吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (5): 1628-1634.doi: 10.13229/j.cnki.jdxbgxb20200410

• 车辆工程·机械工程 • 上一篇

低速工况下渐开线圆柱直齿轮齿面粘着磨损计算

陈魏1( ),雷雨龙1,李兴忠1,付尧1(

),雷雨龙1,李兴忠1,付尧1( ),扈建龙2,侯利国1

),扈建龙2,侯利国1

- 1.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

2.吉林大学 青岛汽车研究院,山东 青岛 266100

Calculation of adhesive wear of involute cylindrical spur gear under low⁃speed conditions

Wei CHEN1( ),Yu-long LEI1,Xing-zhong LI1,Yao FU1(

),Yu-long LEI1,Xing-zhong LI1,Yao FU1( ),Jian-long HU2,Li-guo HOU1

),Jian-long HU2,Li-guo HOU1

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.Qingdao Automotive Research Institute,Jilin University,Qingdao 266100,China

摘要:

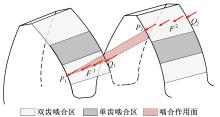

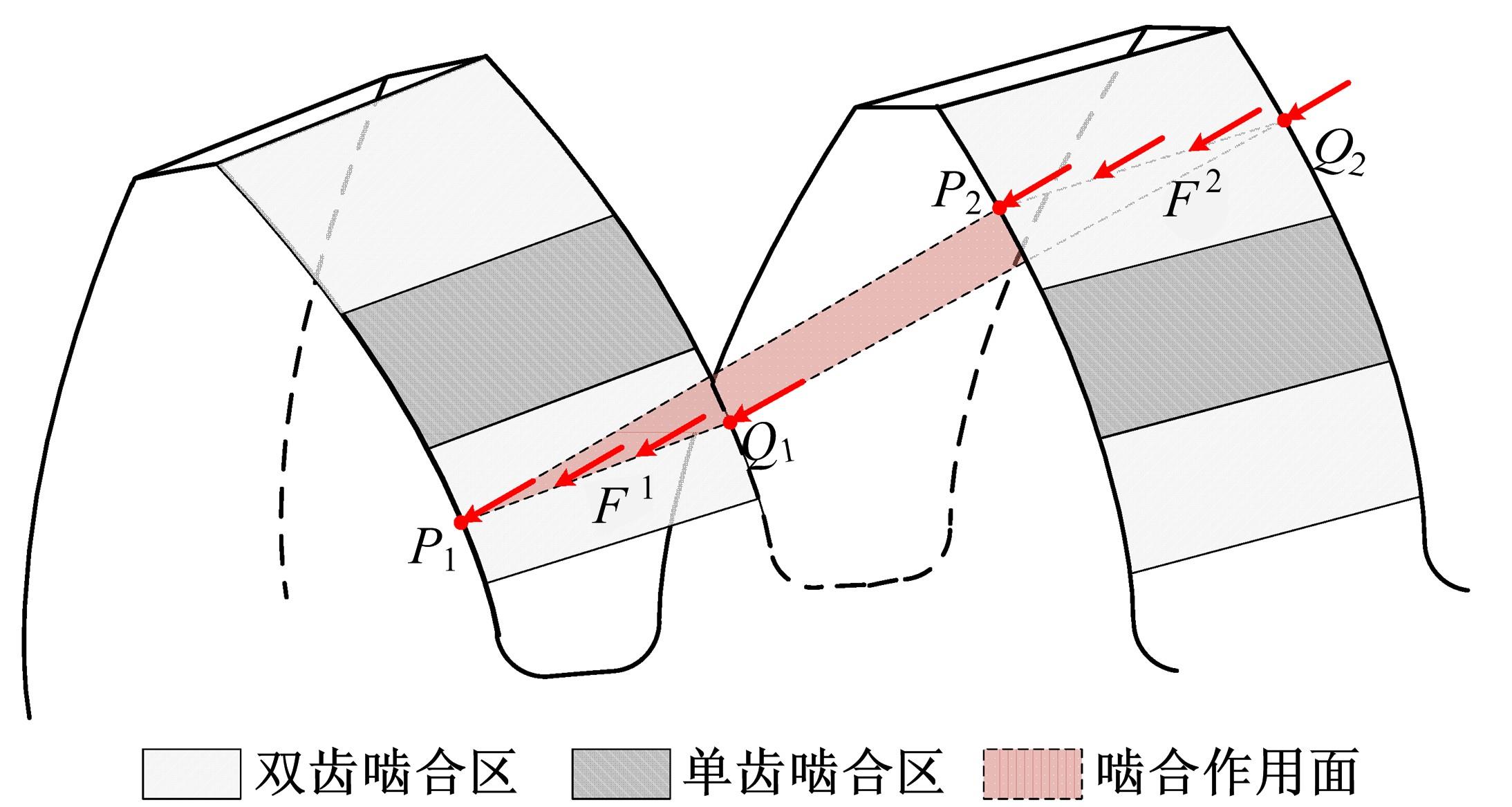

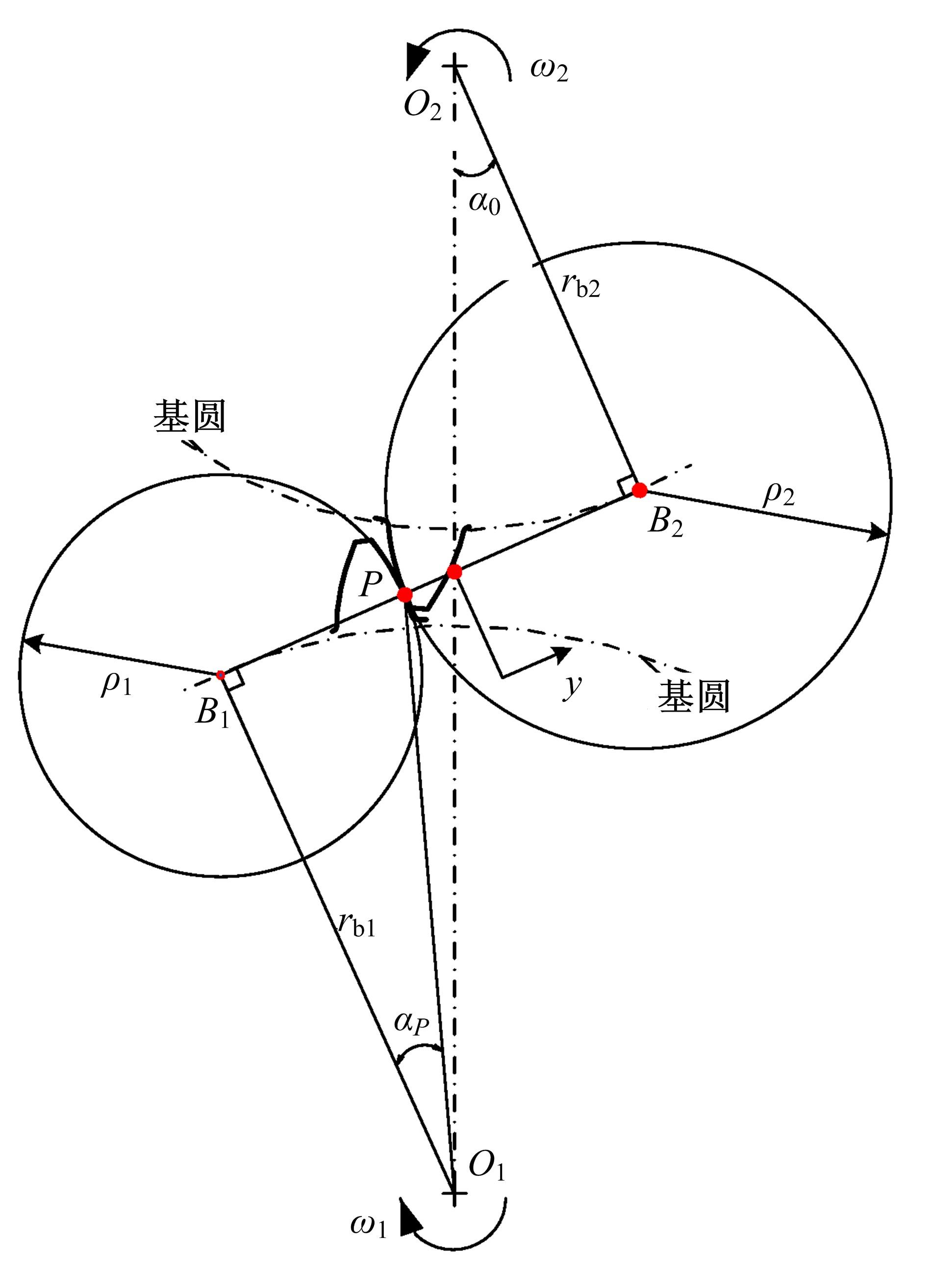

