吉林大学学报(工学版) ›› 2020, Vol. 50 ›› Issue (2): 472-482.doi: 10.13229/j.cnki.jdxbgxb20181071

• 车辆工程·机械工程 • 上一篇

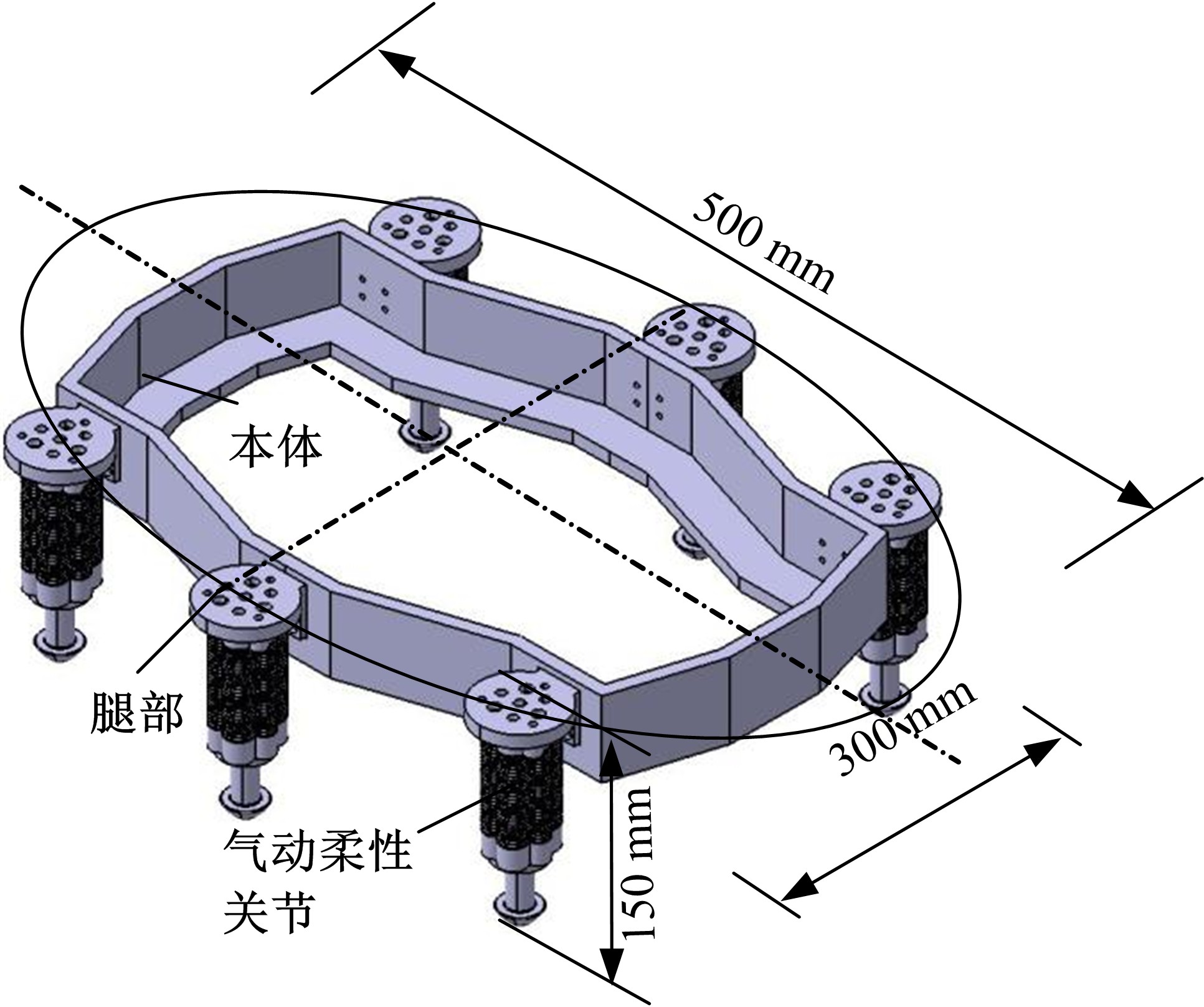

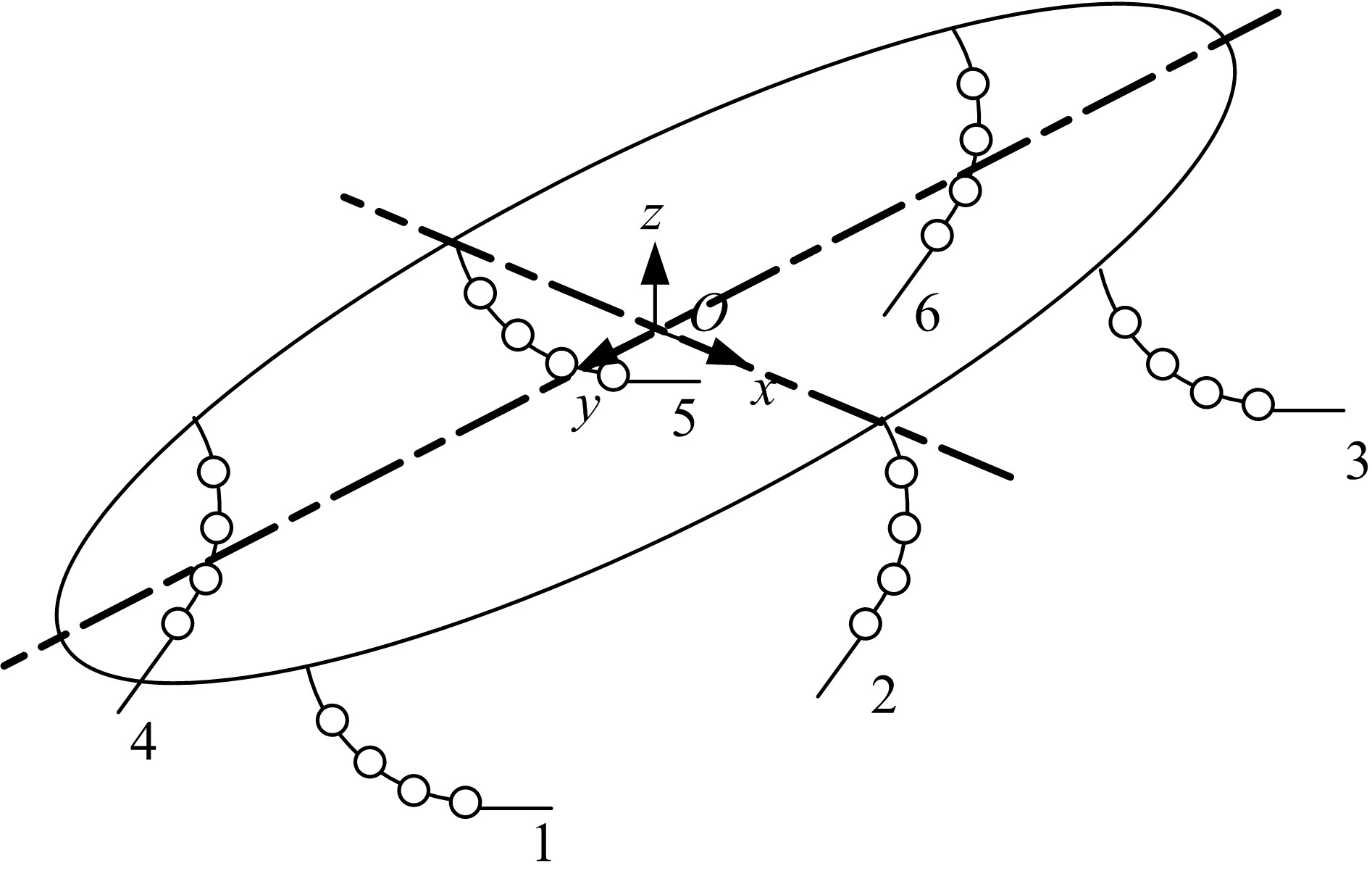

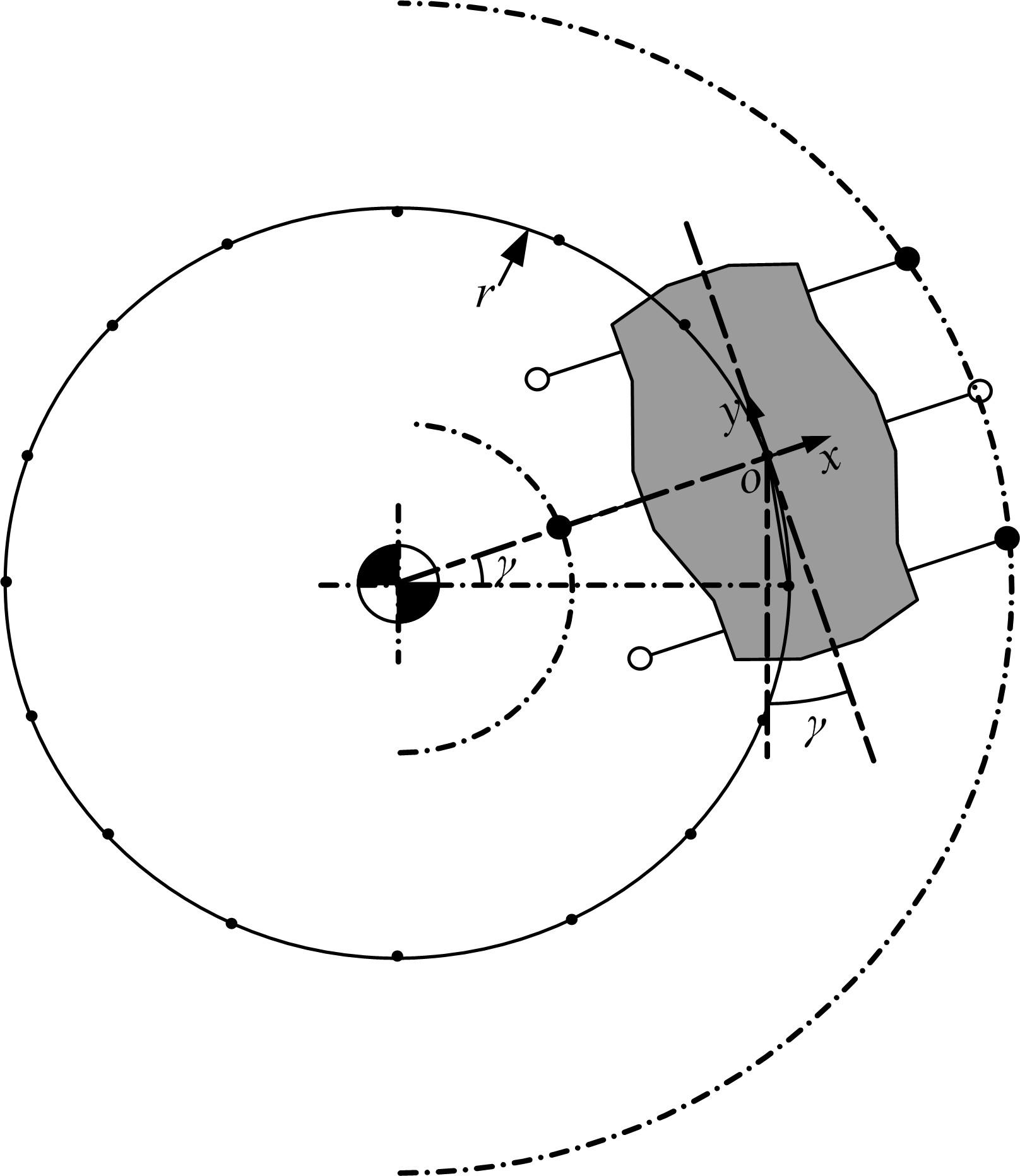

