吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (4): 1194-1202.doi: 10.13229/j.cnki.jdxbgxb20180336

• • 上一篇

双圆弧谐波传动柔轮齿形参数多目标优化设计

王家序1,2( ),蒋倩倩1,李俊阳1,韩彦峰1,张雷1,唐挺1

),蒋倩倩1,李俊阳1,韩彦峰1,张雷1,唐挺1

- 1. 重庆大学 机械传动国家重点实验室,重庆 400044

2. 四川大学 空天科学与工程学院,成都 610065

Multi⁃objective optimization design of flexspline profile parameters of double⁃arc harmonic drive

Jia⁃xu WANG1,2( ),Qian⁃qian JIANG1,Jun⁃yang LI1,Yan⁃feng HAN1,Lei ZHANG1,Ting TANG1

),Qian⁃qian JIANG1,Jun⁃yang LI1,Yan⁃feng HAN1,Lei ZHANG1,Ting TANG1

- 1. State Key Laboratory of Mechanical Transmission, Chongqing University, Chongqing 400044, China

2. School of Aeronautics and Astronautics, Sichuan University, Chengdu 610065, China

摘要:

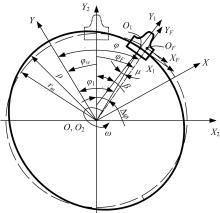

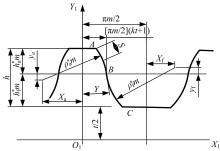

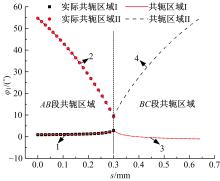

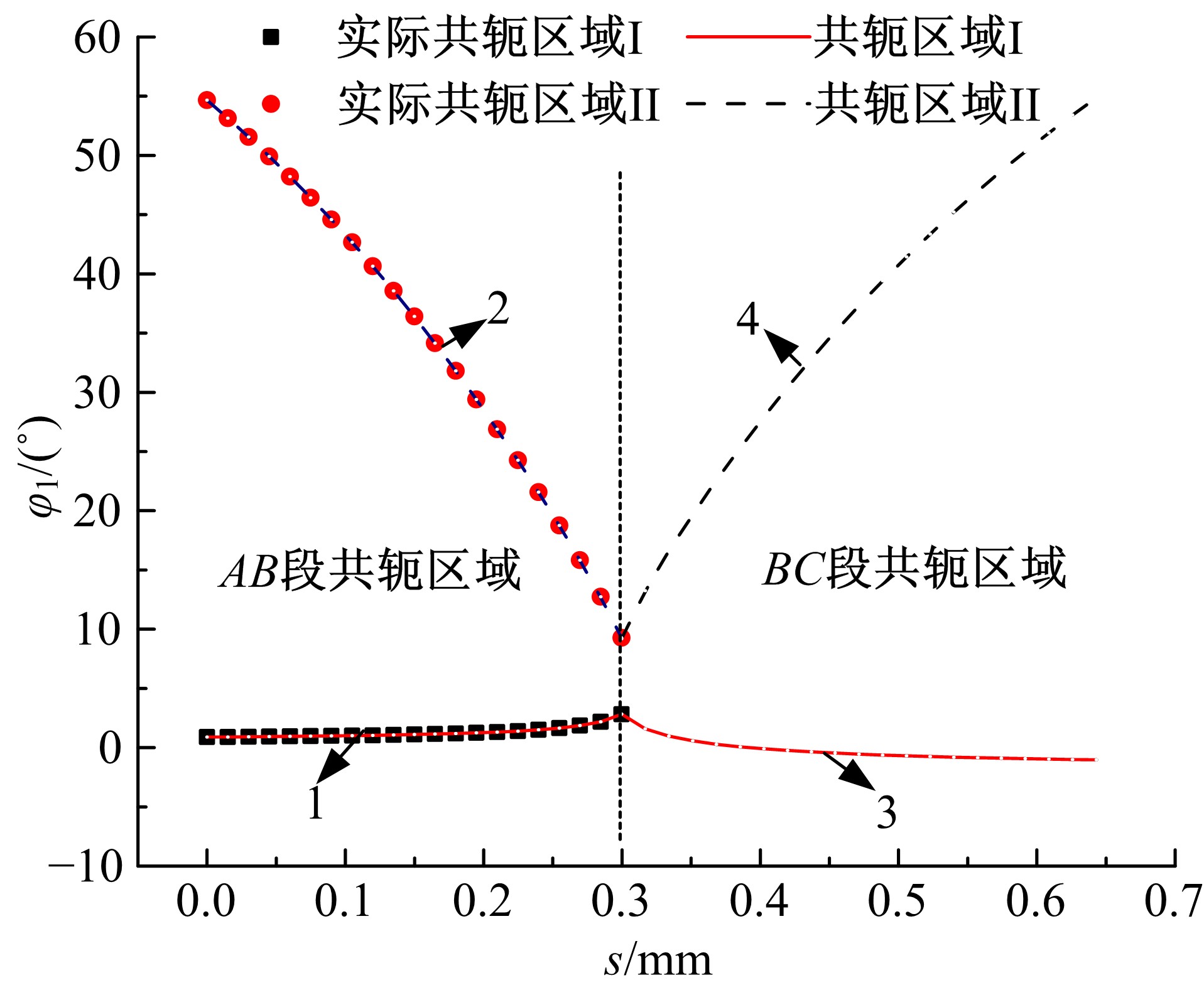

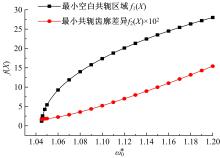

