吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (2): 297-311.doi: 10.13229/j.cnki.jdxbgxb20220175

• 综述 • 下一篇

水泥稳定碎石材料干燥收缩研究综述

- 东南大学 交通学院,南京 211189

Dry shrinkage in cement⁃stabilized macadam: a review

Yang ZHANG( ),Ao-peng WANG,Jing-lin ZHANG,Tao MA(

),Ao-peng WANG,Jing-lin ZHANG,Tao MA( ),Si-yu CHEN

),Si-yu CHEN

- School of Transportation,Southeast University,Nanjing 211189,China

摘要:

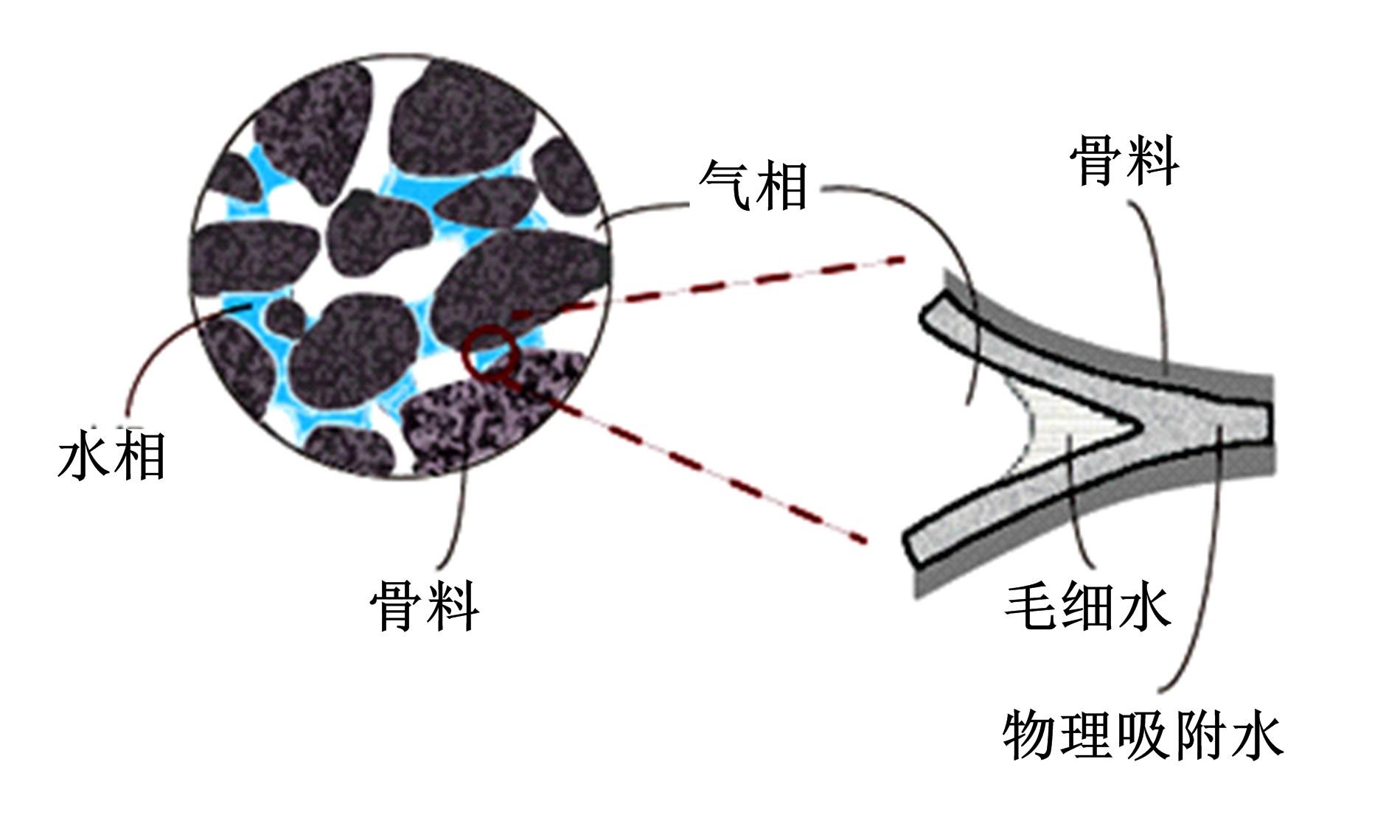

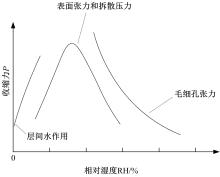

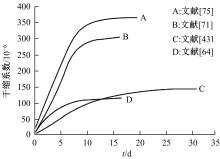

为进一步研究水泥稳定碎石的干燥收缩行为,改善其在道路基层的抗开裂性能,针对水泥稳定碎石材料基层由于干燥收缩而引起沥青路面面层反射裂缝的问题,通过对现有资料与研究成果的总结,对水泥稳定碎石干燥收缩机理以及调控措施进行了综述。减少水泥用量,采用骨架密实级配类型,使用振动搅拌或者振动压实成型方式,添加橡胶、钢渣、纤维等改性剂可以有效减少水泥稳定碎石材料的干燥收缩,提高其收缩性能与路用性能。在此基础上分析了水泥稳定碎石的收缩机理、综合优化方法、干燥收缩测量评价方法以及收缩预估模型存在的问题,提出了水泥稳定碎石收缩性能研究的发展趋势与展望。

中图分类号:

- U414

| 1 | 蒋应军. 水泥稳定碎石基层收缩裂缝防治研究[D]. 西安: 长安大学公路学院, 2001. |

| Jiang Ying-jun. Study on the shrinkage crack prevention and cure problem on the stable crushed stones base[D]. Xi'an: School of Highway, Chang'an University, 2001. | |

| 2 | Wu L, Farzadnia N, Shi C,et al.Autogenous shrinkage of high performance concrete: a review[J]. Construction and Building Materials, 2017, 149: 62-75. |

| 3 | 张君, 侯东伟, 高原. 混凝土自收缩与干燥收缩的统一内因[J]. 清华大学学报:自然科学版, 2010, 50(9): 1321-1324. |

| Zhang Jun, Hou Dong-wei, Gao Yuan. The uniform internal cause of the self-shrinking and drying contraction of concrete[J]. Journal of Tsinghua University (Science and Technology), 2010, 50(9): 1321-1324. | |

