吉林大学学报(工学版) ›› 2021, Vol. 51 ›› Issue (1): 1-26.doi: 10.13229/j.cnki.jdxbgxb20190951

• 综述 •

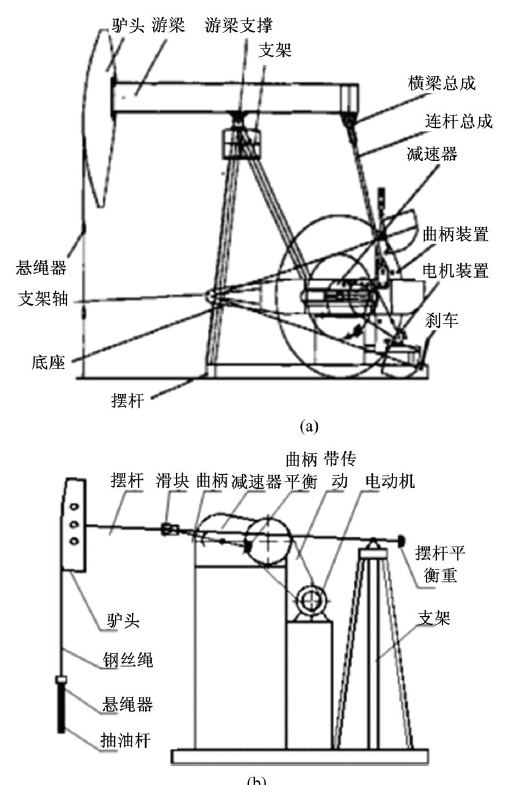

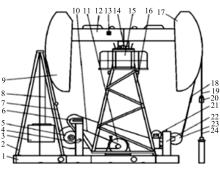

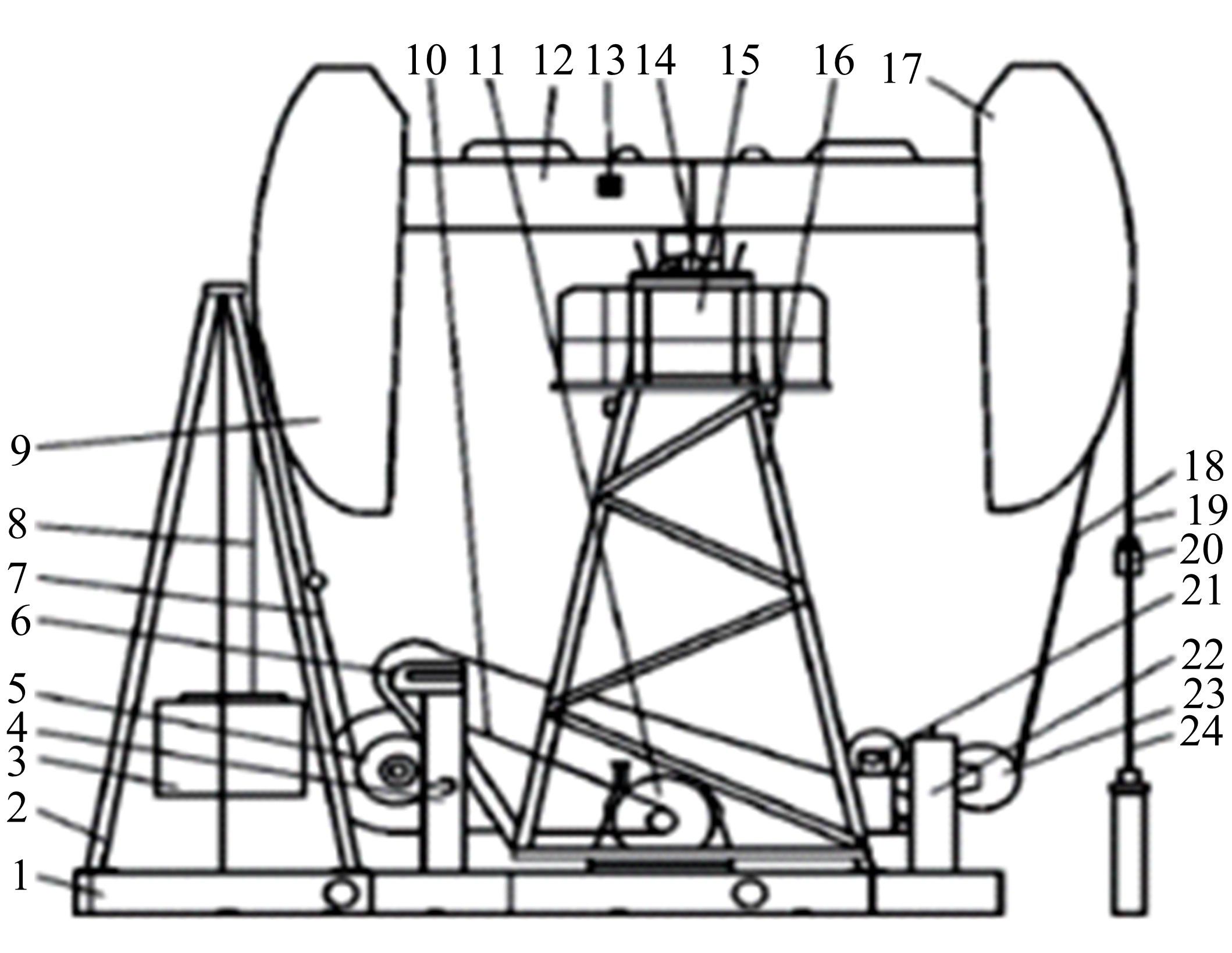

游梁式抽油机节能技术综述

- 1.吉林大学 机械与航空航天工程学院,长春 130022

2.上海汽车变速器有限公司 新能源驱动系统集成部,上海 201800

3.多伦多大学 机械与工业工程学院,加拿大 多伦多 M5T 1P7

Review of energy saving technologies for beam pumping units

Xin-hui LIU1( ),Chun-shuang LI1,Lin CHEN1,2,Xin WANG1,3(

),Chun-shuang LI1,Lin CHEN1,2,Xin WANG1,3( )

)

- 1.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

2.E -propulsion Division,Shanghai Automobile Gear Works,Shanghai 201800,China

3.School of Mechanical and Industry Engineering,University of Toronto,Toronto M5T 1P7,Canada

摘要:

游梁式抽油机是陆上油田中主要的采油装备,其采油能耗占油田总能耗的三分之一,但局限于系统的结构和使用条件,抽油机电动机平均负载率都很低,用电效率平均在30%以下。针对上述问题,科技工作者们提出并尝试了大量新技术、新方法,这些技术改进提高了采油能源利用效率,但也存在局限性和技术风险。作者首先分析了抽油机系统能耗的主要来源,通过对比指出最具节能潜力的是电动机部分。进而对目前公开报导的关于提升电动机用电效率的相关研究进行了分类总结,将相关技术研究主要分为机械传动结构改进、电动机及其控制技术改进、增设节能装置三大方向,并对其中的各种技术方案进行了概括和分析。通过分析和对比,并结合目前海洋石油开采和页岩油气开采的大背景,提出了在传统抽油设备上增设节能装置将是未来一段时间内游梁式抽油机节能的最有效的技术方向,而其中的液压混合动力节能技术是一种优势较为明显的技术方案。

中图分类号:

- TE933

| 1 | 周伊敏, 王永中. 世界石油市场回顾与展望:反弹和平衡[W/OL]. [2019-08-27]. . |

| 2 | 张弓. 油田抽油机的现状及节能方式综述[J]. 中国石油石化, 2017(1): 38-39. |

| Zhang Gong. Review of energy-saving methods and present situation of oilfield pumping units[J]. China Petrochem, 2017(1): 38-39. | |

| 3 | 刘合, 郝忠献, 王连刚, 等. 人工举升技术现状与发展趋势[J]. 石油学报, 2015, 36(11): 1441-1448. |

| Liu He, Hao Zhong-xian, Wang Liang-gang, et al. Current technical status and development trend of artificial lift[J]. Acta Petrolei Sinica, 2015, 36(11): 1441-1448. | |

| 4 | 罗林.2018年全年中国原油行业分析:产量接近1.9 |

| 亿吨,进口量达4.62亿吨[EB/OL].[2019–02–15]. . | |

| 5 | 朱荣东. 游梁抽油机增产节能方式研究[D].成都:西南石油学院机械设计理论系, 2005. |

| Zhu Rong-dong. Study on energy-saving way for increasing production of beam pumping unit[D]. Chengdu: Department of Mechanical Design Theory, Southwest Petroleum Institute,2005. | |

