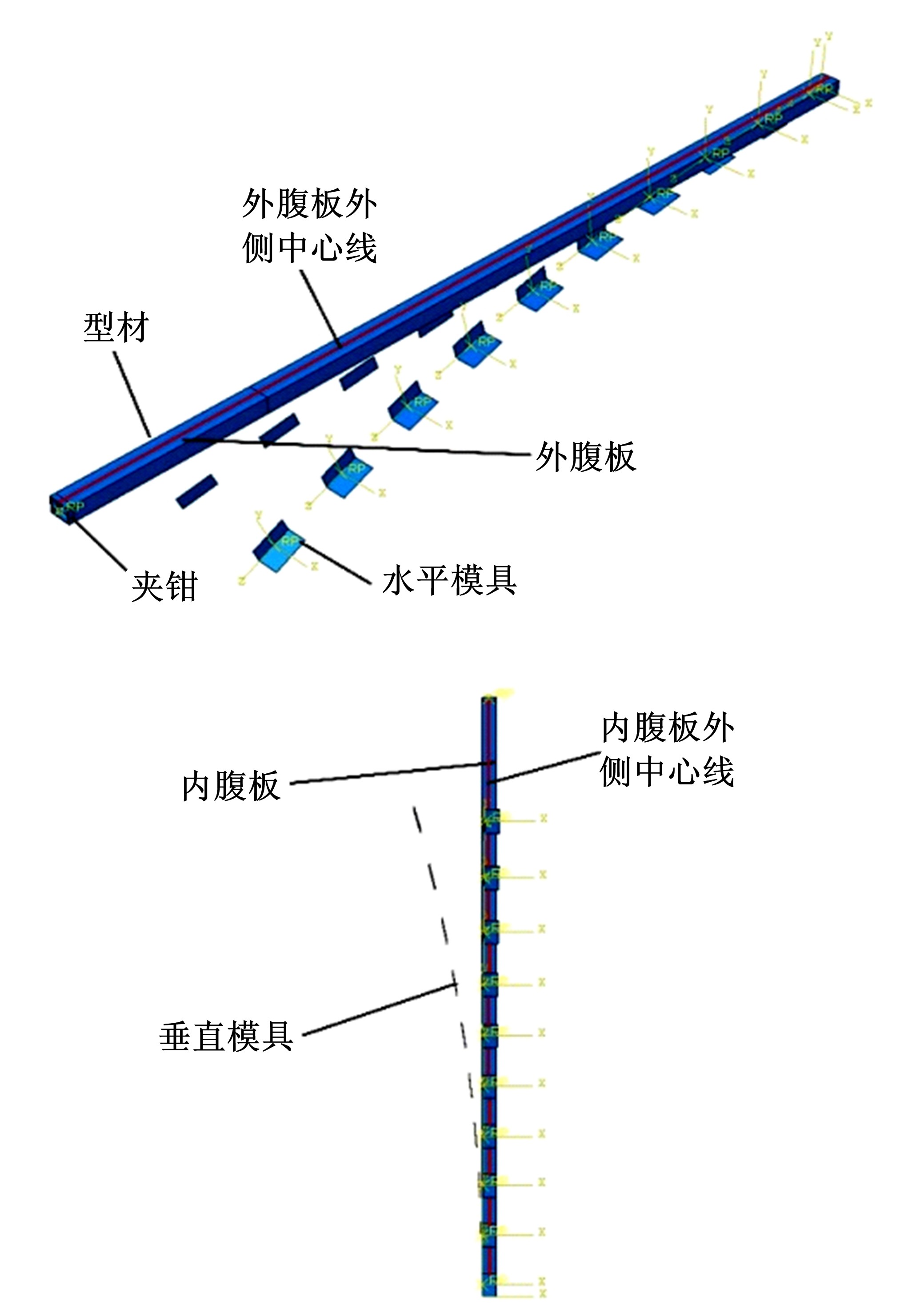

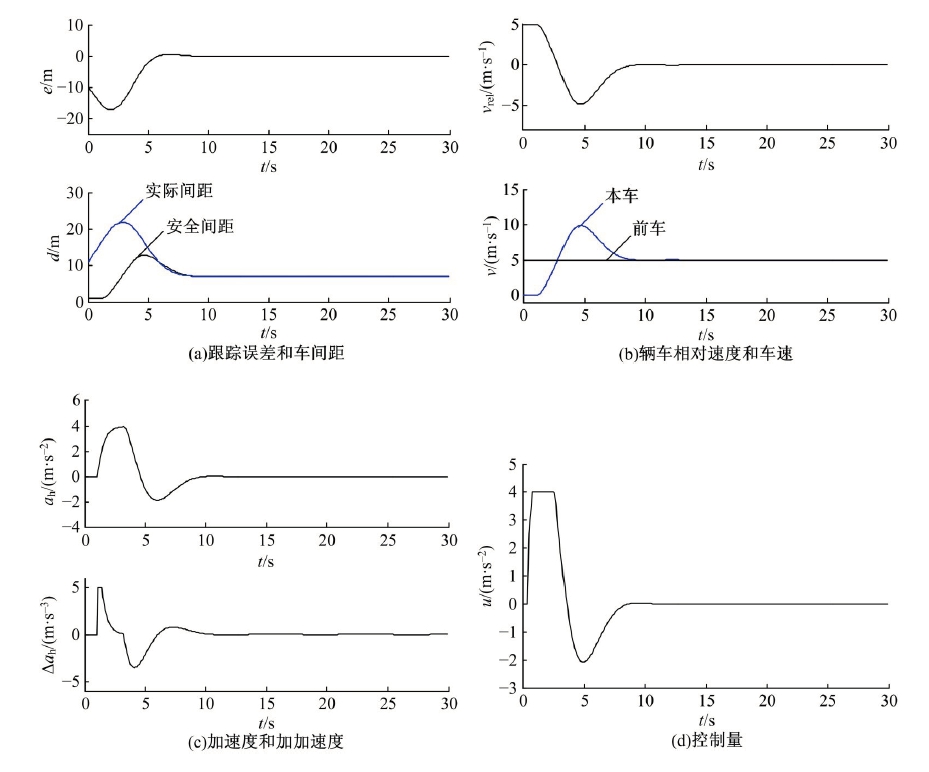

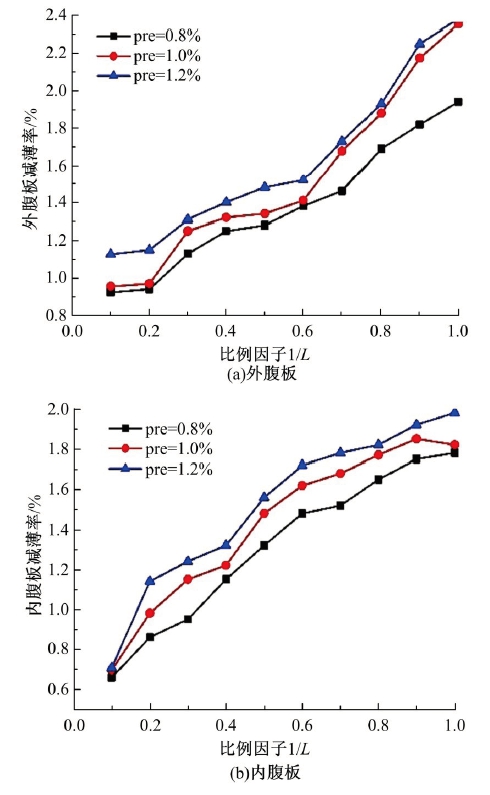

针对铝型材在加工过程中易出现的减薄缺陷,在自主研制的铝型材柔性三维拉弯装置上,进行多点柔性成形制件的减薄率研究。矩形截面型材三维多点拉弯变形后,外腹板与内腹板沿着型材长度方向减薄率的变化结果表明:成形过程中型材的外腹板与内腹板减薄率会从型材的对称中心沿着型材方向逐渐变大,外腹板的减薄率比内腹板的减薄率大;模具头体个数的变化使得外腹板的减薄率最大为1.682%,最小为1.317%,减薄率变化幅度为0.365%;内腹板减薄率最大为1.657%,最小为1.198%,变化幅度为0.459%,单元体个数是引起制件减薄率变化的主要加工参数。

中图分类号:

- TG356

| 1 | 滕菲. 铝型材柔性三维拉弯回弹预测及工艺优化[D]. 大连:大连理工大学材料科学与工程学院, 2015. |

| Teng Fei. Prediction and process optimization of flexible three-dimensional bending and bending of aluminum profiles [D]. Dalian: College of Materials Sciences and Engineering, Dalian University of Technology, 2015. | |

| 2 | 张学广, 贾明萌, 刘纯国, 等. 基于增量控制的型材拉弯轨迹设计及有限元仿真[J]. 吉林大学学报:工学版, 2019, 49 (4): 1272-1279. |

| Zhang Xue-guang, Jia Ming-meng, Liu Chun-guo, et al. Design and finite element simulation of profile bending trajectory based on incremental control[J]. Journal of Jilin University(Engineering and Technology Edition), 2019,49 (4):1272-1279. | |

| 3 | 郑楠, 贾彬彬, 王卫卫. 力-位移分控多点成形新工艺及其回弹控制机理[J]. 精密成形工程, 2017,9(4):25-30. |

| Zheng Nan, Jia Bin-bin, Wang Wei-wei. A novel forming technology for multi-point forming with individually controlled force-displacement and the mechanism of controlling springback[J]. Journal of Netshape Forming Engineering, 2017, 9(4):25-30. | |

| 4 | Gao S, Liang J C, Li Y, et al. Precision forming of the 3D curved structure parts in flexible multi-points 3D stretch-bending process[J]. International Journal of Advanced Manufacturing Technology, 2017, 95(1):1-9. |

| 5 | Gu Z W, Jia L, Li X, et al. Stretch bending defect control of L-section SUS301L stainless-steel components with variable contour curvatures[J]. Journal of Iron and Steel Research International,2019(26):1376-1384. |

| 6 | 林坚磊. 板材柔性压边多点成形工艺及其数值模拟研究[D].长春:吉林大学材料科学与工程学院,2019. |

| Lin Jian-lei. Multi-point forming process and numerical simulation of flexible blank holder for sheet metal[D]. Changchun: College of Materials Sciences and Engineering, Jilin University, 2019. | |

| 7 | 张昊晗. 多辊下压式柔性拉形过程及其数值模拟研究[D].长春:吉林大学材料科学与工程学院,2011. |

| Zhang Hao-han. Research on the multi-roller pressing flexible drawing process and its numerical simulation[D]. Changchun: College of Materials Sciences and Engineering, Jilin University, 2011. | |

| 8 | 何芯,周佳,李落星,等.镁合金薄壁空心型材挤压壁厚减薄问题的有限元分析及解决方案[J]. 塑性工程学报,2010,17(2):62-67. |

| He Xin, Zhou Jia, Li Luo-xing, et al. Finite element analysis and solution of extrusion wall thickness reduction of magnesium alloy thin wall hollow profile[J]. Journal of Plasticity Engineering, 2010, 17(2):62-67. | |

| 9 | 李义, 梁策, 于佳奇, 等. 管材多点柔性拉弯成形制件形状误差研究[J]. 华南理工大学学报:自然科学版, 2018, 46 (7): 24-29. |

| Li Yi, Liang Ce, Yu Jia-qi, et al. Study on shape error of multi-point flexible bending and forming parts of pipe[J]. Journal of South China University of Technology (Natural Science Edition), 2018, 46(7): 24-29. | |

| 10 | 高嵩, 于鹏, 梁继才, 等. 型材三维拉弯成形数值模拟及回弹特性研究[J]. 锻压技术, 2018, 43(6): 53-59. |

| Gao Song, Yu Peng, Liang Ji-cai, et al. Study on numerical simulation and springback characteristics of three-dimensional stretch forming of profiles[J]. Forging & Stamping Technology, 2018, 43(6): 53-59. | |

| 11 | 蔡中义, 张海明, 李光俊, 等. 多点拉形数值模拟及模具型面补偿方法[J]. 吉林大学学报:工学版, 2008, 38(2): 329-333. |

| Cai Zhong-yi, Zhang Hai-ming, Li Guang-jun, et al. Numerical simulation of multi-point drawing and mold profile compensation method[J]. Journal of Jilin University(Engineering and Technology Edition), 2008, 38(2): 329-333. | |

| 12 | 李小强, 杨永真, 李东升, 等. 型材数控拉弯装备技术研究进展[J]. 锻压技术, 2017, 42(4): 1-7, 13. |

| Li Xiao-qiang, Yang Yong-zhen, Li Dong-sheng, et al. Research progress in numerical control bending equipment technology of profiles[J]. Forging & Stamping Technology, 2017, 42(4): 1-7, 13. | |

| 13 | 梁继才, 李义. 型材多点拉弯成形制件的形状偏差控制[J]. 华南理工大学学报:自然科学版, 2016, 44(7): 29-33. |

| Liang Ji-cai, Li Yi. Shape deviation control of multi-point bending and forming parts of profiles[J]. Journal of South China University of Technology (Natural Science Edition), 2016, 44(7): 29-33. | |

