吉林大学学报(工学版) ›› 2018, Vol. 48 ›› Issue (6): 1777-1786.doi: 10.13229/j.cnki.jdxbgxb20170879

一种新型张拉整体并联机构刚度及动力学分析

- 常州大学 机械工程学院,江苏 常州 213016

Stiffness and dynamics analysis of a new type of tensegrity parallel mechanism

ZHU Wei( ),WANG Chuan-wei,GU Kai-rong,SHEN Hui-ping,XU Ke,WANG Yuan

),WANG Chuan-wei,GU Kai-rong,SHEN Hui-ping,XU Ke,WANG Yuan

- School of Mechanical Engineering,Changzhou University,Changzhou 213016,China

摘要:

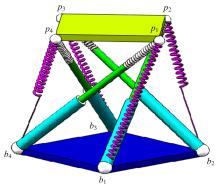

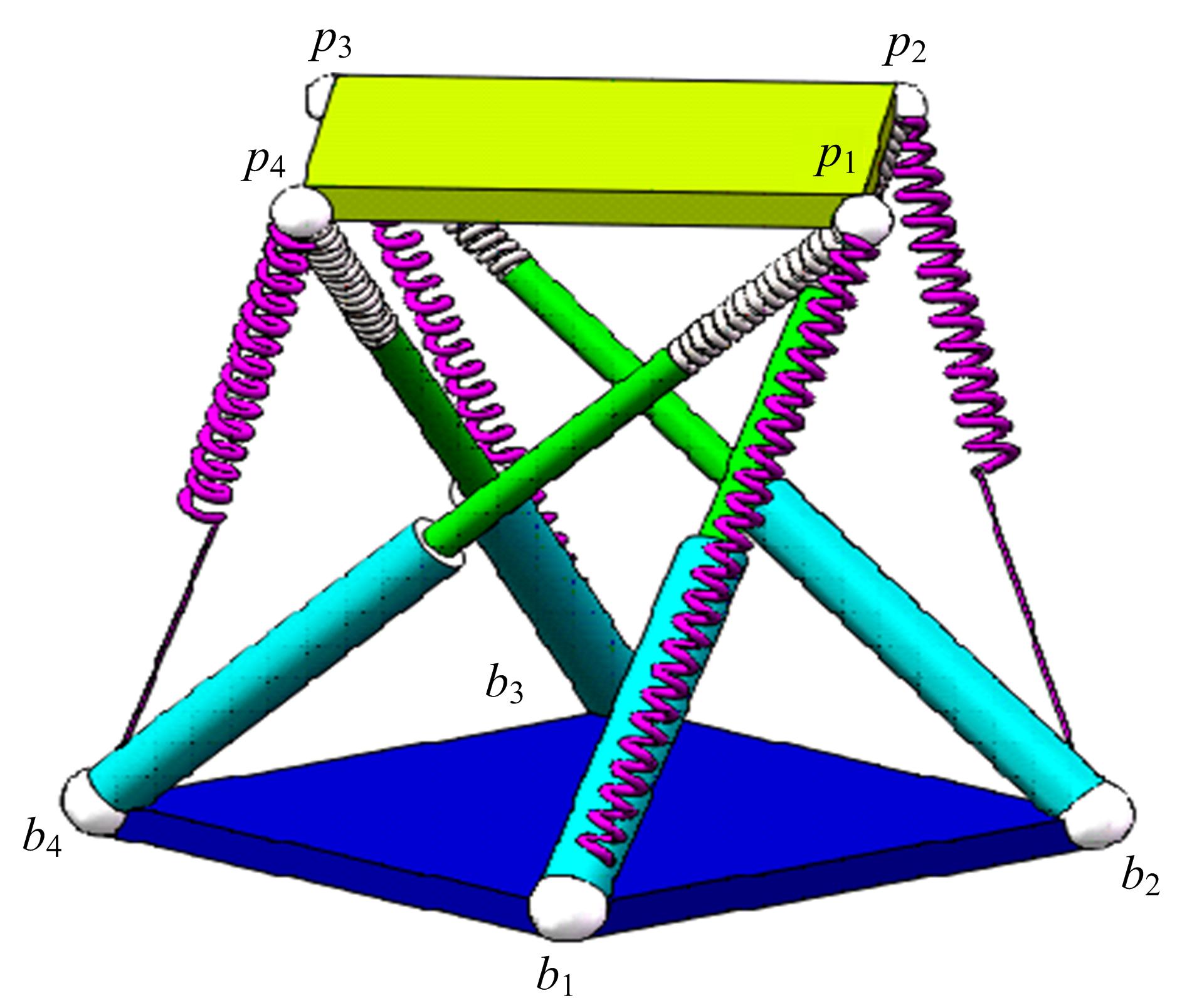

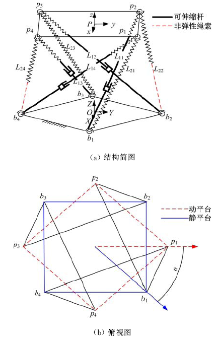