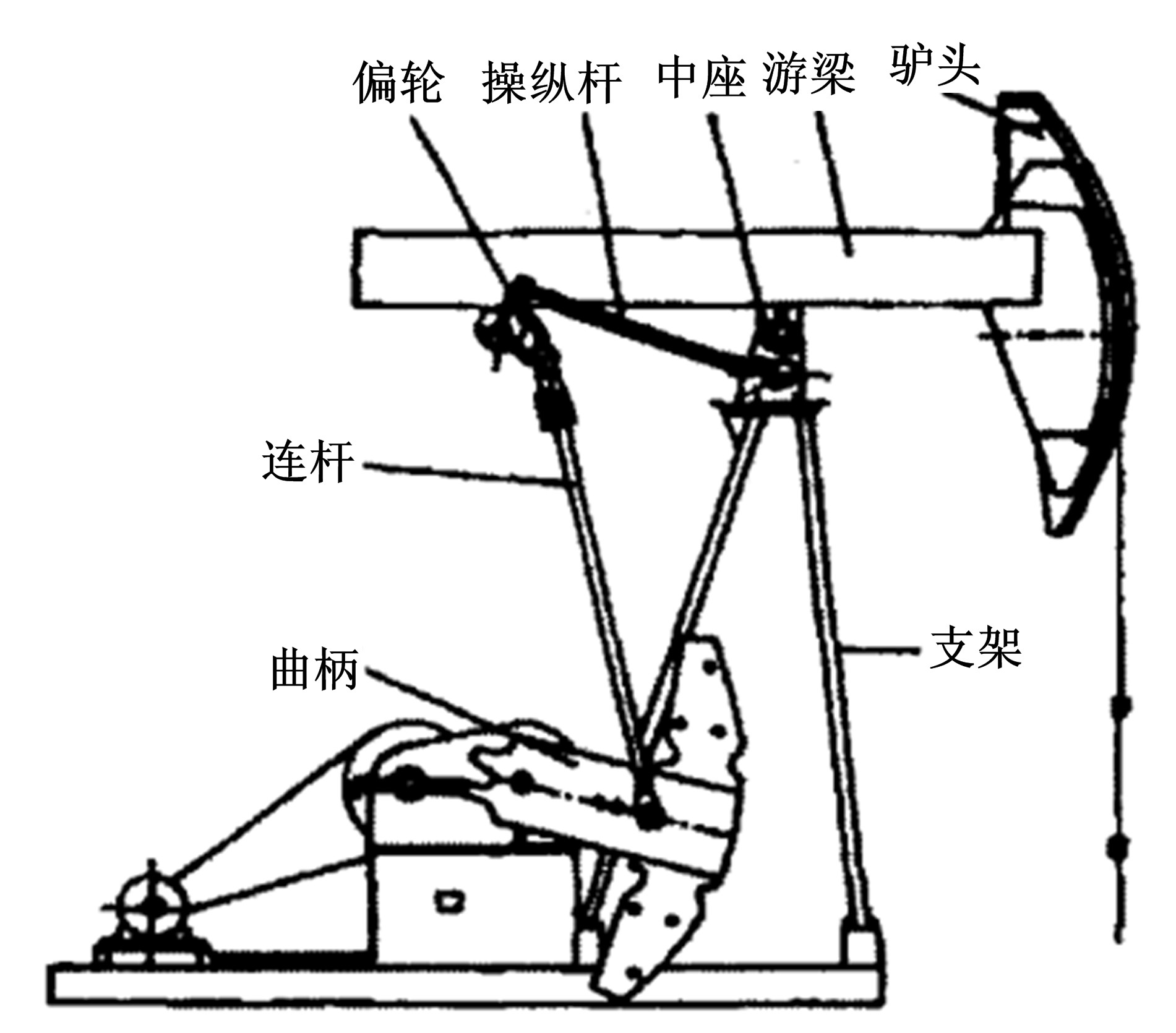

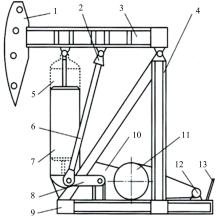

| 6 | 百度百科. 常规型游梁式抽油机[W/OL].[2019-08-27]. |

| 7 | 西林电气. EH600A在油田磕头机上的应用[W/OL].[2019-08-27]. |

| 8 | 邹振春, 邓立新, 王艳华. 游梁式抽油机节能技术及最新进展[J]. 承德石油高等专科学校学报, 2005, 7(1): 16-19. |

| Zou Zhen-chun, Deng Li-xin, Wang Yan-hua. Technology of energy saving and latest progress in beam pumping unit[J]. Journal of Chengde Petroleum College, 2005, 7(1): 16-19. | |

| 9 | 郎立术. 游梁式抽油机电动机存在问题及节电方法浅析[J]. 石油石化节能, 2012(11): 19-21. |

| Lang Li-shu. Brief analysis on the existing problems of the motor of the beam pumping unit and the method of saving electricity [J]. Energy Conservation in Petroleum & Petrochemical Industry, 2012(11): 19-21. | |

| 10 | Zhao Hai-sen, Wang Yi-long, Zhan Yang, et al. Practical model for energy consumption analysis of beam pumping motor systems and its energy saving applications[J]. IEEE Transactions on Industry Applications, 2018, 54(2):1006-1016. |

| 11 | 张继震, 马广杰, 孙景丽, 等. 游梁抽油机的用电发电与节电[J]. 石油矿场机械, 2001, 30(4): 36-38. |

| Zhang Ji-zhen, Ma Guang-jie, Sun Jing-li, et al. Energy consumption power generation and power saving of beam-pumping unit[J]. Oil Field Equipment, 2001, 30(4): 36-38. | |

| 12 | 徐金超. 游梁抽油机正扭矩调制方法及关键技术[D].青岛:中国石油大学(华东)石油工程学院, 2014. |

| Xu Jin-chao.The method and key technology of beam pumping unit positive torque modulation[D]. Qingdao: School of Petroleum Engineering, China University of Petroleum (East China), 2014. | |

| 13 | 苏德胜, 刘先刚, 吕卫祥, 等. 游梁式抽油机节能机理综述[J]. 石油机械, 2001, 29(5): 49-53. |

| Su De-sheng, Liu Xian-gang, Lv Wei-xiang, et al. Review of energy-saving mechanism of beam pumping units[J]. China Petroleum Machinery, 2001, 29(5): 49-53. | |

| 14 | 祝新苗. 游梁式抽油机节能技术综述[J]. 内蒙古石油化工, 2014, 40(17): 117-118. |

| Zhu Xin-miao. A summary of energy-saving technology of beam pumping units [J]. Inner Mongolia Petrochemical Industry, 2014, 40 (17): 117-118. | |

| 15 | 樊勇, 侯军, 尤小荣. 3型异相曲柄平衡抽油机的技术改造设计[J]. 机械管理开发, 2010, 25(4): 13, 16. |

| Fan Yong, Hou Jun, You Xiao-rong. Transformation of 3-model balance-of-phase crank pumping unit[J]. Mechanical Management & Development, 2010, 25(4): 13, 16. | |

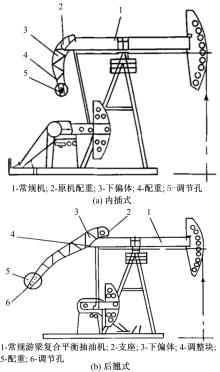

| 16 | 王惠明, 吴世辉, 梁政, 等. 下偏杠铃型抽油机工作性能仿真研究[J]. 石油矿场机械, 2008, 37(6): 6-9. |

| Wang Hui-ming, Wu Shi-hui, Liang Zheng, et al. Perating performance's simulation of a biased downward barbell type pumping unit[J]. Oil Field Equipment, 2008, 37(6): 6-9. | |

| 17 | 郭洵. 抽油机井下偏杠铃节能改造技术[J]. 民营科技, 2015(8):11. |

| Guo Xun. Energy-saving renovation technology for downhole bias barbell of pumping unit [J]. Non-State Running Science & Technology Enterprises, 2015(8): 11. | |

| 18 | 梁宏宝, 伊莲娜, 孙旭东. 游梁式抽油机节能技术改造综述(Ⅱ)[J]. 应用能源技术, 2011(3): 6-9. |

| Liang Hong-bao, Yi Lian-na, Sun Xu-dong. Summary on the energy-saving technical transformation of beam pumping units(II)[J]. Applied Energy Technology, 2011(3): 6-9. | |

| 19 | 李晓慧. 可调径下偏复合平衡抽油机的研制[J]. 石油机械, 2005, 33(10): 24-25. |

| Li Xiao-hui. Development of downward bias compound balanced pumping unit with adjustable diameter [J]. China Petroleum Machinery, 2005, 33(10): 24-25. | |

| 20 | 庞小谦, 季祥云, 于胜存, 等. 下偏杠铃惯性力及其对抽油机的影响[J]. 石油矿场机械, 2007, 36(2): 72-75. |

| Pang Xiao-qian, Ji Xiang-yun, Yu Sheng-cun, et al. Effort of inertial force by down-eccentric barbell to beam pumping unit[J]. Oil Field Equipment, 2007, 36(2): 72-75. | |

| 21 | 朱绍曾. 前置式游梁抽油机的平衡[J]. 石油矿场机械, 1983(5): 10-16. |

| Zhu Shao-zeng. Balance of the front beam pumping unit[J]. Oil Field Equipment, 1983(5): 10-16. | |

| 22 | 朱君, 王增藩, 孙慧峰, 等. 游梁式节能抽油机的原理及性能对比[J]. 大庆石油学院学报, 2005, 29(5): 40-43. |

| Zhu Jun, Wang Zeng-fan, Sun Hui-feng, et al. Energy-saving principle and contrastive analysis of performance of energy-saving beam-pumping unit[J]. Journal of Daqing Petroleum Institute, 2005, 29(5): 40-43. | |

| 23 | 迟鹏, 袁文熙, 赵志鹏, 等. 双驴头抽油机节能效果研究及应用[J]. 内蒙古石油化工, 2011, 37(3): 17-18. |

| Chi Peng, Yuan Wen-xi, Zhao Zhi-peng, et al. Research and application of energy-saving effect of double-donkey-head pumping unit[J]. Inner Mongolia Petrochemical Industry, 2011, 37(3): 17-18. | |

| 24 | 王军. 6型双驴头抽油机应用与节能[J]. 设备管理与维修, 2006(8): 35-36. |

| Wang Jun. Application and energy saving of type 6 double-donkey-head pumping unit[J]. Plant Maintenance Engineering, 2006(8): 35-36. | |

| 25 | 曹刚, 张德实, 单宏宇, 等. 大庆油田抽油机系统节能改造技术应用[J]. 中国设备工程, 2009(7): 5-7. |

| Cao Gang, Zhang De-shi, Shan Hong-yu, et al. Application of energy-saving renovation technology on pumping unit system in Daqing Oilfield[J]. China Equipment Engineering, 2009(7): 5-7. | |

| 26 | Feng Z M, Tan J J, Li Q, et al. A review of beam pumping energy-saving technologies[J]. Journal of Petroleum Exploration & Production Technology, 2017(37): 299-311. |

| 27 | 欧阳新. 节能型抽油机研究[D]. 大庆:东北石油大学土木建筑工程学院, 2007. |

| Ouyang Xin. Research on Energy-saving Pumping Units [D]. Daqing: School of Civil Engineering, Northeast Petroleum University, 2007. | |

| 28 | 刘博威, 冯子明. 双驴头抽油机节能机理分析[J]. 内蒙古石油化工, 2014, 40(19): 43-45. |

| Liu Bo-wei, Feng Zi-ming. Energy-saving mechanism analysis of double-donkey-horsehead pumping unit[J]. Inner Mongolia Petrochemical Industry, 2014, 40(19): 43-45. | |

| 29 | 冯志鹏. 双驴头抽油机游梁承载能力研究[D]. 大庆:东北石油大学机械科学与工程学院, 2003. |

| Feng Zhi-peng. Study on the bearing capacity of double-donkey-horsehead beam pumping units[D]. Daqing: School of Mechanical Science and Engineering, Northeast Petroleum University, 2003. | |

| 30 | 闫金铸. 不同后驴头弧线形式的双驴头抽油机动力学仿真研究[D]. 大庆: 东北石油大学机械科学与工程学院, 2012. |

| Yan Jin-zhu. Dynamics simulation of double-donkey-horsehead pumping units with different back-donkey-head arcs [D]. Daqing: School of Mechanical Science and Engineering, Northeast Petroleum University, 2012. | |

| 31 | 张来斌, 冯树强, 郭东, 等. 异型游梁式抽油机后驴头轮廓曲线的优化设计[J]. 石油矿场机械, 1996, 25(6): 8-12. |

| Zhang Lai-bin, Feng Shu-qiang, Guo Dong, et al. Optimal design of back-donkey-horsehead contour curve of special-shaped beam pumping unit[J]. Oil Field Equipment, 1996, 25(6): 8-12. | |

| 32 | 姜彬. 异型游梁式抽油机后驴头结构优化设计[D]. 大庆:东北石油大学石油工程学院,2009. |

| Jiang Bin. Structural optimization design of rear-donkey-horsehead of special-shaped beam pumping unit [D]. Daqing: Institute of Petroleum Engineering, Northeast Petroleum University, 2009. | |

| 33 | Qu W T, Liao D S, Ren T, et al. Optimum design of double-well pumping units based on calculation of MATLAB optimization toolboxes[J]. Advanced Materials Research, 2012, 479-481:694-698. |

| 34 | 刘健, 綦耀光, 肖世宏, 等. 阿基米德螺线双驴头抽油机优化设计[J]. 石油矿场机械, 2001, 30(3): 14-16. |

| Liu Jian, Qi Yao-guang, Xiao Shi-hong, et al. Optimum design for double-horse head beam pumping unit with rear horse head′s outline of spiral of Archimedes[J]. Oil Field Equipment, 2001,30(3): 14-16. | |

| 35 | 梁柱. 双驴头抽油机主要易损部分的力学性能研究[D]. 大庆:东北石油大学石油工程学院, 2011. |

| Liang Zhu. Study on mchanical poperties of main vulnerable parts of double-donkey-horsehead pumping unit[D]. Daqing: Institute of Petroleum Engineering, Northeast Petroleum University, 2011. | |

| 36 | Zou L Q, Chen G J, Zhang X, et al. Study on mechanical performance simulation method of key components in double horse head pumping unit[C]∥International Conference on Ubiquitous Robots and Ambient Intelligence, Xi'an, China, 2016:152-156. |

| 37 | 杨晓兰. 双驴头抽油机使用寿命研究[D]. 大庆:东北石油大学机械科学与工程学院, 2009. |

| Yang Xiao-lan. Study on service life of double-donkey-horsehead pumping unit[D]. Daqing: School of Mechanical Science and Engineering, Northeast Petroleum University, 2009. | |

