吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (3): 596-603.doi: 10.13229/j.cnki.jdxbgxb20200818

• 交通运输工程·土木工程 • 上一篇

新型装配式双舱综合管廊力学性能试验

匡亚川1( ),宋哲轩1,刘胤虎2,莫小飞3,伏亮明2,罗时权2

),宋哲轩1,刘胤虎2,莫小飞3,伏亮明2,罗时权2

- 1.中南大学 土木工程学院,长沙 410075

2.中国电建集团中南勘测设计研究院有限公司,长沙 410014

3.重庆金科地产集团股份有限公司,重庆 401121

Experiment on mechanical properties of new type assembled double-cabin utility tunnel

Ya-chuan KUANG1( ),Zhe-xuan SONG1,Yin-hu LIU2,Xiao-fei MO3,Liang-ming FU2,Shi-quan LUO2

),Zhe-xuan SONG1,Yin-hu LIU2,Xiao-fei MO3,Liang-ming FU2,Shi-quan LUO2

- 1.School of Civil Engineering,Central South University,Changsha 410075,China

2.Power China Zhongnan Engineering Corporation Limited,Changsha 410014,China

3.Jinke Property Group Co. ,Ltd. ,Chongqing 401121,China

摘要:

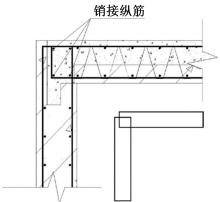

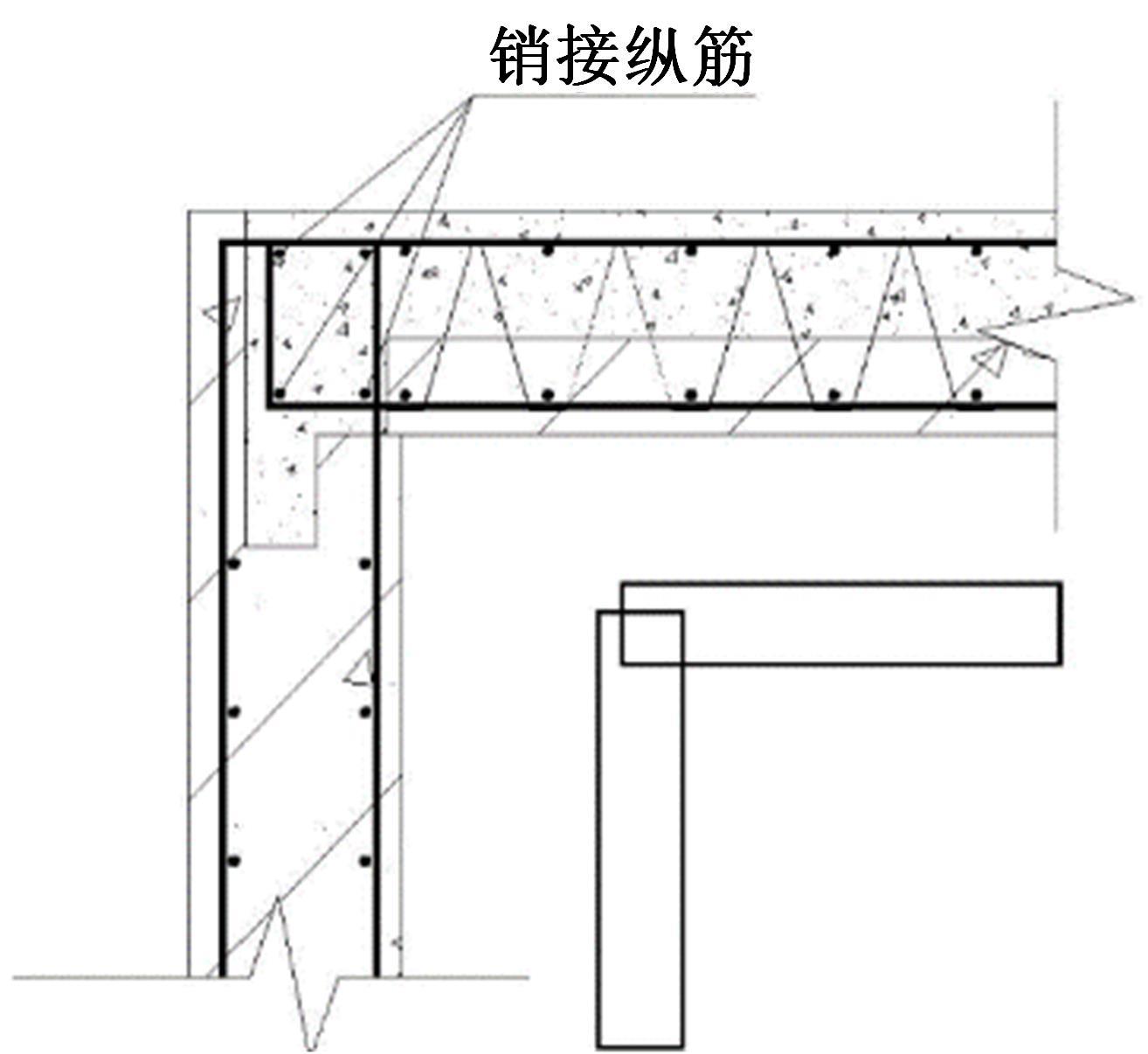

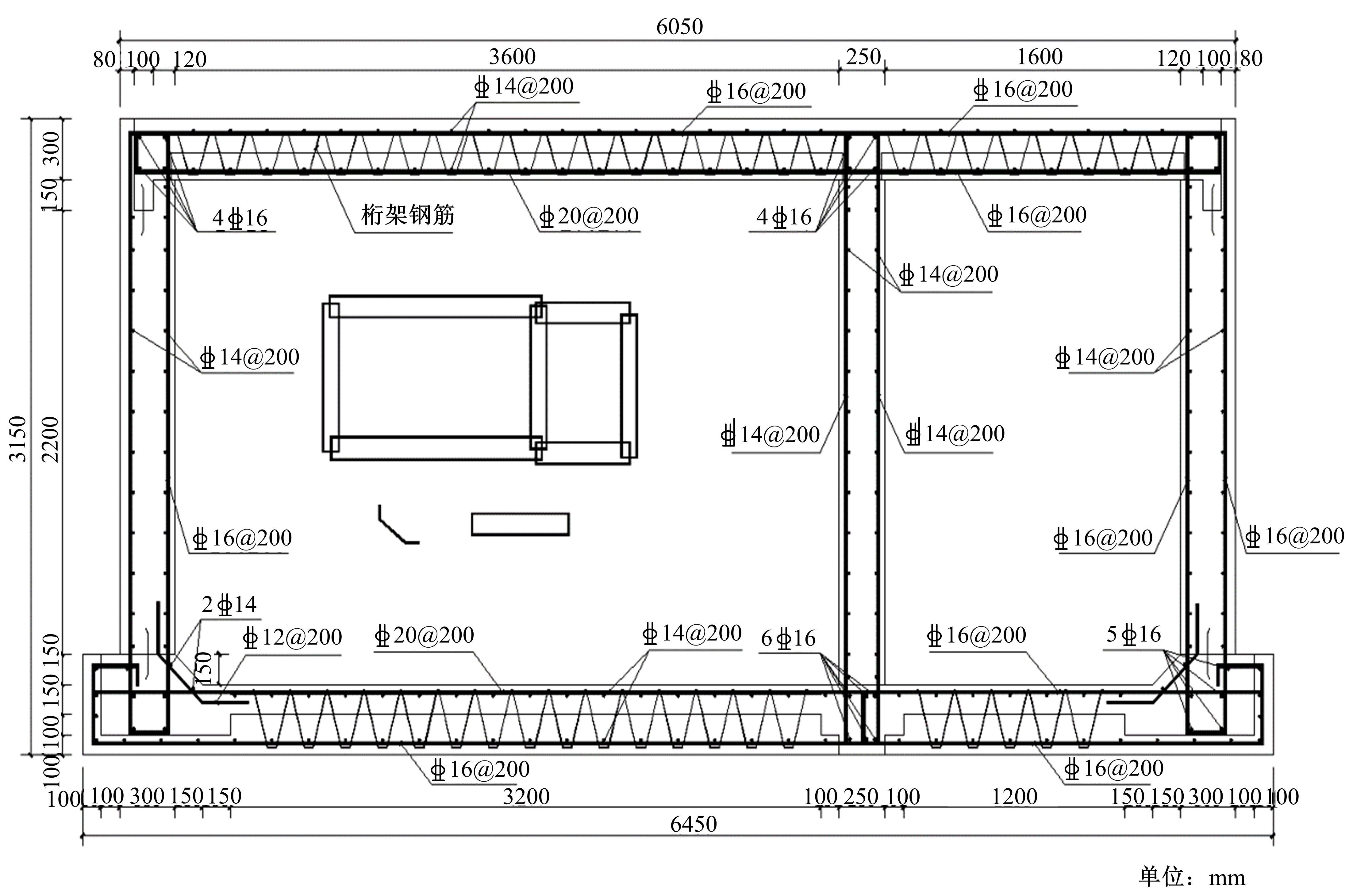

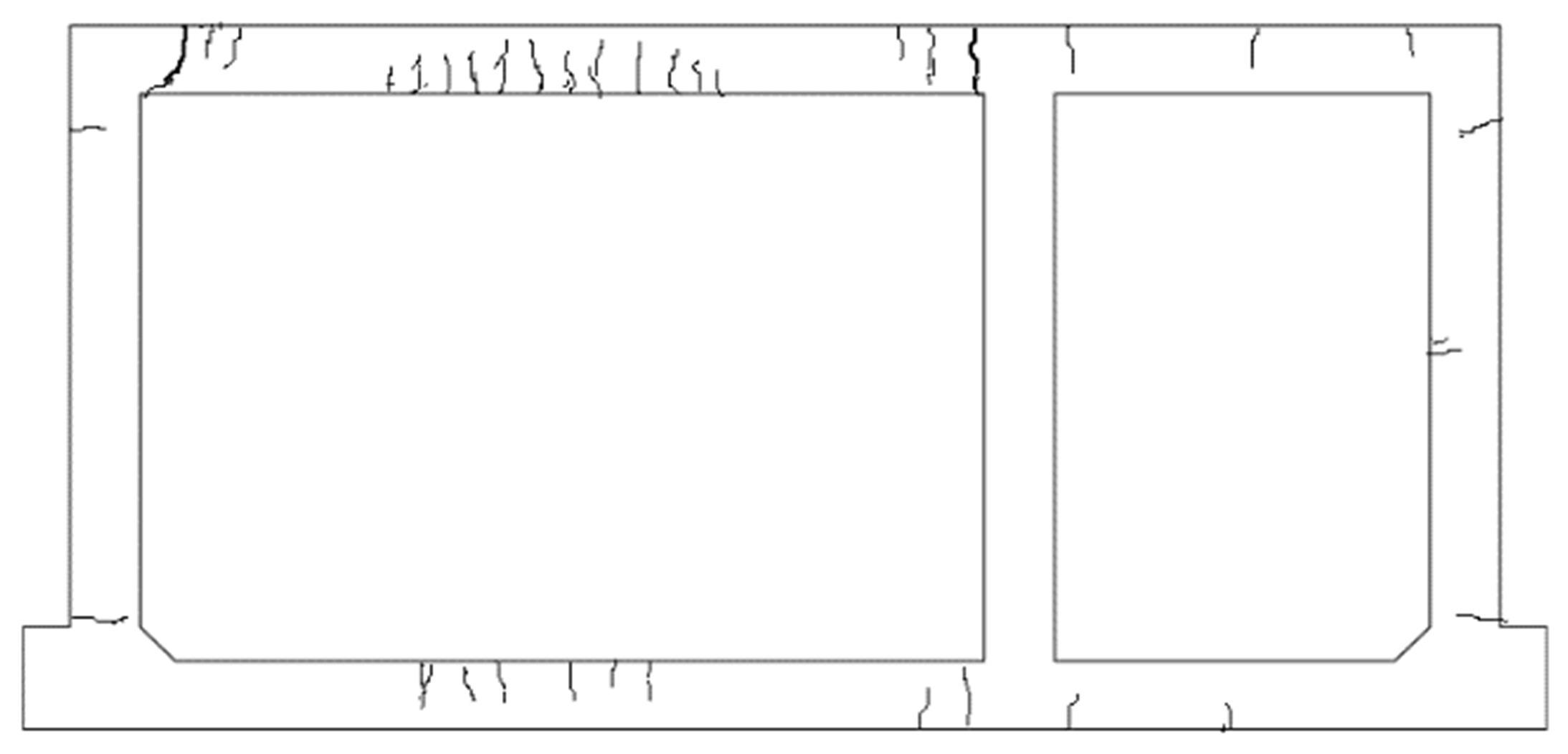

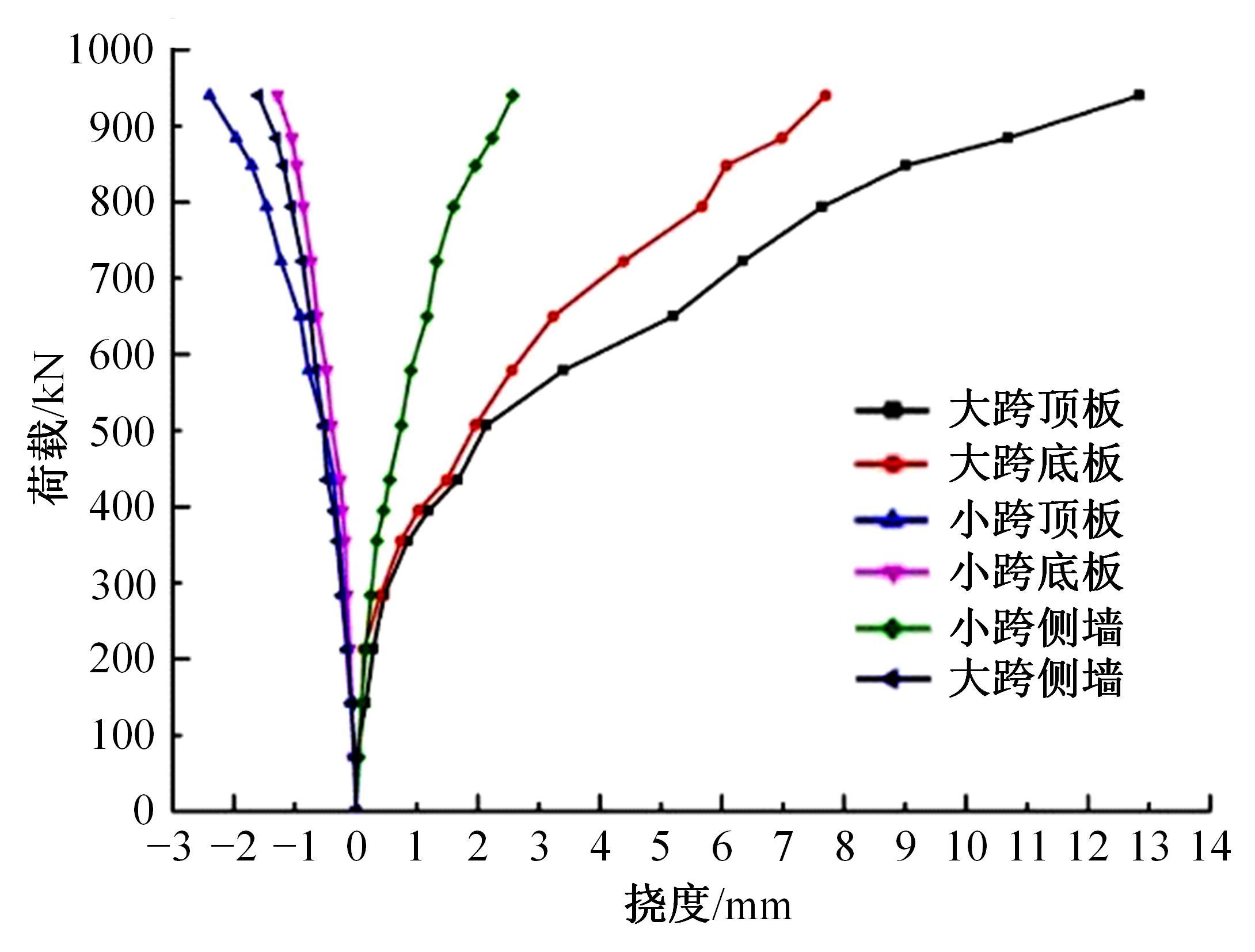

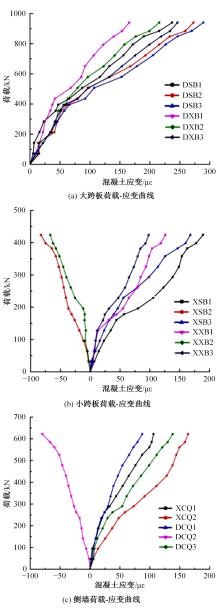

基于“U型套箍销接纵筋连接”技术,提出了一种新型装配式综合管廊。通过足尺模型静力试验,对新型装配式双舱综合管廊的承载能力、变形能力、构件开裂等力学性能进行了系统研究。结果表明:U型套箍销接纵筋连接性能可靠,试验加载到管廊设计荷载为435 kN时,装配式综合管廊结构未出现裂缝;在加载过程中,装配式综合管廊大跨径顶板经历了开裂、刚度退化和极限破坏3个阶段;在荷载标准值作用下,装配式综合管廊裂缝宽度和挠度均没有超过规范限值,满足正常使用极限状态要求;装配式综合管廊极限承载力为荷载设计值的3.71倍,装配式综合管廊的极限承载力满足设计要求,且有较大的安全储备。本文研究成果可为此新型装配方案的综合管廊的实际应用提供技术依据。

中图分类号:

- TU990.3

| 1 | 雷升祥. 综合管廊与管道盾构[M]. 北京: 中国铁道出版社, 2015. |

| 2 | 钱七虎, 陈晓强. 国内外地下综合管线廊道发展的现状、问题及对策[J]. 地下空间与工程学报, 2007, 3(2): 191-194. |