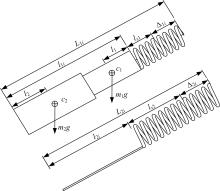

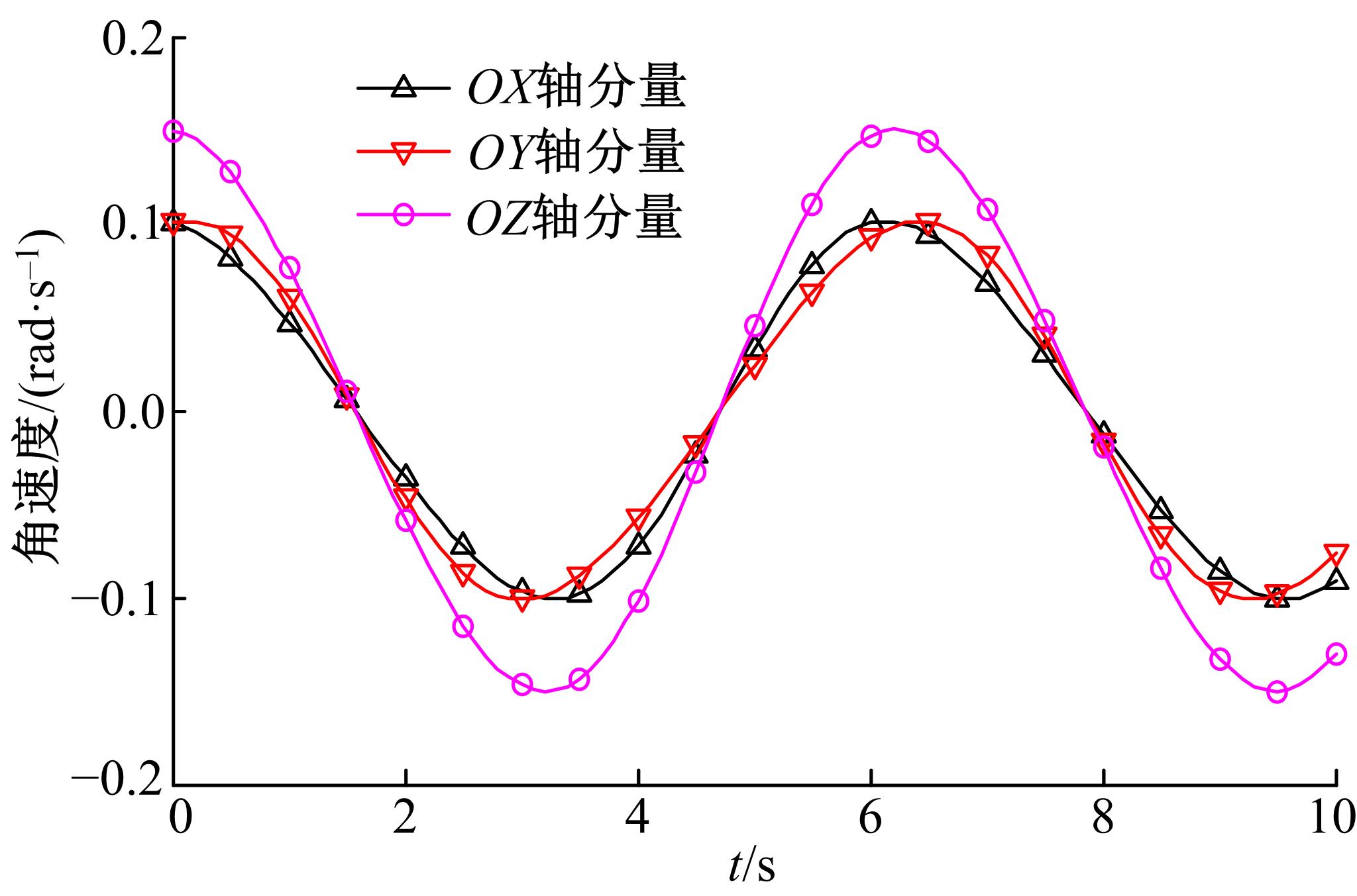

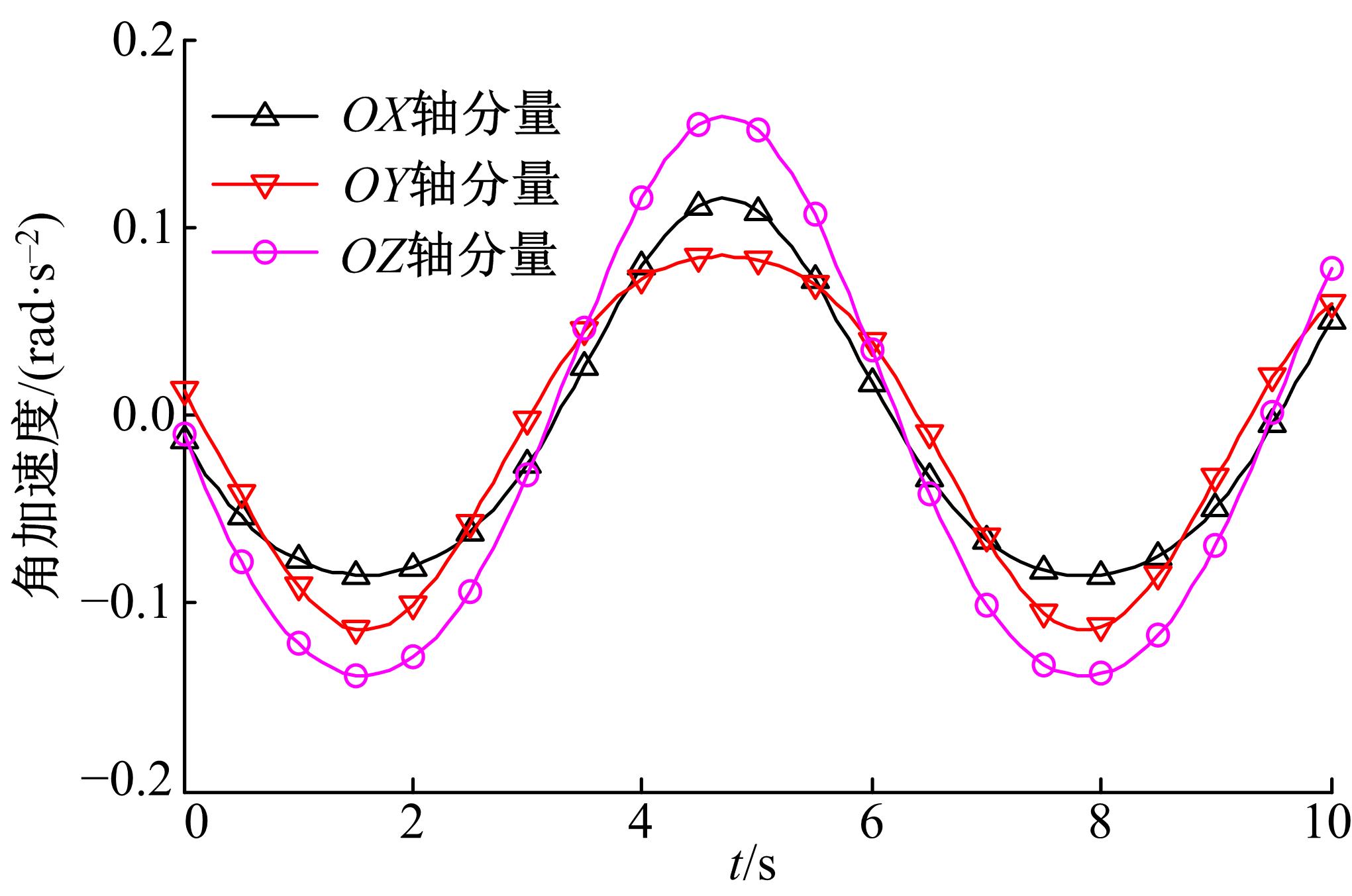

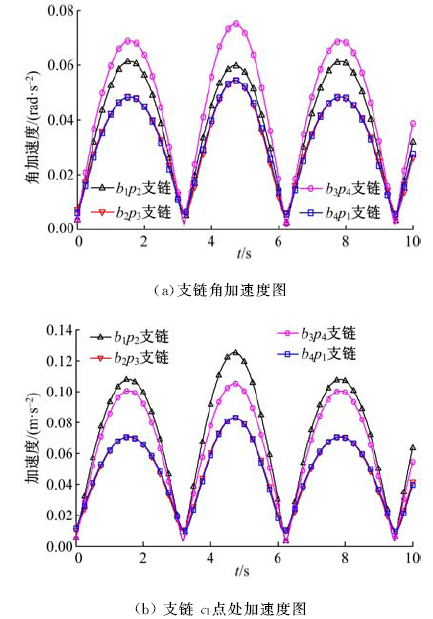

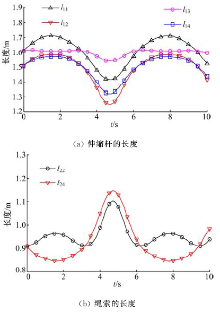

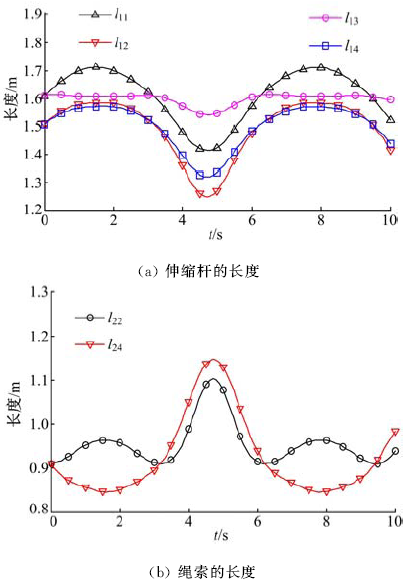

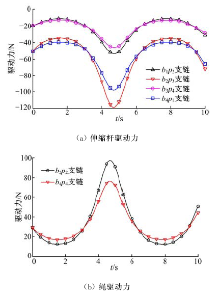