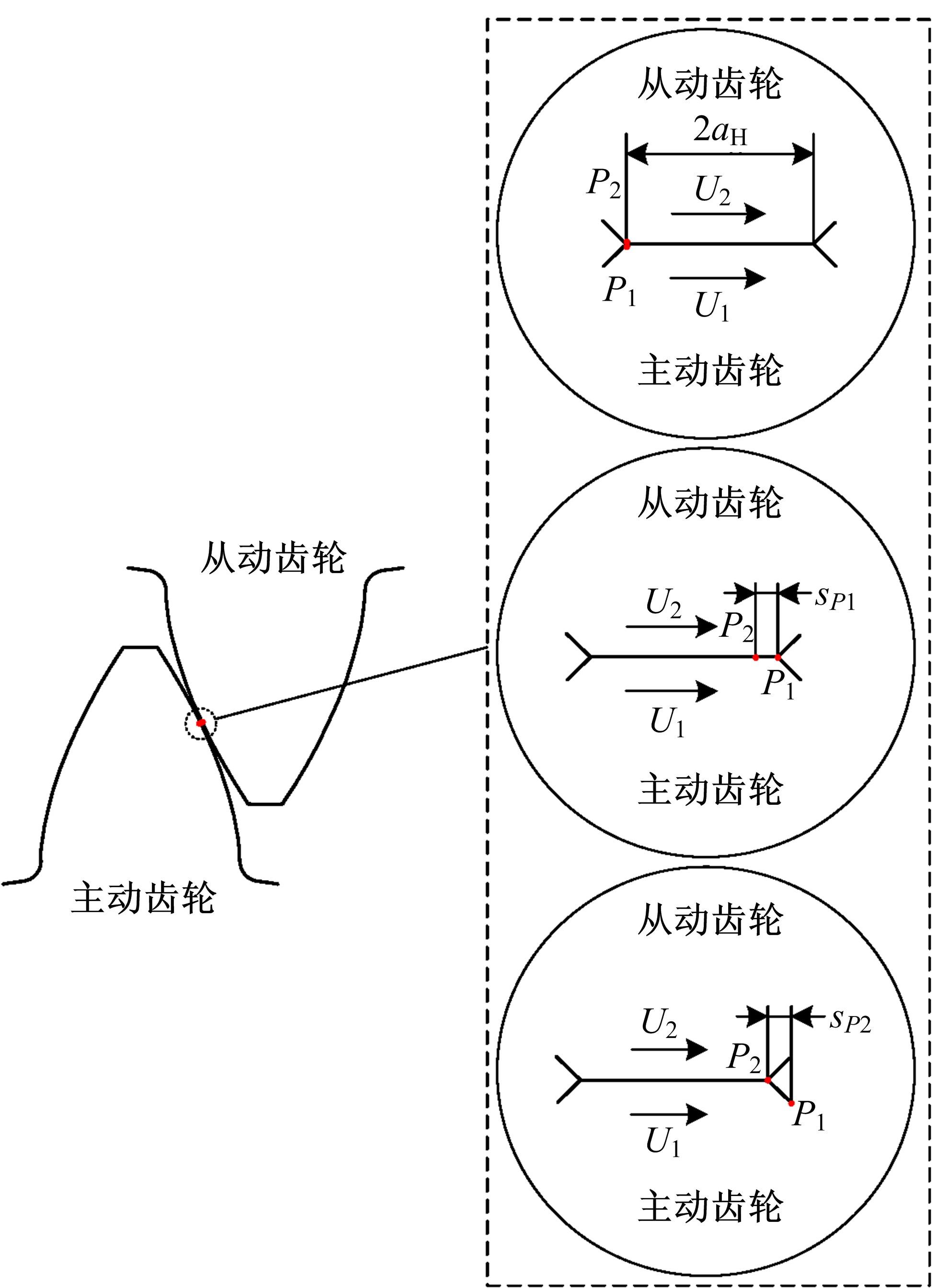

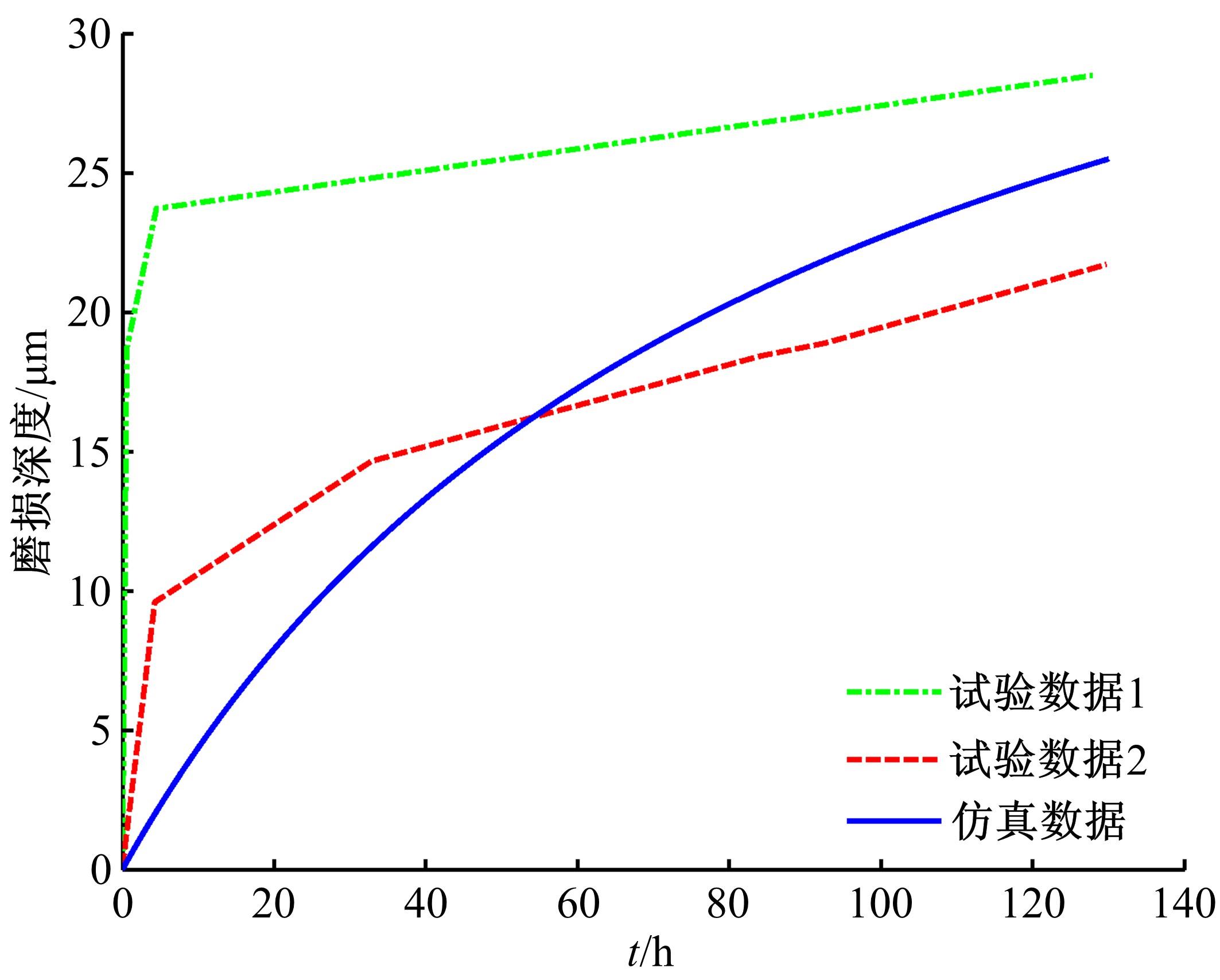

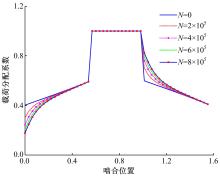

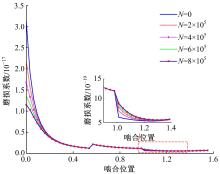

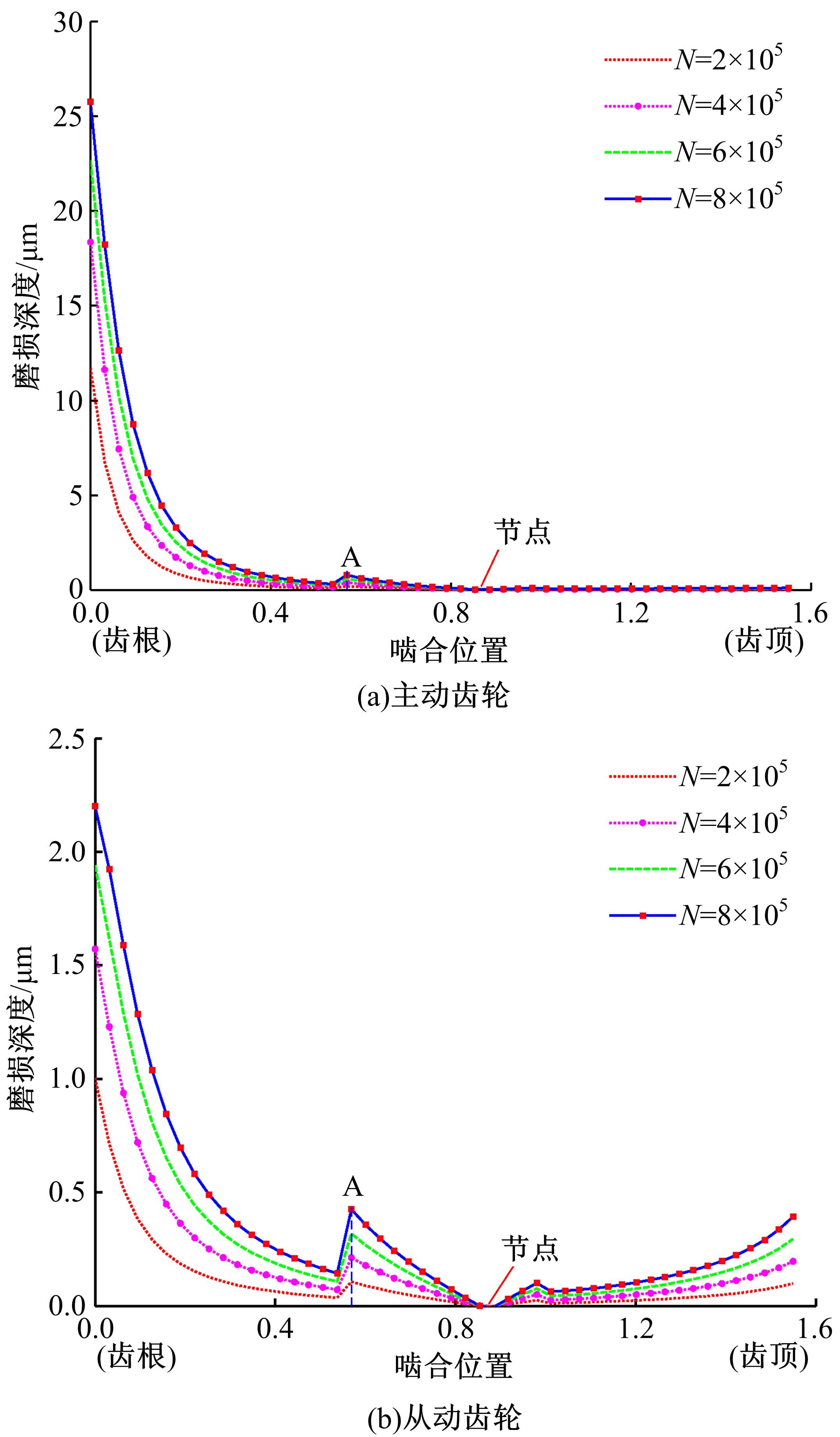

针对低速工况车辆传动系统中齿轮磨损影响系统寿命问题,基于考虑齿面磨损的载荷分配系数模型和Archard磨损模型,提出了一种适用于渐开线圆柱直齿轮的齿面粘着磨损计算方法。通过与试验数据对比,验证了模型的有效性。进而研究了齿面载荷和磨损因数等因素对齿面磨损深度影响规律,仿真结果表明:渐开线直齿轮节点附近磨损量几乎为零;小齿轮齿根附近齿面磨损最为严重;单、双齿啮合交替区域齿面磨损量相对于其他位置有突变。本文提出的齿面粘着磨损计算模型可以为低速工况齿轮磨损寿命的预测提供理论基础。

