吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (2): 739-748.doi: 10.13229/j.cnki.jdxbgxb20191083

• 农业工程·仿生工程 • 上一篇

青饲玉米收获机械切碎装置参数优化试验

薛钊1,2( ),付君1,2(

),付君1,2( ),陈志2,3,王锋德3,韩少平4,任露泉1,2

),陈志2,3,王锋德3,韩少平4,任露泉1,2

- 1.吉林大学 工程仿生教育部重点实验室,长春 130022

2.吉林大学 生物与农业工程学院,长春 130022

3.中国农业机械化科学研究院,北京 100083

4.甘肃省机械科学研究院有限责任公司,兰州 730030

Optimization experiment on parameters of chopping device of forage maize harvester

Zhao XUE1,2( ),Jun FU1,2(

),Jun FU1,2( ),Zhi CHEN2,3,Feng-de WANG3,Shao-ping HAN4,Lu-quan REN1,2

),Zhi CHEN2,3,Feng-de WANG3,Shao-ping HAN4,Lu-quan REN1,2

- 1.Key Laboratory of Bionic Engineering, Ministry of Education, Jilin University, Changchun 130022, China

2.College of Biological and Agricultural Engineering, Jilin University, Changchun 130022, China

3.China Academy of Agricultural Mechanizaiton Sciences, Beijing 100083, China

4.Gansu Institute of Mechanical Science Co. Ltd. , Lanzhou 730030, China

摘要:

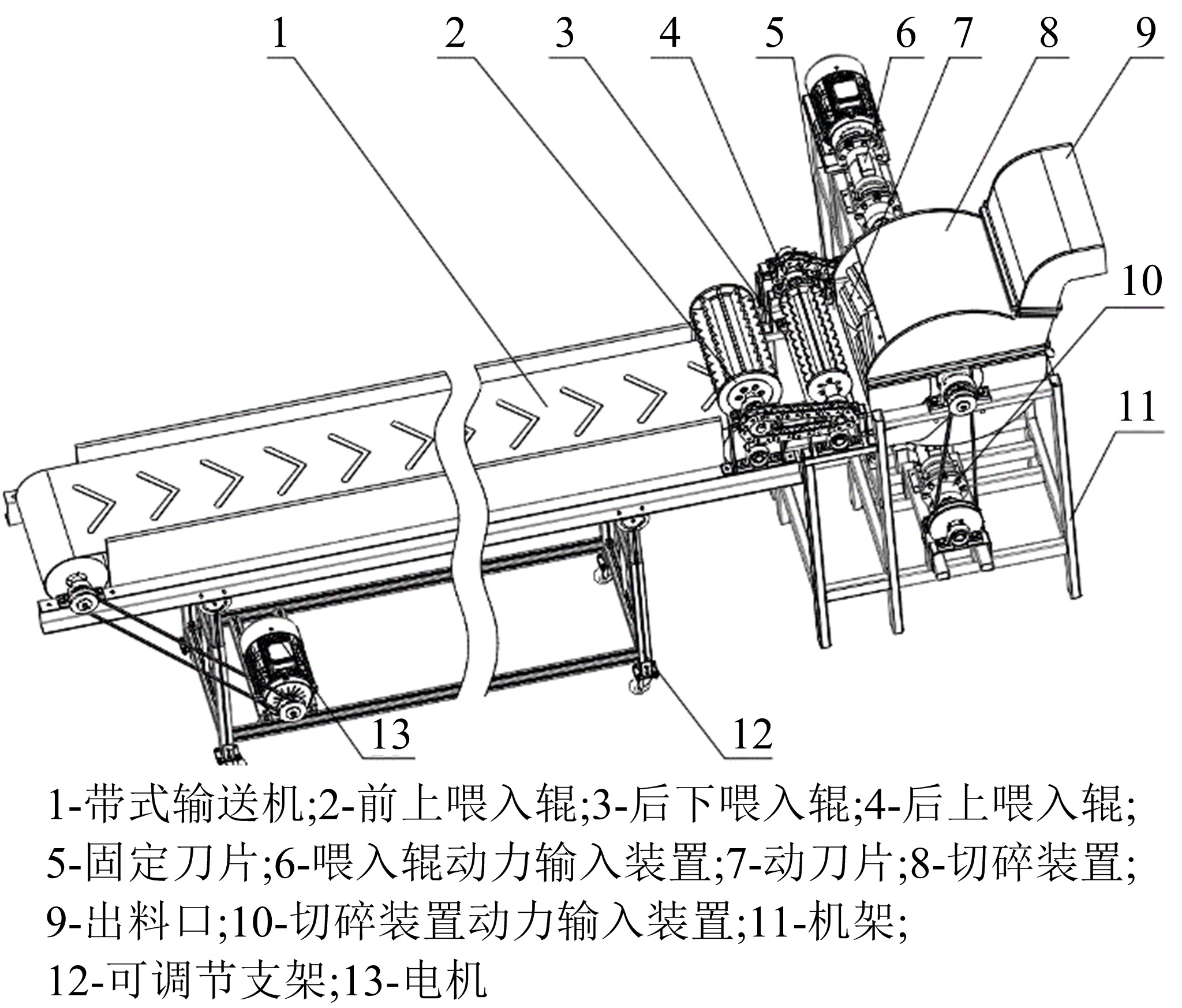

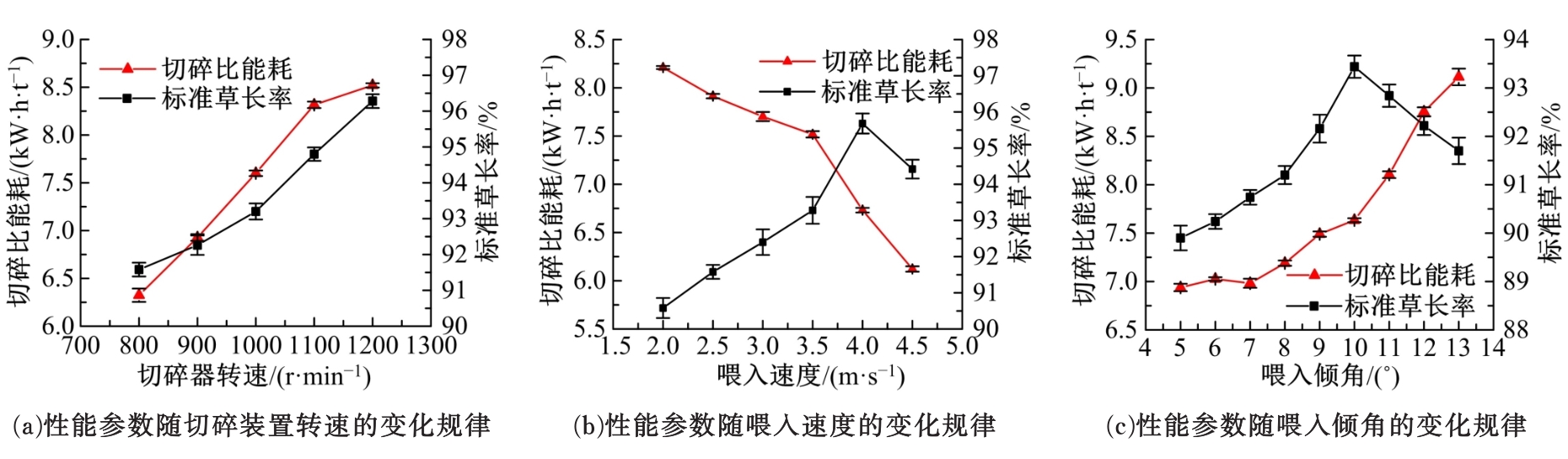

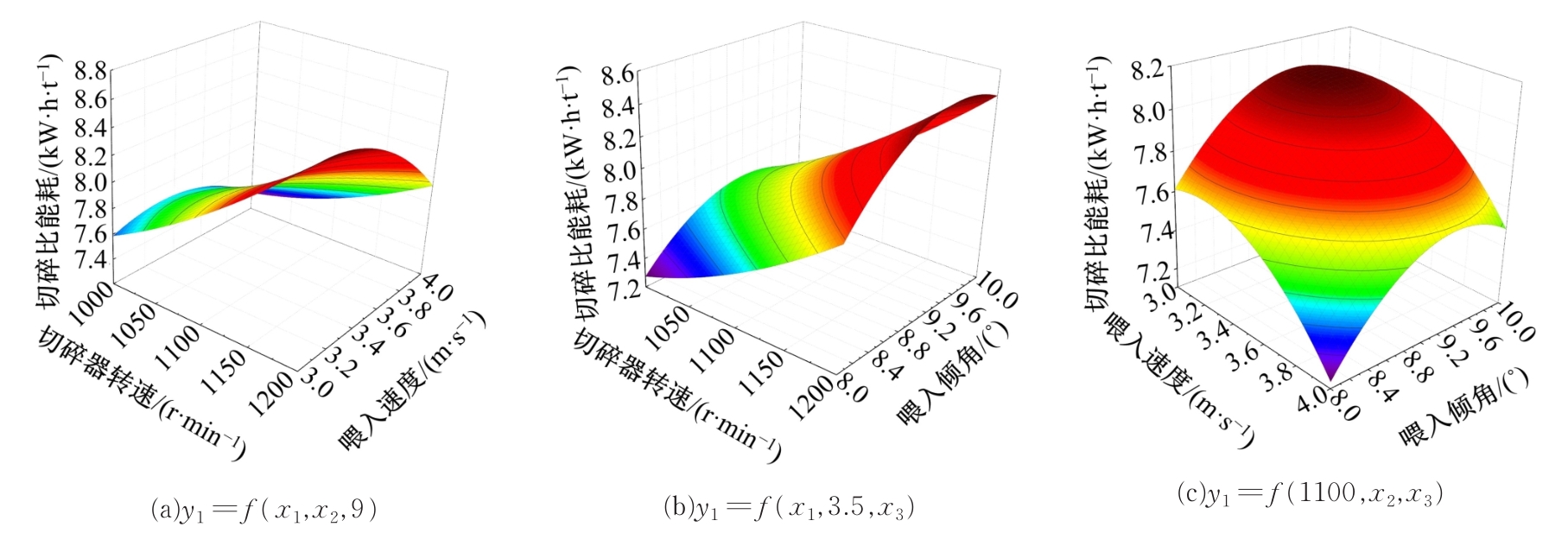

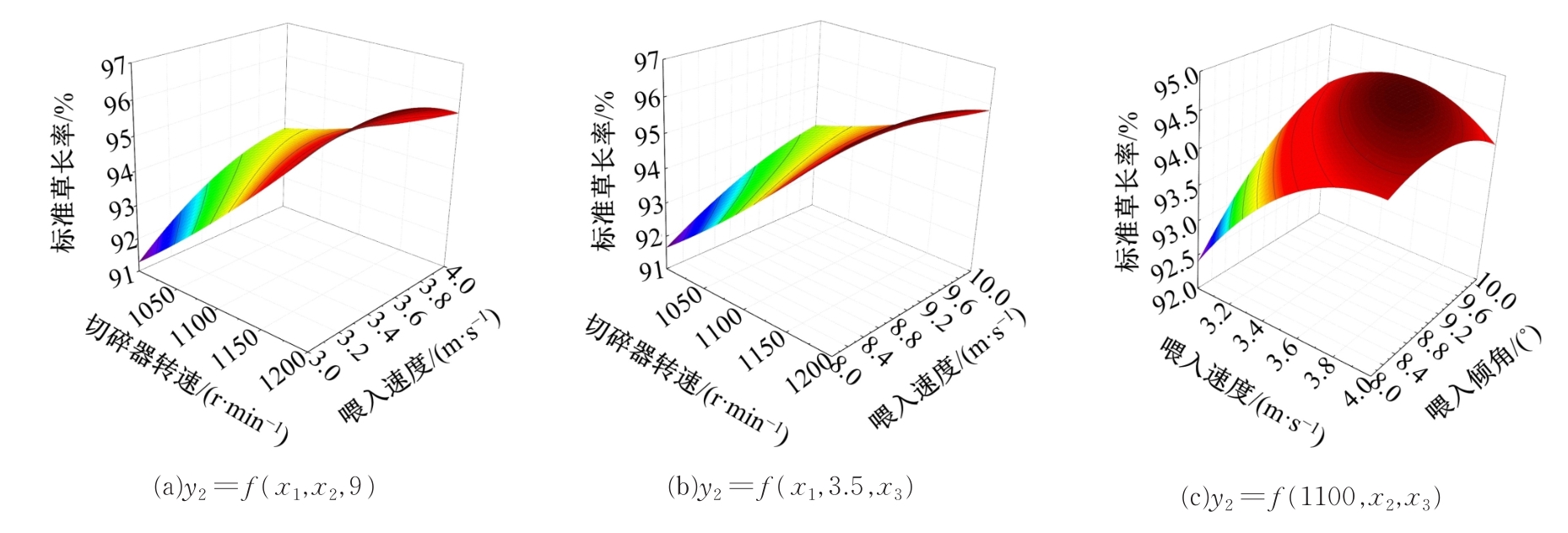

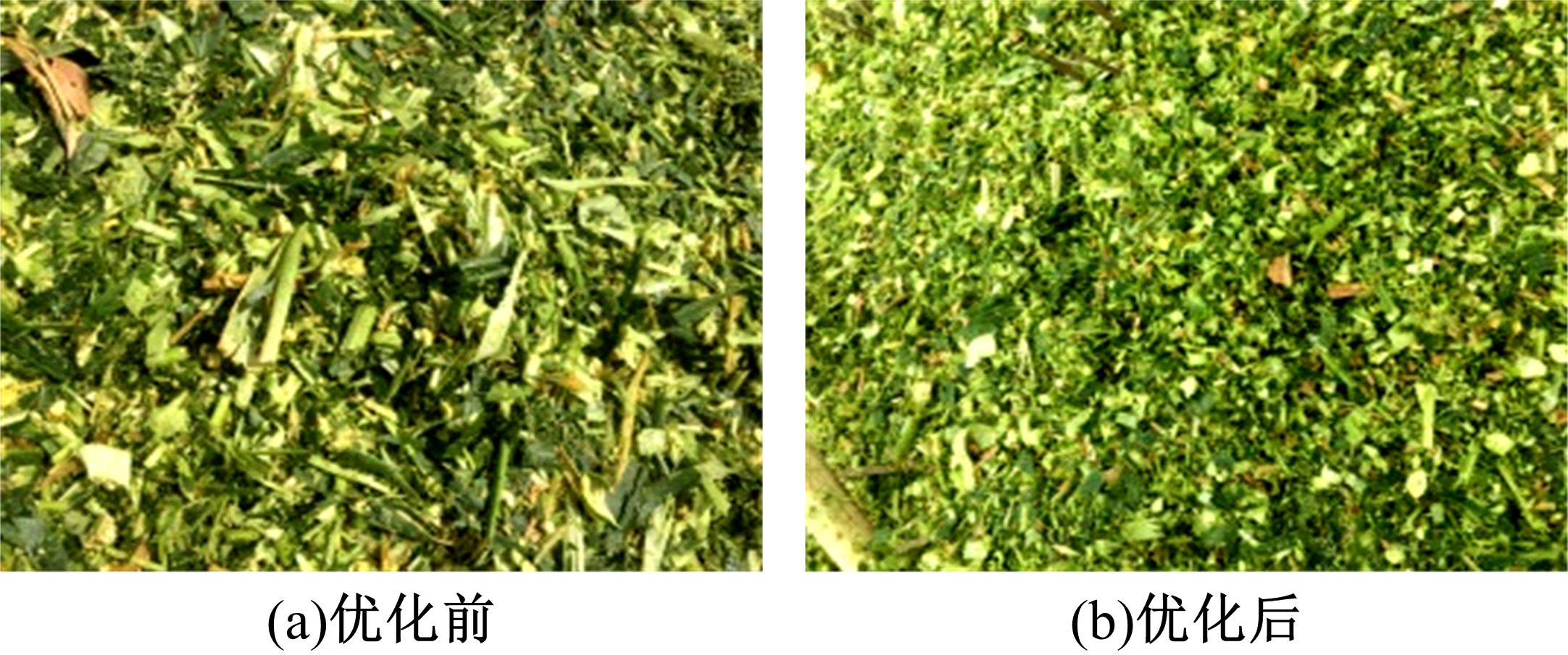

针对青饲玉米收获机械作业能耗大、切碎质量差的问题,利用自制青饲玉米收获机切碎试验台开展作业参数优化试验,分析作业参数对作业能耗和切碎质量的影响规律。以切碎比能耗、标准草长率为主要性能指标,切碎装置转速、喂入速度和喂入倾角为试验因素,设计单因素试验,确定各试验因素的较优水平区间;通过正交试验,建立各因素与指标之间的数学回归模型,探究各因素对指标的影响规律。试验结果表明:切碎比能耗最小时的最优作业参数组合如下:切碎器转速为1 005 r/min,喂入速度为4 m/s,喂入倾角为8.4°;标准草长率达到最高时的最优组合如下:切碎器转速为1 200 r/min,喂入速度为3.5 m/s,喂入倾角为8.5°。