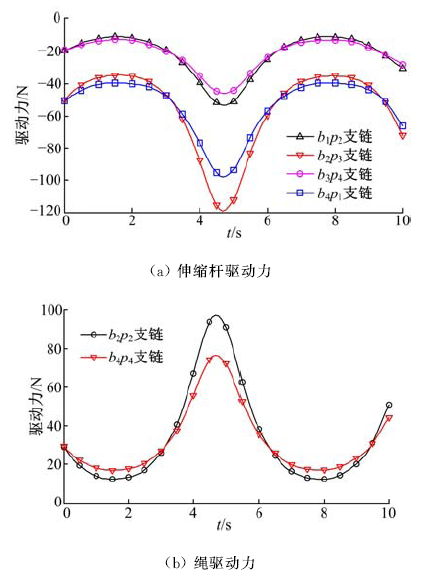

为了提高精密机械手的操作柔顺性,提出了一种四棱柱型六自由度张拉整体并联机构模型,由4条刚性驱动支链、2条绳索驱动支链和2条弹簧支链组成。建立了机构的运动学模型,推导了机构动平台角速度、角加速度与欧拉角之间的转化关系;根据螺旋理论建立了机构的静态平衡方程,从而进一步推导出机构的刚度矩阵表达式,并得到矩阵数值解;运用虚功原理建立了机构的伪刚体动力学方程。最后,对机构的速度、加速度、动力学方程进行数值计算、仿真,验证了上述数学模型的正确性,为该机构动力学特性的深入分析和控制策略的研究提供了理论参考。

中图分类号:

- TH112

| [1] | Snelson K D . Continuous tension, discontinuous compression structures[P]. US 3169611, 1965. |

| [2] | Fuller R B . Tensile-integrity structures[P]. US 3063521, 1962. |

| [3] | 李团结, 车明奎 . 张拉整体结构外力与形变间关系分析及实验验证[J]. 西安电子科技大学学报, 2017,44(1):24-28. |

| Li Tuan-jie, Che Ming-kui . Analysis and experimental verification of relationship between external force and deformation of tensegrity structures[J]. Jouranal of Xidian University, 2017,44(1):24-28. | |

| [4] |

罗阿妮, 王龙昆, 刘贺平 . 张拉整体三棱柱构型和结构稳定性分析[J]. 哈尔滨工业大学学报, 2016,48(7):82-87.

doi: 10.11918/j.issn.0367-6234.2016.07.013 |

|

Luo A-ni, Wang Long-kun, Liu He-ping . Analysis of configuration and structural stability of 3-bar tensegrity prism[J]. Journal of Harbin Institute of Technolocy, 2016,48(7):82-87.

doi: 10.11918/j.issn.0367-6234.2016.07.013 |

|

| [5] | Oppenheim I, Williams W . Tensegrity prisms as adaptive structures[J]. ASME Int'l Mechanical Engineering Congress, 1997,54(8):113-120. |

| [6] |

Arsenault M . Determination of the analytical workspace boundaries of a novel 2-DoF planar tensegrity mechanism[J]. Transactions of the Canadian Society for Mechanical Engineering, 2010,34(1):75-91.

doi: 10.1139/tcsme-2010-0005 |

| [7] | Arsenault M, Gosselin C M . Kinematic, static and dynamic analysis of a planar 2-DoF tensegrity mechanism[J]. Mechanism & Machine Theory, 2005,41(9):1072-1089. |

| [8] | Marshall M Q . Analysis of tensegrity-based parallelplatform devices[D]. Gainesville: Department of Mechanical and Aerospace Engineering, University of Florida, 2003. |

| [9] |

Arsenault M, Gosselin C M . Kinematic and static Analysis of 3-PUPS spatial tensegrity mechanism[J]. Mechanism & Machine Theory, 2009,44(1):162-179.

doi: 10.1016/j.mechmachtheory.2008.02.005 |

| [10] | Shekarforoush S M M, Eghtesad M, Farid M. Design of statically balanced six-degree-of-freedom parallel mechanisms based on tensegrity system [C]//ASME 2009 International Mechanical Engineering Congress and Exposition, Lake Buena Vista, Florida,USA, 2009: 245-253. |

| [11] | Abadi B N R, Farid M, Mahzoon M . Introducing and analyzing a novel three-degree-of-freedom spatial tensegrity mechanism[J]. Journal of Computational & Nonlinear Dynamics, 2014,9(2):94-94. |

| [12] |

Moon Y , Crane Ⅲ C D,Roberts R G. Reserve kinetostatic analysis and stiffness of a spatial tensegrity-based compliant mechanism[J]. Mechanism and Machine Theory, 2013,70(6):320-337.

doi: 10.1016/j.mechmachtheory.2013.05.001 |

| [13] | 纪志飞 . 3-SPS张拉整体并联机构的构型综合与运动性能分析及能量采集研究[D]. 西安:西安电子科技大学机电工程学院, 2014. |

| Ji Zhi-fei . On type synthesis, kinematic performances and energy harvesting of 3-SPS tensegrity parallel mechanisms[D]. Xi'an:School of Mechano-electronic Engineering,Xidian University, 2014. | |

| [14] | Chen S, Arsenault M. Workspace computation and analysis of a planar 2-DoF translational tensegrity mechanism [C]//ASME 2010 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Montreal, Quebec, Canada, 2010: 223-232. |

| [15] |

Arsenault M, Gosselin C M . Kinematic and static analysis of a three-degree-of-freedom spatial modular tensegrity mechanism.[J]. International Journal of Robotics Research, 2008,27(8):951-966.

doi: 10.1177/0278364908091152 |

| [16] | Ji Zhe-fei, Li Tuan-jie, Lin Min . Kinematics, singularity, and workspaces of a planar 4-Bar tensegrity mechanism[J]. Journal of Robotics, 2014,2014(11):1-10. |

| [17] |

Ji Zhe-fei, Li Tuan-jie, Lin Min . Kinematic and static analysis of a planar compliant tensegrity-like parallel mechanism[J]. Australian Journal of Mechanical Engineering, 2014,12(1):49-59.