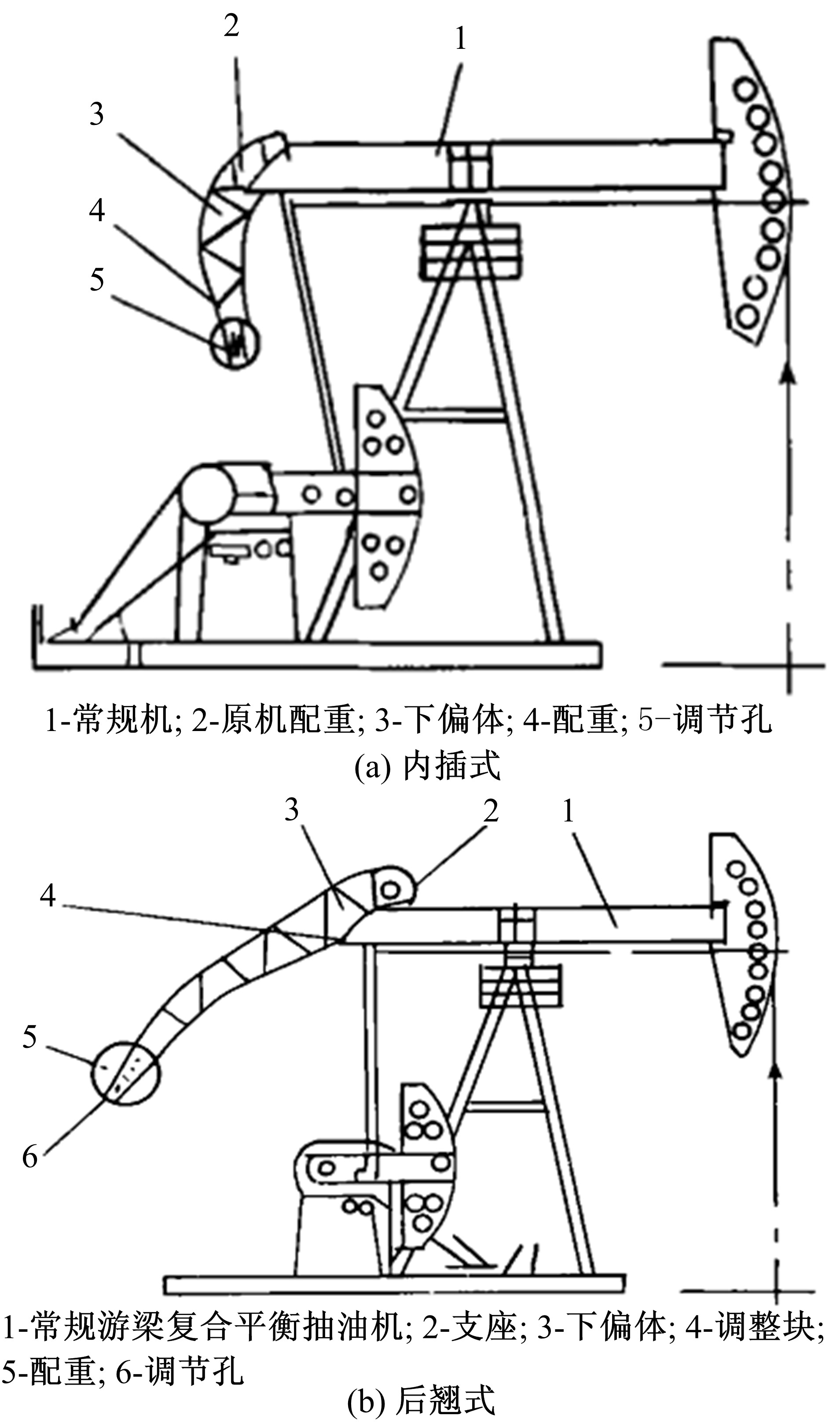

| 38 | 王逢焰, 蔡雄飞, 卞和满, 等. 偏轮游梁抽油机的特征分析[J]. 石油矿场机械, 2001, 30(4): 51-52. |

| Wang Feng-yan, Cai Xiong-fei, Bian He-man, et al. Analysis of the offset-wheel beam pump unit's characteristics[J]. Oil Field Equipment, 2001, 30(4): 51-52. | |

| 39 | 梁宏宝, 伊莲娜, 孙旭东. 游梁式抽油机节能技术改造综述(Ⅰ)[J]. 应用能源技术, 2011(2): 4-7. |

| Liang Hong-bao, Irina, Sun Xu-dong. Summary on the energy-saving technical transformation of beam pumping unit(I)[J]. Applied Energy Technology, 2011(2): 4-7. | |

| 40 | Xing M M, Dong S M, Tong Z X, et al. Dynamic simulation and efficiency analysis of beam pumping system[J]. Journal of Central South University, 2015, 22 (9): 3367-3379. |

| 41 | Ghareeb M, Shedid S A, Ibrahim M. Simulation investigations for enhanced performance of beam pumping system for deep high volume wells[C]∥ International Oil Conference & Exhibition. Mexico: Society of Petroleum Engineers, 2007: 70-75. |

| 42 | 朱永敏, 杨蓬强. 常规抽油机改造成变臂型抽油机的具体实践[J]. 河南石油, 2006, 20(1): 81-82. |

| Zhu Yong-min, Yang Peng-qiang. Practice of transforming conventional pumping units into variable arm pumping units[J]. Henan Petroleum, 2006, 20(1): 81-82. | |

| 43 | 郭登明, 艾薇, 李东平, 等. 常规抽油机改造成变臂型抽油机的具体实践[J]. 石油天然气学报, 2004(): 127-128. |

| Guo Deng-ming, Ai Wei, Li Dong-ping, et al. Practice of transforming conventional pumping units into variable arm pumping units[J]. Journal of Oil and Gas Technology, 2004(Sup.1): 127-128. | |

| 44 | 齐俊林, 张宏, 赵铁光. 摆杆型游梁式抽油机的节能效果分析[J]. 石油矿场机械, 2007, 36(1): 12-17. |

| Qi Jun-lin, Zhang Hong, Zhao Tie-guang. Energy-saving effect analysis of swing rod beam pumping unit[J]. Oil Field Equipment, 2007, 36(1): 12-17. | |

| 45 | 王尚元, 唐卫军, 李志诚, 等. 新型摆杆式游梁抽油机[J]. 石油矿场机械, 2001, 30(3): 25-27. |

| Wang Shang-yuan, Tang Wei-jun, Li Zhi-cheng, et al. A new type of swing-pod pumping unit[J]. Oil Field Equipment, 2001, 30(3): 25-27. | |

| 46 | Kang X, Zhang F, Ren T. Performance analysis of a novel swing crank-slide bar beam pumping unit[C]∥ International Conference on Mechanical Engineering, Materials and Energy,Hong Kong, China,2016:168-172. |

| 47 | 秦殿花. 天平式节能抽油机适用性探讨[J]. 石油石化节能, 2015, 5(8): 16-18. |

| Qin Dian-hua. Discussion on the applicability of balance energy-saving pumping unit[J]. Energy Conservation in Petroleum & Petrochemical Industry, 2015, 5(8): 16-18. | |

| 48 | 郑严. 永磁同步电动机在天平游梁式抽油机上的应用研究[D]. 北京:华北电力大学电气与电子工程学院, 2013. |

| Zheng Yan. Research of permanent magnet synchronous motor usage candidate on the balance beam pumping unit [D]. Beijing: College of Electrical and Electronic Engineering, North China Electric Power University, 2013. | |

| 49 | 杨信飞. 游梁式抽油机传动系统效能分析与节能技术研究[D]. 北京: 华北电力大学电气与电子工程学院, 2015. |

| Yang Xin-fei. Efficiency Analysis and energy saving technology research of beam pumping unit transmission system[D]. Beijing:College of electrical and Electronic Engineering, North China Electric Power University, 2015. | |