| 4 | 陈宝春, 李聪, 黄伟, 等. 超高性能混凝土收缩综述[J]. 交通运输工程学报, 2018, 18(1): 13-28. |

| Chen Bao-chun, Li Cong, Huang Wei,et al.Review of ultra-high performance concrete shrinkage[J]. Journal of Traffic and Transportation Engineering, 2018, 18(1): 13-28. | |

| 5 | 韩宇栋,张君,岳清瑞,等.现代混凝土收缩研究评述[J]. 混凝土, 2019(2): 1-12, 16. |

| Han Yu-dong, Zhang Jun, Yue Qing-rui,et al.Review on shrinkage of modern concrete[J]. Concrete, 2019(2): 1-12, 16. | |

| 6 | Ye H, Aleksandra R. A review and comparative study of existing shrinkage prediction models for portland and non-portland cementitious materials[J]. Advances in Materials Science and Engineering, 2016: 1-13. |

| 7 | Kovler K, Zhutovsky S. Overview and future trends of shrinkage research[J]. Materials and Structures, 2006, 39(9): 827-847. |

| 8 | Bella C D, Wyrzykowski M, Lura P. Evaluation of the ultimate drying shrinkage of cement-based mortars with poroelastic models[J]. Materials and Structures, 2017, 50(1): 52. |

| 9 | Idiart A. Coupled analysis of degradation processes in concrete specimens at the meso-level[D]. Barcelona: Universitat Polit'ecnica de Catalunya, 2009. |

| 10 | Duckheim C, Setzer M J. Drying shrinkage mechanisms of hardened cement paste[C]∥Creep, Shrinkage and Durability Mechanics of Concrete and Concrete Structures, Two Volume Set, London, 2008: 49-55. |

