吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (2): 329-337.doi: 10.13229/j.cnki.jdxbgxb20211079

• 车辆工程·机械工程 • 上一篇

考虑工况变化的数控刀架运行状态异常检测方法

胡炜1,2,3( ),陈传海1,2,郭劲言1,2(

),陈传海1,2,郭劲言1,2( ),刘志峰1,2,申桂香1,2,于春明4

),刘志峰1,2,申桂香1,2,于春明4

- 1.吉林大学 数控装备可靠性教育部重点实验室,长春 130022

2.吉林大学 机械与航空航天工程学院,长春 1300225

3.瑞典皇家理工学院,瑞典 斯德哥尔摩 25175

4.沈阳机床股份有限公司,沈阳 110142

An Anomaly detection method for numerical control turrets considering working conditions

Wei HU1,2,3( ),Chuan-hai CHEN1,2,Jin-yan GUO1,2(

),Chuan-hai CHEN1,2,Jin-yan GUO1,2( ),Zhi-feng LIU1,2,Gui-xiang SHEN1,2,Chun-ming YU4

),Zhi-feng LIU1,2,Gui-xiang SHEN1,2,Chun-ming YU4

- 1.Key Laboratory of CNC Equipment Reliability,Ministry of Education,Jilin University,Changchun 130022,China

2.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

3.KTH Royal Institute of Technology,Stockholm 25175,Sweden

4.Shenyang Machine Tool Co. ,Ltd. ,Shenyang 110142,China

摘要:

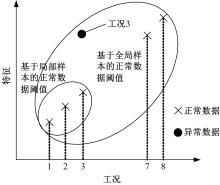

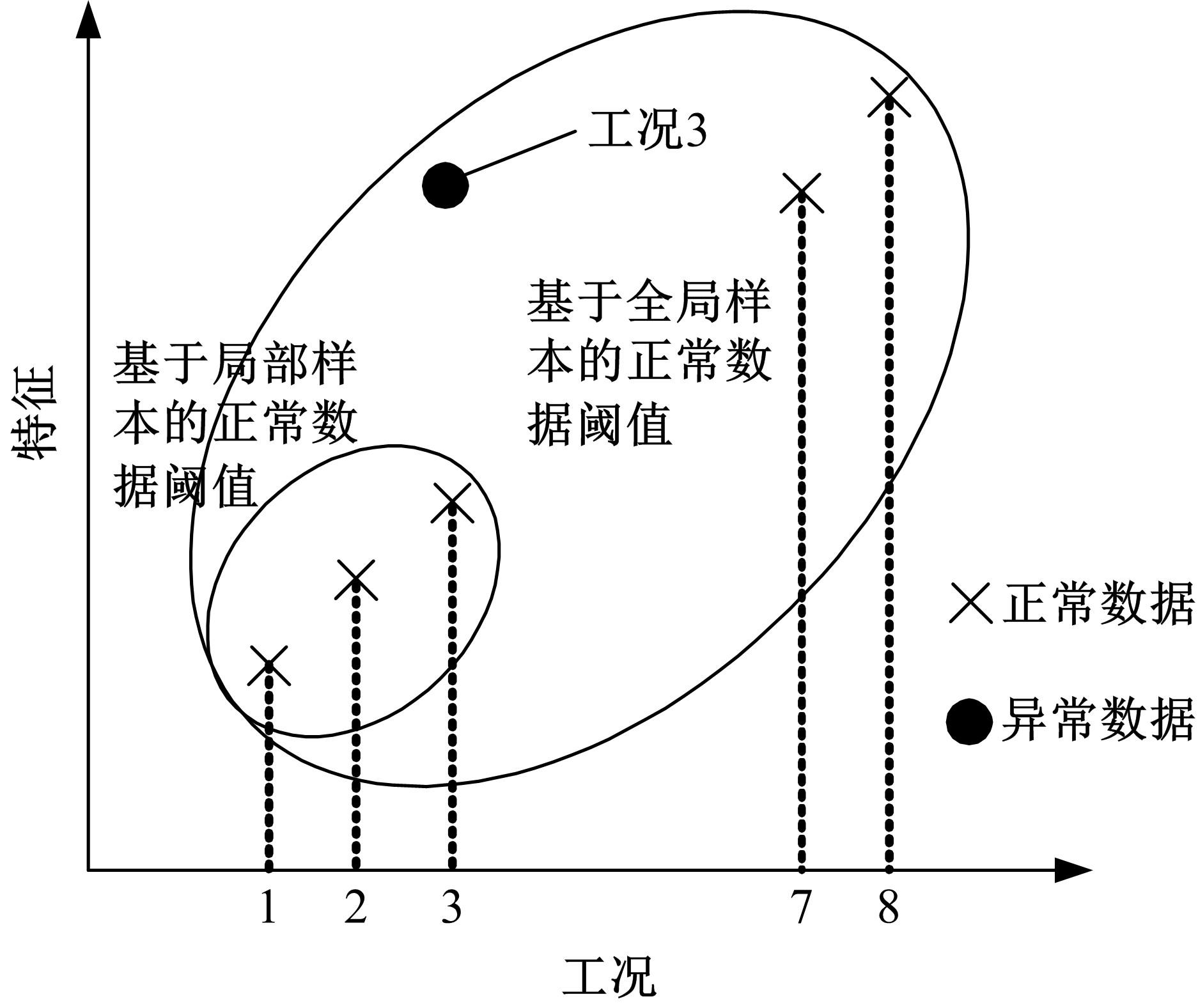

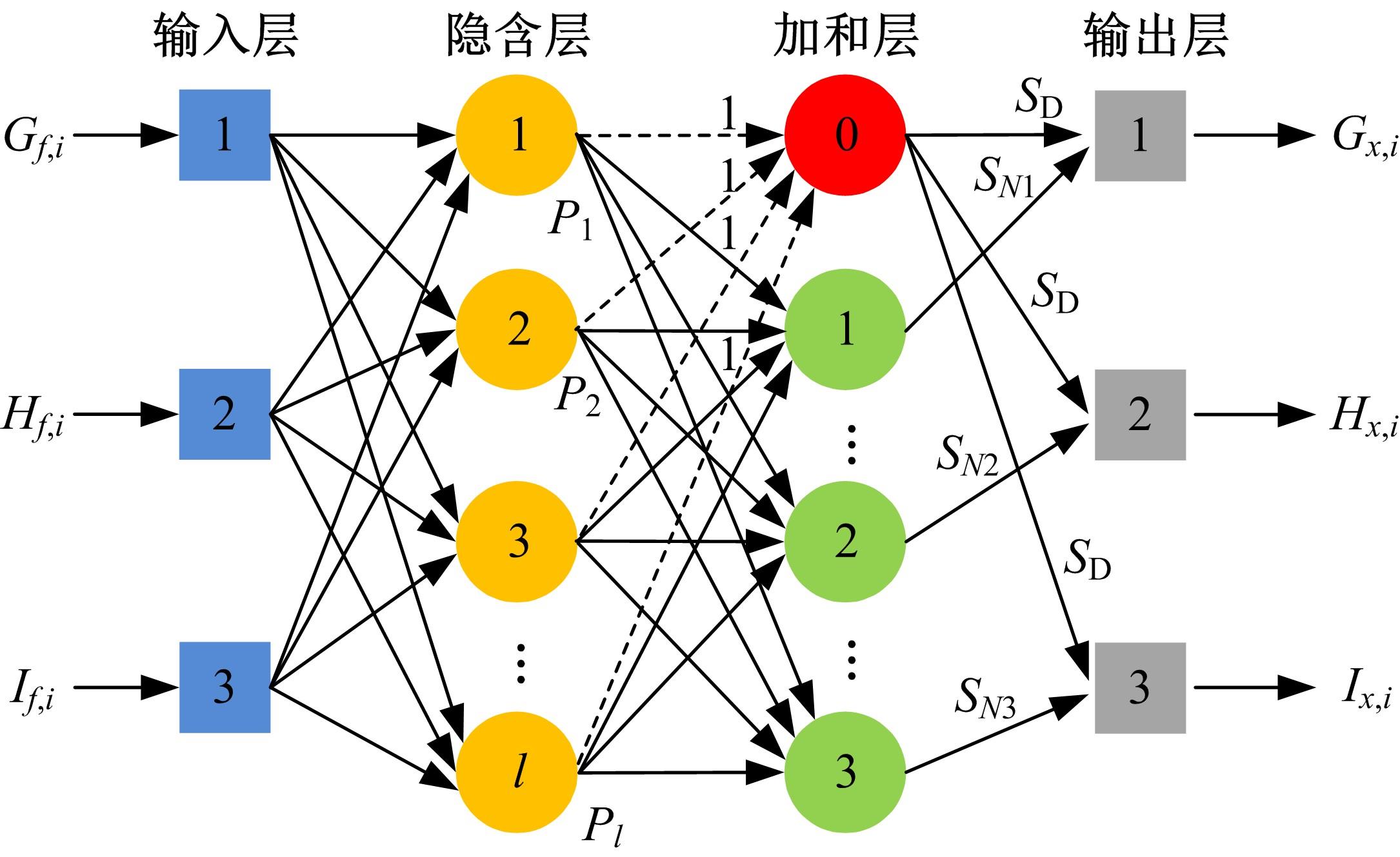

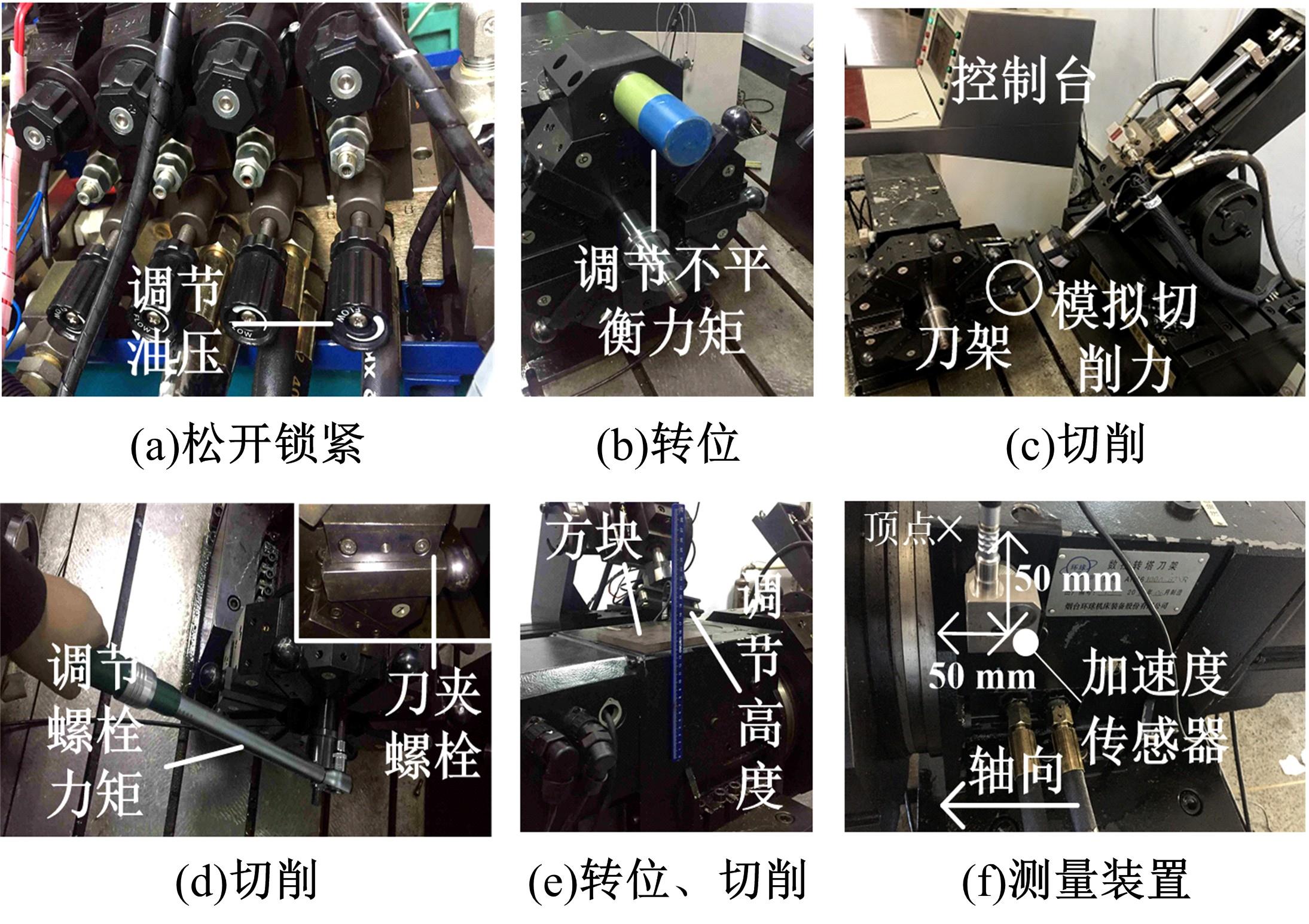

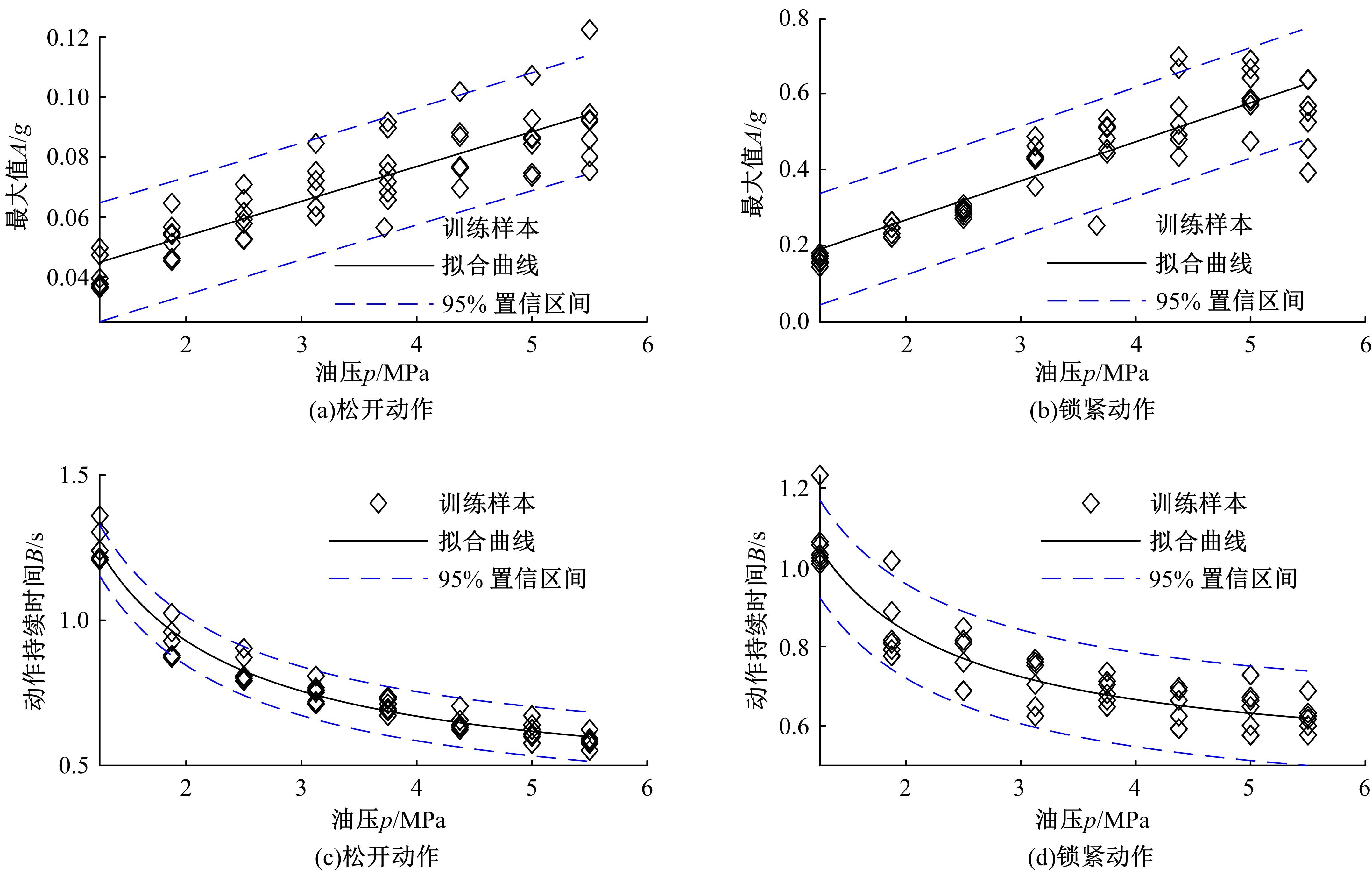

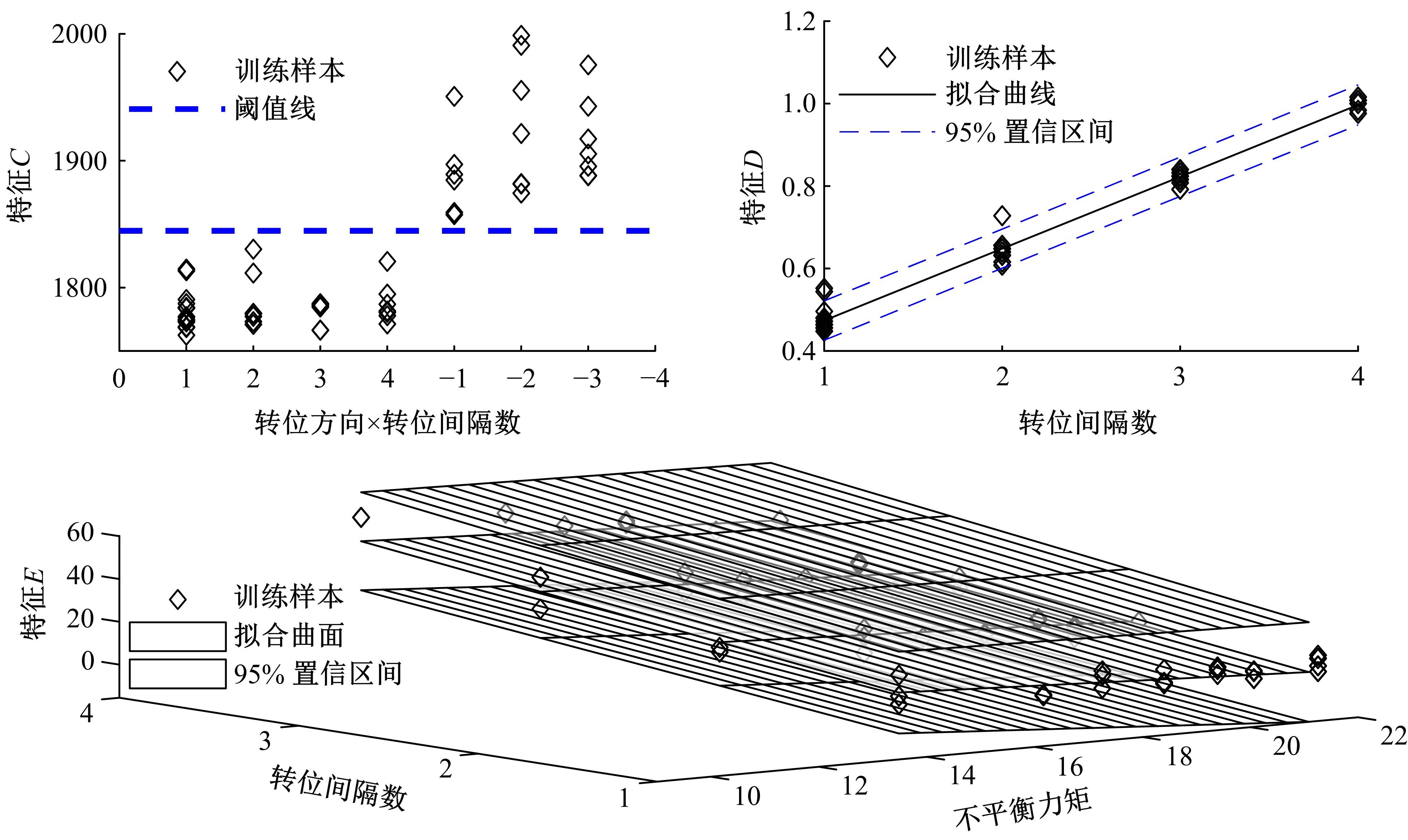

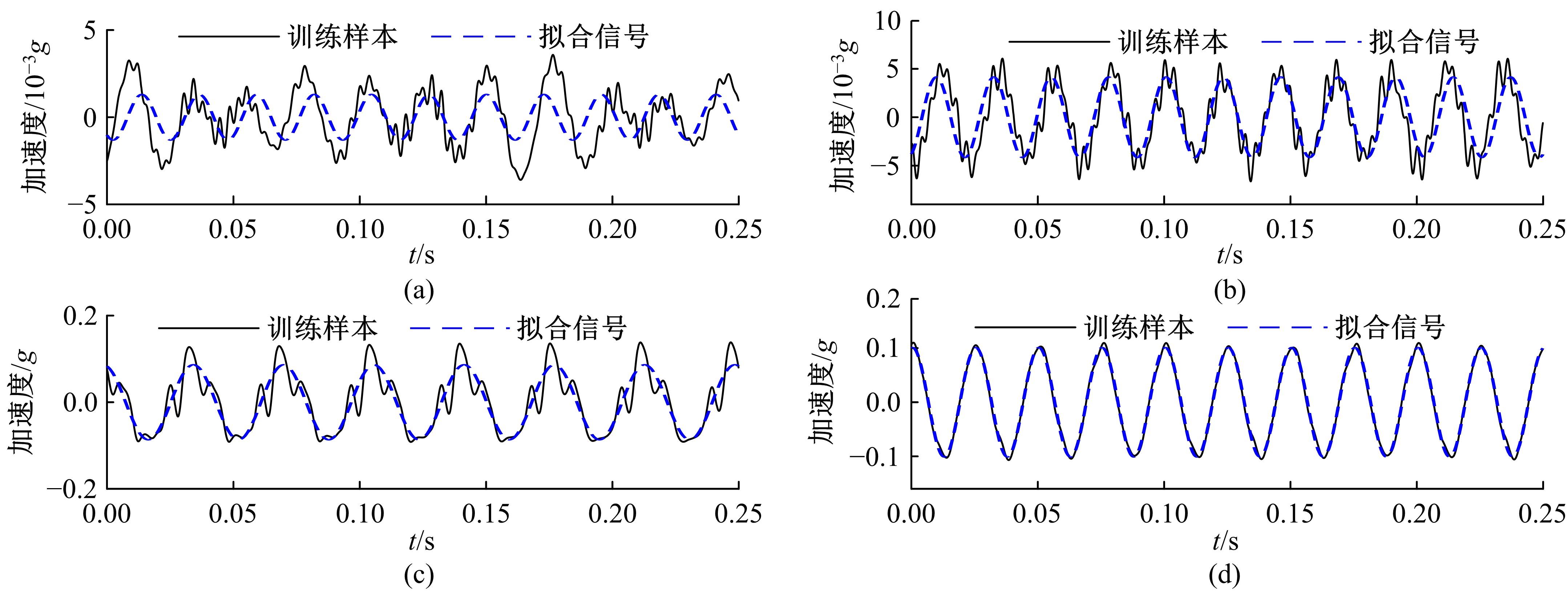

针对数控刀架故障数据少、难获取,且运行数据随工况变化致使故障诊断困难的问题,提出了一种基于非故障数据并考虑工况变化的运行状态异常检测方法。该方法通过多元高斯分布模型和考虑工况变化的偏差特征建模,确定刀架运行状态异常数据的评判依据。首先,通过统计分析找到刀架在不同工作过程中的关键工况与信号特征;其次,分别选择线性回归、信息增益判别、广义回归神经网络方法建立工况与信号特征的关系模型,得到观测信号特征与给定信号特征之间的偏差;最后,采用刀架正常状态时的数据训练模型。通过大量工况变化实验与异常模拟实验,并与传统多元高斯分布模型比较,得出本文所提模型能排除工况变化的影响,并能更好地识别异常状态。