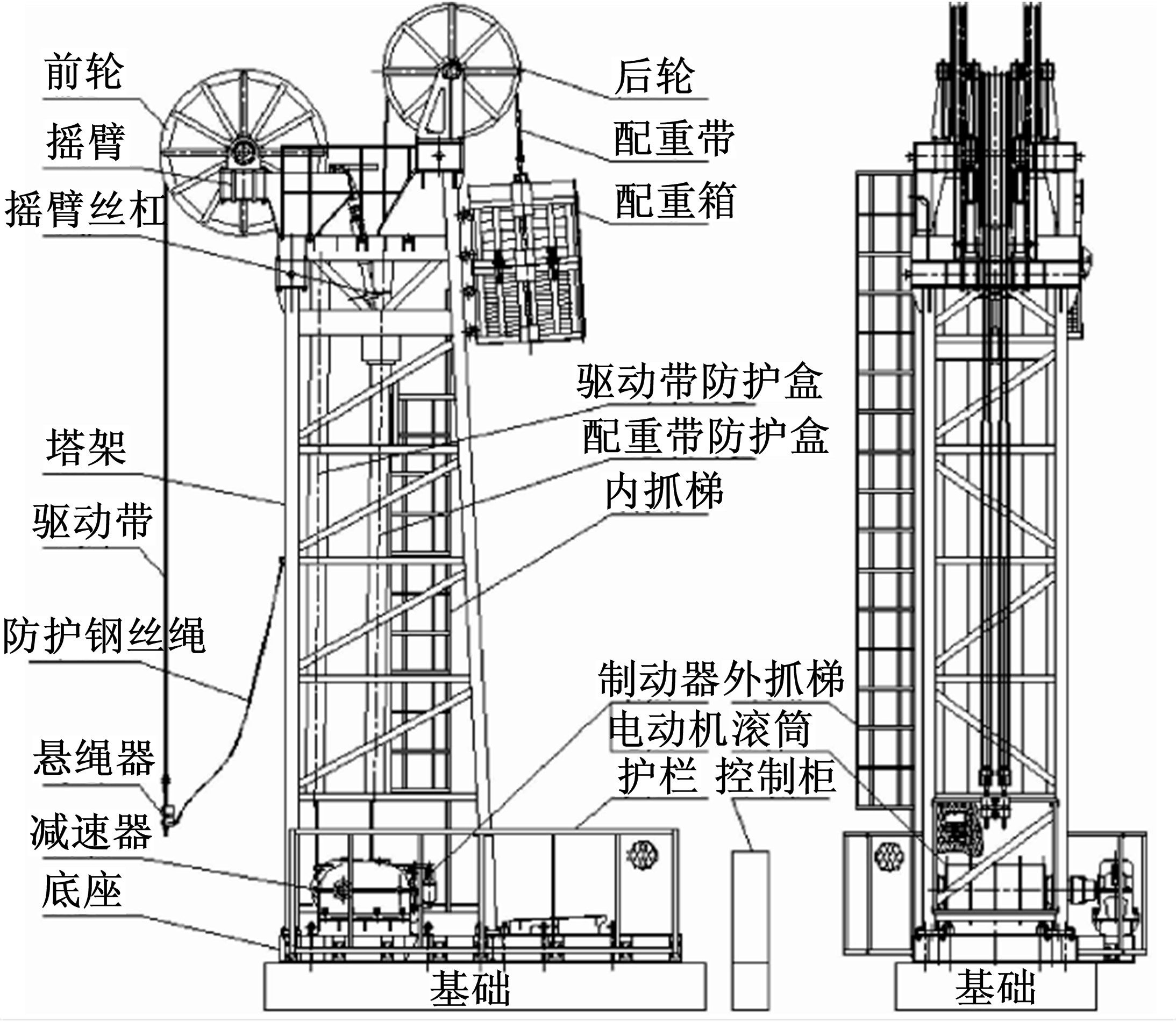

| 50 | 王泰华, 陈致富. 基于PSO自整定PID的塔架式抽油机调速系统研究[J]. 电子测量与仪器学报, 2014, 28(9): 998-1004. |

| Wang Tai-hua, Chen Zhi-fu. Research on speed control system for tower mounted pumping unit based on PSO self-adjusting PID control[J]. Journal of Electronic Measurement and Instrumentation, 2014, 28(9): 998-1004. | |

| 51 | 魏华. 行星齿环式无游梁抽油机的理论分析及设计[D].成都:西华大学机械工程学院, 2010. |

| Wei Hua. Theoretical analysis and design of planetary toothed ring pumping unit without beam[D]. Chengdu: College of Mechanical Engineering, Xihua University, 2010. | |

| 52 | 邢延方, 彭章建, 王德威. 塔架式一机双井抽油机研制[J]. 科技与企业, 2016(3): 148-149. |

| Xing Yan-fang, Peng Zhang-jian, Wang De-wei. Derrick double-well pumping units research[J]. Science and technology and enterprise, 2016(3): 148-149. | |

| 53 | 朱文广. 油田常用节能抽油机分析及应用[J]. 石油石化节能, 2016, 6(4): 33-34. |

| Zhu Wen-guang. Analysis and application of energy-saving pumping units commonly used in oilfields [J]. Energy Conservation in Petroleum & Petrochemical Industry, 2016, 6(4): 33-34. | |

| 54 | Chen You-quan, Liu Xin-hui, Wang Xin, et al. Simulation and data analysis of energy recovery sensing on parallel hydraulic hybrid crane[J]. Intelligent Automation and Soft Computing, 2018, 24(3): 613-622. |

| 55 | 王昕. 静液传动混合动力轮边驱动车辆节能与控制特性研究[D]. 哈尔滨:哈尔滨工业大学机械工程学院, 2010. |

| Wang Xin. Research on energy saving and control performances of wheel drive hydraulic hybrid vehicle[D]. Harbin:College of Mechanical Engineering, Harbin Institute of Technology, 2010. | |

| 56 | 薛鑫, 綦耀光, 余焱群, 等. 液压抽油机的适应性分析与应用现状综述[J]. 机床与液压, 2016, 44(10): 151-154. |

| Xue Xin, Qi Yao-guang, Yu Yan-qun, et al. Adaptability analysis and application status summary for hydraulic pumping units[J]. Machine Tool & Hydraulics, 2016, 44 (10): 151-154. | |

| 57 | 薄涛. 中国液压抽油机的发展概况与技术水平[J]. 钻采工艺, 2002, 25(2): 60-62. |

| Bo Tao. Development and technical level of hydraulic pumping units in China[J]. Drilling and Production Technology, 2002, 25(2): 60-62. | |

| 58 | 陈春安, 陈铁民. YCH—Ⅱ型液压抽油机的研制[J]. 石油机械, 1988, 16(11): 10-14. |

| Chen Chun-an, Chen Tie-min. Development of YCH-II hydraulic pumping unit[J]. China Petroleum Machinery, 1988, 16(11): 10-14. | |

| 59 | 严少雄, 白树泰. 长冲程滚筒式液压抽油机[J]. 石油矿场机械, 1994(1): 40-43. |

| Yan Shao-xiong, Bai Shu-tai. Long stroke drum hydraulic pumping unit [J]. Oil Field Equipment, 1994(1): 40-43. | |

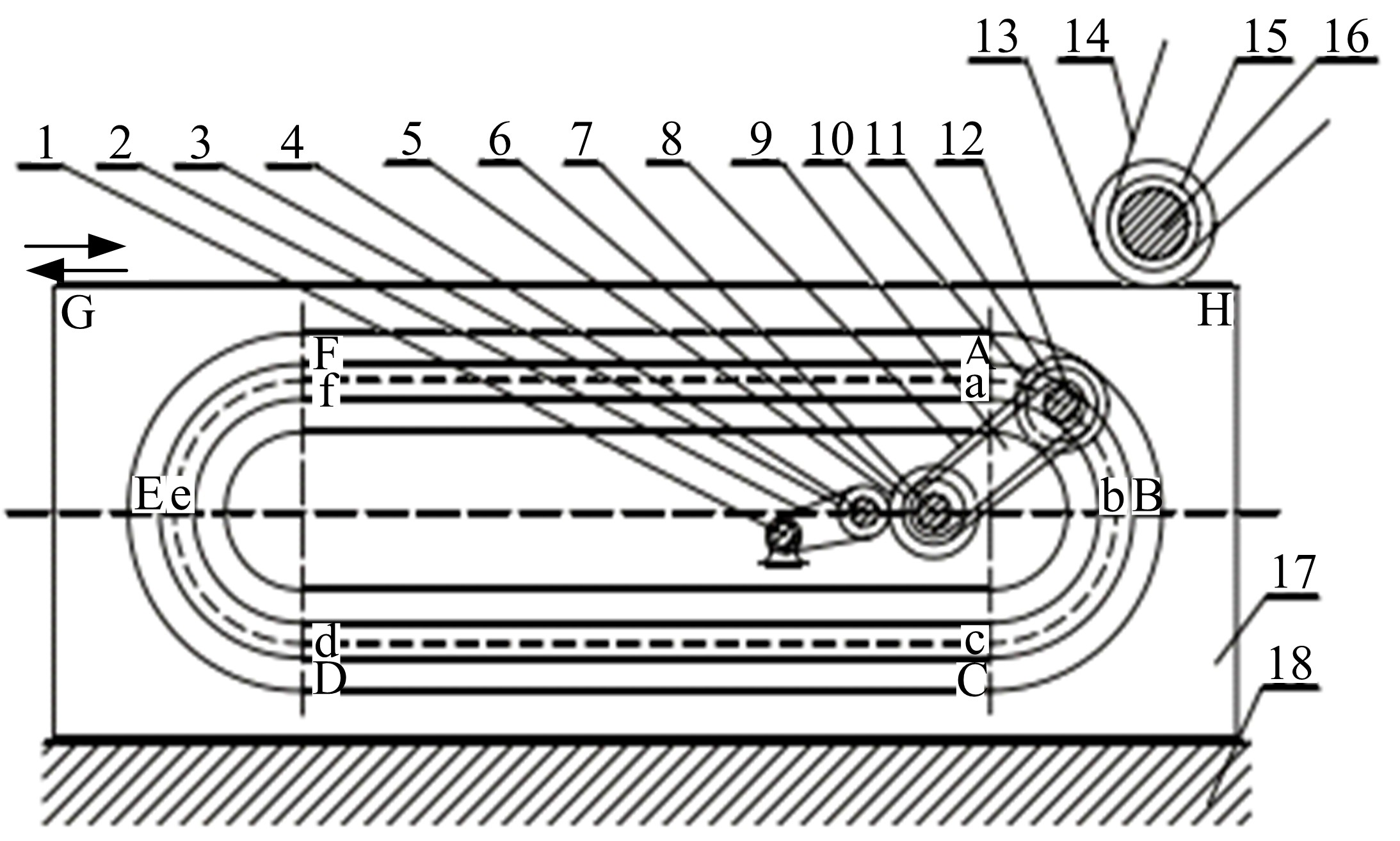

| 60 | 俞浙青, 王秋成, 姜伟, 等. 功率回收型液压抽油机实验系统的设计与建立[J]. 石油机械, 1999, 26(6): 18-21. |

| Yu Zhe-qing, Wang Qiu-cheng, Jiang Wei, et al. Design and establishment of experimental system of hydraulic pumping unit with power recovery[J]. China Petroleum Machinery, 1999, 26(6): 18-21. | |

| 61 | 刘长年. 液压式与机械式两种抽油机的效率分析[J].液压与气动, 2004(6): 41-43. |

| Liu Chang-nian. Efficiency analyses for the two types of hydraulic and mechanical pumping units[J]. Chinese Hydraulics & Pneumatics, 2004(6): 41-43. | |

| 62 | 姜继海, 于庆涛, 刘宇辉, 等. 二次调节静液传动液压抽油机[J]. 机床与液压, 2005(8): 59-61. |

| Jiang Ji-hai, Yu Qing-tao, Liu Yu-hui, et al. Secondary regulation hydrostatic drive hydraulic pumping unit[J]. Machine Tool & Hydraulics, 2005(8): 59-61. | |

| 63 | 姜继海, 刘宇辉. 二次调节静液传动液压抽油机液压系统设计[J]. 液压与气动, 2007(12): 60-62. |

| Jiang Ji-hai, Liu Yu-hui. Hydraulic system design of oil pumping unit with secondary regulation technique[J]. Chinese Hydraulics & Pneumatics, 2007(12): 60-62. | |

| 64 | Liu H, Jiang J. Flywheel energy storage-an upswing technology for energy sustainability[J]. Energy and Buildings, 2007, 39(5): 599-604. |

| 65 | 董晗, 刘昕晖, 王昕, 等. 并联式液压混合动力系统制动能量回收特性[J]. 吉林大学学报:工学版, 2014, 44(6): 1655-1663. |

| Dong Han, Liu Xin-hui, Wang Xin, et al. Parallel hydraulic hybrid braking regenerative characteristics[J]. Journal of Jilin University(Engineering and Technology Edition), 2014, 44(6): 1655-1663. | |

| 66 | 董晗, 刘昕晖, 王昕, 等. 并联式液压混合动力系统中蓄能器各主要参数对系统性能的影响[J]. 吉林大学学报:工学版, 2015, 45(2): 420-428. |