| Qian Qi-hu, Chen Xiao-qiang. Development status, problems and countermeasures of utility tunnel at home and abroad[J]. Journal of Underground Space and Engineering, 2007, 3(2): 191-194. | |

| 3 | 孙浩康. 装配整体式综合管廊施工技术探讨[J]. 建材发展导向, 2017, 15(7): 173-175. |

| Sun Hao-kang. Discussion on the construction technology of monolithic precast concrete utility tunnel gallery[J]. Development Guide to Building Materials,2017, 15(7): 173-175. | |

| 4 | 胡翔, 薛伟辰. 预制预应力综合管廊受力性能试验研究[J]. 土木工程学报, 2010, 43(5): 29-37. |

| Hu Xiang, Xue Wei-chen. Experimental study of mechanical properties of PPMT[J]. China Civil Engineering Journal, 2010, 43(5): 29-37. | |

| 5 | 王恒栋, 薛伟辰. 综合管廊工程理论与实践[M]. 北京:中国建筑工业出版社, 2013. |

| 6 | Khaled A. Soudki S H R B. Horizontal connection for precast concrete shear walls subjected to cyclic deformations part 2: prestressed connections[J]. PCI Journal, 1995, 40(5): 82-96. |

| 7 | Khaled A, Soudki S H R. Horizontal connections for precast concrete shear walls subjected to cyclic deformations part1:mild steel connections[J]. PCI Journal, 1995, 40(4): 78-96. |

| 8 | 薛伟辰, 胡翔, 王恒栋. 上海世博园区预制预应力综合管廊力学性能试验研究[J]. 特种结构, 2009, 26(1): 105-108, 116. |

| Xue Wei-chen, Hu Xiang, Wang Heng-dong. Experimental studies on mechanical properties of PPMT in Shanghai expo area[J]. Special Structures, 2009, 26 (1): 105-108, 116. | |

| 9 | 田子玄. 装配叠合式混凝土地下综合管廊受力性能试验研究[D]. 哈尔滨:哈尔滨工业大学土木工程学院, 2016. |

| Tian Zi-xuan. Experimental research on force performance of precast concrete underground comprehensive municipal tunnel[D]. Harbin: College of Civil Engineering, Harbin Institute of Technology, 2016. | |

| 10 | 易伟建, 颜良, 彭真. 无腋角综合管廊结构足尺模型静载试验及有限元分析[J]. 湖南大学学报: 自然科学版, 2019, 46(7): 1-10. |

| Yi Wei-jian, Yan Liang, Peng Zhen. Static load test and finite element analysis of full-scale model of assembled utility tunnel structure without axillary angle[J]. Journal of Hunan University(Natural Sciences), 2019, 46(7): 1-10. | |

| 11 | 彭真. 综合管廊节段模型足尺寸试验与有限元模拟[D]. 长沙: 湖南大学土木工程学院, 2017. |

| Peng Zhen. Full-scale test and finite element analysis of the municipal tunnel section model[D]. Changsha: College of Civil Engineering, Hunan University, 2017. | |

| 12 | 黄文翾. 预制拼装式城市地下综合管廊地震动力响应研究[D]. 成都: 西南交通大学土木工程学院, 2018. |

| Huang Wei-xuan. Study on seismic dynamic response of prefabricated integrated urban underground pipe gallery[D]. Chengdu: College of Civil Engineering, Southwest Jiaotong University, 2018. | |