| 11 | Maruyama I, Nishioka Y, Igarashi G, et al. Microstructural and bulk property changes in hardened cement paste during the first drying process[J]. Cement & Concrete Research, 2014, 58: 20-34. |

| 12 | Andrade C, Sarrı́a J, Alonso C. Relative humidity in the interior of concrete exposed to natural and artificial weathering[J].Cement and Concrete Research, 1999, 29( 8): 1249-1259. |

| 13 | 王振军. 水泥乳化沥青混凝土浆体—集料界面区结构与性能研究[D]. 陕西: 长安大学公路学院, 2007. |

| Wang Zhen-jun. Study on structure and properties of slurry aggregate interface of cement emulsified asphalt concrete[D].Xi'an:School of Highway,Chang'an University,2007. | |

| 14 | Splittgerber H, Wittmann F. Einfluss adsorbierter wasserfilme auf die Van der Waals kraft zwischen quarzglasoberflchen[J]. Surface Science, 1974, 41(2): 504-514. |

| 15 | Maruyama I, Igarashi G, Nishioka Y. Bimodal behavior of C-S-H interpreted from short-term length change and water vapor sorption isotherms of hardened cement paste[J]. Cement & Concrete Research, 2015, 73: 158-168. |

| 16 | Rahimi-Aghdam S, Masoero E, Rasoolinejad M, et al. Century-long expansion of hydrating cement counteracting concrete shrinkage due to humidity drop from selfdesiccation or external drying[J]. Materials and Structures, 2019, 52(1): 1-21. |

| 17 | Maruyama I, Ohkubo T, Haji T, et al. Dynamic microstructural evolution of hardened cement paste during first drying monitored by 1 H NMR relaxometry[J]. Cement and Concrete Research, 2019, 122: 107-117. |

| 18 | Hamlin M J, Aditya K, Gaurav S. A quantitative discrimination of the nano-pore-structure of cement paste during drying: new insights from water sorption isotherms[J]. Cement & Concrete Research, 2015, 76: 27-36. |

| 19 | Pinson M B, Masoero E, Bonnaud P A, et al. Hysteresis from multiscale porosity: modeling water sorption and shrinkage in cement paste[J]. Physical Review Applied, 2015, 3(6): 64009. |

| 20 | 曾梦澜, 罗迪, 吴超凡, 等. 不同级配类型水泥稳定碎石路面基层材料的抗裂性能[J]. 湖南大学学报: 自然科学版, 2013, 40(10): 1-7. |

| Zeng Meng-lan, Luo Di, Wu Chao-fan, et al. Anti-cracking properties of cement stabilized crushed stone pavement base materials of different aggregate structures[J]. Journal of Hunan University(Nature Science), 2013, 40(10): 1-7. | |

| 21 | 查旭东, 曹艳霞, 刘国才. 抗裂型水泥稳定碎石配合比设计及路用性能研究[J]. 长沙理工大学学报: 自然科学版, 2013, 10(1): 1-6. |

| Zha Xu-dong, Cao Yan-xia, Liu Guo-cai, et al. Research on mix design and pavement performances for anti-crack cement stabilized macadam[J]. Journal of Changsha University of Science and Technology(Nature Science), 2013, 10(1): 1-6. | |

| 22 | 彭波,李龙刚,尹光凯,等.低水泥剂量稳定碎石级配组成设计与性能研究[J].公路, 2018, 63(5): 26-33. |

| Peng Bo, Li Long-gang, Yin Guang-kai, et al. Gradation composition design and performance study of low dose cement stabilized macadam[J]. Highway, 2018, 63(5): 26-33. | |

| 23 | 梁春雨, 郭有蒙, 张利东, 等. 季冻区多指标水泥稳定碎石性能评价及级配优选[J]. 吉林大学学报: 工学版, 2020, 50(3): 998-1005. |

| Liang Chun-yu, Guo You-meng, Zhang Li-dong, et al. Performance evaluation and gradation optimal selection of multi-index cement stabilized macadam in seasonal frozen area[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(3): 998-1005. | |

