吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (3): 604-614.doi: 10.13229/j.cnki.jdxbgxb20200825

• 交通运输工程·土木工程 • 上一篇

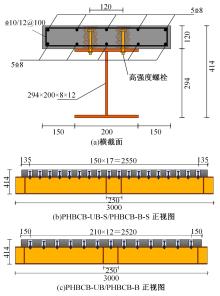

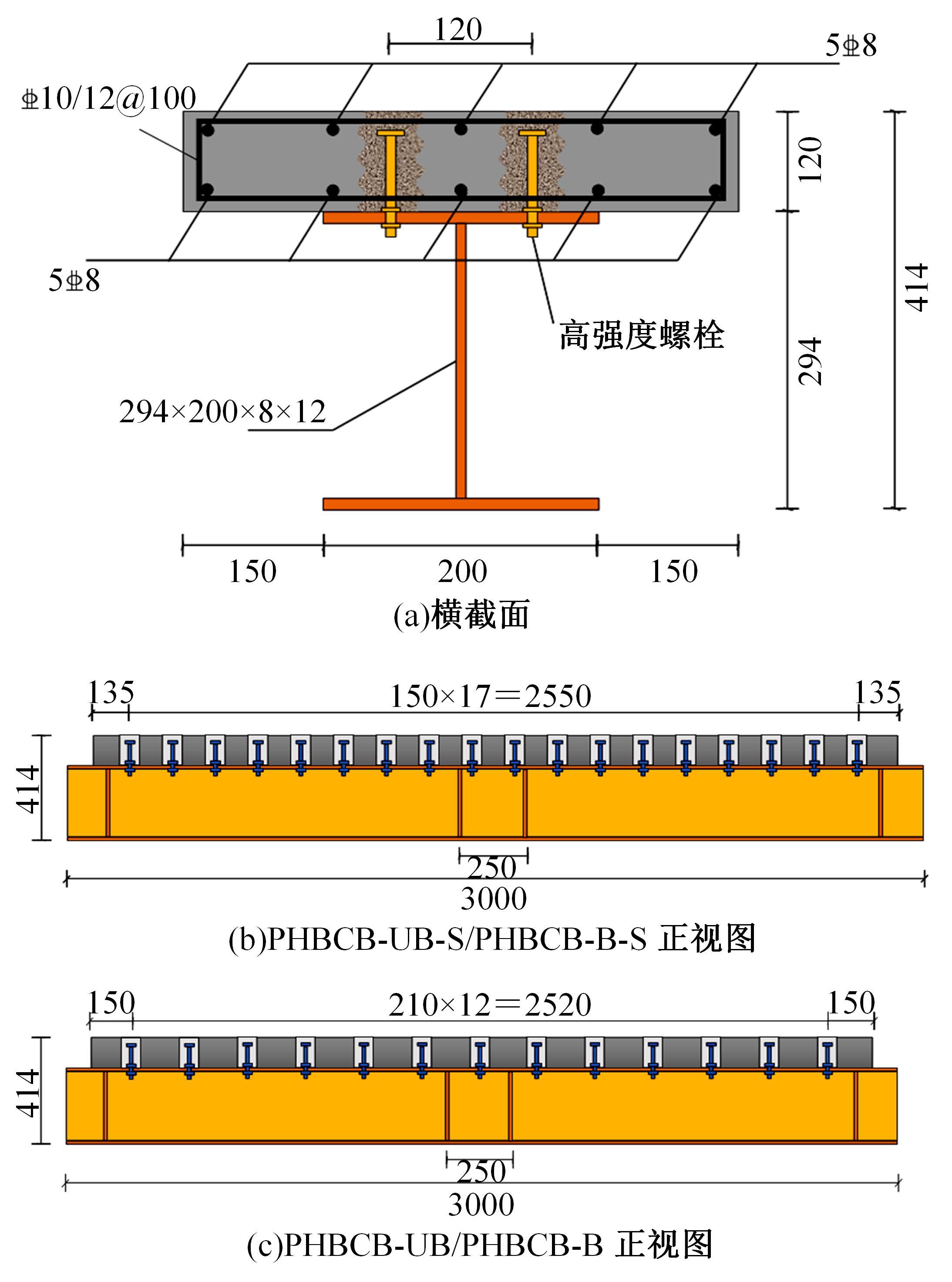

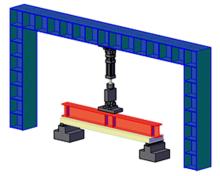

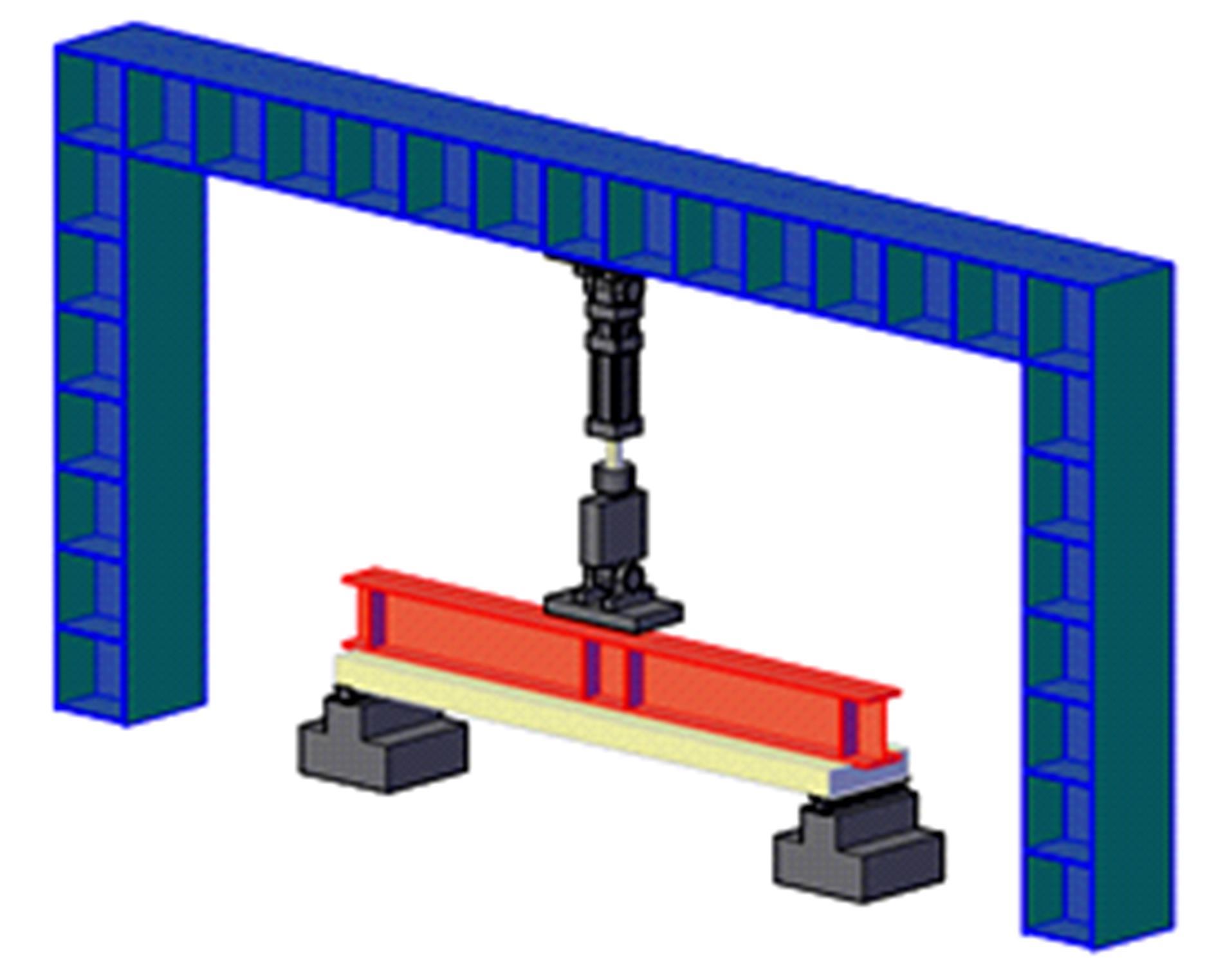

负弯矩作用下可拆卸预制装配式组合梁力学性能试验

陈俊1( ),王韶纤1,胥卉1,莫端泉2,霍静思3,邓旭华1(

),王韶纤1,胥卉1,莫端泉2,霍静思3,邓旭华1( )

)

- 1.湘潭大学 土木工程与力学学院,湖南 湘潭 411105

2.湖南恒运建筑科技发展有限公司,湖南 湘潭 411101

3.华侨大学 土木工程学院,福建 厦门 361021

Experiment on mechanical properties of detachable prefabricated composite beams subjected to negative bending moment

Jun CHEN1( ),Shao-xian WANG1,Hui XU1,Duan-quan MO2,Jing-si HUO3,Xu-hua DENG1(

),Shao-xian WANG1,Hui XU1,Duan-quan MO2,Jing-si HUO3,Xu-hua DENG1( )

)

- 1.College of Civil Engineering and Mechanics,Xiangtan University,Xiangtan 411105,China

2.Hunan Hengyun Construction Technology Development Co. ,Ltd. ,Xiangtan 411101,China

3.College of Civil Engineering,Huaqiao University,Xiamen 361021,China

摘要:

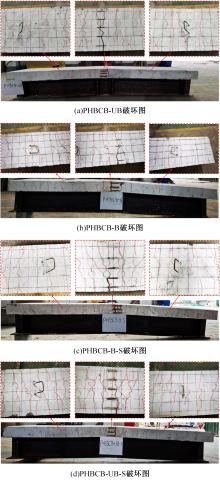

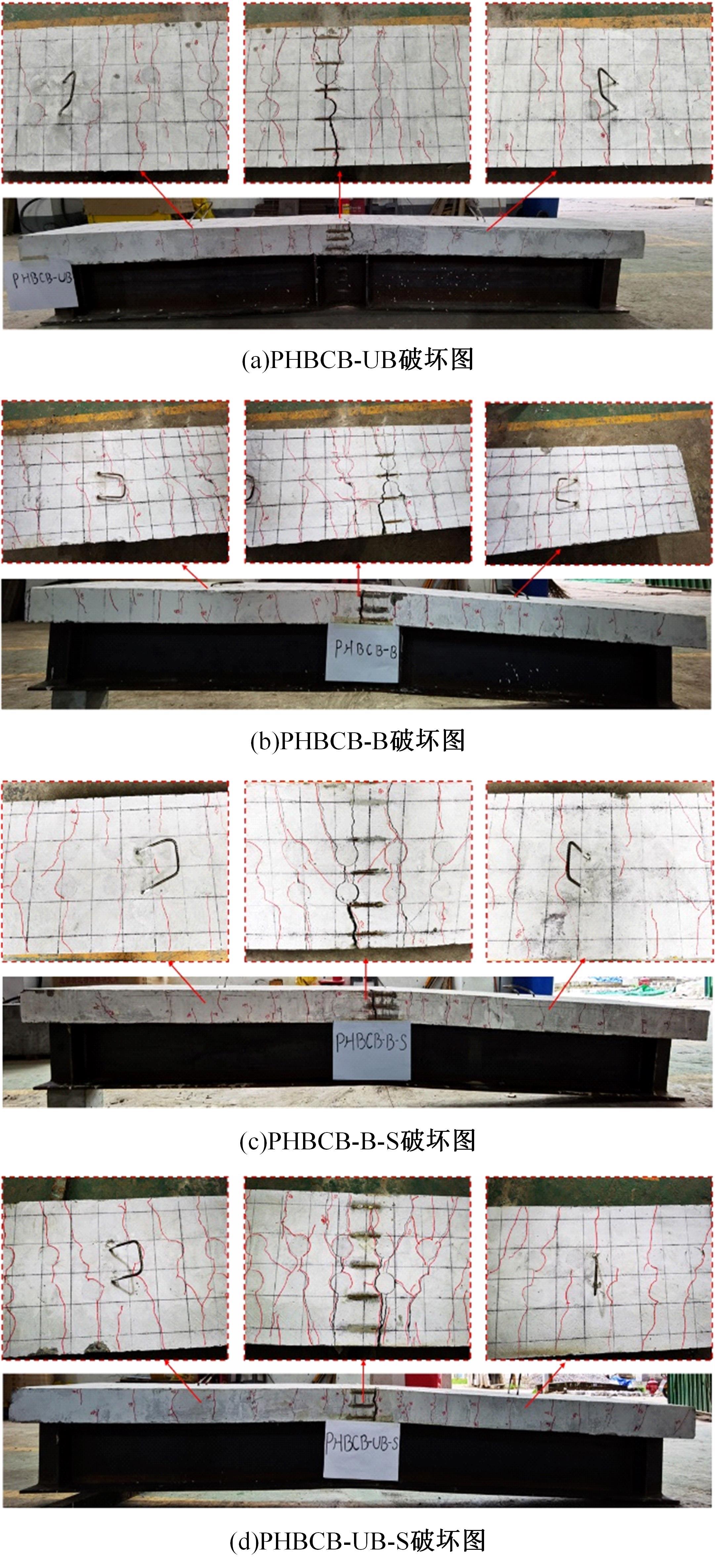

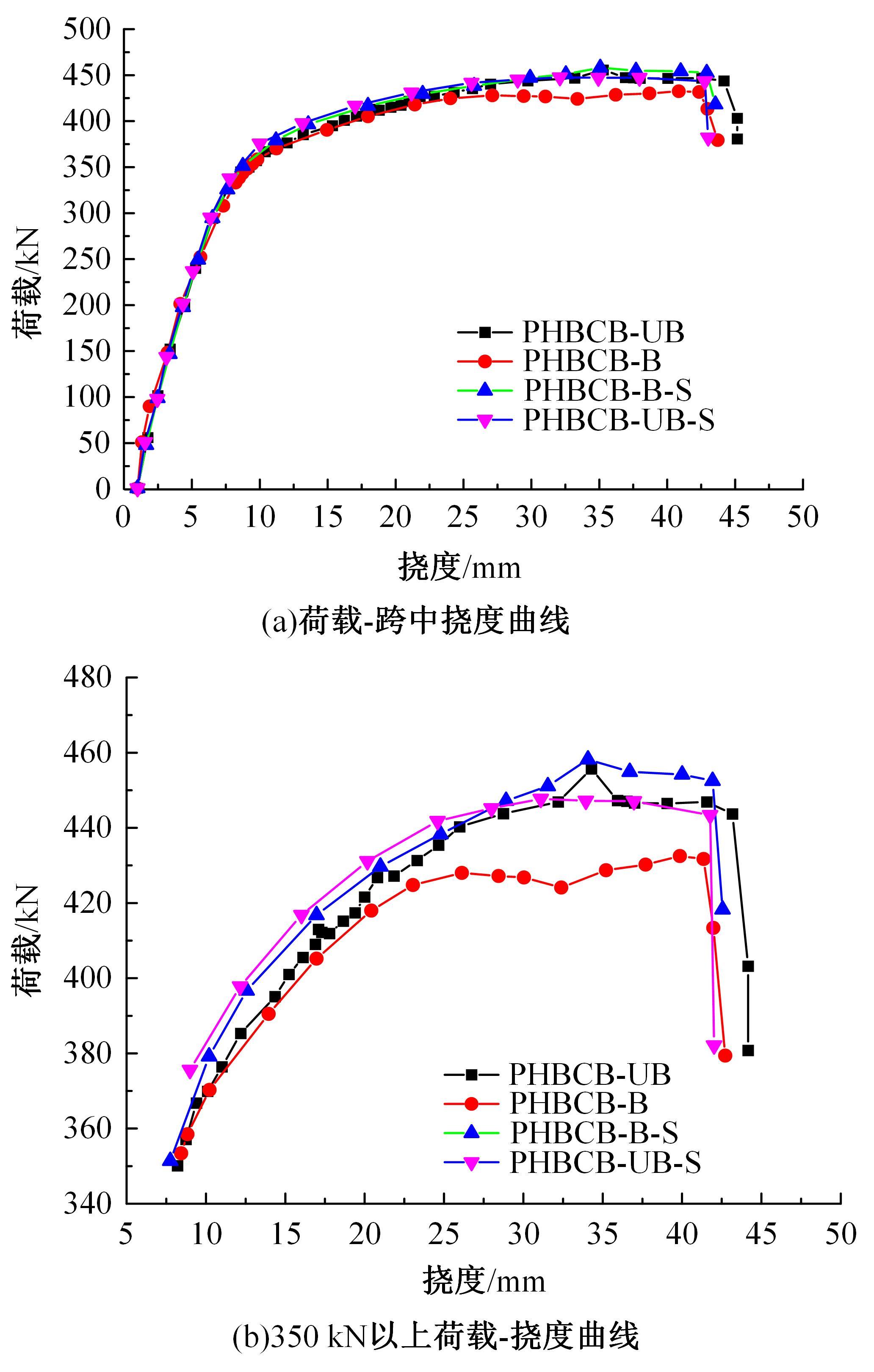

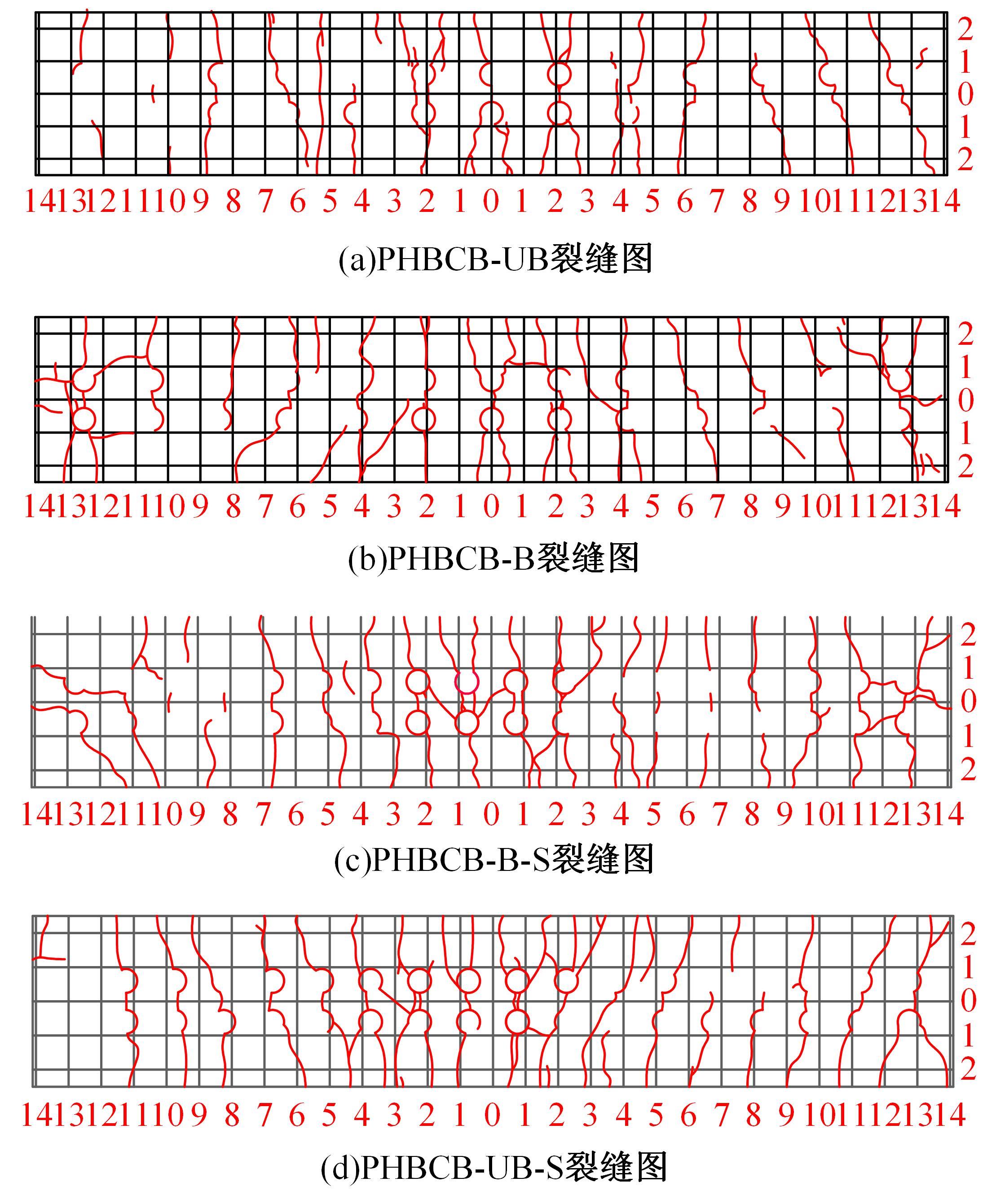

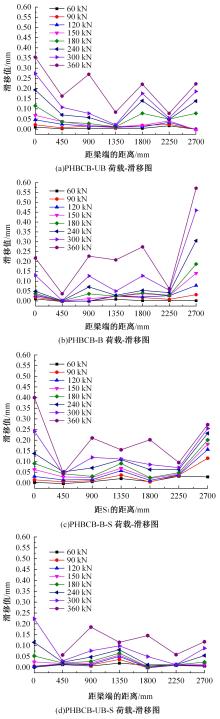

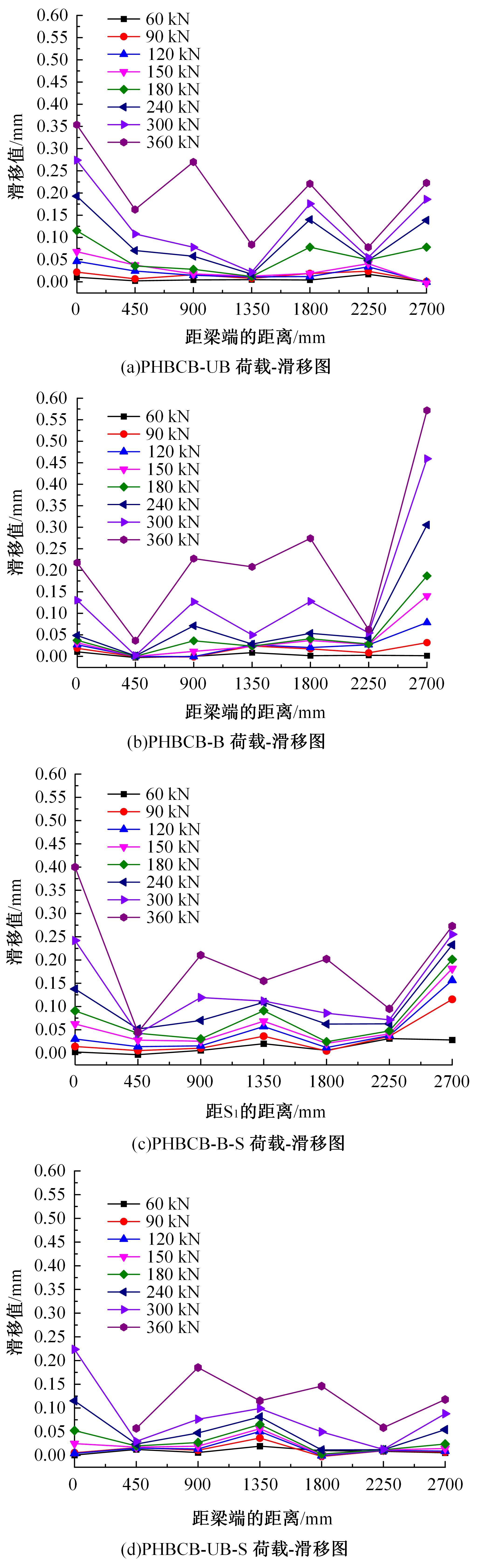

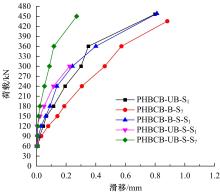

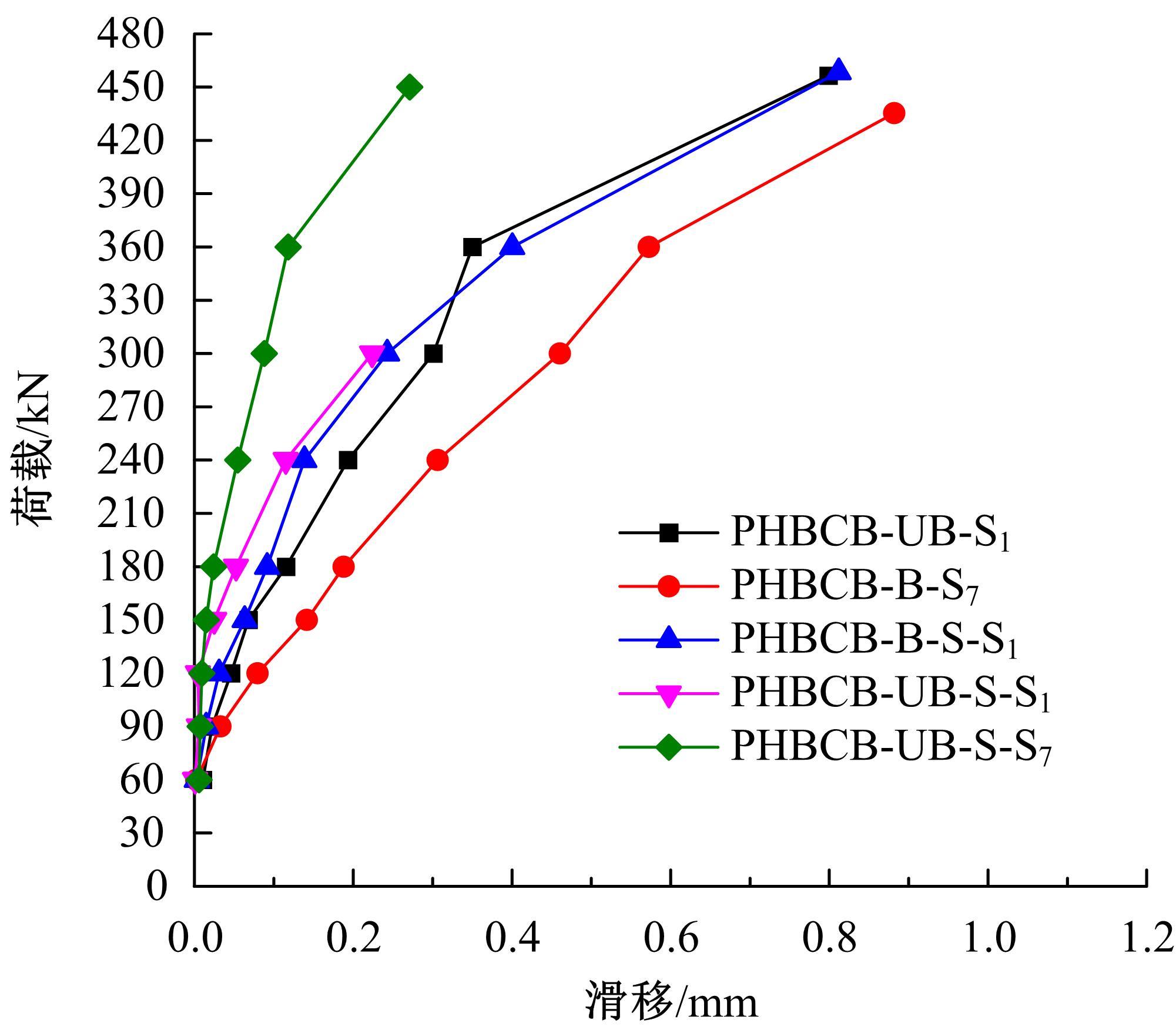

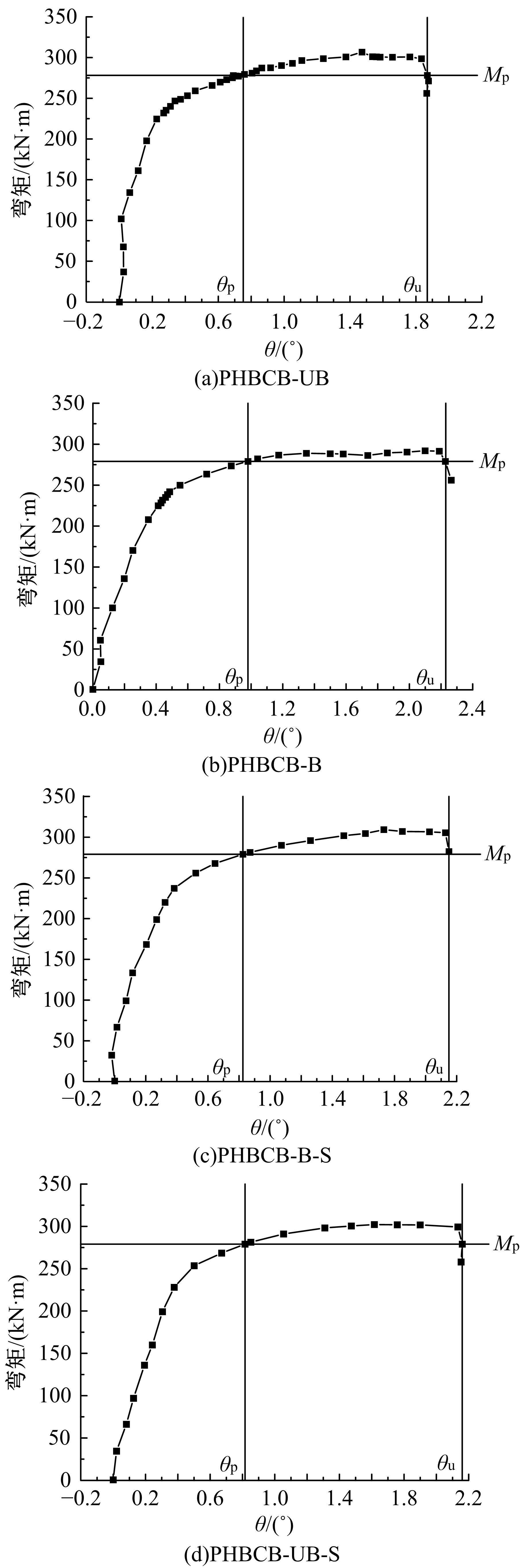

