吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (6): 1301-1307.doi: 10.13229/j.cnki.jdxbgxb20210073

• 材料科学与工程 • 上一篇

新型5Cr5MoV模具钢修复性能

- 1.吉林大学 材料科学与工程学院,长春 130022

2.中国科学院金属研究所,沈阳 110016

Performance of repaired 5Cr5MoV die steel

Yan LIANG1( ),Qiang WANG2,Yu-lai SONG1(

),Qiang WANG2,Yu-lai SONG1( ),Yao-hui LIU1

),Yao-hui LIU1

- 1.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

2.Institute of Metal Research,Chinese Academy of Sciences,Shenyang 110016,China

摘要:

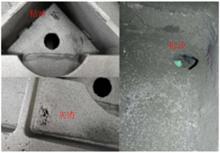

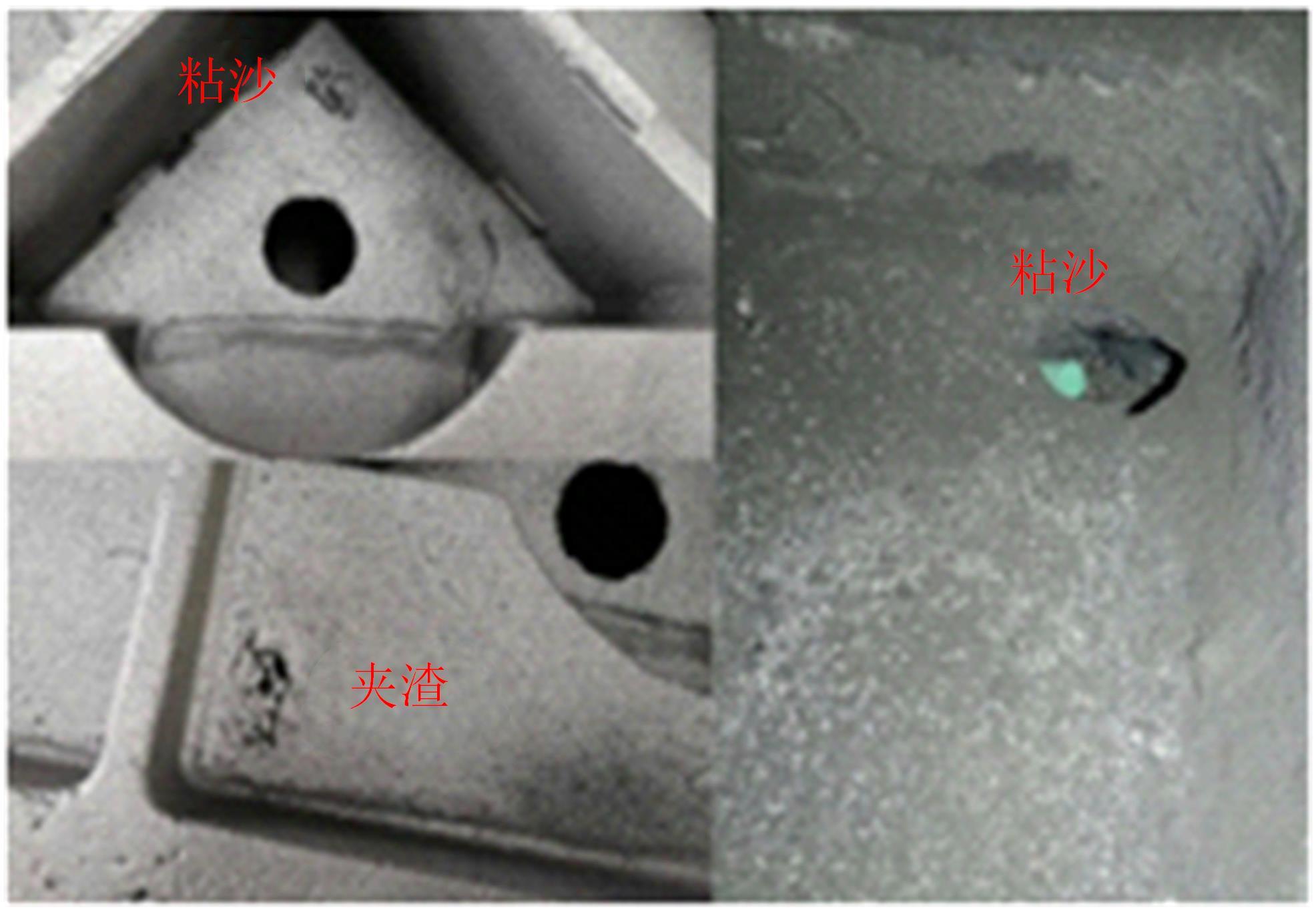

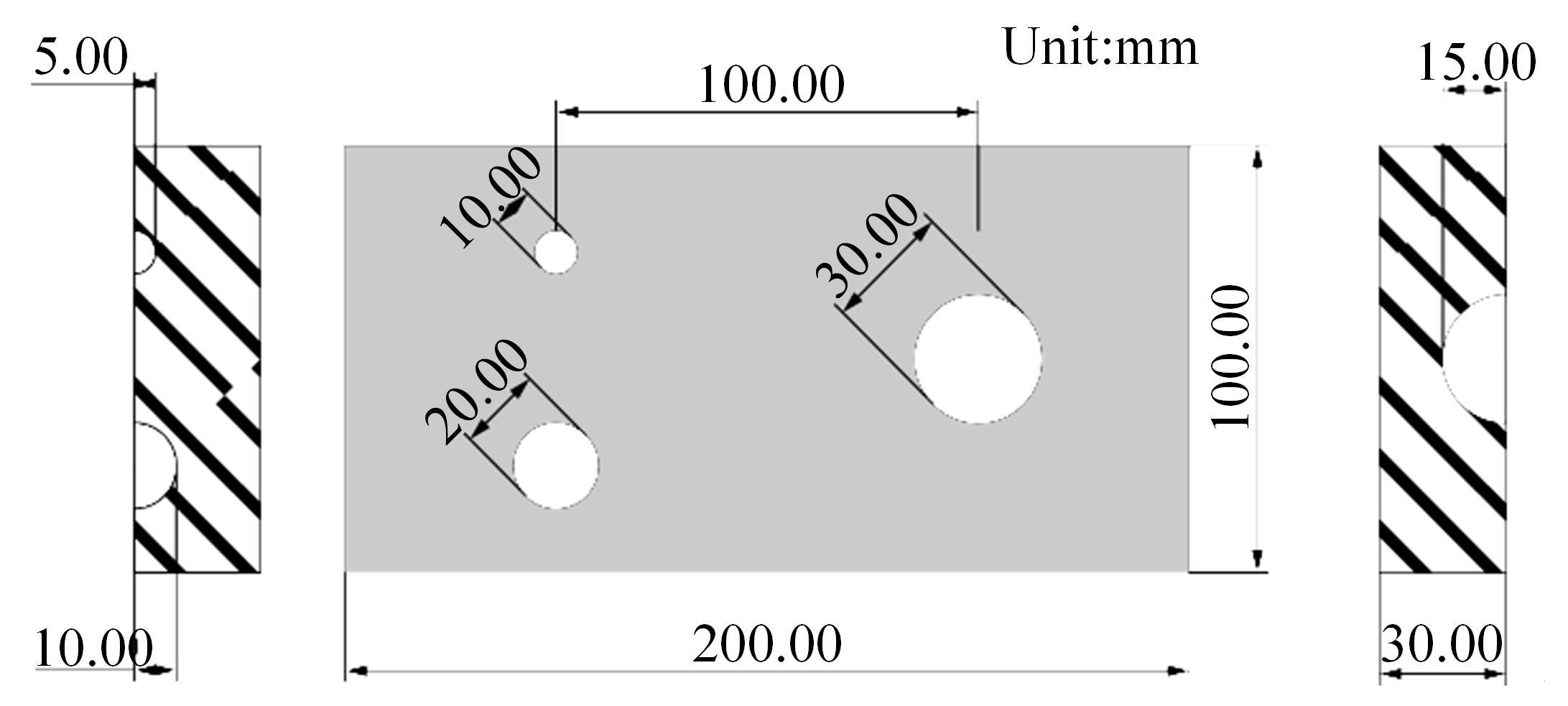

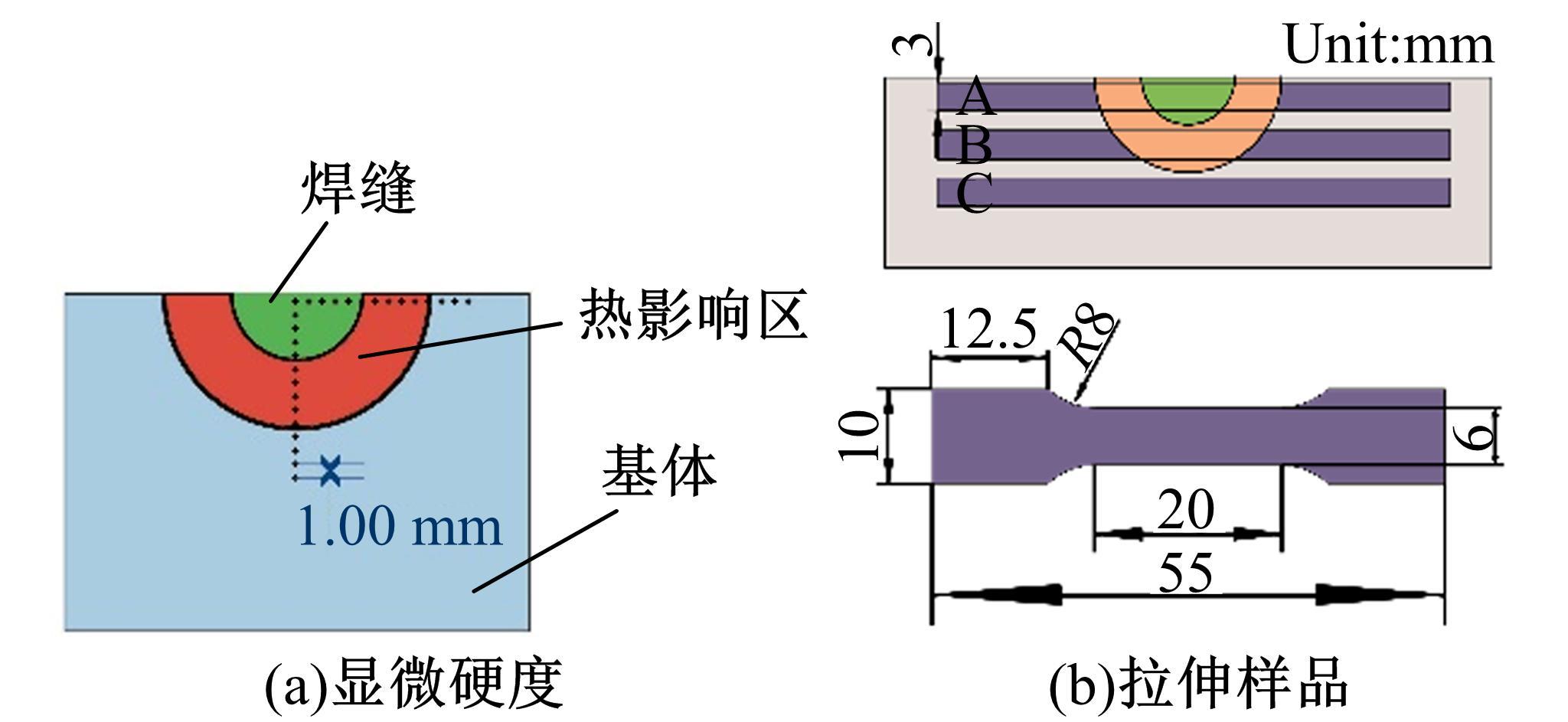

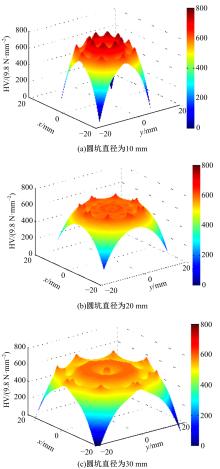