中图分类号:

- TG659

| 1 | 杨兆军, 陈传海, 陈菲, 等. 数控机床可靠性技术的研究进展[J].机械工程学报, 2013, 49(20): 130-139. |

| Yang Zhao-jun, Chen Chuan-hai, Chen Fei, et al. Progress in the research of reliability technology of machine tools[J]. Journal of Mechanical Engineering, 2013, 49(20): 130-139. | |

| 2 | 张英芝, 郑珊, 申桂香, 等. 采用重要度和模糊推理的数控刀架危害性分析[J]. 吉林大学学报: 工学版, 2012, 42(5): 1157-1162. |

| Zhang Ying-zhi, Zheng Shan, Shen Gui-xiang, et al. Criticality analysis for CNC turret adopting importance and fuzzy reasoning[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(5): 1157-1162. | |

| 3 | 陈斌, 陈松灿, 潘志松, 等. 异常检测综述[J]. 山东大学学报: 工学版, 2009, 39(6): 13-23. |

| Chen Bin, Chen Song-can, Pan Zhi-song, et al. Survey of outlier detection technologies[J]. Journal of Shandong University(Engineering Science), 2009, 39(6): 13-23. | |

| 4 | 周东华, 魏慕恒, 司小胜. 工业过程异常检测、寿命预测与维修决策的研究进展[J]. 自动化学报, 2013, 39(6): 711-722. |