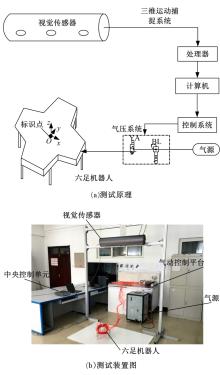

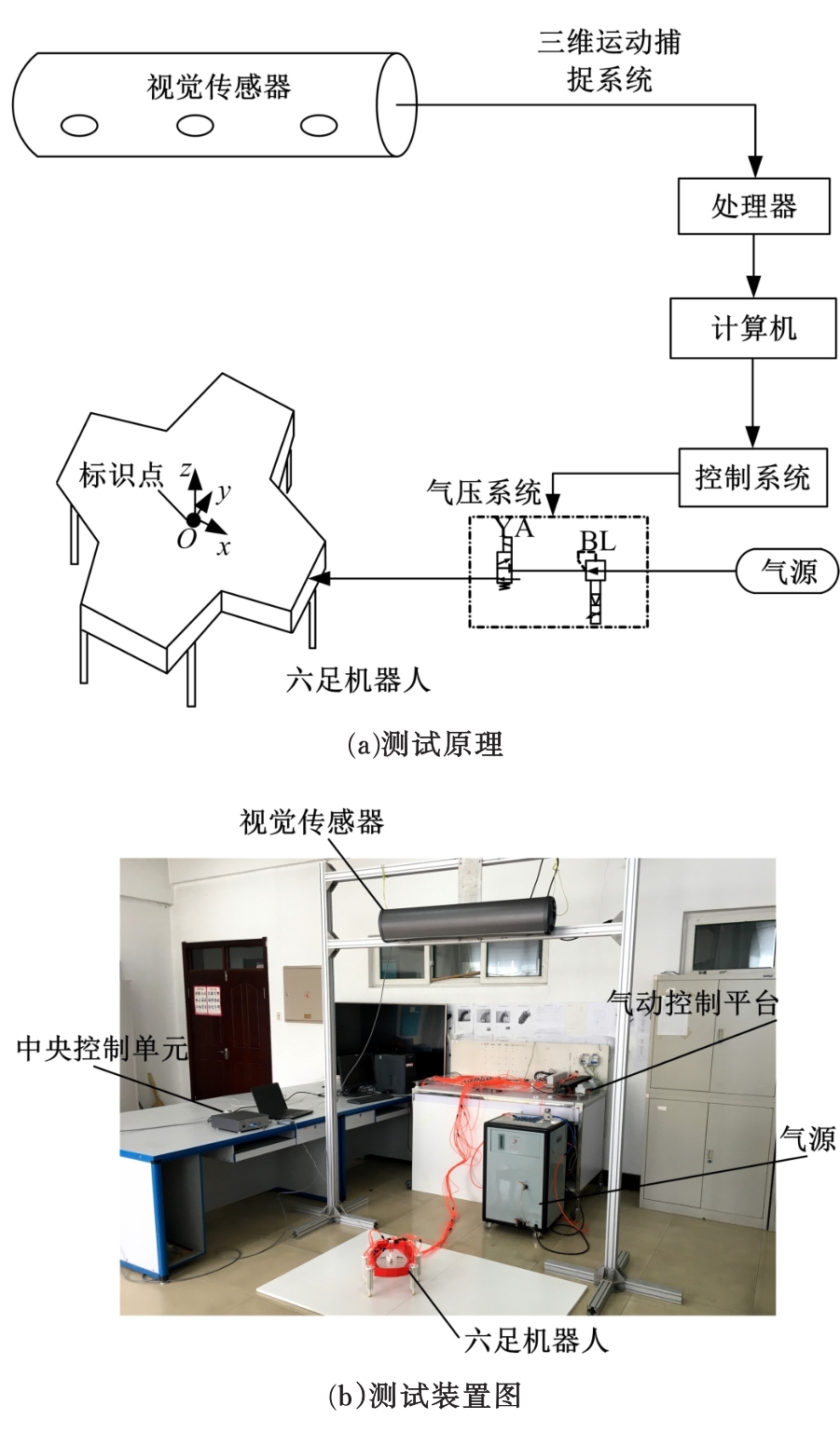

气动柔性六足机器人定半径转弯实现方法与稳定性

- 1.北华大学 工程训练中心,吉林省 吉林市 132021

2.北华大学 机械工程学院,吉林省 吉林市 132021

Implementation and stability on turning with constant radius of pneumatic flexible hexapod robot

Yun-wei ZHAO1( ),De-xu GENG2(

),De-xu GENG2( ),Xiao-min LIU1,Qi LIU2

),Xiao-min LIU1,Qi LIU2

- 1.Engineering Training Center, Beihua University, Jilin 132021, China

2.College of Mechanical Engineering, Beihua University, Jilin 132021, China

摘要:

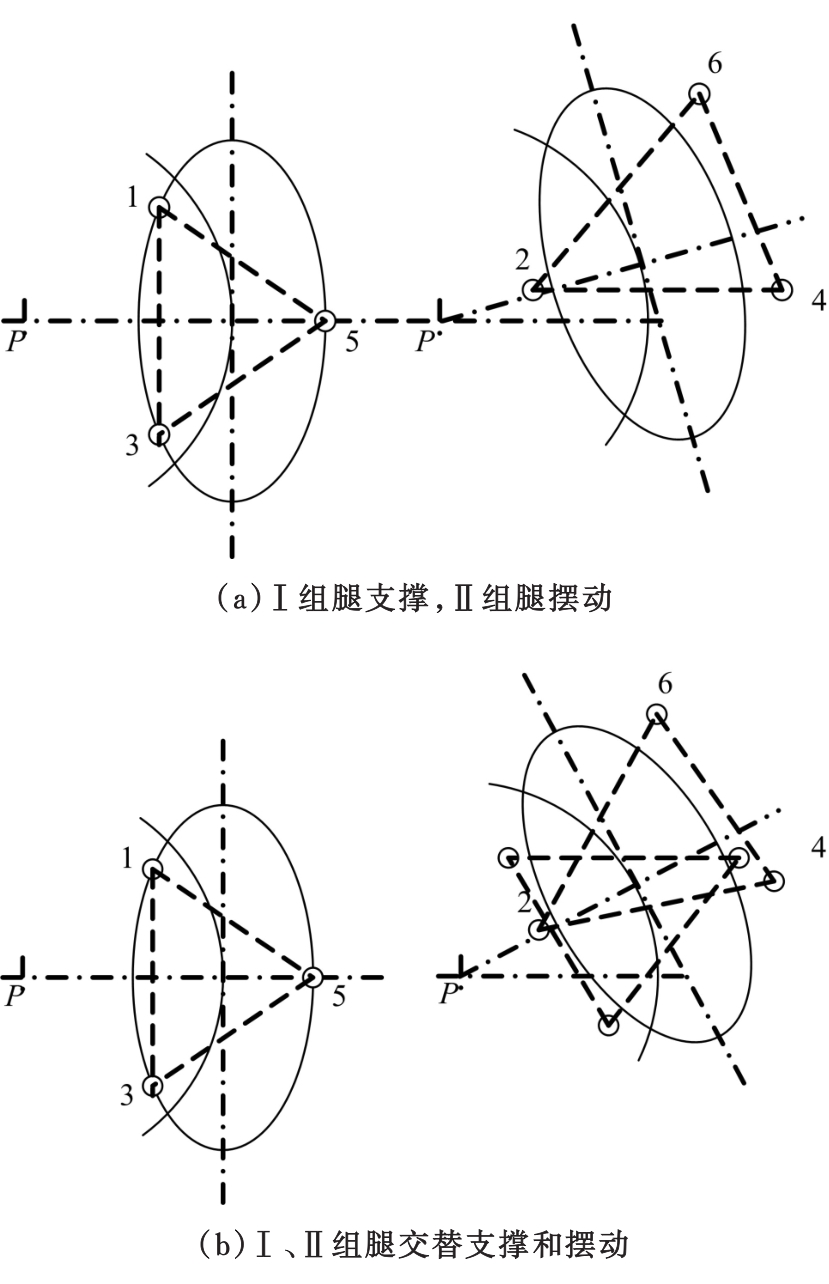

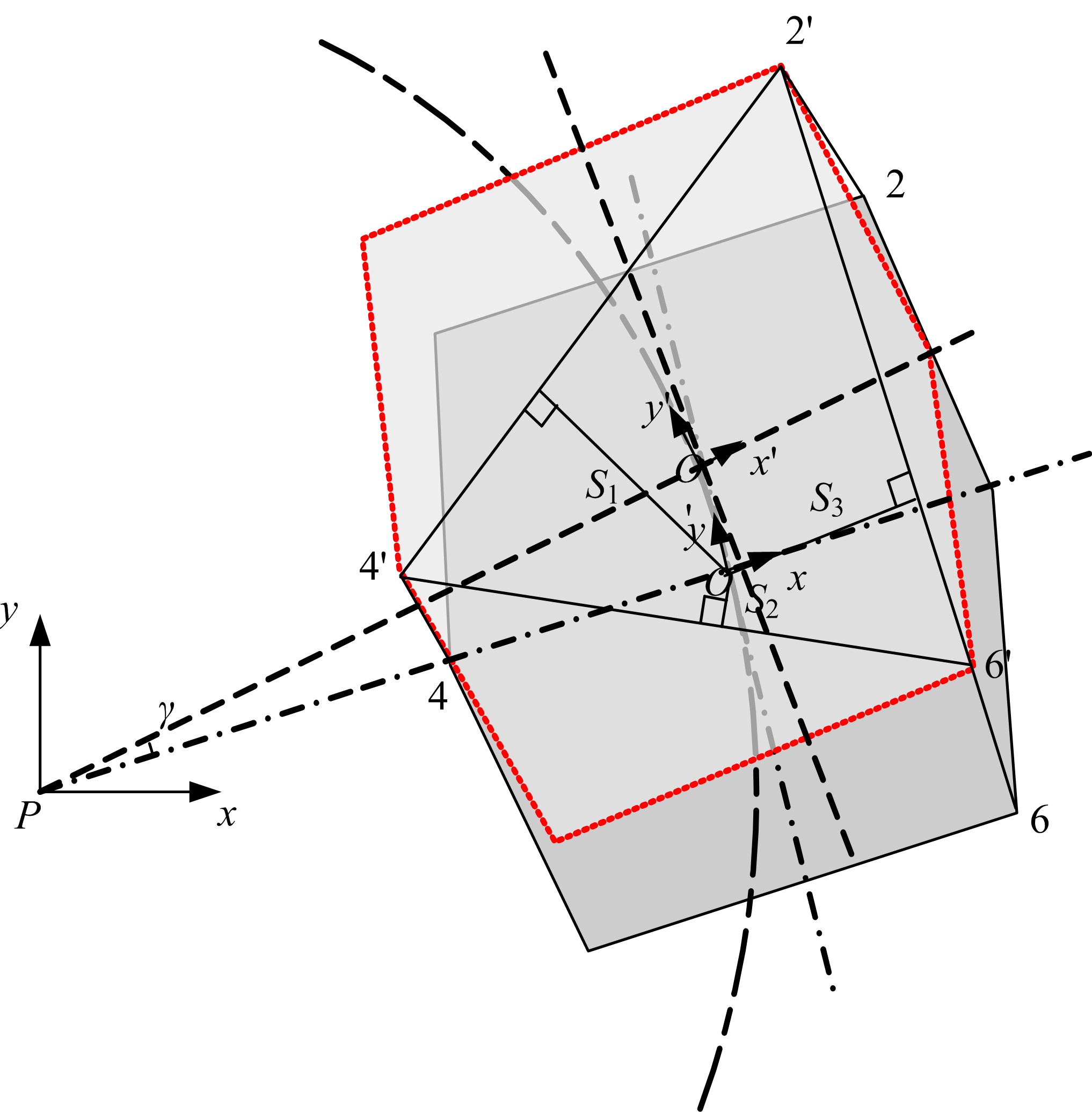

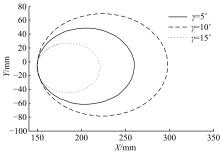

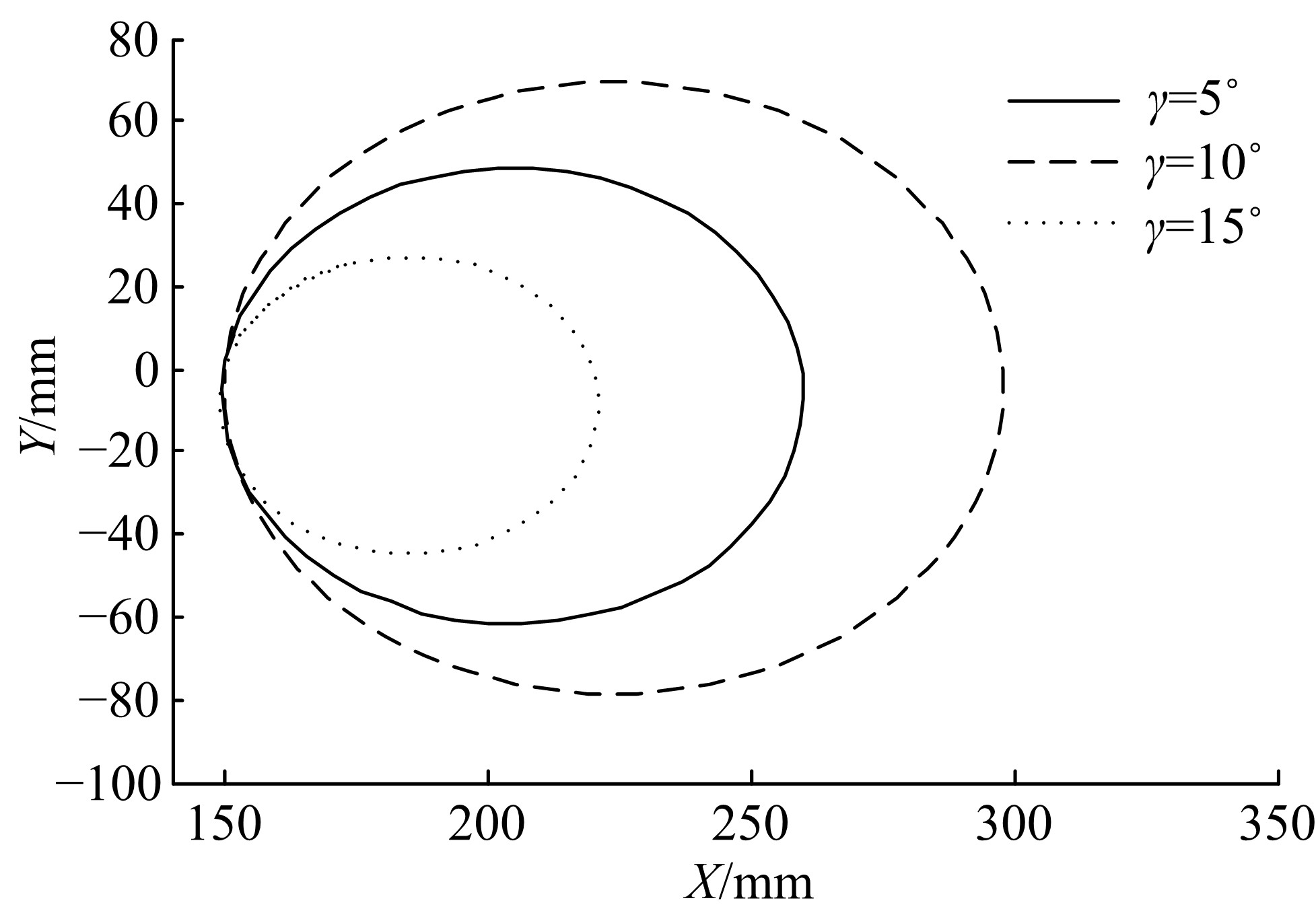

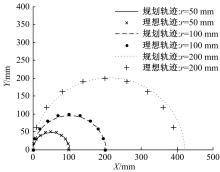

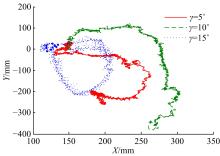

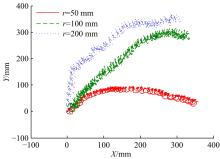

针对气动柔性关节仿生六足机器人提出基于三角步态和重心轨迹跟踪法的定半径转弯步态规划方法。采用预设机器人步态转角和转弯半径逆向建立转动过程中机器人重心轨迹模型,获得机器人足部的落足点位置,并进行了机器人重心轨迹仿真,研究了重心规划轨迹与理想轨迹的偏离误差。根据静态稳定裕度模型建立了最大步态转角模型,并以此作为判据分析机器人定半径转弯步态规划的稳定性。利用三维运动捕捉系统进行了机器人定点和定半径转弯性能实验,获得了不同步态转角和转弯半径下机器人的转弯性能,验证了转弯步态规划方法的正确性。该机器人动作灵活,可实现任意半径转弯,当规划步态转角小于最大步态转角时机器人转弯过程行进平稳。

中图分类号:

- TH138.5

| 1 | Zhang H, Liu Y, Zhao J, et al. Development of a bionic hexapod robot for walking on unstructured terrain[J]. Journal of Bionic Engineering, 2014, 11(2): 176-187. |

| 2 | Bartsch S, Birnschein T, Römmermann M, et al. Development of the six-legged walking and climbing robot SpaceClimber[J]. Journal of Field Robotics, 2012, 29(3): 506-532. |

| 3 | Kondo N, Yata K, Iida M, et al. Development of an end-effector for a tomato cluster harvesting robot[J]. Engineering in Agriculture Environment & Food, 2010, 3(1): 20-24. |

| 4 | 荣誉, 金振林, 崔冰艳. 六足农业机器人并联腿构型分析与结构参数设计[J]. 农业工程学报, 2012, 28(15): 9-14. |

| Rong Yu, Jin Zhen-lin, Cui Bing-yan. Configuration analysis and structure parameter design of six-leg agricultural robot with parallel-leg mechanisms[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(15): 9-14. | |

| 5 | Bodrov A, Cheah W, Green P N, et al. Joint space reference trajectory to reduce the energy consumption of a six-legged mobile robot[C]∥2018 25th International Workshop on Electric Drives: Optimization in Control of Electric Drives (IWED), IEEE, Moscow, 2018: 1-6. |

| 6 | Bjelonic M, Kottege N, Homberger T, et al. Weaver: hexapod robot for autonomous navigation on unstructured terrain[J]. Journal of Field Robotics, 2018, 35(7): 1063-1079. |

| 7 | 刘逸群, 邓宗全, 赵亮, 等. 液压驱动六足机器人步行腿性能[J]. 吉林大学学报: 工学版, 2015, 45(5): 1512-1518. |

| Liu Yi-qun, Deng Zong-quan, Zhao Liang,et al. Performance of walking leg of a hydraulically actuated hexapod robot[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(5): 1512-1518. | |

| 8 | Wang Z, Ding X, Rovetta A, et al. Mobility analysis of the typical gait of a radial symmetrical six-legged robot[J]. Mechatronics, 2011, 21(7): 1133-1146. |

| 9 | Deng H, Xin G, Zhong G, et al. Object carrying of hexapod robots with integrated mechanism of leg and arm[J]. Robotics and Computer-Integrated Manufacturing, 2018(54): 145-155. |

| 10 | 陈甫, 臧希喆, 闫继宏, 等. 适合航行的六足仿生机器人Spider的研制[J]. 吉林大学学报: 工学版, 2011, 41(3): 765-770. |

| Chen Fu, Zang Xi-zhe, Yan Ji-hong, et al. Development of navigable hexapod biomimetic robot Spider[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41(3): 765-770. | |

| 11 | Erden M S, Leblebicio, Lu K. Free gait generation with reinforcement learning for a six-legged robot[J]. Robotics & Autonomous Systems, 2008, 56(3): 199-212. |

| 12 | Roy S S, Pratihar D K. Effects of turning gait parameters on energy consumption and stability of a six-legged walking robot[J]. Robotics & Autonomous Systems, 2012, 60(1): 72-82. |

| 13 | Roy S S, Pratihar D K. Soft computing-based expert systems to predict energy consumption and stability margin in turning gaits of six-legged robots[J]. Expert Systems with Applications, 2012, 39(5): 5460-5469. |

| 14 | Agheli M, Qu L, Nestinger S S. SHeRo: scalable hexapod robot for maintenance, repair, and operations[J]. Robotics and Computer-Integrated Manufacturing, 2014, 30(5): 478-488. |

| 15 | Belter D, Wietrzykowski J, Skrzypczyński P. Employing natural terrain semantics in motion planning for a multi-legged robot[J]. Journal of Intelligent & Robotic Systems, 2019, 93(3/4): 723-743. |

| 16 | Belter D, Nowicki M R. Optimization-based legged odometry and sensor fusion for legged robot continuous localization[J]. Robotics and Autonomous Systems, 2019, 111: 110-124. |

| 17 | Buchanan R, Bandyopadhyay T, Bjelonic M, et al. Walking posture adaptation for legged robot navigation in confined spaces[J]. IEEE Robotics and Automation Letters, 2019, 4(2): 2148-2155. |

| 18 | 姜树海, 孙培, 唐晶晶, 等. 仿生甲虫六足机器人结构设计与步态分析[J]. 南京林业大学学报: 自然科学版, 2012, 36(6): 115-120. |

| Jiang Shu-hai, Sun Pei, Tang Jing-jing, et al. Structural design and gait analysis of hexapod bionic robot[J]. Journal of Nanjing Forestry University (Natural Science Edition), 2012, 36(6): 115-120. | |

| 19 | 陈刚, 金波, 陈鹰. 六足步行机器人定半径转弯步态[J]. 浙江大学学报: 工学版, 2014, 48(7): 1278-1286. |

| Chen Gang, Jin Bo, Chen Ying. Turning gait with constant radius of six-legged waling robot[J]. Joural of Zhejiang University (Engineering Science), 2014, 48(7): 1278-1286. | |

| 20 | 李满宏, 张建华, 张小俊, 等. 基于马尔可夫决策过程的六足机器人自由步态规划[J]. 机器人, 2015, 37(5): 529-537. |

| Li Man-hong, Zhang Jian-hua, Zhang Xiao-jun, et al. Free gait planning for a hexapod robot based on markov decision process[J]. Robot, 2015, 37(5): 529-537. | |