| Dong Han, Liu Xin-hui, Wang Xin, et al. Impact of main parameters of accumulator on parallel hydraulic hybrid[J]. Journal of Jilin University(Engineering and Technology Edition), 2015,45(2):420-428. | |

| 67 | 董晗, 刘昕晖, 王昕, 等. 基于AMESim的液压混合动力系统节能特性[J]. 吉林大学学报:工学版, 2013, 43(5): 1264-1270. |

| Dong Han, Liu Xin-hui, Wang Xin, et al. Energy saving performance of hydraulic hybrid system with AMESim[J]. Journal of Jilin University(Engineering and Technology Edition), 2013, 43(5): 1264-1270. | |

| 68 | 姜继海, 刘海昌, 谷峰, 等. 基于二次调节静液传动—变频回馈技术的电能回馈型液压抽油机[J]. 液压与气动, 2009(11): 41-43. |

| Jiang Ji-hai, Liu Hai-chang, Gu Feng, et al. Hydraulic-pumping unit using secondary regulation technology and variable frequency feedback technology [J]. Chinese Hydraulics & Pneumatics, 2009(11): 41-43. | |

| 69 | 林安明. 基于二次调节技术的液压抽油机节能技术研究[D]. 秦皇岛:燕山大学机械工程学院, 2017. |

| Lin An-ming. Based on the secondary regulation technology of hydraulic pumping unit energy saving technology research[D]. Qinhuangdao: School of Mechanical Engineering, Yanshan University, 2017. | |

| 70 | 徐兵, 黄方平, 张斌. 新型节能变频闭式液压抽油机的设计[J]. 机床与液压, 2006(1): 72-74, 14. |

| Xu Bing, Huang Fang-ping, Zhang Bin. Design of a new energy-saving hydraulic pumping unit with variable speed control and closed oil circuits[J]. Machine Tool & Hydraulics, 2006(1): 72-74, 14. | |

| 71 | 张路军, 解恒述. 组合液压缸节能液压抽油机的研究[J]. 液压与气动, 2008(9): 63-64. |

| Zhang Lu-jun, Xie Heng-shu. Study on energy-saving hydraulic sucker rig with compound cylinder[J]. Chinese Hydraulics & Pneumatics, 2008(9): 63-64. | |

| 72 | 魏新, 孙军, 周华, 等. 新型电液比例控制液压抽油机的设计[J]. 机床与液压, 2009, 37(2): 39-41. |

| Wei Xin, Sun Jun, Zhou Hua, et al. Design of a new hydraulic pumping unit with electro-hydraulic proportional control[J]. Machine Tool & Hydraulics, 2009, 37(2): 39-41. | |

| 73 | Chang L J, Lin S Z, Zheng H W. Hydraulic system research of the pumping unit based on electro-hydraulic proportional control technology[J]. Applied Mechanics and Materials, 2013, 373-375: 1340-1344. |

| 74 | 齐保良, 杨宝昆, 高鹤. 风电互补液压抽油机的设计[J]. 液压与气动, 2010(12): 72-74. |

| Qi Bao-liang, Yang Bao-kun, Gao He. The design of wind power complementary hydraulic pumping unit[J]. Chinese Hydraulics & Pneumatics, 2010(12): 72-74. | |

| 75 | 周广清. 低矮型长冲程节能抽油机的研制及应用[J]. 石油机械, 2014, 42(3): 88-91. |

| Zhou Guang-qing. Development and application of low-rise long-stroke pumping unit[J]. China Petroleum Machinery, 2014, 42(3): 88-91. | |

| 76 | 梁宏宝, 王晓宇, 石镇铭, 等. 液压抽油机的研究进展[J]. 机床与液压, 2015, 43(1): 175-180, 140. |

| Liang Hong-bao, Wang Xiao-yu, Shi Zhen-ming, et al. Research progress of hydraulic pumping unit[J]. Machine Tools and Hydraulic, 2015, 43(1): 175-180, 140. | |

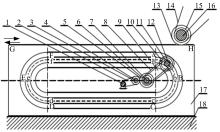

| 77 | 刘峰, 肖富强, 王永信, 等. 滑轮增程式液压抽油机液压系统设计研究[J]. 液压与气动, 2015(4): 98-101. |

| Liu Feng, Xiao Fu-qiang, Wang Yong-xin, et al. Design of hydraulic system of pulley increasing stroke hydraulic pumping unit[J]. Chinese Hydraulics & Pneumatics, 2015(4): 98-101. | |

| 78 | 王太星. 滑轮增程式液压抽油机关键技术研究[D]. 青岛:中国石油大学(华东)石油工程学院, 2014. |

| Wang Tai-xing. Research on key technologies of pulley increasing stroke hydraulic pumping unit[D]. Qingdao:School of Petroleum Engineering, China University of Petroleum(East China), 2014. | |

| 79 | 赵鹏宇, 陈英龙, 孙军, 等. 基于液压平衡的试油试采系统建模与仿真[J]. 浙江大学学报:工学版, 2016, 50(4): 650-656. |

| Zhao Peng-yu, Chen Ying-long, Sun Jun, et al. Modeling and simulation of well test and production test system based on hydraulic balance[J]. Journal of Zhejiang University(Engineering Science), 2016, 50(4): 650-656. | |

| 80 | 韩景山. 飞轮储能型液压抽油机的系统设计[J]. 石油矿场机械, 2018, 47(2): 42-45. |

| Han Jing-shan. Systematic design of hydraulic pumping unit with flywheel energy storage[J]. Oil Field Equipment, 2018, 47(2): 42-45. | |

| 81 | 何刚. 功率回收型液压抽油机的设计与研究[J]. 锻压装备与制造技术, 2018, 53(6): 59-60, 106. |

| He Gang. Design and study of a power recovery hydraulic pumping unit[J]. China Metalforging Equipment & Manufacturing Technology, 2018, 53(6): 59-60, 106. | |

| 82 | Mcinroy J E, Lebowski S R. Using power measurements to diagnose degradations in motor drive power systems: a case study of oilfield pump jacks[J]. IEEE Transactions on Industry Applications, 2001, 37(6): 1574-1581. |

| 83 | Gibbs S G, Miller D L. Inferring power consumption and electrical performance from motor speed in oil-well pumping units[J]. IEEE Transactions on Industry Applications, 2002, 33(1): 187-193. |

| 84 | Schroeder C C, Elahinia M H. Research and education with a hydraulic hybrid vehicle laboratory[C]∥ASME International Mechanical Engineering Congress and Exposition. American Society of Mechanical Engineers, Boston, USA,2008: 423-430. |

| 85 | 吉效科, 高长乐, 郭顺清, 等. 国内外抽油机平衡测试技术综述[J]. 石油地质与工程, 2013, 27(2): 121-124. |

| Ji Xiao-ke, Gao Chang-le, Guo Shun-qing, et al. Overview of balance test technology of pumping units at home and abroad[J]. Petroleum Geology and Engineering, 2013, 27(2): 121-124. | |

| 86 | 王明军. 一拖二相位平衡抽油机应用探讨[J]. 中国石油和化工标准与质量, 2017, 37(24): 103-104. |

| Wang Ming-jun. Discussion on the application of one driving two phased balanced pumping unit[J]. China Petroleum and Chemical Standards and Quality, 2017,37(24): 103-104. | |

| 87 | 李振河, 宋锦春. 一种新型节能液压抽油机的设计与分析[J]. 机床与液压, 2016, 44(13): 101-103. |

| Li Zhen-he, Song Jin-chun. Design and analysis of a new energy-saving hydraulic pumping unit[J]. Machine Tool & Hydraulics, 2016, 44(13): 101-103. | |

| 88 | 徐甫荣, 赵锡生. 抽油机节能电控装置综述(2)[J]. 电源技术应用, 2004, 7(4): 251-256. |

| Xu Fu-rong, Zhao Xi-sheng. Summarization of power control device with energy-saving for pumping jack(Part 2)[J]. Application of power technology, 2004, 7(4): 251-256. | |

| 89 | 陈磊. 抽油机超高转差率电动机的应用效果研究[J]. 石油石化节能, 2017, 7(7): 1-2, 5. |

| Chen Lei. Study on application effect of pumping unit with super high slip motor[J]. Energy Conservation in Petroleum & Petrochemical Industry, 2017, 7(7): 1-2, 5. | |

| 90 | 刘国琴, 庞福松, 于红业, 等. 石油专用高、超高转差率电动机[J]. 石油科技论坛, 2016, 35(): 122-124, 248. |

| Liu Guo-qin, Pang Fu-song, Yu Hong-ye, et al. Oil-dedicated high/ ultra high slip motors[J]. Petroleum Science and Technology Forum, 2016, 35(Sup.1): 122-124, 248. | |

| 91 | 马晓薇. 双速电动机与变频技术在抽油机上的应用[J]. 石油石化节能, 2016, 6(10): 30-31. |

| Ma Xiao-wei. Application of dual-speed motor and frequency conversion technology in pumping units[J]. Energy Conservation in Petroleum & Petrochemical Industry, 2016, 6(10): 30-31. | |

| 92 | 钟力, 陈天为, 胡理想. 抽油机双绕组双功率电动机的节电分析[J]. 石油机械, 2004, 32(7):41-42. |

| Zhong Li, Chen Tian-wei, Hu Li-xiang. Analysis of power saving of duplex winding dual-power motor on pumping unit[J]. China Petroleum Machinery, 2004, 32(7): 41-42. | |

| 93 | 龚宇, 周和平, 胡松华, 等. 永磁复合电机直驱游梁式抽油机的应用[J]. 石油学报, 2018, 39(8): 955-962. |

| Gong Yu, Zhou He-ping, Hu Song-hua, et al, Application of beam pumping unit directly driven by permanent magnet integrated motor[J]. Acta Petrolei Sinica, 2018, 39(8): 955-962, | |

| 94 | Ding T, Takorabet N, Sargos F M, et al. Design and analysis of different line-start PM synchronous motors for oil-pump applications[J]. IEEE Transactions on Magnetics, 2009, 45(3): 1816-1819. |

| 95 | Ma W Z, Zhang H M, Sun J Y, et al. Research on the design of linear drive motor of new pumping unit[J]. Advanced Materials Research, 2012, 383-390: 1391-1398. |

| 96 | Gu Yu-hong, Xiao Wen-sheng, Zhou Xiao-xi, et al. Full-scale test of ZXCY-Series linear motor pumping units[J]. Petroleum Exploration and Development, 2008, 35(3): 366-372. |

| 97 | Li L, Mei C S, Ping Z, et al. Experimental study on a novel linear electromagnetic pumping unit[J]. IEEE Transactions on Magnetics, 2001, 37(1): 219-222. |

| 98 | Lu Q F, Fan C Z, Ye Y Y, et al. A high torque density permanent magnet motor for oil pumping unit[J]. Journal of Applied Physics, 2008, 103(7): 680-682. |

| 99 | 费飞. 抽油机电机节能方法探讨[J]. 中国电力教育, 2011(3):139-141. |

| Fei Fei. Discussion on energy saving method of pumping unit motor[J]. China Electric Power Education, 2011(3): 139-141. | |