以抗剪连接度和是否脱黏处理为试验参数,设计了4根可拆卸预制装配式组合梁并研究了其在负弯矩作用下的力学性能。试验结果表明:①剪力连接度的提升可以改善可拆卸式组合梁在负弯矩作用下的抗裂性能,但是对其极限承载力和刚度影响不大;②对抗剪连接件进行局部脱黏处理可以改善可拆卸式组合梁在负弯矩作用下的力学性能,延缓裂缝的发展,并且对试件的刚度、极限承载力影响较小,且该处理对于完全剪力连接的试件改善效果更为明显;③可拆卸式组合梁在负弯矩作用下的转动能力依然有较大的提升空间,脱黏处理和抗剪连接度的提升都可以改善组合梁的转动能力,可以对此进行进一步的优化。

中图分类号:

- TU398.9

| 1 | 钟琼. 预制装配式钢-混凝土组合梁的试验研究[D]. 长沙:湖南大学建筑安全与节能教育部重点实验室, 2017. |

| Zhong Qiong. The experimental study on composite steel-prefabricated precast concrete slab beam[D]. Changsha: Key Laboratory of the Ministry of Building Safety and Energy Conservation, Hunan University, 2017. | |

| 2 | 钟琼, 霍静思, 王海涛, 等. 预制装配式组合梁栓钉连接件抗剪性能试验研究[J]. 建筑钢结构进展, 2018, 20(2): 13-19, 27. |

| Zhong Qiong, Huo Jing-si, Wang Hai-tao, et al. Experimental study on the shear bearing capacity of stud connectors in prefabricated compositebeams[J]. Progress in Steel Building Structures, 2018, 20(2): 13-19, 27. | |

| 3 | 刘中良. 装配式组合梁高强螺栓连接件抗剪性能试验研究[D]. 湘潭:湘潭大学土木工程与力学学院, 2017. |

| Liu Zhong-liang. Experimental study on the shear behavior of the prefabricated composite beam high strength bolt connector[D]. Xiangtan: College of Civil Engineering and Mechanics, Xiangtan University, 2017. | |