综合优化得到影响切碎作业性能的综合最优组合如下:切碎器转速为1 200 r/min,喂入速度为4 m/s,喂入倾角为 8°。田间验证试验表明:切碎比能耗相对误差为5.23%,标准草长率相对误差为3.15%,最优作业参数综合表现良好,且回归模型可靠。

中图分类号:

- S225.5

| 1 | FAOSTAT. Food and agriculture organization of the united nations statistics[EB/OL]. [2018-08-10]. |

| 2 | 梁荣庆, 张翠英, 李青江, 等. 4QG-2型青贮收获机切碎揉搓装置的设计[J]. 农机化研究, 2018, 40(11): 99-104. |

| Liang Rong-qing, Zhang Cui-ying, Li Qing-jiang, et al. Design of chopping and rubbing device of 4QG-2 silage harvester[J]. Journal of Agricultural Mechanization Research, 2018, 40(11): 99-104. | |

| 3 | 薛飞. 自走式青饲料收获机关键部件设计与仿真[D]. 秦皇岛: 河北科技师范学院机电工程学院, 2017. |

| Xue Fei. Design and simulation of key componets of self-walking green fodder harvester[D]. Qinhuangdao: College of Mechanical and Electronic Engineering, Hebei Normal University of Science&Technology, 2017. | |

| 4 | 吴巧梅. 平板刀式滚筒切碎装置的参数的研究与优[D]. 咸阳: 西北农林科技大学机械与电子工程学院, 2010. |

| Wu Qiao-mei. Study and optimization of the parameter of slab cutter cylinder type shredding mechanism[D]. Xianyang: College of Mechanical and Electronic Engineering, Northwest A&F University, 2010. | |

| 5 | 任冬梅. 一种全齿轮传动青饲料收获机关键技术研究和设计[D]. 济南: 山东大学机械工程学院, 2017. |

| Ren Dong-mei. Research and design on all-gear transmission corn silage machine[D]. Jinan: College of Mechanical Engineering, Shandong University, 2017. | |