| 21 | 邓宗全, 刘逸群, 高海波, 等. 液压驱动六足机器人步行腿节段长度比例研究[J]. 机器人, 2014, 36(5): 544-551. |

| Deng Zong-quan, Liu Yi-qun, Gao Hai-bo, et al. On the segment length ratio of the walking leg of a hydraulically actuated hexapod robot[J]. Robot, 2014, 36(5): 544-551. | |

| 22 | 赵云伟, 耿德旭, 刘晓敏, 等. 三自由度气动柔性驱动器结构功能与形变特性研究[J]. 农业机械学报, 2017, 48(9): 392-401. |

| Zhao Yun-wei, Geng De-xu, Liu Xiao-min, et al. Structure and deformation characteristics of 3-DOF pneumatic flexible actuator[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(9): 392-401. | |

| 23 | 赵云伟, 耿德旭, 刘晓敏, 等. 气动柔性关节仿生六足机器人步态规划与运动性能研究[J]. 农业机械学报, 2018, 49(2): 385-394, 418. |

| Zhao Yun-wei, Geng De-xu, Liu Xiao-min, et al. Gait planning and kinematics of bionic hexapod robot based on pneumatic flexible join[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(2): 385-394, 418. | |

| 24 | 赵云伟, 耿德旭, 刘晓敏, 等. 气动空间弯曲关节动力学性能实验研究[J]. 机床与液压, 2017, 45(23): 10-23. |

| Zhao Yun-wei, Geng De-xu, Liu Xiao-min, et al. Experimental study on dynamic properties of pneumatic space bending joint[J]. Machine Tool & Hydraulics, 2017, 45(23): 10-23. | |

| 25 | Estremera J, Cobano J A. Continuous free-crab gaits for hexapod robots on a natural terrain with forbidden zones: an application to humanitarian demining[J]. Robotics and Autonomous Systems, 2010, 58(5): 700-711. |

| [1] | 曲兴田, 赵永兵, 刘海忠, 王昕, 杨旭, 陈行德. 串并混联机床几何误差建模与实验[J]. 吉林大学学报(工学版), 2017, 47(1): 137-144. |

| [2] | 任书楠, 杨向东, 王国磊, 刘志, 陈恳. 大部件喷涂中的移动机械臂站位规划[J]. 吉林大学学报(工学版), 2016, 46(6): 1995-2002. |

| [3] | 沈志煌, 姚斌, 陆如升, 冯伟, 张祥雷, 王萌萌. 精密螺杆转子齿廓成形磨削的误差分析[J]. 吉林大学学报(工学版), 2016, 46(3): 831-838. |

| [4] | 王延忠, 侯良威, 吕庆军, 赵兴福, 吴灿辉. 基于总线控制的面齿轮复杂曲面加工技术[J]. 吉林大学学报(工学版), 2015, 45(6): 1836-1843. |

| [5] | 陈健, 葛连正, 李瑞峰. 考虑摩擦特性的机器人柔性关节鲁棒控制器设计[J]. 吉林大学学报(工学版), 2015, 45(6): 1906-1912. |

| [6] | 刘逸群, 邓宗全, 赵亮, 丁亮, 佟志忠, 高海波. 液压驱动六足机器人步行腿性能[J]. 吉林大学学报(工学版), 2015, 45(5): 1512-1518. |

| [7] | 郭黎滨, 张彬, 崔海, 张志航. 微细电火花线切割表面三维粗糙度的结构性参数[J]. 吉林大学学报(工学版), 2015, 45(3): 851-856. |

| [8] | 王继利, 杨兆军, 李国发, 朱晓翠. EM算法的多重威布尔可靠性建模[J]. 吉林大学学报(工学版), 2014, 44(4): 1010-1015. |

| [9] | 杨兆军,王继利,李国发,张新戈. 冲压机床可靠性增长的模糊层次分析预测方法[J]. 吉林大学学报(工学版), 2014, 44(3): 686-691. |

| [10] | 佟金, 王亚辉, 卢纪生, 张书军, 陈东辉. 基于CCD的大型台阶轴锻件同轴度测量[J]. 吉林大学学报(工学版), 2013, 43(04): 945-950. |

| [11] | 张雷, 赵云伟, 杨卓, 赵继. 电流变抛光液剪切屈服特性[J]. , 2012, 42(05): 1145-1150. |

| [12] | 王国富, 高峰, 徐国艳. 转向盘式全方位六足机器人运动分析及控制[J]. , 2012, 42(04): 1008-1014. |

| [13] | 史永杰, 郑堤, 胡利永, 王龙山. 非球面件数控研抛力、研抛工具位置和姿态解耦技术[J]. 吉林大学学报(工学版), 2012, 42(01): 116-121. |

| [14] | 张英芝1,郑锐2,申桂香1,王志琼1,李怀洋1,郑珊1. 基于Copula理论的数控装备故障相关性[J]. 吉林大学学报(工学版), 2011, 41(6): 1636-1640. |

| [15] | 陈甫,臧希喆,闫继宏,赵杰. 适合航行的六足仿生机器人Spider的研制[J]. 吉林大学学报(工学版), 2011, 41(03): 765-770. |

|

||