| 14 | 李义, 梁继才, 滕菲, 等. 型材多点拉弯成形模具型面的分段补偿迭代方法[J]. 吉林大学学报:工学版, 2016, 46(6): 1961-1966. |

| Li Yi, Liang Ji-cai, Teng Fei, et al. A piecewise compensation iterative method for profile drawing of multi-point drawing and forming of profiles[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(6): 1961-1966. | |

| 15 | 滕菲, 刘博, 张万喜, 等. 柔性三维拉弯成形工艺稳健设计[J]. 吉林大学学报:工学版, 2015, 45(5): 1481-1487. |

| Teng Fei, Liu Bo, Zhang Wan-xi, et al. The robust design of flexible three-dimensional bending and forming process[J]. Journal of Jilin University(Engineering and Technology Edition), 2015, 45(5): 1481-1487. | |

| 16 | 林祥烽. 铝型材三维拉弯构件成形精度与BP神经网络回弹模型的研究[D]. 长春:吉林大学材料科学与工程学院, 2019. |

| Lin Xiang-feng. Study on forming accuracy of three-dimensional bending members of aluminum profiles and springback model of BP neural network[D]. Changchun:College of Materials Sciences and Engineering,Jilin University, 2019. |

| [1] | 付文智, 刘晓东, 王洪波, 闫德俊, 刘晓莉, 李明哲, 董玉其, 曾振华, 刘桂彬. 关于1561铝合金曲面件的多点成形工艺[J]. 吉林大学学报(工学版), 2017, 47(6): 1822-1828. |

| [2] | 程艳艳, 李明哲, 邢健. 不同单元形式对多点模具柔性拉伸成形质量的影响[J]. 吉林大学学报(工学版), 2016, 46(5): 1552-1557. |

| [3] | 滕菲, 刘博, 张万喜, 高嵩. 柔性三维拉弯成形工艺稳健设计[J]. 吉林大学学报(工学版), 2015, 45(5): 1481-1487. |

| [4] | 高嵩, 梁继才, 陈广义, 魏志勇, 滕菲. 三维拉弯柔性成形装备中单元体快速调形技术[J]. 吉林大学学报(工学版), 2014, 44(6): 1723-1728. |

| [5] | 李任君, 李明哲, 薛鹏飞, 蔡中义, 邱宁佳. 板材曲面柔性轧制方法[J]. 吉林大学学报(工学版), 2013, 43(06): 1529-1535. |

| [6] | 曹鋆汇, 付文智, 李明哲, 彭赫力. 高分子板材多点热成形中的压痕及其影响因素[J]. 吉林大学学报(工学版), 2013, 43(06): 1536-1540. |

| [7] | 刘志卫, 李明哲, 韩奇钢. 具有防皱功能的多点成形工艺数值模拟[J]. , 2012, 42(05): 1208-1213. |

| [8] | 马顺利,李明哲,孙刚,李湘吉,钱直睿 . 拼焊板多点成形过程的数值模拟[J]. 吉林大学学报(工学版), 2008, 38(02): 334-0339. |

| [9] | 孙刚,李明哲,李湘吉,金文姬,杨铁男 . 柔性和刚性压边方式防止薄板多点 成形拉裂的对比分析 [J]. 吉林大学学报(工学版), 2007, 37(05): 1101-1105. |

| [10] | 钱直睿,李明哲,孙刚,谭富星,金文姬 . 球形面多道次多点成形的数值模拟[J]. 吉林大学学报(工学版), 2007, 37(02): 338-0342. |

| [11] | 张全发,李明哲,孙刚,葛欣 . 板材多点成形时柔性压边与刚性压边方式的比较[J]. 吉林大学学报(工学版), 2007, 37(01): 25-30. |

| [12] | 谭富星;李明哲 ;钱直睿;袁媛. 钛合金颅骨修复体的多点成形数值模拟 [J]. 吉林大学学报(工学版), 2006, 36(06): 851-0855. |

| [13] | 郝瑞霞,付文智,李明哲 . 分段多点成形技术及数值模拟[J]. 吉林大学学报(工学版), 2006, 36(05): 723-0726. |

| [14] | 付文智,李明哲,邓玉山. 多点成形压力机的调形方式[J]. 吉林大学学报(工学版), 2005, 35(03): 282-286. |

| [15] | 宋雪松, 蔡中义, 李明哲. 板材多点成形过程中成形力的数值模拟[J]. 吉林大学学报(工学版), 2004, (2): 226-231. |

|

||