| 100 | 李明.抽油机智能间抽设备的研制[D]. 新疆:新疆大学机械工程学院, 2006. |

| Li Ming. Development of intelligent equipment for pumping units' intermissive oil-drawing[D]. Xinjiang:College of Mechanical Engineering, Xinjiang University, 2006. | |

| 101 | 谢朝阳,周好斌. 基于动液面控制的抽油机变频控制系统[J]. 石油机械, 2009, 37(9): 122-124. |

| Xie Chao-yang, Zhou Hao-bin. Pumping unit frequency conversion control system based on hydrodynamic level control[J]. China Petroleum Machinery, 2009, 37(9): 122-124. | |

| 102 | 于祥春. 基于直流供电配置的抽油机变频群控系统研发[D]. 青岛:中国石油大学(华东)石油工程学院, 2009. |

| Yu Xiang-chun. Research and development of pumping unit group controlling system with frequency conversion based on DC power supply configuration[D]. Qingdao: School of Petroleum Engineering, China University of Petroleum (East China), 2009. | |

| 103 | Tian Z D, Gao X W, Wang D H. The application research of fuzzy control with self-tuning of scaling factor in the energy saving control system of pumping unit[J]. Engineering Letters, 2016, 24(2): 187-194. |

| 104 | 于小明, 何贯中, 金英兰. 抽油机井间抽制度合理性研究[J]. 大庆石油地质与开发, 2006, 25(4): 78-79. |

| Yu Xiao-ming, He Guan-zhong, Jin Ying-lan. Study on rationality of intermittent pumping system for pumping well[J]. Petroleum Geology and Development in Daqing, 2006, 25(4): 78-79. | |

| 105 | 徐甫荣, 赵锡生. 抽油机节能电控装置综述(1)[J]. 电源技术应用, 2004, 7(3): 182-187. |

| Xu Fu-rong, Zhao Xi-sheng. Summarization of power control device with energy-saving for pumping Jack(Part 1)[J]. Application of Power Technology, 2004, 7(3): 182-187. | |

| 106 | 林立, 邢兆栋. 抽油机单参量功率监测及BSP-1型间抽控制仪[J]. 石油机械, 2001, 29(12): 48-50. |

| Lin Li, Xing Zhao-dong. Single parameter power monitoring of pumping units and BSP-1 inter-pumping controller[J]. China Petroleum Machinery, 2001, 29(12): 48-50. | |

| 107 | 李国伟. 间抽井节能增产的理论与技术实现[D]. 新疆:新疆大学机械工程学院, 2007. |

| Li Guo-wei. Theory and technological implementation of energy-saving plus production-increasing for intermittent pumping Oil-wells[D]. Xinjiang:College of Mechanical Engineering, Xinjiang University, 2007. | |

| 108 | 刘安枕. 基于优化算法的油井间抽控制系统设计与实现[J]. 西安航空技术高等专科学校学报, 2008, 26(3): 39-41. |

| Liu An-zhen. Designing and realization of oil drilling interval pump controlling system based on optimization algorithm [J]. Journal of Xi'an Aeronautical Technology College, 2008, 26(3): 39-41. | |

| 109 | 魏雨. 融合目标优化的抽油机间抽节能算法研究[D]. 西安:西安石油大学计算机技术学院, 2016. |

| Wei Yu. Research on Energy saving algorithms of pumping unit based on the objective optimization[D]. Xi'an: School of Computer Technology, Xi'an Petroleum University, 2016. | |

| 110 | 段毛毛, 贾鹿, 姜力. 基于大数据分析技术的间抽制度制定方法研究[C]∥第四届信息化创新克拉玛依国际学术论坛. 中国工程院:克拉玛依市科学技术协会, 2016. |

| 111 | 张旭华. 基于神经网络的抽油机节能算法研究[D]. 西安:西安石油大学计算机技术学院, 2014. |

| Zhang Xu-hua. Pumping unit energy-saving algorithm based on neural network[D]. Xi'an: School of Computer Technology, Xi'an Petroleum University, 2014. | |

| 112 | 李敏, 何平, 孟臣. 基于模糊神经网络的抽油机节能专家控制器设计[J]. 计算技术与自动化, 2009, 28(4): 56-58. |

| Li Min, He Ping, Meng Chen. The design of oil pump energy saving expert controller based on ARM[J]. Computing Technology and Automation, 2009, 28(4): 56-58. | |

| 113 | Gao M, Tian J, Zhou S, et al. Beam-pumping unit energy-saving control system based on support vector machine[C]∥IEEE International Conference on Automation and Logistics, Qingdao, China, 2008: 1864-1869. |

| 114 | Hea J, Ji K, Xue M, et al. Analysis of variable frequency energy-saving operation of beam pumping unit[J]. IOP Conference Series Materials Science and Engineering, 2018, 452(4): 042185. |

| 115 | 徐甫荣. 变频器在抽油机上应用的若干问题探讨[J]. 电气传动自动化, 2004, 26(2): 4-8. |

| Xu Fu-rong. Analysis of problems on application of frequency converter in oil pumping jack[J]. Electrical Drive Automation, 2004, 26(2): 4-8. | |

| 116 | 齐维贵, 朱学莉, 张延丽. 抽油机节能的模糊神经网络控制研究[J]. 中国电机工程学报, 2004, 24(6): 137-140. |

| Qi Wei-gui, Zhu Xue-li, Zhang Yan-li. A study of fuzzy neural network control of energy-saving of oil pump[J]. Proceedings of the Chinese Society For Electrical Engineering, 2004, 24(6): 137-140. | |

| 117 | 崔学深, 罗应立, 张伟华, 等. 游梁式抽油机电动机断续供电全自动控制装置[P]. 中国:CN2785255,2006-05-31. |

| 118 | 王义龙, 赵海森, 王泽忠, 等. 游梁式抽油机电动机断续供电节能技术断电时刻准确判定方法[J]. 中国电机工程学报, 2018, 38(15): 4537-4545, 4654. |

| Wang Yi-long, Zhao Hai-sen, Wang Ze-zhong, et al. Power-off time precise determination of intermittent power supply technology for beam pumping motor systems[J]. Journal of Electrical Engineering of China, 2018, 38(15): 4537-4545, 4654. | |

| 119 | Zhao H S, Wang Y L, Chen G, et al. Precise determination of power-off time of intermittent supply technology based on fuzzy control for energy saving of beam pumping motor systems[J]. Electric Power Components and Systems, 2018, 46(2): 197-207. |

| 120 | Zhao H S, Wang Y L, Zhan Y, et al. Rapid soft re-switching strategy of intermittent supply for energy saving in beam pumping motors systems with dynamic load conditions[J]. IEEE Transactions on Industry Applications, 2019, 55(4): 3343-3353. |

| 121 | 黄启彪. 抽油机电机的节能标准改造探讨[J]. 中国石油和化工标准与质量, 2016, 36(14): 3, 12. |

| Huang Qi-biao. Discussion on energy-saving standard reform of pumping unit motor[J]. China Petroleum and Chemical Standard and Quality, 2016, 36(14): 3, 12. | |

| 122 | 薄保中, 龚新强. 抽油机电机的节能改造[J]. 节能技术, 2000, 18(2): 31-32. |

| Bo Bao-zhong, Gong Xin-qiang. Motor reconstruction for energy saving of oil-pumping units[J]. Energy Conservation Technology, 2000, 18(2): 31-32. | |

| 123 | 龚元明, 萧德云, 胡郁乐, 等. 抽油机智能控制系统的设计与实现[J]. 石油机械, 2001, 29(1):25-26, 31. |

| Gong Yuan-ming, Xiao De-yun, Hu Yu-le, et al. The design and implementation of intelligent pumping unit control system. CPM[J]. China Petroleum Machinery, 2001, 29(1): 25-26, 31. | |

| 124 | 高佩忠. 抽油机用电动机和外加装置的节能运行分析[J]. 节能技术, 2012, 30(4): 330-334. |

| Gao Pei-zhong. Energy-saving operation analysis of the motors and additional devices in pumping unit[J]. Energy Conservation Technology, 2012, 30(4): 330-334. | |

| 125 | 徐甫荣, 赵锡生. 抽油机电控装置节能综述[J]. 电气传动自动化, 2004, 26(5): 1-8. |

| Xu Fu-rong, Zhao Xi-sheng. Summarization on energy saving of electric control device for oil pumping jack[J]. Electrical Drive Automation, 2004, 26(5): 1-8. | |

| 126 | 朱常青, 王秀和, 申宁, 等. 油田抽油机用感应电动机调压节能控制策略的研究[J]. 自动化学报, 2007, 33(7): 749-752. |

| Zhu Chang-qing, Wang Xiu-he, Shen Ning, et al. [J]. Variable-voltage energy saving strategy for three-phase induction motor in oil pump jacks[J]. Acta Automatica Sinica, 2007, 33(7): 749-752. | |

| 127 | Liu X, Xu J. The method of energy saving in beam pumping unit based on genetic algorithm[J]. Aasri Procedia, 2012, 1(3): 441-447. |

| 128 | 孙其宏, 任新华, 孙志刚, 等. 基于ATT7022A的Y/Δ切换抽油机节能控制器的研制[J]. 科学技术与工程, 2012, 12(17): 4288-4292. |

| Sun Qi-hong, Ren Xin-hua, Sun Zhi-gang, et al. A design Y/Δ energy saving controller for oil-pumping units based on ATT7022A[J]. Science and Technology and Engineering, 2012, 12(17): 4288-4292. | |

| 129 | Li X G, Xiao P P. Study of energy saving controller for beam pumping unit based on neural net PID[J]. Applied Mechanics & Materials, 2014, 687-691: 538-542. |

| 130 | Luo Y, Cui X, Zhao H, et al. A multifunction energy-saving device with a novel power-off control strategy for beam pumping motors[J]. IEEE Transactions on Industry Applications, 2011, 47(4):1605-1611. |

| 131 | 杜永军, 徐秀芬, 姜民政, 等. 可控硅调压式抽油机节能控制器的谐波分析[J]. 大庆石油学院学报, 1999(3): 102-105, 119. |

| Du Yong-jun, Xu Xiu-fen, Jiang Min-zheng, et al. Analysis of harmonic wave from the pumping unit energy-saving controller[J]. Journal of Daqing Petroleum Institute, 1999(3): 102-105, 119. | |

| 132 | 吉文清, 何美华, 毛广海. 电动机液态电阻软启动器在矿渣粉磨系统中的应用[J]. 中国非金属矿工业导刊, 2010(6): 37-38. |

| Ji Wen-qing, He Mei-hua, Mao Guang-hai. Application of soft starter on liquid state resistance of electric motor for the system of slag gringding[J]. China Nonmetallic Mine Industry Herald, 2010(6): 37-38. | |

| 133 | 陶波, 邓建强. 2000kW电动机液态电阻软启动器设计原理及应用[N]. 电子报, 2010-01-24. |

| Tao Bo, Deng Jian-qiang. Design principle and application of liquid resistance soft starter for 2000 kW motor[N]. Electronic Newspaper, 2010-01-24. | |

| 134 | 丁卫红, 赵建洋. 智能抽油机节能器研究与开发[J]. 微计算机信息, 2009, 25(26):124-126, 118. |

| Ding Wei-hong, Zhao Jian-yang. Research and development of oil extraction machinery of intelligent energy-saving equipment[J]. Microcomputer Information, 2009, 25(26): 124-126, 118. | |