| Zhou Dong-hua, Wei Mu-heng, Si Xiao-sheng. A survey on anomaly detection, life prediction and maintenance decision for industrial processes[J]. Acta Automatica Sinica, 2013, 39(6): 711-722. | |

| 5 | 丁建伟. 数据驱动的复杂装备异常检测方法[D]. 北京: 清华大学计算机科学与技术学院, 2015. |

| Ding Jian-wei. Data-driven complex equipment anomaly detection methods[D]. Beijing: College of Computer Science and Technology, Tsinghua University, 2015. | |

| 6 | Ding Nan, Ma Hao-xuan, Gao Huan-bo, et al. Real-time anomaly detection based on long short-Term memory and Gaussian mixture model[J]. Computers & Electrical Engineering, 2019, 79: 106458. |

| 7 | Li G Y, Lee H, Rai A, et al. Analysis of operational and mechanical anomalies in scheduled commercial flights using a logarithmic multivariate Gaussian model[J]. Transportation Research, 2020, 110(1): 20-39. |

| 8 | Zeng X J, Yang M, Bo Y F. Gearbox oil temperature anomaly detection for wind turbine based on sparse Bayesian probability estimation[J]. International Journal of Electrical Power & Energy Systems, 2020, 123: 106233. |

| 9 | Zhao Hong-shan, Liu Hui-hai, Hu Wen-jing, et al. Anomaly detection and fault analysis of wind turbine components based on deep learning network[J]. Renewable Energy, 2018, 127(11): 825-834. |

| 10 | Sarmadi H, Karamodin A. A novel anomaly detection method based on adaptive mahalanobis-squared distance and one-class kNN rule for structural health monitoring under environmental effects[J]. Mechanical Systems and Signal Processing, 2020, 140(1): 106495. |

| 11 | 谢群亚. 基于故障树的数控刀架可靠性分配方法研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2017. |