| 24 | 李明杰, 蒋应军, 戴经梁. 水泥稳定碎石缩裂机理及在级配设计中应用[J]. 武汉理工大学学报, 2010, 32(3): 1-4, 8. |

| Li Ming-jie, Jiang Ying-jun, Dai Jing-liang.Analysis and apply of anti-cracking mechanism of cement stabilization of crushed aggregate[J]. Journal of Wuhan University of Technology, 2010,32(3): 1-4, 8. | |

| 25 | 蒋应军, 陈忠达, 彭波, 等. 密实骨架结构水泥稳定碎石路面配合比设计方法及抗裂性能[J]. 长安大学学报: 自然科学版, 2002(4): 9-12. |

| Jiang Ying-jun, Chen Zhong-da, Peng Bo,et al.Mixture design method and anti-cracking performance of cement stabilized crashed rock pavement with dense skeleton type[J]. Journal of Chang'an University(Nature Science Edition), 2002(4): 9-12. | |

| 26 | 孙兆辉. 基于抗裂性能的水泥稳定碎石级配组成研究[J]. 公路, 2006, 4(8): 34-40. |

| Sun Zhao-hui. A study on gradation composition of cement stabilized macadam base on crack resistance performance[J]. Highway, 2006, 4(8): 34-40. | |

| 27 | 李明, 李昶, 刘继华, 等. 粗集料及界面特性对水泥稳定碎石温缩抗裂性能影响性分析[J]. 公路, 2019, 64(10): 1-7. |

| Li Ming, Li Chang, Liu Ji-hua,et al.Effect of coarse aggregate and interfacial characteristics on crack resistance in temperature shrinkage of cement-stabilized macadam[J]. Highway, 2019, 64(10): 1-7. | |

| 28 | Grassl P, Hong S W, Buenfeld N R.Influence of aggregate size and fraction on shrinkage induced micro-cracking of mortar and concrete[J/OL].[2021-02-27]. |

| 29 | Liu Z, Wei X, Wang D, et al. Performance of cement-stabilized macadam roads based on aggregate gradation interpolation tests[J]. Mathematical Biosciences and Engineering, 2019, 16(4): 2371-2390. |

| 30 | Fujiwara T. Effect of aggregate on drying shrinkage of concrete[J]. Doboku Gakkai Ronbunshu, 2008(1): 31-44. |

| 31 | 于新, 黄晓明. 低剂量水泥稳定碎石基层干缩温缩性能研究[J]. 公路交通科技, 2007(7): 52-55. |

| Yu Xin, Huang Xiao-ming. Study on the dry shrinkage performance of low-dose cement stabilized macadam base[J]. Journal of Highway and Transportation Research and Development, 2007(7): 52-55. | |

| 32 | 张嗄吱. 考虑抗裂性的水泥稳定类材料配合比设计方法研究[D]. 西安: 长安大学公路学院, 2001. |

| Zhang Ga-zi. Research on the design method of cement stabilized material mix ratio considering crack resistance[D]. Xi'an: School of Highway, Chang'an University, 2001. | |

| 33 | Maruyama I, Sugie A. Numerical study on drying shrinkage of concrete affected by aggregate size[J]. Journal of Advanced Concrete Technology, 2014, 12(8): 279-288. |

| 34 | 赵利军,蒋文志,侯劲汝,等.搅拌方式对水泥稳定碎石混合料抗压强度的影响[J].中国公路学报,2018, 31(1): 151-158. |

| Zhao Li-jun, Jiang Wen-zhi, Hou Jin-ru, et al. Influence of mixing methods on performance of compressive strength for cement stabilized macadam mixture[J]. China Journal of Highway and Transport, 2018, 31(1): 151-158. | |

| 35 | 董武, 谢诗元, 赵利军, 等. 振动对水泥稳定碎石搅拌过程和性能的影响[J]. 中国公路学报, 2019, 32(5): 181-190. |

| Dong Wu, Xie Shi-yuan, Zhao Li-jun, et al. Influence of vibration on mixing process of cement stabilized macadam and its performance[J]. China Journal of Highway and Transport, 2019, 32(5): 181-190. | |