| 13 | 宫亚峰, 逄蕴泽, 王博, 等. 基于吉林省路况的新型预制装配式箱涵结构的力学性能[J]. 吉林大学学报: 工学版, 2021, 51(3): 917-924. |

| Gong Ya-feng, Pang Yun-ze, Wang Bo, et al. Mechanical properties of new prefabricated box culvert structure based on road conditions in Jilin province[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 917-924. | |

| 14 | . 城市综合管廊工程技术规范 [S]. |

| 15 | . 混凝土结构设计规范(2015年版) [S]. |

| 16 | Yang Y, Zhou B, Xie X, et al. Characteristics and causes of cracking and damage of shield tunnel segmented lining in construction stage—a case study in Shanghai soft soil[J]. European Journal of Environmental and Civil Engineering, 2017, 22(Sup.1): 213-227. |

| 17 | Wong R C K, Ma S K Y, Wong R C H, et al. Shear strength components of concrete under direct shearing[J]. Cement and Concrete Research, 2007, 37(8): 1248-1256. |

| [1] | 樊学平,杨光红,尚志鹏,赵小雄,肖青凯,刘月飞. 考虑适用性的大跨桥梁主梁动态可靠性融合预测[J]. 吉林大学学报(工学版), 2022, 52(1): 144-153. |

| [2] | 刘福寿,魏琦,徐文婷,谭国金. 基于弹性波传播和谱单元法的桁架结构损伤检测[J]. 吉林大学学报(工学版), 2021, 51(6): 2087-2095. |

| [3] | 魏海斌,王相焱,王富玉,张勇. 基于振动成型AC-25沥青混合料力学性能及细观分析[J]. 吉林大学学报(工学版), 2021, 51(4): 1269-1276. |

| [4] | 樊学平,杨光红,肖青凯,刘月飞. 大跨桥梁主梁失效概率分析的最优R-Vine Copula[J]. 吉林大学学报(工学版), 2021, 51(4): 1296-1305. |

| [5] | 刘寒冰,高鑫,宫亚峰,刘诗琪,李文俊. 表面处理对玄武岩纤维活性粉末混凝土力学性能的影响及断裂特性[J]. 吉林大学学报(工学版), 2021, 51(3): 936-945. |

| [6] | 程永春,李赫,李立顶,王海涛,白云硕,柴潮. 基于灰色关联度的矿料对沥青混合料力学性能的影响分析[J]. 吉林大学学报(工学版), 2021, 51(3): 925-935. |

| [7] | 于江,赵志浩,秦拥军. 基于声发射和分形的钢筋混凝土受剪梁损伤[J]. 吉林大学学报(工学版), 2021, 51(2): 620-630. |

| [8] | 熊二刚,徐涵,谭赐,王婧,丁若愚. 基于弹塑性应力场理论的钢筋混凝土梁受剪承载力[J]. 吉林大学学报(工学版), 2021, 51(1): 259-267. |

| [9] | 许卫晓,程扬,杨伟松,鞠佳昌,于德湖. RC框架⁃抗震墙并联结构体系拟静力试验[J]. 吉林大学学报(工学版), 2021, 51(1): 268-277. |

| [10] | 向红亮,陈盛涛,邓丽萍,张伟,詹土生. 微合金化2205双相不锈钢组织及性能[J]. 吉林大学学报(工学版), 2020, 50(5): 1645-1652. |

| [11] | 高昊,王君杰,刘慧杰,王剑明. 连续梁桥地震行为可控设计准则及实用装置[J]. 吉林大学学报(工学版), 2020, 50(5): 1718-1727. |

| [12] | 王金国,王志强,任帅,闫瑞芳,黄恺,郭劲. Ti添加量对球墨铸铁组织及力学性能的影响[J]. 吉林大学学报(工学版), 2020, 50(5): 1653-1662. |

| [13] | 李明,王浩然,赵唯坚. 单向带抗剪键叠合板的受力性能试验[J]. 吉林大学学报(工学版), 2020, 50(2): 654-667. |

| [14] | 修文翠,吴化,韩英,刘云旭. 等温热处理温度对超级贝氏体组织与性能的影响[J]. 吉林大学学报(工学版), 2020, 50(2): 520-525. |

| [15] | 樊学平,屈广,刘月飞. 应用新数据同化算法的桥梁极值应力预测[J]. 吉林大学学报(工学版), 2020, 50(2): 572-580. |

|

||