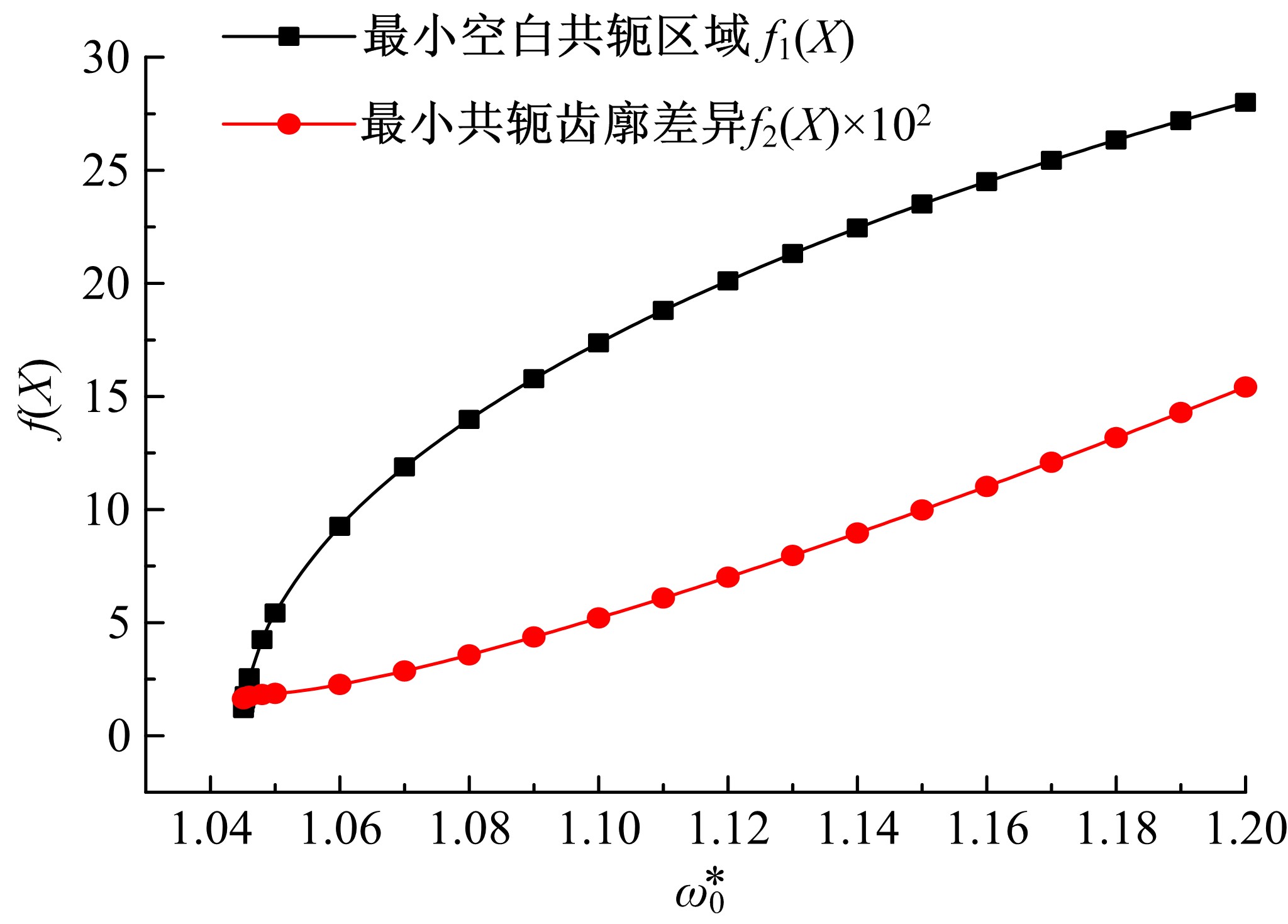

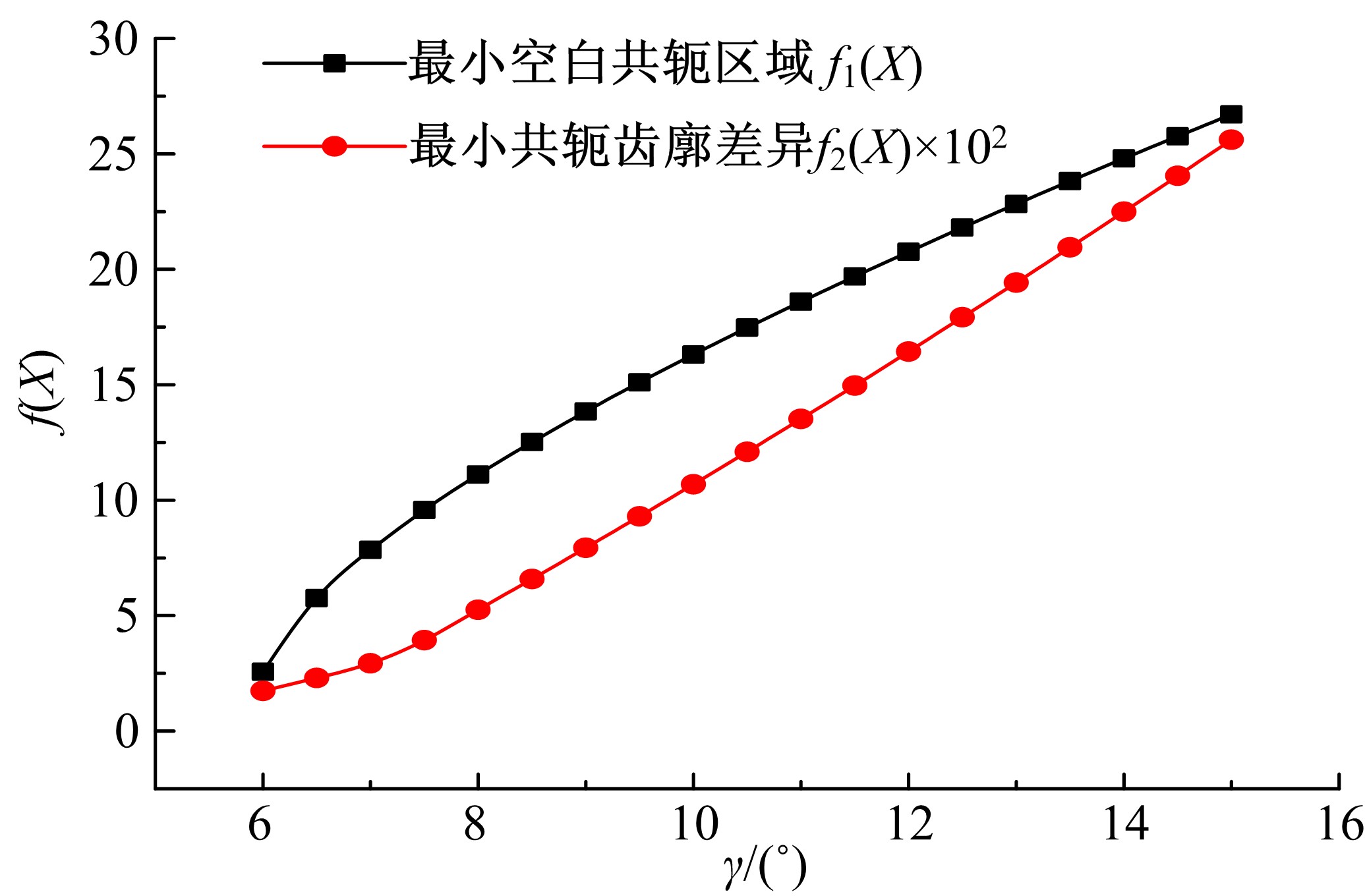

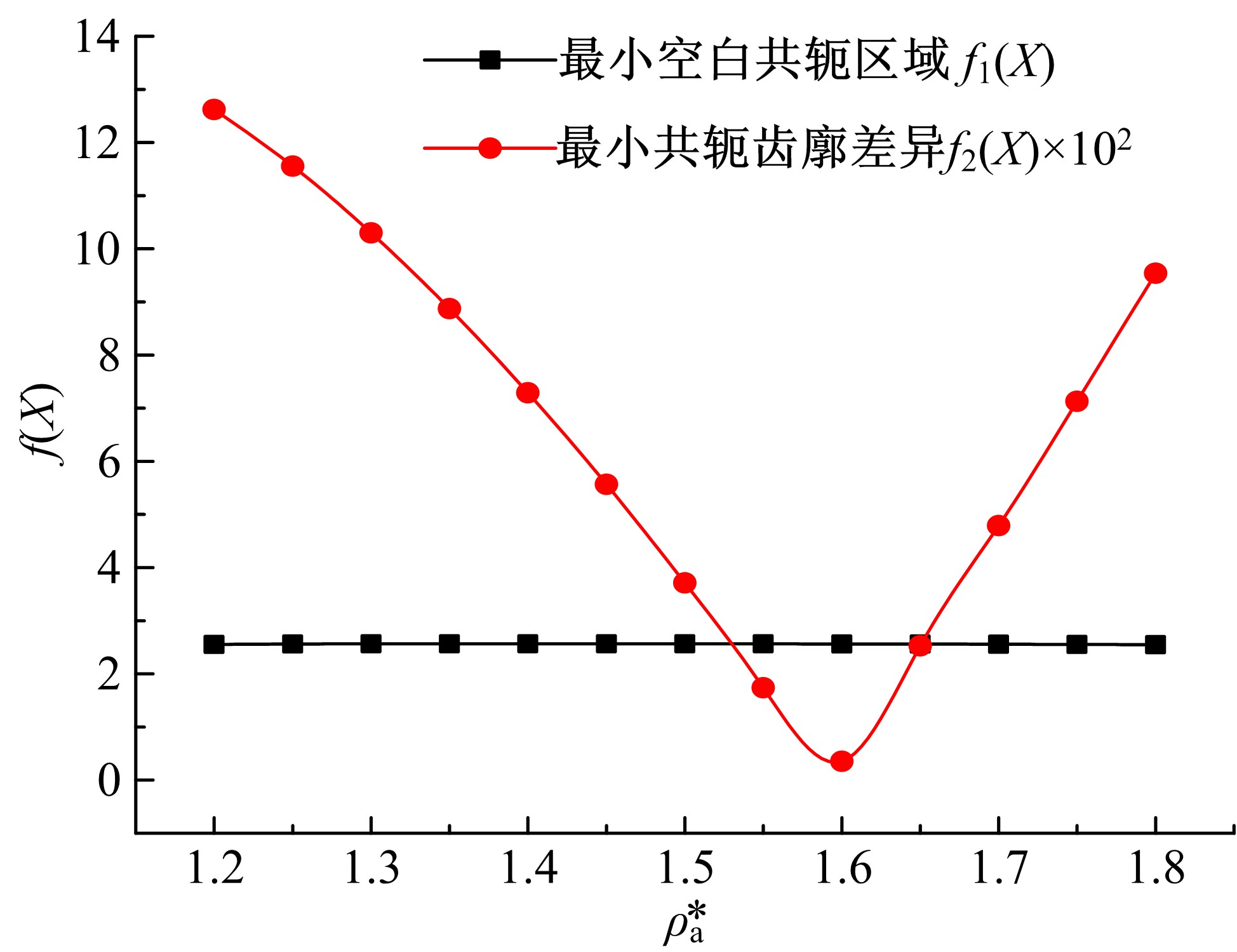

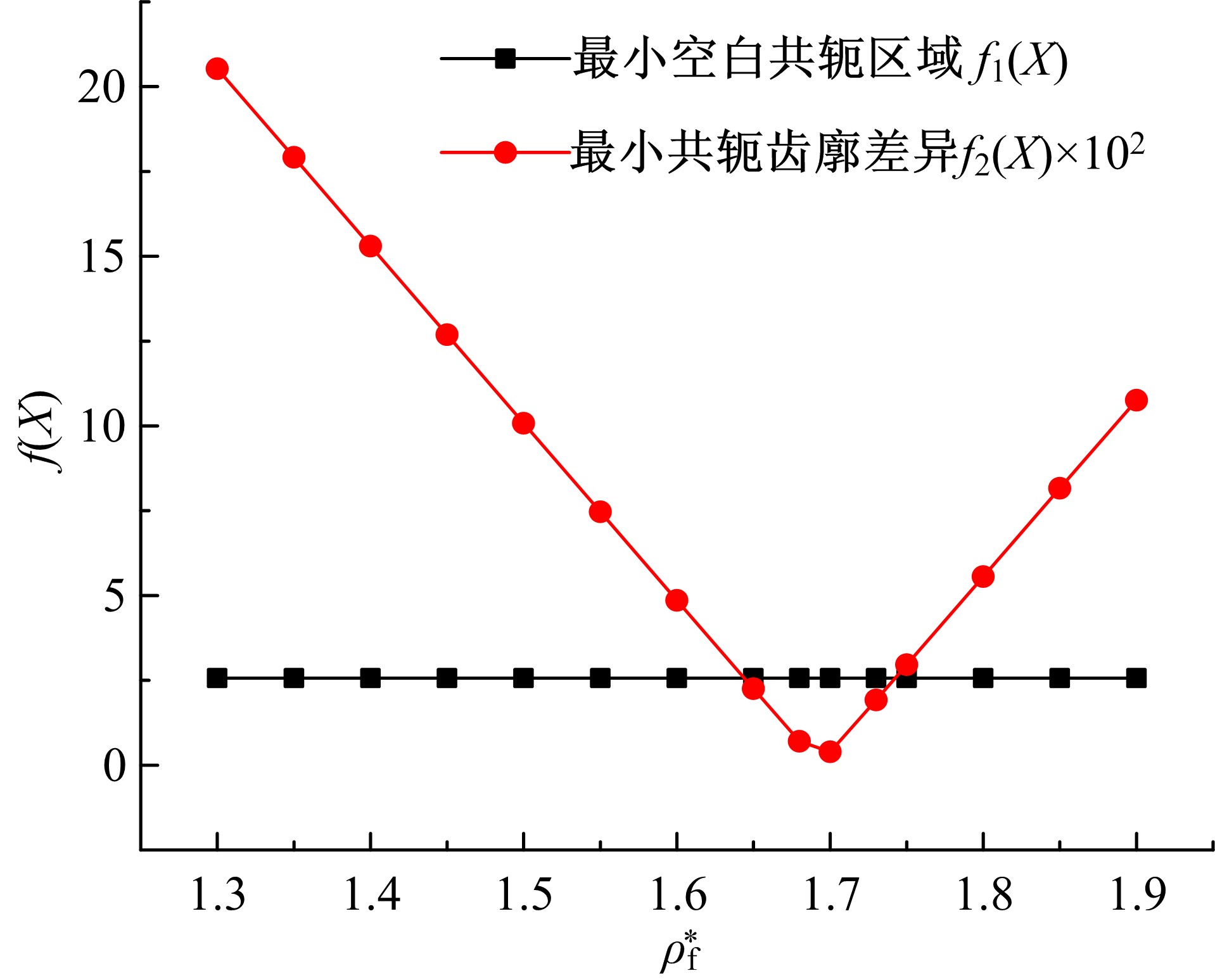

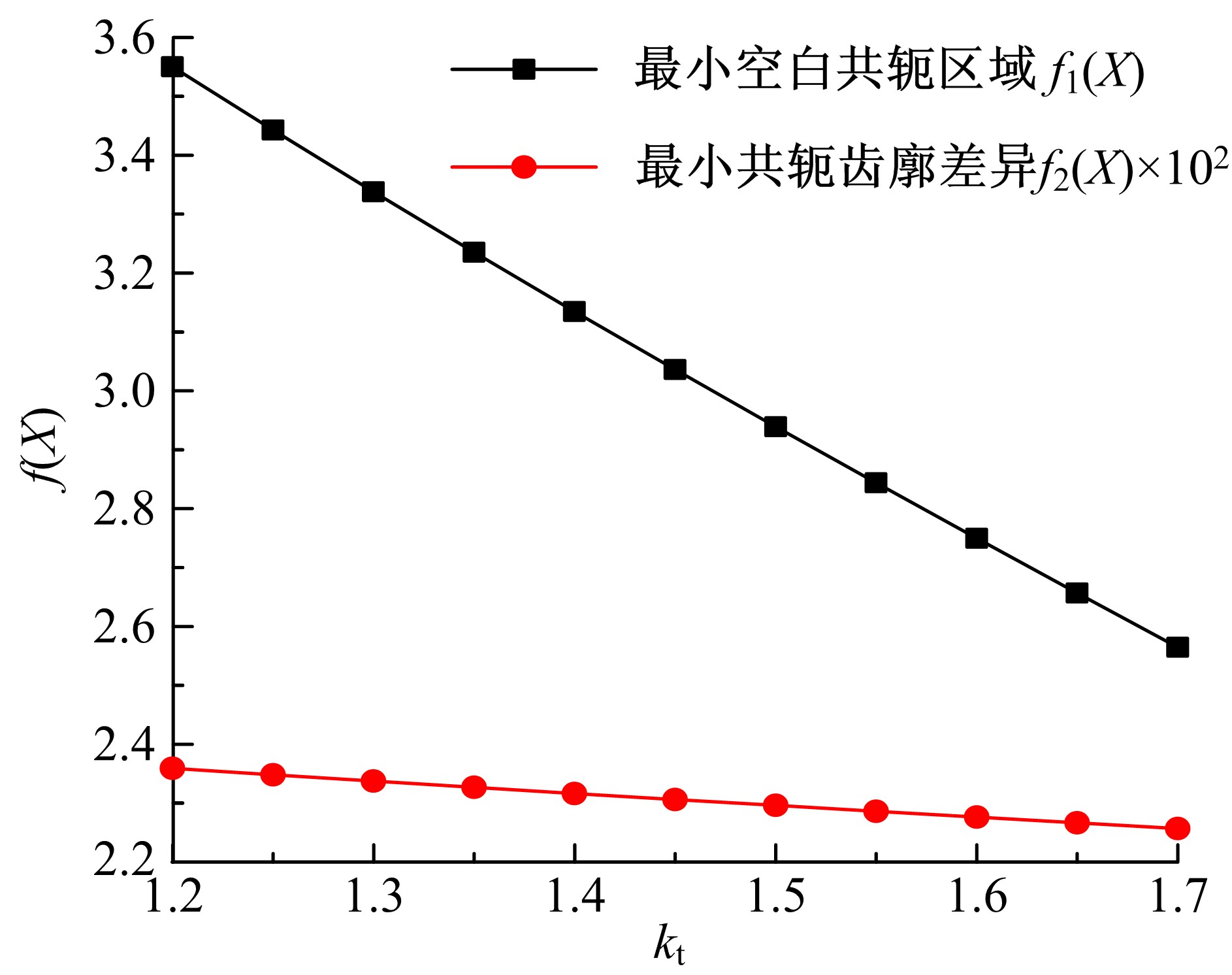

根据刚轮和柔轮空载下连续不断啮合和“双共轭”现象能有效提高双圆弧谐波齿轮装置的啮合性能,提出了一种圆弧柔轮齿形参数的多目标优化设计方法。针对无公切线双圆弧齿廓,采用改进运动学法和精确转角关系进行共轭齿廓设计,以缩小共轭空白区间与共轭齿廓差异为优化目标,考虑共轭齿廓的存在条件,建立谐波传动多目标优化模型,进行单目标分析及多目标优化。结果表明:该优化方法可实现柔轮齿形参数的合理选择,使空载状态刚轮与柔轮啮合空白区域小于1.2°,共轭齿廓间差异在0.83 μm左右,能满足工程应用要求,保证空载连续啮合及“双共轭”传动精度。