| 4 | 刘中良, 陈俊, 霍静思. 装配式组合梁高强螺栓连接件抗剪性能试验研究[J]. 建筑结构, 2017, 47(10): 65-70, 64. |

| Liu Zhong-liang, Chen Jun, Huo Jing-si. Experimental study on shear behavior of high strength bolt connection for prefabricated composite beam[J]. Building Structure, 2017, 47(10): 65-70, 64. | |

| 5 | 汪威. 装配式组合梁高强螺栓连接件力学性能研究[D]. 湘潭:湘潭大学土木工程与力学学院, 2019. |

| Wang Wei. Mechanical performance study on high-strength bolt connectors in prefabricated steel-concrete composite beams[D]. Xiangtan: College of Civil Engineering and Mechanics, Xiangtan University, 2019. | |

| 6 | 陈俊,汪威,丁发兴,等. 钢-混凝土组合梁高强螺栓抗剪连接件受剪性能[J]. 铁道科学与工程学报, 2019, 16(10): 2553-2561. |

| Chen Jun, Wang Wei, Ding Fa-xing, et al. Shear bearing capacity of high-strength bolt connectors in steel-concrete composite beams[J]. Journal of Railway Science and Engineering, 2019, 16(10): 2553-2561. | |

| 7 | 聂建国. 钢-混凝土组合梁结构[M]. 北京:科学出版社, 2005. |

| 8 | 樊健生,聂建国,贾维,等. 钢-混凝土连续组合梁的设计方法[J]. 建筑结构, 2003, 33(1): 41-44. |

| Fan Jian-sheng, Nie Jian-guo, Jia Wei, et al. Design method of steel-concrete continuous composite beam[J]. Building Structure, 2003, 33(1): 41-44. | |

| 9 | 戴益民. 钢-混凝土预制板组合梁的试验研究[D].长沙:湖南大学土木工程学院, 2005. |

| Dai Yi-min. The experimental studies on composite steel-FDPCP beam[D]. Changsha: College of Civil Engineering, Hunan University, 2005. | |

| 10 | 刘寒冰,时成林,谭国金.考虑剪切滑移效应的叠合梁有限元解[J].吉林大学学报: 工学版, 2016, 46(3): 792-797. |

| Liu Han-bing, Shi Cheng-lin, Tan Guo-jin. Finite element solution of composite beams considering shear slip effect[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(3): 792-797. | |

| 11 | 刘寒冰, 刘天明, 张云龙. 钢-混凝土组合连续梁抗弯性能[J]. 吉林大学学报: 工学版, 2009, 39(6): 1486-1491. |

| Liu Han-bing, Liu Tian-ming, Zhang Yun-long. Flexural behavior of steel-concrete composite continuous beams[J]. Journal of Jilin University (Engineering and Technology Edition), 2009, 39(6): 1486-1491. | |

| 12 | 刘寒冰, 代艳杰, 韩硕, 等. 预应力钢-轻骨料混凝土组合梁抗弯承载力[J]. 吉林大学学报: 工学版, 2009, 39(): 138-140. |

| Liu Han-bing, Dai Yan-jie, Han Shuo. Flexural capacity of prestressed steel lightweight aggregate concrete composite beams [J]. Journal of Jilin University (Engineering and Technology Edition), 2009, 39(Sup.1): 138-140. | |

| 13 | 樊健生, 聂建国, 张彦玲. 钢-混凝土组合梁抗裂性能的试验研究[J]. 土木工程学报, 2011, 44(2): 1-7. |

| Fan Jian-sheng, Nie Jian-guo, Zhang Yan-ling. Experimental study of crack resistance of steel-concrete beams[J]. China Civil Engineering Journal, 2011, 44(2): 1-7. | |

| 14 | 樊健生,聂建国. 钢-混凝土组合桥梁研究及应用新进展[J]. 建筑钢结构进展, 2006, 8(5): 35-39. |

| Fan Jian-sheng, Nie Jian-guo. Progress in research and application of composite steel-concrete bridges[J]. Progress in Steel Building Structures, 2006, 8(5): 35-39. | |

| 15 | 聂建国, 樊健生. 组合梁在负弯矩作用下的刚度分析[J]. 工程力学, 2002, 19(4): 33-36, 28. |

| Nie Jian-guo, Fan Jian-sheng. Analysis of composite beam stiffness under negative bending[J]. Engineering Mechanics, 2002, 19(4): 33-36, 28. | |

| 16 | 胡少伟, 叶祥飞. 预应力连续组合梁负弯矩区抗弯承载力分析[J]. 工程力学, 2013, 30(11): 160-165. |

| Hu Shao-wei, Ye Xiang-fei. Analysis on the bending capacity of the negative-moment region in prestressed continuous composite beam[J]. Engineering Mechanics, 2013, 30(11): 160-165. | |

| 17 | 聂建国, 陶慕轩, 聂鑫, 等. 抗拔不抗剪连接新技术及其应用[J]. 土木工程学报, 2015, 48(4): 7-14, 58. |

| Nie Jian-guo, Tao Mu-xuan, Nie Xin, et al. New technique and application of uplift-restricted and slip-permitted connection[J]. China Civil Engineering Journal, 2015, 48(4): 7-14, 58. | |