| 36 | 蒋应军. 基于振动法设计的抗裂型水泥稳定碎石基层应用研究[J]. 公路, 2008, 4(12): 36-41. |

| Jiang Ying-jun. Application research on anti-crack cement stabilized macadam base on vibration method design[J]. Highway, 2008, 4(12): 36-41. | |

| 37 | 李立寒,黄璞,刘栋.旋转与静压成型对水泥稳定碎石性能的影响[J].长安大学学报:自然科学版,2016, 36(6): 17-25. |

| Li Li-han, Huang Pu, Liu Dong. Impact on performance of cement stabilized macadam mixtures between gyratory compaction and static compaction methods[J]. Journal of Chang'an University(Nature Science Edition), 2016, 36(6): 17-25. | |

| 38 | 吕松涛,郑健龙,仲文亮.养生期水泥稳定碎石强度、模量及疲劳损伤特性[J].中国公路学报, 2015, 28(9): 9-15, 45. |

| Song-tao Lyu, Zheng Jian-long, Zhong Wen-liang. Characteristics of strength, modulus and fatigue damage for cement stabilized macadam in curing period[J]. China Journal of Highway and Transport, 2015, 28(9): 9-15, 45. | |

| 39 | 曾梦澜, 阮文, 蒙艺, 等. 二灰钢渣碎石路面基层材的设计与使用性能[J]. 湖南大学学报: 自然科学版, 2012, 39(10): 1-6. |

| Zeng Meng-lan, Ruan Wen, Meng Yi, et al. Design and performance of lime and fly-ash stabilized steel-slag and crushed-stone pavement base materials[J]. Journal of Hunan University(Nature Science), 2012, 39(10): 1-6. | |

| 40 | 李飞, 陈勇鸿, 高伏良, 等. 掺钢渣无机结合料稳定路面基层材料干缩温缩试验研究[J]. 公路, 2012, 4(12): 186-191. |

| Li Fei, Chen Yong-hong, Gao Fu-liang, et al. Experiment and study om dry and temperature induced shrinkage properties of inorganic binder stabilized pavement base material with steel slag[J]. Highway, 2012, 4(12): 186-191. | |

| 41 | Li W, Lang L, Lin Z, et al. Characteristics of dry shrinkage and temperature shrinkage of cement-stabilized steel slag[J]. Construction and Building Materials, 2017, 134(1): 540-548. |

| 42 | 郑武西. 钢渣在水泥稳定碎石基层中的应用研究[D]. 西安: 长安大学公路学院, 2018. |

| Zheng Wu-xi. Application of steel slag in cement stabilized crushed stone base[D]. Xi'an: School of Highway, Chang'an University, 2018. | |

| 43 | 肖杰, 龙晨杰, 何建刚, 等. 大掺量激活钢渣微粉-水泥稳定碎石性能及微观特性研究[J]. 中国公路学报, 2021, 34(10): 1-12. |

| Xiao Jie, Long Chen-jie, He Jian-gang, et al. Study on performance and micro characteristics of cement stabilized macadam with large amount of activated steel slag powder[J]. China Journal of Highway and Transport, 2021, 34(10): 1-12. | |

| 44 | Liu Z. Experimental research on the engineering characteristics of polyester fiber-reinforced cement-stabilized macadam[J]. Journal of Materials in Civil Engineering, 2015, 27(10): 1-10. |

| 45 | Banthia N, Gupta R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete[J]. Cement & Concrete Research, 2006, 36(7): 1263-1267. |

| 46 | 贺亚飞. 掺聚乙烯醇(PVA)纤维水泥稳定碎石的力学及抗裂性能研究[D]. 重庆: 重庆交通大学交通运输学院, 2016. |

| He Ya-fei. Study on mechanical properties and cracking resistance of the cement-stabilized macadam mixed with polyvinyl alcohol(PVA) fiber[D]. Chongqing: College of Traffic&Transportation, Chongqing Jiaotong University, 2016. | |

| 47 | Zhao Y, Yang X, Zhang Q, et al. Crack resistance and mechanical properties of polyvinyl alcohol fiber-reinforced cement-stabilized macadam base[J]. Advances in Civil Engineering, 2020(1): 1-15. |