| 6 | 杨颖, 尚琴琴, 王英博, 等. 4QX-12型玉米青贮收获机的切碎性能分析与试验[J]. 农机化研究, 2017, 39(3): 42-46. |

| Yang Ying, Shang Qin-qin, Wang Ying-bo, et al. Chopped performance analysis and test on 4QX-12 silage maize harvester[J]. Journal of Agricultural Mechanization Research, 2017, 39(3): 42-46. | |

| 7 | O'Dogherty M J, Hubent J A, Dyson J, et al. A study of the physical and mechanical properties of wheat straw[J]. Journal of Agricultural Engineering Research, 1995, 62(2): 133-142. |

| 8 | O'Dogherty M J. A review of research on forage chopping[J]. Journal of Agricultural Engineering Research, 1982, 27(4): 267-289. |

| 9 | Ige M T, Finner M F. Particle movement through the cutterhead of a cylindrical type forage harvester[J]. Transactions of Asae, 1975, 18(6): 1017-1020. |

| 10 | Johnson P C, Clementson C L, Mathanker S K, et al. Cutting energy characteristics of miscanthus x giganteus stems with varying oblique angle and cutting speed[J]. Biosystems Engineering, 2012, 112(1): 42-48. |

| 11 | 吴子岳, 高焕文, 张晋国. 玉米秸秆切断速度和切断功耗的试验研究[J]. 农业机械学报, 2001, 32(2): 38-41. |

| Wu Zi-yue, Gao Huan-wen, Zhang Jin-guo. Study on cutting velocity and power requirementin a maize stalk chopping process[J]. Transactions of the Chinese Society for Agricultural Machinery, 2001, 32(2): 38-41. | |

| 12 | 万霖, 车刚, 汪春, 等. 4QZR-30型青贮饲料收获机设计与试验[J]. 农业机械学报, 2008, 39(3): 187-190. |

| Wan Lin, Che Gang, Wang Chun, et al. Design and experiment of 4QZR-30 forage harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(3): 187-190. | |

| 13 | McRandal D M, McNulty P B. Impact cutting behaviour of forage crops I. Mathematical models and laboratory tests[J]. Journal of Agricultural Engineering Research, 1978, 23(3): 313-328. |

| 14 | 魏元振, 李其昀, 曹树红, 等. 玉米植株受切运动规律试验分析[J]. 农业机械学报, 2012, 43(增刊1): 116-119, 145. |

| Wei Yuan-zhen, Li Qi-yun, Cao Shu-hong, et al. Experiment on motion law of being cutted maize stalk[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(Sup.1): 116-119, 145. | |

| 15 | 张宗玲, 韩增德, 李晓栋, 等. 玉米穗茎兼收割台切碎装置参数优化[J]. 农业机械学报, 2018, 49(增刊1): 265-274. |

| Zhang Zong-ling, Han Zeng-de, Li Xiao-dong, et al. Optimization of parameters for stalk chopper of corn harvester for reaping both corn stalk and spike[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(Sup.1): 265-274. | |

| 16 | Jamshidpouya M, Najafi G, Hashjin T T. Design, fabrication and evaluation of electric forage chopper with adjustable[J]. Journal of Agricultural Science and Technology, 2018, 20(5): 923-938. |

| 17 | 车刚, 万霖, 张伟, 等. 青贮饲料收获机实体设计与试验[J]. 农业机械学报, 2010, 41(2): 82-86. |

| Che Gang, Wan Lin, Zhang Wei, et al. Solid design and experiment of forage harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(2): 82-86. | |

| 18 | 吕金庆, 杨颖, 尚琴琴, 等. 玉米青贮收获机切碎性能试验研究[J]. 东北农业大学学报, 2016, 47(4): 102-108. |

| Jin-qing Lyu, Yang Ying, Shang Qin-qin, et al. Study on chopping performance of silage maize harvester[J]. Journal of Northeast Agricultural University, 2016, 47(4): 102-108. | |

