吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (2): 280-287.doi: 10.13229/j.cnki.jdxbgxb20211196

• 车辆工程·机械工程 • 上一篇

基于贝叶斯网络的盘式刀库故障分析

- 1.清华大学 机械工程系,北京 100084

2.德大机械(昆山)有限公司,江苏 苏州 215314

Fault analysis of circular tool magazine based on Bayesian network

Li-ping WANG1( ),Bin ZHU1,Jun WU1(

),Bin ZHU1,Jun WU1( ),Zi-han TAO2

),Zi-han TAO2

- 1.Department of Mechanical Engineering,Tsinghua University,Beijing 100084,China

2.Deda Machinery (Kunshan) Co. ,Ltd. ,Suzhou 215314,China

摘要:

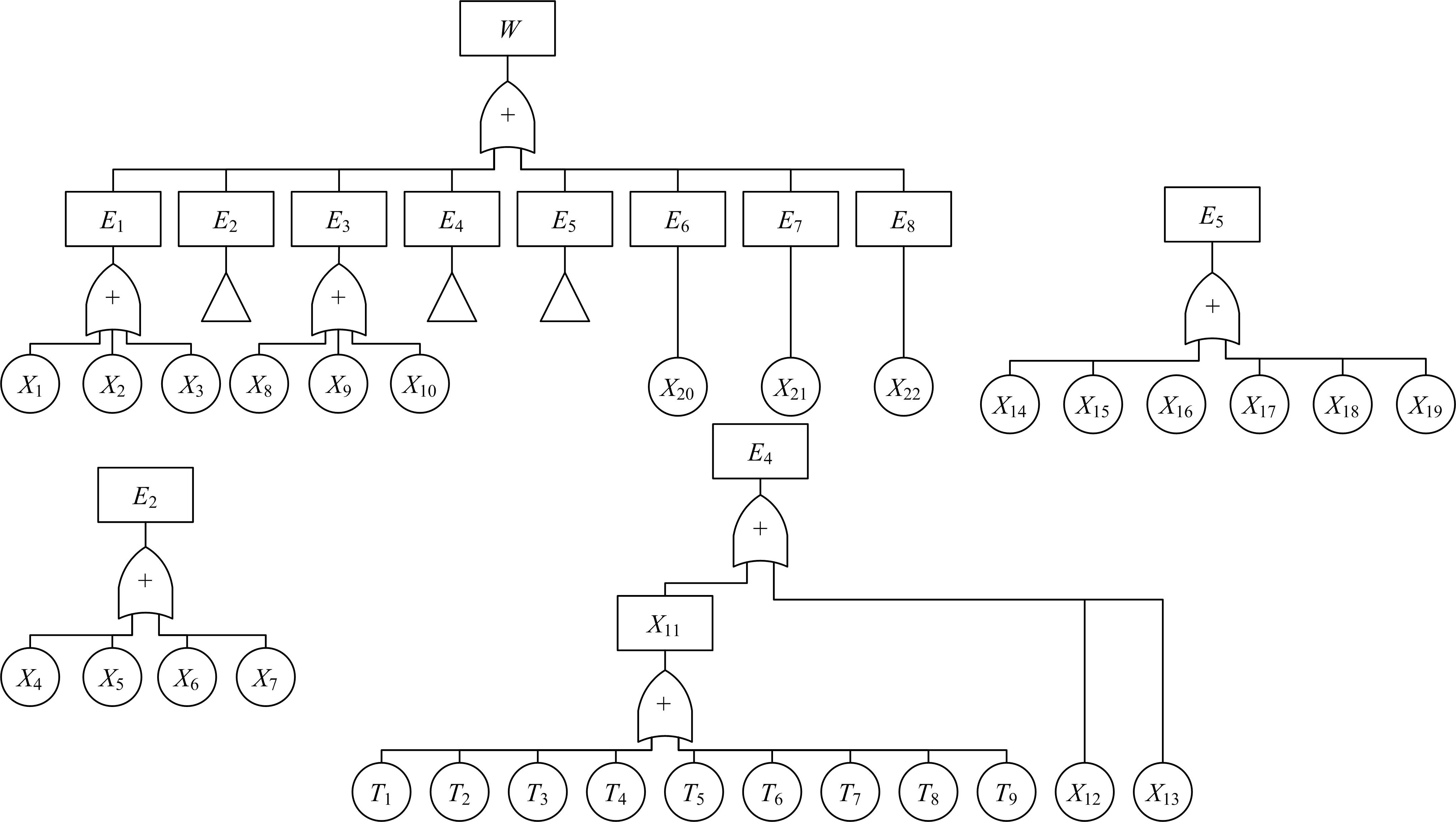

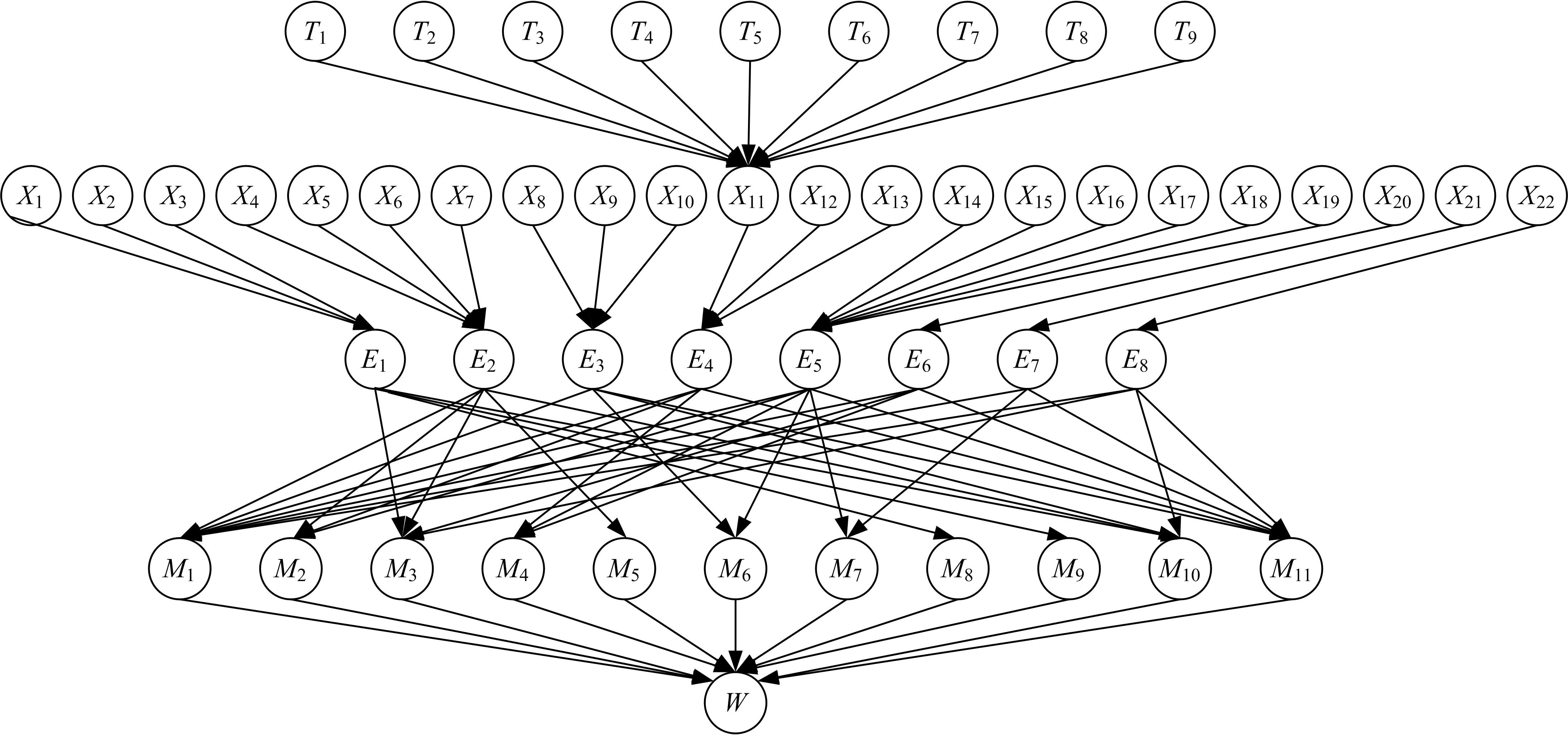

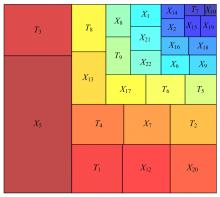

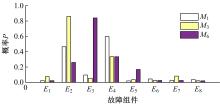

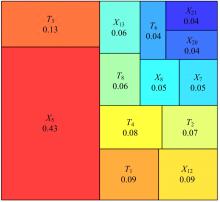

针对刀库故障模式多样、故障原因不明的问题,基于刀库故障树分析,建立了盘式刀库系统贝叶斯网络,并利用一批故障数据求解网络节点的先验概率与条件概率。由贝叶斯网络节点重要度分析发现,刀盘电机、刀臂定位键及刀臂本体为盘式刀库的可靠性薄弱环节。此外,由贝叶斯父节点后验故障概率分析发现,换刀组件、储刀组件故障是造成刀库掉刀的主要原因,若发生掉刀应优先检修刀臂及刀盘电机。