中图分类号:

- TH117.1

| 1 | Tunalioğlu M Ş, Tuç B. Theoretical and experimental investigation of wear in internal gears[J]. Wear, 2014, 309(1/2): 208-215. |

| 2 | 周长江, 雷玉英, 汪红兵, 等. 准静态与动态载荷下斜齿轮齿面粘着磨损计算[J]. 机械工程学报, 2018, 54(23): 10-22. |

| Zhou Chang-jiang, Lei Yu-ying, Wang Hong-bing, et al. Calculation of adhesive wear of helical gear tooth surfaces under quasi-static and dynamic loads[J]. Journal of Mechanical Engineering, 2018, 54(23): 10-22. | |

| 3 | Ding H. Dynamic wear models for gear systems[D]. Ohio: Graduate School, Ohio State University, 2007. |

| 4 | Kuang J H, Lin A D. The effect of tooth wear on the vibration spectrum of a spur gear pair[J]. Journal of Vibration and Acoustics, 2001, 123(3): 311-317. |

| 5 | Choy F K, Polyshchuk V, Zakrajsek J J, et al. Analysis of the effects of surface pitting and wear on the vibration of a gear transmission system[J]. Tribology international, 1996, 29(1): 77-83. |

| 6 | Archard J F. Contact and rubbing of flat surfaces[J]. Journal of Applied Physics, 1953, 24(8): 981-988. |

| 7 | Bajpai P, Kahraman A, Anderson N E. A surface wear prediction methodology for parallel-axis gear pairs[J]. Journal Tribology, 2004, 126(3): 597-605. |