| 19 | DG/T052-2019. 青饲料收获机[S]. |

| 20 | 任露泉. 试验设计及其优化[M]. 北京: 科学出版社, 2009. |

| 21 | 程超, 付君, 陈志, 等. 玉米籽粒收获机清选装置参数优化试验[J]. 农业机械学报, 2019, 50(7): 151-158. |

| Cheng Chao, Fu Jun, Chen Zhi, et al. Optimization experiment on cleaning device parameters of corn kernel harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(7): 151-158. | |

| 22 | 付乾坤, 付君, 陈志, 等. 秸秆捡拾打捆机振动去土作业参数优化[J]. 农业工程学报, 2018, 34(8): 26-33. |

| Fu Qian-kun, Fu Jun, Chen Zhi, et al. Optimization of working parameters on soil removal of stover pickupbaler by vibration[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(8): 26-33. | |

| 23 | 周杰,罗艳,王珣,等. 基于响应面的封头冲压成形工艺多目标优化[J]. 吉林大学学报: 工学版, 2016, 46(1): 205-212. |

| Zhou Jie, Luo Yan, Wang Xun, et al. Multi-objective optimization of stamping forming process of head based on response surface model [J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(1): 205-212. | |

| 24 | 于昭洋, 胡志超, 王海鸥, 等. 大蒜果秧分离机构参数优化及试验[J]. 农业工程学报, 2015, 31(1): 40-46. |

| Yu Zhao-yang, Hu Zhi-chao, Wang Hai-ou, et al. Parameters optimization and experiment of garlic picking mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(1): 40-46. | |

| 25 | 葛云, 张立新, 谷家伟, 等. 对辊式红花采收装置参数优化及试验[J]. 农业工程学报, 2015, 31(21): 35-42. |

| Ge Yun, Zhang Li-xin, Gu Jia-wei, et al. Parameter optimization and experiment of dual rollerharvesting device for safflower[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(21): 35-42. | |

| 26 | 王磊, 张宏文, 刘巧. 胶棒滚筒棉花采摘头采收性能试验[J]. 农业工程学报, 2016, 32(18): 35-41. |

| Wang Lei, Zhang Hong-wen, Liu Qiao. Test on harvest performance of cotton picking head with rubber-bar roller[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(18): 35-41. | |

| 27 | 曹卫彬, 连国党, 牛驰, 等. 梳夹式红花丝采摘头等高采收性能试验与参数优化[J]. 农业工程学报, 2018, 34(22): 36-44. |

| Cao Wei-bin, Lian Guo-dang, Niu Chi, et al. Harvest performance test and parameteroptimization of comb-type safflower-filaments picking head at same height[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(22): 36-44. | |

| 28 | 刘颖, 张凯, 于向军. 基于代理模型的中空轴式大型静压轴承多目标优化[J]. 吉林大学学报: 工学版,2017, 47(4): 1130-1137. |

| Liu Ying, Zhang Kai, Yu Xiang-jun.Multi-objective optimization of hydrostatic bearing of hollow shaft based on surrogate model [J]. Journal of Jilin University (Engineering and Technology Edition), 2017, 47(4): 1130-1137. |

| [1] | 付君,张屹晨,程超,陈志,唐心龙,任露泉. 刚柔耦合式小麦脱粒弓齿设计及试验[J]. 吉林大学学报(工学版), 2020, 50(2): 730-738. |

| [2] | 程超,付君,郝付平,陈志,周德义,任露泉. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报(工学版), 2020, 50(1): 351-360. |

| [3] | 程超,付君,唐心龙,陈志,任露泉. 振动形式对水稻脱出物界面粘附规律的影响[J]. 吉林大学学报(工学版), 2019, 49(4): 1228-1235. |

| [4] | 付君,钱志辉,尹维,王甲甲,任露泉. 小麦摩擦与拉伸性能[J]. 吉林大学学报(工学版), 2015, 45(2): 501-507. |

|

||