中图分类号:

- TG659

| 1 | Li Guo-fa, Wang Yan-bo, He Jia-long, et al. Fault forecasting of a machining center tool magazine based on health assessment[J]. Mathematical Problems in Engineering, 2020,(2020): 5796965. |

| 2 | 李国发, 李屹, 王大川, 等. 盘式刀库可靠性试验状态监测及故障预警研究[J]. 组合机床与自动化加工技术, 2018(8): 86-89. |

| Li Guo-fa, Li Yi, Wang Da-chuan, et al. Research on status monitoring and fault warning for reliability testing of circular tool magazine[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2018(8): 86-89. | |

| 3 | 张跃明, 黄文杰, 牟宏明, 等. 基于加权数据融合的刀库及ATC系统可靠性评测研究[J]. 组合机床与自动化加工技术, 2015(5): 152-155. |

| Zhang Yue-ming, Huang Wen-jie, Mu Hong-ming, et al. The research on tool change precision of knife library and automatic tool changer[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2015(5): 152-155. | |

| 4 | 段炜. 加工中心盘式刀库换刀系统的故障预警方法研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2014. |

| Duan Wei. Fault prediction for atc of a disc-type tool changer of machining center[D]. Changchun: College of Mechanical and Aerospace Engineering, Jilin University, 2014. | |

| 5 | 杨兆军, 陈传海, 陈菲, 等. 数控机床可靠性技术的研究进展 [J]. 机械工程学报, 2013, 49(20): 130-139. |

| Yang Zhao-jun, Chen Chuan-hai, Chen Fei, et al. Progress in the research of reliability technology of machine tools[J]. Journal of Mechanical Engineering, 2013, 49(20): 130-139. | |

| 6 | 王宁. 盘式刀库机械手多应力可靠性加速试验方法研究[D]. 长春: 吉林大学机械与航空航天工程学院, 2020. |

| Wang Ning. Research on accelerated test method of multi-stress reliability for disc tool magazine automatic tool changing system[D]. Changchun: College of Mechanical and Aerospace Engineering, Jilin University, 2020. | |

| 7 | 薛玉霞, 申桂香, 张英芝. 基于模糊逻辑的数控机床故障分析[J]. 吉林大学学报: 工学版, 2008, 38(): 115-118. |

| Xue Yu-xia, Shen Gui-xiang, Zhang Ying-zhi. Fault analysis for numerical control machine tools based on fuzzy logic[J]. Journal of Jilin University(Engineering and Technology Edition), 2008, 38(Sup.1): 115-118. | |

| 8 | 郑玉彬, 申桂香, 张英芝, 等. 基于贝叶斯网络的链式刀库系统重要度分析[J]. 吉林大学学报: 工学版, 2019, 49(2): 466-471. |

| Zheng Yu-bin, Shen Gui-xiang, Zhang Ying-zhi, et al. Importance analysis of chain-type tool magazine system based on bayesian network[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(2): 466-471. | |

| 9 | Jin Chuan-xi, Ran Yan, Zhang Gen-bao. Interval-valued q-rung orthopair fuzzy FMEA application to improve risk evaluation process of tool changing manipulator[J]. Applied Soft Computing, 2021, 104: 107192. |

| 10 | 罗巍, 王贤琳. 基于模糊故障树的刀库系统可靠性分析[J]. 机床与液压, 2016, 44(9): 165-169. |

| Luo Wei,Wang Xian-lin. Reliability analysis for tool magazine system based on fuzzy fault tree[J]. Machine Tool & Hydraulics, 2016, 44(9): 165-169. | |

| 11 | 张根保, 许智, 王国强, 等. 基于模糊理论的GO法多时序可靠性分析研究[J]. 机械设计, 2010, 27(11):15-18, 72. |

| Zhang Gen-bao, Xu Zhi, Wang Guo-qiang, et al. Reliability analysis of GO method multi-temporal based on fuzzy theory[J]. Journal of Machine Design, 2010, 27(11): 15-18, 72. | |

| 12 | 许智. 加工中心及其功能部件可靠性技术研究[D]. 重庆: 重庆大学机械工程学院, 2011. |

| Xu Zhi. Research on reliability technology of machining center and its functional units[D]. Chongqing: College of Mechanical Engineering, Chongqing University, 2011. | |