doi: 10.7158/M12-077.2014.12.1 |

| [18] | Ji Zhe-fei, Li Tuan-jie, Lin Min . Kinematics, workspaces and stiffness of a planar class-2 tensegrity mechanism[J]. UPB Sci Bull, 2014,76(3):53-64. |

| [19] | 王征 . 张拉整体结构的找形和稳定性分析[D]. 西安:西安电子科技大学机电工程学院, 2012. |

| Wang Zheng . Analysis of form-finding and stability of tensegrity structures[D]. Xi'an:School of Mechano-electronic Engineering, Xidian University, 2012. | |

| [20] | Wittenburg J . Dynamics of Multibody Systems[M]. New York: Springer, 2008: 80-96. |

| [21] | Ball R S. A Treatise on the Theory of Screws[M]. New York: Cambridge University Press, 1900: 120-160. |

| [1] | 贾拓,赵丁选,崔玉鑫. 铰接式装载机倾翻预警方法[J]. 吉林大学学报(工学版), 2018, 48(6): 1762-1769. |

| [2] | 李战东,陶建国,罗阳,孙浩,丁亮,邓宗全. 核电水池推力附着机器人系统设计[J]. 吉林大学学报(工学版), 2018, 48(6): 1820-1826. |

| [3] | 刘兆惠, 王超, 吕文红, 管欣. 基于非线性动力学分析的车辆运行状态参数数据特征辨识[J]. 吉林大学学报(工学版), 2018, 48(5): 1405-1410. |

| [4] | 毛宇泽, 王黎钦. 鼠笼支撑一体化结构对薄壁球轴承承载性能的影响[J]. 吉林大学学报(工学版), 2018, 48(5): 1508-1514. |

| [5] | 胡满江, 罗禹贡, 陈龙, 李克强. 基于纵向频响特性的整车质量估计[J]. 吉林大学学报(工学版), 2018, 48(4): 977-983. |

| [6] | 刘祥勇, 李万莉. 包含蓄能器的电液比例控制模型[J]. 吉林大学学报(工学版), 2018, 48(4): 1072-1084. |

| [7] | 张琳, 章新杰, 郭孔辉, 王超, 刘洋, 刘涛. 未知环境下智能汽车轨迹规划滚动窗口优化[J]. 吉林大学学报(工学版), 2018, 48(3): 652-660. |

| [8] | 王靖宇, 于旭涛, 胡兴军, 郭鹏, 辛俐, 郭峰, 张扬辉. 汽车外后视镜流致振特性及其流动机理[J]. 吉林大学学报(工学版), 2017, 47(6): 1669-1676. |

| [9] | 李静, 张家旭, 张艳华, 陈立军. 采用强跟踪中心差分滤波器的汽车状态和参数估计[J]. 吉林大学学报(工学版), 2017, 47(5): 1329-1335. |

| [10] | 许金凯, 王煜天, 张世忠. 驱动冗余重型并联机构的动力学性能[J]. 吉林大学学报(工学版), 2017, 47(4): 1138-1143. |

| [11] | 王倩, 赵丁选, 赵颖, 陈娜. 舰载直升机复杂舰面上的动力学分析[J]. 吉林大学学报(工学版), 2017, 47(4): 1109-1113. |

| [12] | 李显生, 孟祥雨, 郑雪莲, 程竹青, 任圆圆. 非满载罐体内液体冲击动力学特性[J]. 吉林大学学报(工学版), 2017, 47(3): 737-743. |

| [13] | 张义花, 许洪国, 刘宏飞, 王发继. 双挂汽车列车高速阶跃横向失稳能量分析[J]. 吉林大学学报(工学版), 2017, 47(1): 71-75. |

| [14] | 李玲, 施树明, 王宪彬, 于壮. 发动机制动下高速转弯车辆稳定性[J]. 吉林大学学报(工学版), 2017, 47(1): 64-70. |

| [15] | 罗乐, 郑旭, 吕义, 郝志勇. 高速列车车轮及轮对的声辐射特性[J]. 吉林大学学报(工学版), 2016, 46(5): 1464-1470. |

|