中图分类号:

- TH132.43

| 1 | Preumont P , Szewczyk R . Key Factors Influencing the Accuracy of Harmonic Gears for Space Applications[C] ∥Szewczyk R , Zieliński C , Kaliczyńska M . Automation 2018. Berlin: Springer, 2018: 483⁃489. |

| 2 | Timofeev G A . Drives with harmonic gears for servo systems[J]. Russian Engineering Research, 2016, 36(3): 187⁃193. |

| 3 | 董惠敏 . 基于柔轮变形函数的谐波齿轮传动运动几何学及其啮合性能研究[D]. 大连: 大连理工大学机械工程学院, 2008. |

| Dong Hui⁃min . Study of kinematics and meshing characteristic of harmonic drive based on the deformation function of the flexspline[D]. Dalian: School of Mechanical Engineering, Dalian University of Technology, 2008. | |

| 4 | 刘邓辉, 邢静忠, 陈晓霞 . 渐开线谐波齿轮的空间齿廓设计及啮合特性分析[J]. 机械设计, 2016, 33(3): 24⁃29. |

| Liu Deng⁃hui , Xing Jing⁃zhong , Chen Xiao⁃xia . Spatial tooth profile design and engagement analysis of harmonic gear with involute profile[J]. Journal of Machine Design, 2016, 33(3): 24⁃29. | |

| 5 | Ishikawa S , Takizawa N . Wave gear drive having negative deflection meshing tooth profile[P]. US Patent: 7735396, 2010⁃06⁃15. |

| 6 | Ishikaua S . Wave gear device having three⁃dimensionally contactable shifted tooth profile[P]. US Patent: 8776638, 2014⁃07⁃15. |

| 7 | 王家序, 周祥祥, 李俊阳, 等 . 不同共轭原理的双圆弧齿廓谐波齿轮传动分析[J]. 四川大学学报: 工程科学版, 2015, 47(5): 160⁃166. |

| Wang Jia⁃xu , Zhou Xiang⁃xiang , Li Jun⁃yang , et al . Double⁃circular⁃arc tooth profile of harmonic drive analysis based on different conjugate principle[J]. Journal of Sichuan University(Engineering Science Edition), 2015, 47(5): 160⁃166. | |

| 8 | 王家序, 周祥祥, 李俊阳,等 . 公切线式双圆弧齿廓谐波齿轮传动设计[J]. 湖南大学学报: 自然科学版, 2016, 43(2): 56⁃63. |

| Wang Jia⁃xu , Zhou Xiang⁃xiang , Li Jun⁃yang , et al . Design of double⁃circular⁃arc and common tangent tooth profile of harmonic drive[J]. Journal of Hunan University (Natural Sciences), 2016, 43(2):56⁃63. | |

| 9 | Chen Xiao⁃xia , Liu Yu⁃sheng , Xing Jing⁃zhong , et al . The parametric design of double⁃circular⁃arc tooth profile and its influence on the functional backlash of harmonic drive[J]. Mechanism and Machine Theory, 2014, 73(2): 1⁃24. |

| 10 | Chen Xiao⁃xia , Lin Shu⁃zhong , Xing Jing⁃zhong , et al . Simulation on gear backlash and interference check of harmonic drive with circular⁃arc teeth profile[J]. Computer Integrated Manufacturing Systems, 2011, 17(3): 643⁃648. |

| 11 | Xin Hong⁃bing . Design for basic rack of harmonic drive with double⁃circular⁃arc tooth profile[J]. China Mechanical Engineering, 2011, 22(6): 656⁃662. |

| 12 | 杨勇, 王家序, 周青华, 等 . 双圆弧谐波齿轮传动柔轮齿廓参数的优化设计[J]. 四川大学学报: 工程科学版, 2016, 48(1):186⁃193. |