| 48 | 谭国金, 朱德祺, 梁春雨, 等. 桥梁用聚丙烯纤维增强水泥基复合材料的力学性能[J]. 吉林大学学报: 工学版, 2020, 50(4): 1396-1402. |

| Tan Jin-guo, Zhu De-qi, Liang Chun-yu, et al. Mechanical properties of polypropylene fiber reinforced engineering cementitious composites for bridges[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(4): 1396-1402. | |

| 49 | 杨红辉,王建勋,郝培文,等.纤维在水泥稳定碎石基层中的应用[J].长安大学学报:自然科学版,2006,4(3): 14-16, 20. |

| Yang Guo-jin, Wang Jian-xun, Hao Pei-wen,et al. Utilization of fiber in cement-stabilized aggregate mixture[J]. Journal of Chang'an University(Nature Science Edition), 2006, 4(3): 14-16, 20. | |

| 50 | Peng Z, Li Q. Experimental study on shrinkage properties of cement-stabilized macadam reinforced with polypropylene fiber[J]. Journal of Reinforced Plastics and Composites, 2010, 29(12): 1851-1860. |

| 51 | Peng Z, Li Q. Effect of polypropylene fibre on mechanical and shrinkage properties of cement-stabilised macadam[J]. International Journal of Pavement Engineering, 2009, 10(6): 435-445. |

| 52 | 李远厂. 乳化沥青-柔性纤维改性水泥稳定碎石的路用性能研究[D]. 重庆: 重庆交通大学交通运输学院, 2015. |

| Li Yuan-chang.Study on pavement performance of cement stabilized macadam with emulsified asphalt and flexible fiber[D]. Chongqing: College of Traffic&Transportation, Chongqing Jiaotong University, 2015. | |

| 53 | 徐建成. 掺聚丙烯纤维的水泥稳定碎石在市政道路中的应用研究[D]. 扬州: 扬州大学建筑科学与工程学院, 2012. |

| Xu Jian-cheng. The research on the cement-stabilized aggregate mixtures adding polypropylene fiber applied to municipal roads[D]. Yangzhou: College of Building Science and Engineering, Yangzhou University, 2012. | |

| 54 | Grilli A, Bocci M, Tarantino A M. Experimental investigation on fibre-reinforced cement-treated materials using reclaimed asphalt[J]. Construction and Building Materials, 2013, 38(1): 491-496. |

| 55 | 白云. 玻璃纤维水泥稳定碎石路用性能研究[D]. 西安: 长安大学公路学院, 2014. |

| Bai Yun. Glass fiber cement stabilized aggregate performance study[D] Xi'an: School of Highway, Chang'an University, 2014. | |

| 56 | 杨明. 掺玄武岩纤维水泥稳定碎石基层抗裂性能研究[D]. 哈尔滨: 东北林业大学交通运输学院, 2011. |

| Yang Ming. Study of crack resistance on cement stabilized macadam base with mixed basalt fiber[D]. Harbin: School of Traffic and Transportation, Northeast Forestry University, 2011. | |

| 57 | 李淑. 玄武岩纤维水泥稳定碎石路用性能试验研究[D]. 青岛: 中国海洋大学工程学院, 2014. |

| Li Shu. Experiment study on pavement performance of basalt fiber cement stabilized macadam[D]. Qingdao: College of Engineering, Ocean University of China, 2014. | |

| 58 | 范文孝. 玄武岩纤维增强路面材料性能试验研究[D]. 大连: 大连理工大学土木水利学院, 2011. |

| Fan Wen-xiao. Experimental investigation on performance of basalt fiber-reinforced pavement materials[D]. Dalian: School of Civil Engineering and Water Resources, Dalian University of Technology, 2011. | |

| 59 | 暴英波. 玄武岩纤维水泥稳定碎石性能研究[D]. 西安: 长安大学公路学院, 2017. |

| Bao Ying-bo. Performance study of the cement stabilized macadam with basalt fiber[D]. Xi'an: School of Highway, Chang'an University, 2017. | |