| 8 | Dhanasekaran S, Gnanamoorthy R. Gear tooth wear in sintered spur gears under dry running conditions[J]. Wear, 2008, 265(1): 81-87. |

| 9 | Park D, Kolivand M, Kahraman A. An approximate method to predict surface wear of hypoid gears using surface interpolation[J]. Mechanism and Machine Theory, 2014, 71: 64-78. |

| 10 | 王晓笋, 巫世晶, 陈杰, 等. 考虑动载荷与动态磨损系数的直齿轮传动系统动态磨损特性[J]. 中南大学学报: 自然科学版, 2014, 45(2): 408-413. |

| Wang Xiao-sun, Wu Shi-jing, Chen Jie, et al. Dynamic wear characteristics of spur gear transmission system considering dynamic load and dynamic wear coefficient[J]. Journal of Central South University (Natural Science Edition), 2014, 45(2): 408-413. | |

| 11 | 张建阁, 刘少军, 方特. 混合润滑下齿面磨损预测研究及试验验证[J]. 华南理工大学学报: 自然科学版, 2018, 46(2): 22-30. |

| Zhang Jian-ge, Liu Shao-jun, Fang Te. Research and experimental verification of tooth surface wear prediction under mixed lubrication[J]. Journal of South China University of Technology(Natural Science Edition), 2018, 46(2): 22-30. | |

| 12 | Flodin A. Wear investigation of spur gear teeth[J]. Tribotest, 2000, 7(1): 45-60. |

| 13 | Brandão J A, Cerqueira P, Seabra J H O, et al. Measurement of mean wear coefficient during gear tests under various operating conditions[J]. Tribology International, 2016, 102: 61-69. |

| 14 | Dhanasekaran S, Gnanamoorthy R. Gear tooth wear in sintered spur gears under dry running conditions[J]. Wear, 2008, 265(1/2): 81-87. |

| 15 | Chen Z, Shao Y. Mesh stiffness calculation of a spur gear pair with tooth profile modification and tooth root crack[J]. Mechanism and Machine Theory, 2013, 62: 63-74. |

| 16 | Põdra P, Andersson S. Wear simulation with the winkler surface model[J]. Wear, 1997, 207(1/2): 79-85. |

| 17 | 程功, 肖科, 王家序, 等. 混合润滑状态下齿轮接触刚度[J]. 吉林大学学报: 工学版, 2020, 50(2): 484-503. |

| Cheng Gong, Xiao Ke, Wang Jia-xu, et al. Gear contact stiffness under mixed lubrication status[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 484-503. | |

| 18 | Wang H, Zhou C, Lei Y, et al. An adhesive wear model for helical gears in line-contact mixed elastohydrodynamic lubrication[J]. Wear, 2019, 426: 896-909. |

| 19 | Priest M, Taylor C M. Automobile engine tribology—approaching the surface[J]. Wear, 2000, 241(2): 193-203. |

| 20 | Dowson D. Modelling of elastohydrodynamic lubrication of real solids by real lubricants[J]. Meccanica, 1998, 33(1): 47-58. |

| 21 | Janakiraman V, Li S, Kahraman A. An investigation of the impacts of contact parameters on wear coefficient[J]. Journal of Tribology, 2014, 136(3): 031602. |

| [1] | 郭震,于红英,滑忠鑫,赵娣. 刚性折纸机构运动分析及折叠过程仿真[J]. 吉林大学学报(工学版), 2020, 50(1): 66-76. |

| [2] | 朱伟,王传伟,顾开荣,沈惠平,许可,汪源. 一种新型张拉整体并联机构刚度及动力学分析[J]. 吉林大学学报(工学版), 2018, 48(6): 1777-1786. |

| [3] | 毛宇泽, 王黎钦. 鼠笼支撑一体化结构对薄壁球轴承承载性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1508-1514. |

|

||