| 135 | 赵鹏飞. 油田抽油机节能方式综述及解决方案[J]. 科技资讯, 2007(6): 96-97. |

| Zhao Peng-fei. Overview and solution of eenergy-saving ways of oilfield pumping units[J]. Science and Technology Information, 2007(6): 96-97. | |

| 136 | 于建平. 无功补偿电容器运行特性参数选取[J]. 供用电, 2005, 22(4): 20-21. |

| Yu Jian-ping. Selection of operating characteristic parameter for reactive compensation capacitor banks[J]. Distribution & Utilization, 2005, 22(4): 20-21. | |

| 137 | 黄炯舟. 抽油机电动机负载自动跟踪节能器应用效果探讨[J]. 石油石化节能, 2016, 6(2): 24-25. |

| Huang Jiong-zhou. Application effect of automatic load tracking energy saver for pumping unit motor[J]. Energy Conservation in Petroleum & Petrochemical Industry, 2016, 6(2): 24-25. | |

| 138 | 葛苏鞍. 论抽油机的无功补偿方式[J]. 新疆石油科技, 1997, 7(2): 43-45. |

| Ge Su-an.On reactive power compensation of pumping units[J]. Xinjiang Petroleum Science & Technology, 1997, 7(2): 43-45. | |

| 139 | 田金艳. 基于静止无功发生器的抽油机自动补偿节能系统研究[D]. 大庆:东北石油大学电气信息工程学院, 2016. |

| Tian Jin-yan. Study on automatic compensation energy-saving system for pumping unit based on static reactive power generator[D]. Daqing: College of Electrical and Information Engineering, Northeast Petroleum University, 2016. | |

| 140 | 崔岩. 基于遗传神经网络的油田配电网静动态无功优化研究[D]. 青岛:中国石油大学(华东)信息与控制工程学院, 2011. |

| Cui Yan. Research on the reactive power optimization of static and dynamic of oil field distribution network based on genetic neural network[D]. Qingdao:College of Information & Control Engineering, China University of Petroleum(East China), 2011. | |

| 141 | 石成柱. 井组平台无功动态补偿技术的研究[D]. 青岛:中国石油大学(华东)信息与控制工程学院, 2010. |

| Shi Cheng-zhu. The research on technology of reactive power dynamic compensation in oil well group platform [D]. Qingdao:College of Information & Control Engineering, China University of Petroleum(East China), 2010. | |

| 142 | 董世红. 游梁式抽油机变频调速技术改造及应用[J]. 长江大学学报:自然科学版, 2010, 7(1): 197-198. |

| Dong Shi-hong. Technical transformation and application of variable frequency speed regulation for beam pumping units[J]. Journal of Yangtze University(Natural Science Edition), 2010, 7(1): 197-198. | |

| 143 | Peng Y, Liu X. Application of variable frequency speed control to beam pumping units based on mechanical properties in mechanical controlling engineering[J]. Advanced Materials Research, 2013, 648: 365-369. |

| 144 | 周明卿, 李勃. 抽油机调速电机的应用[J]. 石油矿场机械, 1995, 24(2): 15-17. |

| Zhou Ming-qing, Li Bo. Application of pumping unit speed regulating motor[J]. Oil Field Equipment, 1995, 24(2): 15-17. | |

| 145 | 徐军. 抽油机倒发电与节能自动控制系统的研究[D]. 合肥:合肥工业大学电气与自动化工程学院, 2003. |

| Xu Jun. The beam pumping motor generates electricity with economy energy autoumatically handle the system's research[D]. Hefei:School of Electrical and Automation Engineering, Hefei University of Technology, 2003. | |

| 146 | 冯耀忠, 李光, 韩炜. 国外抽油技术的新发展(一)[J]. 石油机械, 2000, 28(10): 58-60. |

| Feng Yao-zhong, Li Guang, Han Wei. New development of oil pumping technology abroad(1)[J]. China Petroleum Machinery, 2000, 28(10): 58-60. | |

| 147 | 张彬. 抽油机倒发电与节能自动控制系统的研究[J]. 中国石油和化工标准与质量, 2012, 32(3): 174. |

| Zhang Bin. The beam pumping motor generates electricity with economy energy autoumatically handle the system's research[J]. Standards and quality of China Petroleum and Chemical Industry, 2012, 32(3): 174. | |

| 148 | Lu J M, He J P, Mao C X, et al. Design and implementation of a dual PWM frequency converter used in beam pumping unit for energy saving[J]. IEEE Transactions on Industry Applications, 2014, 50(5): 2948-2956. |

| 149 | 王宇鸿. 基于DSP的抽油机用感应电机双PWM变频调速系统研究[J]. 机电信息, 2011(36): 153, 156. |

| Wang Yu-hong. Research on dual PWM frequency conversion speed regulation system of induction motor for pumping unit based on DSP[J]. Mechanical and Electrical Information, 2011(36): 153, 156. | |

| 150 | 朱益飞, 杨梅, 史红芳, 等. 变频技术与能量回馈控制在游梁式抽油机上的应用[J]. 电力需求侧管理, 2013, 15(4): 27-29. |

| Zhu Yi-fei, Yang Mei, Shi Hong-fang, et al. Application of frequency conversion technology and energy feedback control on the beam pumping unit[J]. Power Demand Side Management, 2013, 15(4): 27-29. | |

| 151 | 赵海森, 王博, 王义龙, 等. 势能负载条件下感应电机变频–调压分段节能控制策略研究[J]. 中国电机工程学报, 2015, 35(6): 1490-1497. |

| Zhao Hai-sen, Wang Bo, Wang Yi-long, et al. Research on sectionalized energy-saving control strategy based on frequency and voltage regulator technique for induction motor with potential loads[J]. Proceedings of The Chinese Society for Electrical Engineering, 2015, 35(6): 1490-1497. | |

| 152 | 王福家. 抽油机用感应电机变频调速及能量回馈控制系统的研究[D]. 哈尔滨:哈尔滨理工大学电气工程及其自动化学院, 2009. |

| Wang Fu-jia. Study on induction motor control system with variable frequency variable voltage and energy feedback for pumping unit[D]. Harbin: College of Electrical Engineering and Automation, Harbin University of Technology, 2009. | |

| 153 | 董世民, 李伟成, 赵晓芳, 等. 变频游梁式抽油系统动态仿真与实时频率优化[J]. 中国机械工程, 2016, 27(12): 1585-1590. |

| Dong Shi-min, Li Wei-cheng, Zhao Xiao-fang, et al. Frequency conversion beam pumping system dynamic simulation and real time frequency optimization[J]. China Mechanical Engineering, 2016, 27(12): 1585-1590. | |

| 154 | 金锋. 抽油机加装超越离合器实现节能[J]. 石油机械,1998, 26(6):34-36. |

| Jin Feng. Mounting overdrive clutch on pumping unit for power saving[J]. China Petroleum Machinery, 1998, 26(6): 34-36. | |

| 155 | 孙亚州. 抽油机用超越离合器提高系统效率与节能效果分析[J]. 石油石化节能, 2015, 5(7): 47-48. |

| Sun Ya-zhou. Analysis of the effect of overrunning clutch for pumping unit on improving system efficiency and energy saving[J]. Energy Conservation in Petroleum & Petrochemical Industry, 2015, 5(7): 47-48. | |

| 156 | 石秀凡. 抽油机超越离合器节能增产技术应用与分析[J]. 黑龙江科技信息, 2007(11): 25. |

| Shi Xiu-fan. Application and analysis of energy-saving and production-increasing technology for pumping unit overrunning clutch[J]. Heilongjiang Science and Technology Information, 2007(11): 25. | |

| 157 | 张波. 抽油机超越离合器在安塞油田应用效果分析[J]. 石油石化节能, 2015, 5(9):38-39, 45. |

| Zhang Bo. Application effect analysis of pumping unit overrunning clutch in Ansai oilfield[J]. Energy Conservation in Petroleum & Petrochemical Industry, 2015, 5(9): 38-39, 45. | |

| 158 | 季祥云, 刘浦安, 王新华. 游梁式抽油机皮带轮内加装超越离合器探讨[J]. 石油矿场机械, 2000, 29(6): 49. |

| Ji Xiang-yun, Liu Pu-an, Wang Xin-hua. Discussion on installation of overrunning clutch in belt wheel of beam pumping unit[J]. Oil Field Equipment, 2000, 29(6): 49. | |

| 159 | 孙正贵, 徐军, 匡耀武, 等. 游梁式抽油机倒发电现象的消除与节能[J]. 承德石油高等专科学校学报, 2003, 5(1): 28-30. |

| Sun Zheng-gui, Xu Jun, Kuang Yao-wu, et al. Energy-saving and avoidance of the electric motor generate electricities of beam pumper[J]. Journal of Chengde Petroleum College, 2003, 5(1): 28-30. | |

| 160 | 肖志勇, 焦裕玺, 王晓东, 等. 抽油机电动机驱动设备的节能改造[J]. 石油石化节能, 2015, 5(8): 44-45. |

| Xiao Zhi-yong, Jiao Yu-xi, Wang Xiao-dong, et al. Energy-saving renovation of motor drive equipment for pumping unit [J]. Energy Conservation in Petroleum & Petrochemical Industry, 2015, 5(8): 44-45. | |

| 161 | Velichkovich A S. Shock absorber for oil-well sucker-rod pumping unit[J]. Chemical & Petroleum Engineering, 2005, 41(9/10): 544-546. |

| 162 | Niculescu A I, Sireteanu T, Dumitriu D. Simulation results using shock absorbers with primary intelligence-VZN[C]∥ Proceedings of the European Computing Conference, Berlin:Springer, 2008: 185-197. |

| 163 | 赵晓波, 韩兵奇, 张军, 等. ZJZ型抽油杆减振器的研制[J]. 液压气动与密封, 2014, 34(9): 45-47. |

| Zhao Xiao-bo, Han Bing-qi, Zhang Jun, et al. Development of ZJZ Type Rod String Absorber[J]. Hydraulics Pneumatics & Seals, 2014, 34(9): 45-47. | |

| 164 | 卢玉. 游梁式抽油机空气弹簧悬绳器仿真与试验研究[D]. 大庆: 东北石油大学石油工程学院, 2015. |

| Lu Yu. Simulation and experimental study on air spring suspension of beam pumping unit [D]. Daqing: Institute of Petroleum Engineering, Northeast Petroleum University,2015. | |

| 165 | Lv H Q, Liu J, Han J Q, et al. An energy saving system for a beam pumping unit[J]. Sensors, 2016, 16(5): 685. |

| 166 | Zhao H J, Zhang Y, Zhu L J, et al. Power integration based dynamic equilibrium measurement and control device of beam pumping unit[C]∥ Instrumentation and Measurement Technology Conference Proceedings, Taipei, China,2016: 1-6. |

| 167 | Wei H X, Wang W F. Intelligent balanced device and its sensing system for beam pumping units[J]. Sensors & Transducers, 2014, 182(11): 62-68. |