| Xie Qun-ya. Research on reliability allocation method of CNC servo turret based fault tree analysis[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2017. | |

| 12 | 杨兆军, 杨川贵, 陈菲, 等. 基于最小二乘算法和SVDUKF算法的电液伺服加载优化[J]. 吉林大学学报: 工学版, 2014, 44(2): 392-397. |

| Yang Zhao-jun, Yang Chuan-gui, Chen Fei, et al. Optimization of the electro-hydraulic servo loading based on least square and SVDUKF algorithms[J]. Journal of Jilin University(Engineering and Technology Edition), 2014, 44(2): 392-397. | |

| 13 | 胡炜. 面向数控刀架可靠性试验的CPS研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2019. |

| Hu Wei. Research on CPS of NC turret reliability test[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2019. |

| [1] | 董绍江,朱朋,裴雪武,李洋,胡小林. 基于子领域自适应的变工况下滚动轴承故障诊断[J]. 吉林大学学报(工学版), 2022, 52(2): 288-295. |

| [2] | 侯春萍,赵春月,王致芃,田海瑞. 基于有效异常样本构造的视频异常检测算法[J]. 吉林大学学报(工学版), 2021, 51(5): 1823-1829. |

| [3] | 曾小华,宋美洁,宋大凤,王越. 基于车联网信息的公交客车行驶工况数据处理方法[J]. 吉林大学学报(工学版), 2021, 51(5): 1692-1699. |

| [4] | 陈魏,雷雨龙,李兴忠,付尧,扈建龙,侯利国. 低速工况下渐开线圆柱直齿轮齿面粘着磨损计算[J]. 吉林大学学报(工学版), 2021, 51(5): 1628-1634. |

| [5] | 李洪雪,李世武,孙文财,李玮,郭梦竹. 重型危险品半挂列车行驶工况的构建[J]. 吉林大学学报(工学版), 2021, 51(5): 1700-1707. |

| [6] | 宋大凤,杨丽丽,曾小华,王星琦,梁伟智,杨南南. 基于行驶工况合成的混合动力汽车电池寿命优化[J]. 吉林大学学报(工学版), 2021, 51(3): 781-791. |

| [7] | 李小雨,许男,仇韬,郭孔辉. 各向异性刚度对轮胎力学特性及车辆操纵性的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 389-398. |

| [8] | 刘玉梅,乔宁国,庄娇娇,刘鹏程,胡婷,陈立军. 基于多传感器数据融合的轨道车辆齿轮箱异常检测[J]. 吉林大学学报(工学版), 2019, 49(5): 1465-1470. |

| [9] | 周华,杨志刚,朱晖. 基于整车风洞试验的MIRA车型数值计算[J]. 吉林大学学报(工学版), 2019, 49(4): 1043-1053. |

| [10] | 林学东, 江涛, 许涛, 李德刚, 郭亮. 高压共轨柴油机起动工况高压泵控制策略[J]. 吉林大学学报(工学版), 2018, 48(5): 1436-1443. |

| [11] | 宋大凤, 吴西涛, 曾小华, 杨南南, 李文远. 基于理论油耗模型的轻混重卡全生命周期成本分析[J]. 吉林大学学报(工学版), 2018, 48(5): 1313-1323. |

| [12] | 曹骞, 李君, 刘宇, 曲大为. 基于马尔科夫链的长春市乘用车行驶工况构建[J]. 吉林大学学报(工学版), 2018, 48(5): 1366-1373. |

| [13] | 张曼, 施树明. 典型汽车运行工况的状态转移特征分析[J]. 吉林大学学报(工学版), 2018, 48(4): 1008-1015. |

| [14] | 于赫, 秦贵和, 孙铭会, 闫鑫, 王璇喆. 车载CAN总线网络安全问题及异常检测方法[J]. 吉林大学学报(工学版), 2016, 46(4): 1246-1253. |

| [15] | 秦大同, 詹森, 漆正刚, 陈淑江. 基于K-均值聚类算法的行驶工况构建方法[J]. 吉林大学学报(工学版), 2016, 46(2): 383-389. |

|

||