| 18 | 聂建国, 李一昕, 陶慕轩. 新型抗拔不抗剪连接件的滑移性能及其滞回模型[J]. 工程力学, 2014, 31(11): 46-52. |

| Nie Jian-guo, Li Yi-xin, Tao Mu-xuan. Slip performance and hysteresis model of a new type of uplift restricted-slipfree connectors[J]. Engineering Mechanics, 2014, 31(11): 46-52. | |

| 19 | 庄亮东, 陈伟, 聂鑫, 等. 抗拔不抗剪连接件在钢-混凝土组合框架结构中的应用[J]. 建筑结构学报, 2020, 41(1): 104-112. |

| Zhuang Liang-dong, Chen Wei, Nie Xin, et al. Application of uplift-restricted and slip-permitted connectorsin steel-concrete composite frame structures[J]. Journal of Building Structures, 2020, 41(1): 104-112. | |

| 20 | John O D, George S. Composite beams with limited-slip-capacity shear connectors[J]. Journal of Structural Engineering, 1995, 121(6): 932-938. |

| 21 | Nie J G, Li Y X, Tao M X, et al. Uplift-restricted and slip-permitted t-shape connectors[J]. Journal of Bridge Engineering, 2015, 20(4): No.04014073. |

| 22 | Duan Lin-li. Research on application of uplift-restricted slip-permitted (URSP) connectors in steel-concrete composite frames[J]. Applied Science, 2019, 9(11): 2235. |

| 23 | . 混凝土结构设计规范 [S]. |

| 24 | . 钢结构设计设计标准 [S]. |

| 25 | . 金属材料拉伸试验第1部分:室温试验方法 [S]. |

| 26 | 陈超. 预制装配式组合梁及可拆卸预制装配式组合梁性能研究[D]. 湘潭:湘潭大学土木工程与力学学院, 2020. |

| Chen Chao. Study on the performance of prefabricated composite beams and detchable prefabricated composite beams[D]. Xiangtan: College of Civil Engineering and Mechanics,Xiangtan University, 2020. | |

| 27 | 贾远林,陈世鸣. 预应力组合梁负弯矩作用下梁端转动能力研究[J]. 河北工程大学学报: 自然科学版, 2009, 26(1): 14-20. |

| Jia Yuan-lin, Chen Shi-ming. Buckling coefficient of steel-concrete composite beams in negative bending[J]. Journal of Hebei University of Engineering(Natural Science Edition), 2009, 26(1): 14-20. |

| [1] | 张云龙,郭阳阳,王静,梁东. 钢-混凝土组合梁的固有频率及其振型[J]. 吉林大学学报(工学版), 2020, 50(2): 581-588. |

| [2] | 万世成,黄侨,关健,郭赵元. 预应力碳纤维板加固钢⁃混凝土组合连续梁负弯矩区试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1114-1123. |

| [3] | 尼颖升,孙启鑫,马晔,徐栋,刘超. 基于空间网格分析的多箱室波形钢腹板组合梁腹板剪力分配[J]. 吉林大学学报(工学版), 2018, 48(6): 1735-1746. |

| [4] | 尼颖升, 孙启鑫, 马晔, 徐栋. 基于拉应力域的波形钢腹板组合梁承载力配筋计算[J]. 吉林大学学报(工学版), 2018, 48(1): 148-158. |

| [5] | 魏志刚, 时成林, 刘寒冰, 张云龙. 车辆作用下钢-混凝土组合简支梁动力特性[J]. 吉林大学学报(工学版), 2017, 47(6): 1744-1752. |

| [6] | 尼颖升, 马晔, 徐栋, 李金凯. 波纹钢腹板斜拉桥剪力滞效应空间网格分析方法[J]. 吉林大学学报(工学版), 2017, 47(5): 1453-1464. |

| [7] | 张云龙, 刘占莹, 吴春利, 王静. 钢-混凝土组合梁静动力响应[J]. 吉林大学学报(工学版), 2017, 47(3): 789-795. |

| [8] | 郭学东, 马立军, 张云龙. 集中力作用下考虑剪切滑移效应的双层结合面组合梁解析解[J]. 吉林大学学报(工学版), 2016, 46(2): 432-438. |

| [9] | 张彦玲, 孙瞳, 侯忠明, 李运生. 隔板式钢-混凝土曲线组合梁弯扭性能[J]. 吉林大学学报(工学版), 2015, 45(4): 1107-1114. |

| [10] | 王春刚, 张壮南, 赵大千, 曹宇飞. 腹板开孔Σ形复杂卷边槽钢轴压承载力试验[J]. 吉林大学学报(工学版), 2015, 45(3): 788-796. |

| [11] | 李海锋,郭小农,罗永峰,高轩能. 索支撑柔性摩天轮结构抗倒塌性能分析[J]. 吉林大学学报(工学版), 2015, 45(2): 406-413. |

| [12] | 云迪, 刘贺, 张素梅. 中承式钢管混凝土拱桥弹塑性地震时程分析[J]. 吉林大学学报(工学版), 2014, 44(6): 1633-1638. |

| [13] | 郭俊平1, 邓宗才1, 卢海波2, 林劲松2. 预应力高强钢绞线网抗剪加固钢筋混凝土梁试验[J]. 吉林大学学报(工学版), 2014, 44(4): 968-977. |

| [14] | 魏海斌, 张仰鹏, 焦峪波, 刘寒冰. 钢-混组合梁挠度增大系数的神经网络计算方法[J]. 吉林大学学报(工学版), 2014, 44(4): 963-967. |

| [15] | 姜封国, 赵景鲁. 受火后钢筋混凝土构件的可靠性[J]. 吉林大学学报(工学版), 2013, 43(06): 1500-1503. |

|

||