| 168 | Kang X Q, Ren T, Qu W T. Dynamic adjusting mechanism of counterbalance in beam-pumping unit and its kinetic analysis[J]. Applied Mechanics & Materials, 2014, 455: 274-278. |

| 169 | 胡航行. 自平衡智能抽油机的研制[D]. 荆州:长江大学机械工程学院, 2018. |

| Hu Hang-xing. Development of self-balancing intelligent pumping unit[D]. Jingzhou: College of Mechanical Engineering, Changjiang University, 2018. | |

| 170 | 戴萍, 徐东彦. 抽油机二次平衡的探讨[J]. 大庆石油学院学报, 1997(2): 84-87. |

| Dai Ping, Xu Dong-yan. Discussion on the secondary balance of pumping units[J]. Journal of Daqing Petroleum Institute, 1997(2): 84-87. | |

| 171 | 白树泰, 陈建国, 吴志远, 等. 从前置式气动平衡抽油机试验结果看其优越性[J]. 石油矿场机械, 1987(5): 40-43. |

| Bai Shu-tai, Chen Jian-guo, Wu Zhi-yuan, et al. See its superiority from the test results of the pre-pneumatic balanced pumping unit[J]. Petroleum Mine Machinery, 1987(5): 40-43. | |

| 172 | 沈秀通, 綦耀光, 石临嵩. 我国前置式气平衡抽油机评介[J]. 石油机械, 1993(6): 51-52. |

| Shen Xiu-tong, Qi Yao-guang, Shi Lin-song. Review of China's front-end gas-balanced pumping units[J]. China Petroleum Machinery, 1993(6): 51-52. | |

| 173 | 何帆, 李锴, 辛大勇, 等. 用弹簧储能装置实现抽油机二次平衡的节能分析[J]. 石油矿场机械, 2009, 38(3): 73-76. |

| He Fan, Li Kai, Xin Da-yong, et al. Energy saving analysis of secondary balance achieved by using of spring energy for pumping unit [J]. Oil Field Equipment, 2009, 38(3): 73-76. | |

| 174 | 屈彬, 刘全, 李海梁, 等. 抽油机弹簧节能装置在青海油田的研制与应用[J]. 石油石化节能, 2012, 2(12): 31-32. |

| Qu Bin, Liu Quan, Li Hai-liang, et al. Development and application of pumping unit spring energy-saving device in Qinghai Oilfield [J]. Energy Conservation in Petroleum & Petrochemical Industry, 2012, 2(12): 31-32. | |

| 175 | 杨晓翔, 范家齐, 高生彬, 等. 配置弹簧的游梁式抽油机节能分析[J]. 石油机械, 1999(3): 3-6. |

| Yang Xiao-xiang, Fan Jia-qi, Gao Sheng-bin, et al. Investigation in energy saving of beam pumping units with springs[J]. China Petroleum Machinery, 1999(3): 3-6. | |

| 176 | 梁宏宝, 孟庆伟, 孙旭东, 等. 抽油机二次平衡技术及节能原理分析[J]. 应用能源技术, 2011(7): 1-3. |

| Liang Hong-bao, Meng Qing-wei, Sun Xu-dong, et al. The second balance technology of pumping and the analysis of energy conservation principle[J]. Applied Energy Technology, 2011(7): 1-3. | |

| 177 | 姜民政, 殷兆国, 高春红, 等. 抽油机飞轮蓄能器及其对电机能耗的影响[J]. 油气田地面工程, 2009, 28(1): 62-63. |

| Jiang Min-zheng, Yin Zhao-guo, Gao Chun-hong, et al. Power saving accumulator of pumping unit and the influence of energy consumption on electromotor[J]. Oil-Gasfield Surface Engineering, 2009, 28(1): 62-63. | |

| 178 | 姜民政, 周广玲, 曹彦鹏, 等. 抽油机机械蓄能器及其对电机能耗的影响[J]. 石油矿场机械, 2010, 39(9): 26-28. |

| Jiang Min-zheng, Zhou Guang-ling, Cao Yan-peng, et al. Mechanical accumulator of pumping units and its influence on electromotor consumption[J]. Oil Field Equipment, 2010, 39(9): 26-28. | |

| 179 | 周广玲. 游梁式抽油机二次平衡理论与试验研究[D].大庆:东北石油大学石油工程学院, 2011. |

| Zhou Guang-ling. Theory and experimental study on secondary balance of beam pumping unit[D]. Daqing: School of Petroleum Engineering, Northeast Petroleum University, 2011. | |

| 180 | 姜继海, 谷峰. 常规游梁式抽油机的二次调节液压节能系统[P]. 中国:CN101082334, 2007-12-05. |

| 181 | 姜继海, 谷峰, 秦二卫, 等. 液压能量回收的扭矩平衡游梁式抽油机[J]. 流体传动与控制, 2009(2): 4-7. |

| Jiang Ji-hai, Gu Feng, Qin Er-wei, et al. Walling-beam pumping with torque balance unit through hydraulic energy recovery[J]. Fluid Power Transmission and Control, 2009(2): 4-7. | |

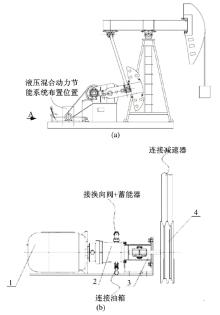

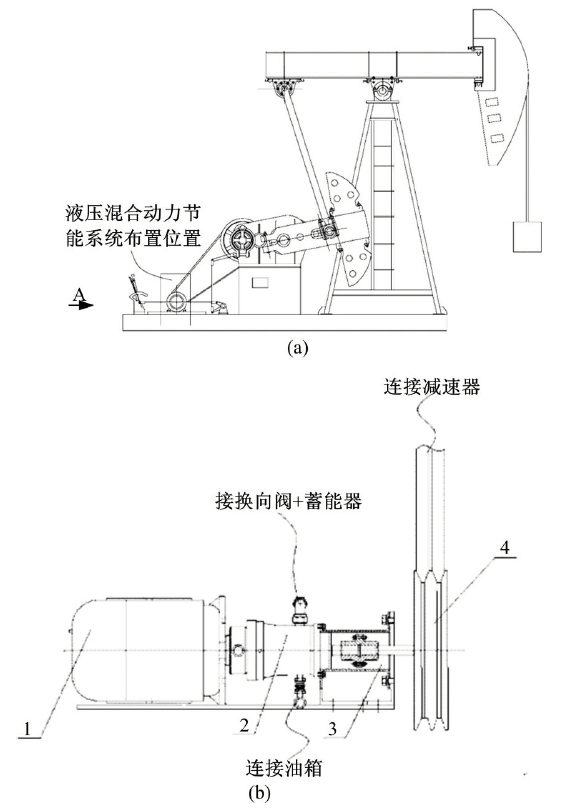

| 182 | 王昕, 刘昕晖, 梁燚杰, 等. 游梁式抽油机液压辅助动力节能系统[P]. 中国:CN104595255A, 2015-05-06. |

| 183 | 王昕, 刘昕晖, 梁燚杰. 游梁式抽油机液压混合动力驱动系统及其控制方法[P]. 吉林:CN105064957A, 2015-11-18. |

| 184 | Liang Y, Wang T, Wang X, et al. Simulation research on hydraulic hybrid assistant beam pumping unit[J]. Proceedings of the Institution of Mechanical Engineers Part C: Journal of Mechanical Engineering Science, 2016, 230(11): 1795-1804. |

| 185 | Li C, Chen L, Wang X, et al. Energy-saving system of secondary balance for the hybrid power of the pumping unit[J]. The Journal of Engineering, 2019(13): 190-195. |

| 186 | 陈琳. 游梁式抽油机混合动力节能系统参数优化及最简控制模型建立[D]. 长春:吉林大学机械与航空航天工程学院, 2019. |

| Chen Lin. Parameters optimization and simplest control model establishment of hybrid energy-saving system in beam pumping unit[D]. Changchun: School of Mechanical and Aerospace Engineering, Jilin University, 2019. |

| [1] | 曾小华, 李广含, 宋大凤, 李胜, 朱志成. 轮毂液压混合动力商用车主动防侧翻控制[J]. 吉林大学学报(工学版), 2018, 48(1): 1-10. |

| [2] | 闻德生, 陈帆, 甄新帅, 周聪, 王京, 商旭东. 双定子泵和马达在压力控制回路中的应用[J]. 吉林大学学报(工学版), 2017, 47(2): 504-509. |

| [3] | 彭贝, 高宇, 冯培恩, 邱清盈. 液压挖掘机回转启动过程节能技术[J]. 吉林大学学报(工学版), 2016, 46(6): 1912-1921. |

| [4] | 王军年, 刘德春, 张运昌, 孙文, 初亮. 新型双电机构型纯电动汽车节能潜力分析[J]. 吉林大学学报(工学版), 2016, 46(1): 28-34. |

| [5] | 匡哲君, 师唯佳, 胡亮, 周航. 基于移动汇聚节点延迟容忍的节能策略[J]. 吉林大学学报(工学版), 2015, 45(5): 1586-1591. |

| [6] | 王志衡, 霍占强, 金顺福. LTE中DRX节能策略的系统建模及性能优化[J]. 吉林大学学报(工学版), 2015, 45(5): 1615-1623. |

| [7] | 叶敏, 易小刚, 蒲东亮, 焦生杰. 基于遗传算法的混凝土泵车全局功率匹配[J]. 吉林大学学报(工学版), 2015, 45(3): 820-828. |

| [8] | 董晗,刘昕晖,王昕,郑博元,梁卫权,王佳怡. 并联式液压混合动力系统中蓄能器各主要参数对系统性能的影响[J]. 吉林大学学报(工学版), 2015, 45(2): 420-428. |

| [9] | 胡东海, 何仁, 顾晓丹. 电涡流缓速器结构参数的节能优化设计[J]. 吉林大学学报(工学版), 2014, 44(5): 1253-1257. |

| [10] | 胡青松, 吴立新, 张申, 丁恩杰. 事件驱动的灾害监测传感网中的节能数据传输[J]. 吉林大学学报(工学版), 2014, 44(5): 1404-1409. |

| [11] | 赵丁选, 张志文, 李天宇, 张民, 董岩, 兰昊. 并联式混合动力装载机模糊逻辑控制策略[J]. 吉林大学学报(工学版), 2014, 44(4): 1004-1009. |

| [12] | 闫丽娟, 孙辉, 刘伟, 姜继海, 赵燕, 韩家威. 行走工程机械液压混合动力技术[J]. 吉林大学学报(工学版), 2014, 44(2): 364-368. |

| [13] | 董晗, 刘昕晖, 王昕, 陈晋市, 王佳怡, 郑博元. 基于AMESim的液压混合动力系统节能特性[J]. 吉林大学学报(工学版), 2013, 43(05): 1264-1270. |

| [14] | 李天宇, 赵丁选, 康怀亮, 张志文, 张正飞, 徐春博. 并联式混合动力装载机的参数匹配[J]. 吉林大学学报(工学版), 2013, 43(04): 916-921. |

| [15] | 姚亮, 初亮, 周飞鲲, 刘明辉, 张永生, 魏文若. 纯电动轿车制动能量回收节能潜力仿真分析[J]. 吉林大学学报(工学版), 2013, 43(01): 6-11. |

|

||