| 60 | Zheng Y, Zhang P, Cai Y, et al. Cracking resistance and mechanical properties of basalt fibers reinforced cement-stabilized macadam[J]. Composites Part B: Engineering, 2019, 165(15): 312-334. |

| 61 | Topcu I B.The properties of rubberized concretes[J].Cement & Concrete Research,1995, 25(2): 304-310. |

| 62 | Grinys A, Sivilevicius H, Pupeikis D, et al. Fracture of concrete containing crumb rubber[J]. Statyba, 2013, 19(3): 447-455. |

| 63 | 吕松涛,王双双,王盘盘,等.橡胶-水泥稳定碎石持强增韧特性研究[J].中国公路学报,2020,33(11): 139-147. |

| Lv Song-tao, Wang Shuang-shuang, Wang Pan-pan, et al. Strength and toughness of rubber-cement stabilized macadam[J]. China Journal of Highway and Transport, 2020, 33(11): 139-147. | |

| 64 | Farhan A H, Dawson A R, Thom N H, et al. Flexural characteristics of rubberized cement-stabilized crushed aggregate for pavement structure[J]. Materials & Design, 2015, 88(25): 897-905. |

| 65 | Sun X, Wu S, Yang J, et al. Mechanical properties and crack resistance of crumb rubber modified cement-stabilized macadam[J]. Construction and Building Materials, 2020, 259: 119708. |

| 66 | 曲美燕. 掺纳米层状材料的水泥稳定碎石抗裂性能研究[D]. 南京: 东南大学化学化工学院, 2015. |

| Qu Mei-yan. Research on anti-cracking performances of the cement stable macadam adding layered materials[D]. Nanjing: Chemistry and Chemical Engineering, Southeast University, 2015. | |

| 67 | 王程.建筑垃圾复合粉体材料在公路半刚性基层材料中的应用研究[D].西安:长安大学公路学院,2017. |

| Wang Cheng. Research on construction waste composite powder materials in the application of highway semi-rigid base[D]. Xi'an: School of Highway, Chang'an University, 2017. | |

| 68 | 徐鸥明, 王有贵, 陈俊宇, 等. 掺粉煤灰水泥稳定碎石收缩特性研究[J]. 重庆交通大学学报: 自然科学版, 2014, 33(4): 72-75. |

| Xu Ou-ming, Wang You-gui, Chen Jun-yu, et al. Shrinkage properties of cement stabilized crushed stones mixed with fly-ash[J]. Journal of Chongqing Jiaotong University(Nature Science), 2014, 33(4):72-75. | |

| 69 | 徐鸥明, 王士珩, 白敏, 等. 粉煤灰与粒化高炉矿渣对水泥稳定碎石强度和收缩特性影响研究[J]. 广西大学学报: 自然科学版, 2019, 44(2): 509-515. |

| Xu Ou-ming, Wang Shi-heng, Bai Min, et al. Influence of fly ash and granulated blast furnace slag on strength and shrinkage characteristics of cement stabilized crushed stone[J]. Journal of Guangxi University (Nature Science Edition), 2019, 44(2): 509-515. | |

| 70 | 贾克聪.乳化沥青对水泥稳定碎石强度特性及力学性能的影响[J].公路工程,2015,40(3):213-217, 229. |

| Jia Ke-cong. The affect of emulsified asphalt on strength characteristics and mechanical properties of cement stabilized macadam[J]. Highway Engineering, 2015, 40(3): 213-217, 229. | |

| 71 | Du S. Mechanical properties and shrinkage characteristics of cement stabilized macadam with asphalt emulsion[J]. Construction & Building Materials, 2019, 203: 408-416. |

| 72 | 王海朋. 掺细废旧料水泥稳定碎石抗裂性研究[D]. 西安: 长安大学公路学院, 2011. |

| Wang Hai-peng. Study on crack resistance property about cement stabilization crushed-stones mixed with particles of reclaimed asphalt pavement[D]. Xi'an:School of Highway, Chang'an University, 2011. | |