| Yang Yong , Wang Jia⁃xu , Zhou Qing⁃hua , et al . Optimization design for flexspline tooth profile parameters of double⁃circular⁃arc harmonic drives[J]. Journal of Sichuan University(Engineering Science Edition), 2016, 48(1): 186⁃193. | |

| 13 | 翟永 . 谐波齿轮传动双圆弧齿形设计与分析[D]. 大连:大连海事大学轮机工程学院, 2015. |

| Zhai Yong . Double⁃arc tooth profile design and analysis of harmonic drive[D]. Dalian: School of Marine Engineering, Dalian Maritime University, 2015. |

| [1] | 夏利红, 邓兆祥. 电子机械制动执行器的整体最优匹配设计[J]. 吉林大学学报(工学版), 2018, 48(4): 998-1007. |

| [2] | 仇艳凯, 李宝仁, 杨钢, 曹博, 刘真. 新型液压消声器吸收液压系统压力脉动的机理和特性[J]. 吉林大学学报(工学版), 2018, 48(4): 1085-1091. |

| [3] | 吉野辰萌, 樊璐璐, 闫磊, 徐涛, 林烨, 郭桂凯. 基于MBNWS算法的假人胸部结构多目标优化设计[J]. 吉林大学学报(工学版), 2018, 48(4): 1133-1139. |

| [4] | 邱小明, 王银雪, 姚汉伟, 房雪晴, 邢飞. 基于灰色关联的DP1180/DP590异质点焊接头工艺参数优化[J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [5] | 吴疆, 徐壮, 刘丽佳, 嵇艳鞠, 李肃义. 基于环绕式血氧探头的睡眠呼吸暂停综合征检测装置原型设计与开发[J]. 吉林大学学报(工学版), 2018, 48(2): 640-644. |

| [6] | 王登峰, 张帅, 汪勇, 陈辉. 基于疲劳和13°冲击性能的组装式车轮优化设计[J]. 吉林大学学报(工学版), 2018, 48(1): 44-56. |

| [7] | 杨诚, 宋萍, 彭文家, 金昊龙, 潘志强. 基于混合总线的装甲车辆实车综合测试系统设计[J]. 吉林大学学报(工学版), 2018, 48(1): 186-198. |

| [8] | 杨诚, 宋萍, 彭文家, 邓高寿, 刘雄军. 装甲车辆综合测试系统上位机平台设计[J]. 吉林大学学报(工学版), 2017, 47(6): 1796-1803. |

| [9] | 柏德恩, 全齐全, 李贺, 陈雅文, 邓宗全. 伺服加载的谐波减速器启动力矩测试系统[J]. 吉林大学学报(工学版), 2017, 47(6): 1804-1810. |

| [10] | 于繁华, 刘仁云, 张义民, 张晓丽, 孙秋成. 机械零部件动态可靠性稳健优化设计的群智能算法[J]. 吉林大学学报(工学版), 2017, 47(6): 1903-1908. |

| [11] | 周放, 宋传学, 梁天唯, 肖峰. 采用NSGA-II算法的车载复合电源参数匹配[J]. 吉林大学学报(工学版), 2017, 47(5): 1336-1343. |

| [12] | 王天皓, 王忠福, 王雨蒙, 杨开宇, 高印寒, 马喜来. 基于混沌多项式展开法的线束串扰统计模型[J]. 吉林大学学报(工学版), 2017, 47(5): 1568-1576. |

| [13] | 王家序, 袁攀, 谭春林, 何永强, 李俊阳, 肖科. 基于齿条近似法的谐波传动空间齿廓设计方法[J]. 吉林大学学报(工学版), 2017, 47(4): 1121-1129. |

| [14] | 刘颖, 张凯, 于向军. 基于代理模型的中空轴式大型静压轴承多目标优化[J]. 吉林大学学报(工学版), 2017, 47(4): 1130-1137. |

| [15] | 陈赫, 杨智君, 吴昭春, 冯志刚, 赵科佳, 李抵非, 田地. 标准失真模拟分量视频信号源及其校准方法[J]. 吉林大学学报(工学版), 2017, 47(4): 1159-1164. |

|

||