| 13 | 申桂香, 李怀洋, 张英芝, 等. 刀库故障重要度分析与可靠性改进设计[J]. 重庆大学学报, 2013, 36(6): 70-75. |

| Shen Gui-xiang, Li Huai-yang, Zhang Ying-zhi, et al. The importance analysis of tool magazine fault and its reliability improved design[J]. Journal of Chongqing University, 2013, 36(6): 70-75. | |

| 14 | 申桂香, 丁烨, 张英芝, 等. 基于云模型的刀库系统故障分析[J]. 中南大学学报(自然科学版), 2013, 44(4): 1420-1424. |

| Shen Gui-xiang, Ding Ye, Zhang Ying-zhi, et al. Failure analysis of tool changer system based on cloud model[J]. Journal of Central South University(Science and Technology), 2013, 44(4): 1420-1424. | |

| 15 | 刘瑞. 基于贝叶斯网络的洪水灾害风险评估与建模研究[D]. 上海: 华东师范大学地理科学学院, 2016. |

| Liu Rui. A study on modeling of flood risk evaluation based on bayesian networks[D]. Shanghai: School of Geographic Sciences, East China Normal University, 2016. | |

| 16 | 周恩泽, 黄勇, 龚博, 等. 基于朴素贝叶斯网络的输电走廊山火风险评估模型[J]. 南方电网技术, 2021, 8(15): 120-129. |

| Zhou En-ze, Huang Yong, Gong Bo, et al. Wildfire risk assessment model of power transmission line corridors based on naive bayes network[J]. Southern Power System Technology, 2021, 8(15): 120-129. |

| [1] | 王利民,刘洋,孙铭会,李美慧. 基于Markov blanket的无约束型K阶贝叶斯集成分类模型[J]. 吉林大学学报(工学版), 2018, 48(6): 1851-1858. |

| [2] | 孙晓颖, 扈泽正, 杨锦鹏. 基于分层贝叶斯网络的车辆发动机系统电磁脉冲敏感度评估[J]. 吉林大学学报(工学版), 2018, 48(4): 1254-1264. |

| [3] | 孙晓颖, 王震, 杨锦鹏, 扈泽正, 陈建. 基于贝叶斯网络的电子节气门电磁敏感度评估[J]. 吉林大学学报(工学版), 2018, 48(1): 281-289. |

| [4] | 蔡朝晖, 张健沛, 杨静. 基于贝叶斯网络的路网位置匿名区域估计[J]. 吉林大学学报(工学版), 2014, 44(2): 454-458. |

| [5] | 许洪国, 张慧永, 宗芳. 交通事故致因分析的贝叶斯网络建模[J]. 吉林大学学报(工学版), 2011, 41(增刊1): 89-94. |

| [6] | 李永丽, 刘衍珩, 李真. 一种用于危险源评估的TAN分类器[J]. 吉林大学学报(工学版), 2010, 40(增刊): 320-0323. |

| [7] | 邵继业,王日新,徐敏强. 贝叶斯网络在模型诊断中的应用[J]. 吉林大学学报(工学版), 2010, 40(01): 234-0237. |

| [8] | 申桂香,何宇,张英芝,郑锐,樊少华. 基于有向因果图的数控车床关联故障分析[J]. 吉林大学学报(工学版), 2009, 39(增刊2): 328-0331. |

| [9] | 祁宏生,王殿海. 信号控制交叉路口车辆排队长度[J]. 吉林大学学报(工学版), 2009, 39(06): 1457-1462. |

| [10] | 王利民,李雄飞,张海龙 . 基于广义信息论的贝叶斯分类器动态建模[J]. 吉林大学学报(工学版), 2009, 39(03): 776-0780. |

| [11] | 王桂萍,贾亚洲,申桂香,乔巍巍 . 基于故障比重比的加工中心整机故障分析 及可靠性改进措施 [J]. 吉林大学学报(工学版), 2008, 38(增刊): 119-0122. |

| [12] | 董立岩,苑森淼,刘光远,李永丽,关伟洲 . 一种基于遗传算法的受限制的分类器学习算法[J]. 吉林大学学报(工学版), 2007, 37(03): 595-0599. |

| [13] | 乔巍巍,贾亚洲,张海波,王桂萍,张日明 . 数控系统故障分析及可靠性提高措施[J]. 吉林大学学报(工学版), 2006, 36(增刊2): 69-72. |

|

||