| 73 | 曲美燕,马全红,许雪松.凹凸棒石黏土对水泥稳定碎石性能的影响[J]. 东南大学学报: 自然科学版, 2015, 45(2): 399-403. |

| Qu Mei-yan, Ma Quan-hong, Xu Xue-song. Influence of palygorskite clay on properties of cement-stabilized macadam[J]. Journal of Southeast University (Nature Science Edition), 2015, 45(2): 399-403. | |

| 74 | 陆青清. 脱硫石膏水泥稳定碎石减缩与增强行为机制[J]. 吉林大学学报:工学版, 2021, 51(1): 252-258. |

| Lu Qing-qing. Strength enhancement and shrinkage reduction mechanism of desulfurized gypsum cement stabilized aggregates[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(1): 252-258. | |

| 75 | Li X, Lv X, Wang W,et al.Crack resistance of waste cooking oil modified cement stabilized macadam[J]. Journal of Cleaner Production,2020,243(10): 118525. |

| 76 | Yan K, Gao F, Sun H, et al. Effects of municipal solid waste incineration fly ash on the characterization of cement-stabilized macadam[J]. Construction and Building Materials, 2019, 207(20): 181-189. |

| 77 | Baant Z P, Panula L. Practical prediction of time-dependent deformations of concrete[J]. Matériaux Et Construction, 1978, 11(5): 317-328. |

| 78 | Kass R E, Eden U T, Brown E N. Propagation of Uncertainty and the Bootstrap[M]. New York:Springer, 2014. |

| 79 | Coussy O, Damgla P, Lassabatere T, et al. The equivalent pore pressure and the swelling and shrinkage of cement-based materials[J]. Materials & Structures, 2004, 37(265): 15-20. |

| 80 | 李侠, 耿敏, 张永芳. 水泥稳定碎石干缩应变BP网络预测模型[J]. 低温建筑技术, 2011, 33(3): 80-82. |

| Li Xia, Geng Min, Zhang Yong-fang. BP network prediction model for shrinkage strain of cement stabilized macadam[J]. Low Temperature Architecture Technology, 2011, 33(3): 80-82. | |

| 81 | Wang Y, Ni F, Xuan W. Research on dry-shrinkage performance of cement-treated base materials[C]∥Geohunan International Conference, Changsha,China, 2009: 81-86. |

| 82 | 李娟燕,周娟.水泥稳定碎石干缩研究进展简述[J]. 交通科技, 2017(6): 103-106, 112. |

| Li Juan-yan, Zhou Juan. A brief review of research progression on shrinkage of cement-stabilized macadam[J].Transportation Science and Technology,2017(6): 103-106, 112. |

| [1] | 商拥辉,徐林荣,刘维正,蔡雨. 重载铁路改良土和A组填料过渡段的动力特性[J]. 吉林大学学报(工学版), 2021, 51(6): 2128-2136. |

| [2] | 张姝玮,郭忠印,杨轸,柳本民. 驾驶行为多重分形特征在驾驶疲劳检测中的应用[J]. 吉林大学学报(工学版), 2021, 51(2): 557-564. |

| [3] | 陆青清. 脱硫石膏水泥稳定碎石减缩与增强行为机制[J]. 吉林大学学报(工学版), 2021, 51(1): 252-258. |

| [4] | 刘昕晖,李春爽,陈琳,王昕. 游梁式抽油机节能技术综述[J]. 吉林大学学报(工学版), 2021, 51(1): 1-26. |

| [5] | 凌建明,陈卉,钱劲松,周定. 湿度有限波动下非饱和黏土路基动态回弹模量[J]. 吉林大学学报(工学版), 2020, 50(2): 613-620. |

| [6] | 李阳,王连俊. 高铁站场宽路基复合地基二维模型适用性分析[J]. 吉林大学学报(工学版), 2020, 50(2): 621-630. |

| [7] | 宋玉泉,徐 进, 胡 萍,杨正海. 结 构 陶 瓷 的 超 塑 性[J]. 吉林大学学报(工学版), 2005, 35(03): 225-242. |

| [8] | 赵丁选 ,杨力夫,李锁云,尚 涛,乌效鸣. 国内外非开挖定向钻机及其智能控制技术[J]. 吉林大学学报(工学版), 2005, 35(01): 44-0048. |

|