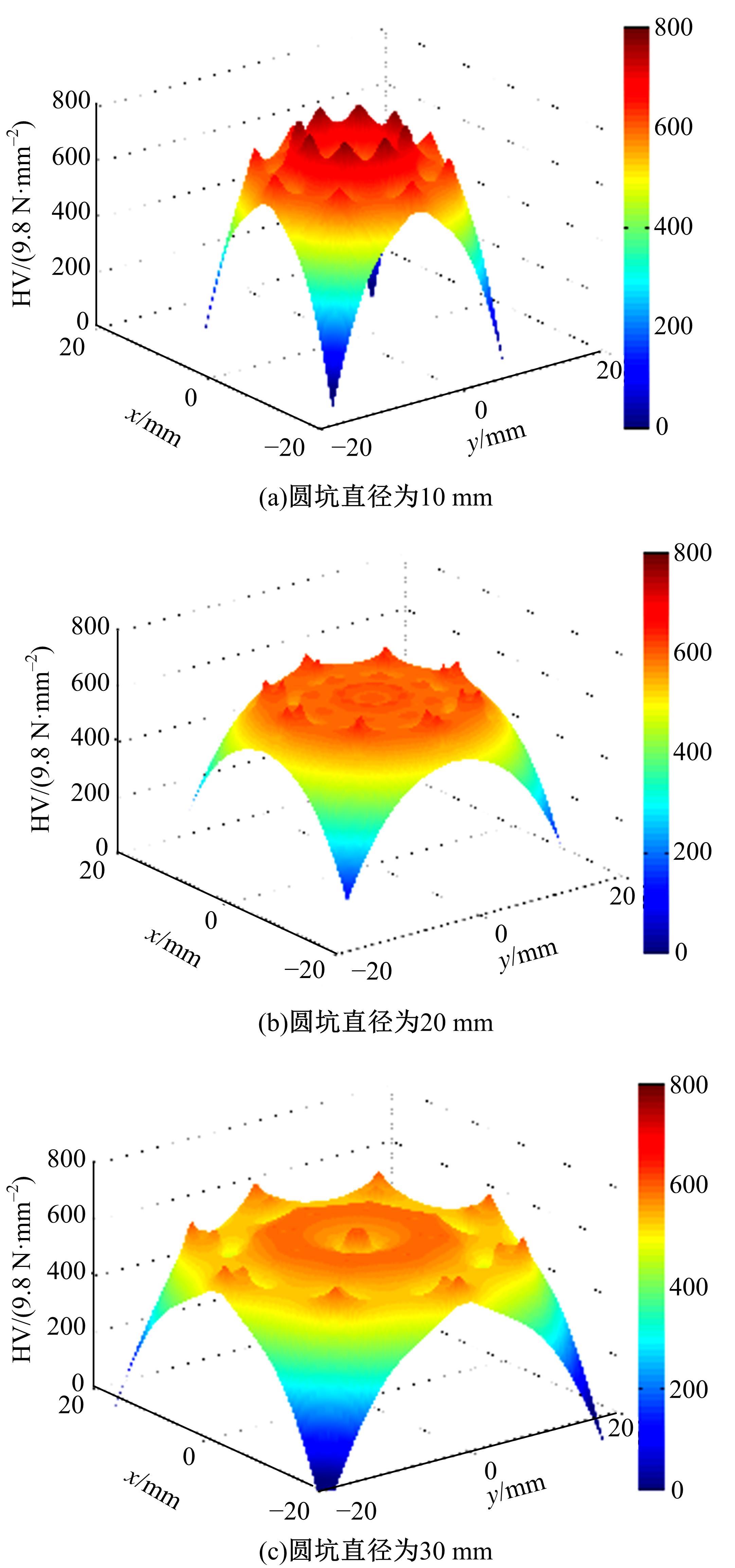

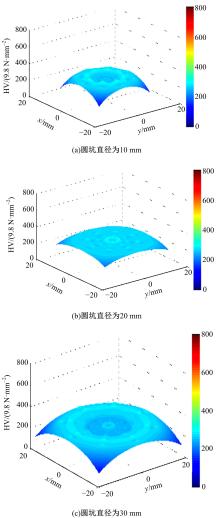

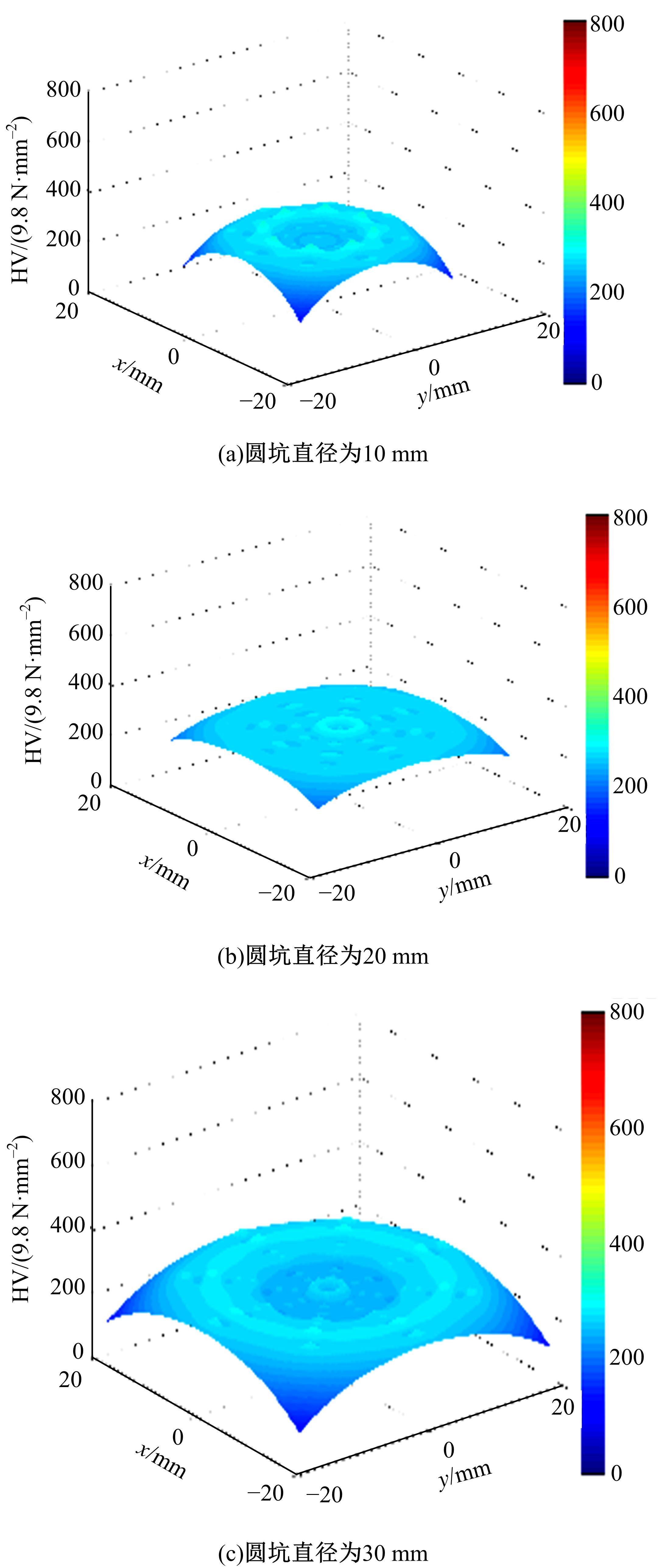

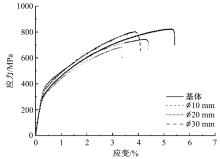

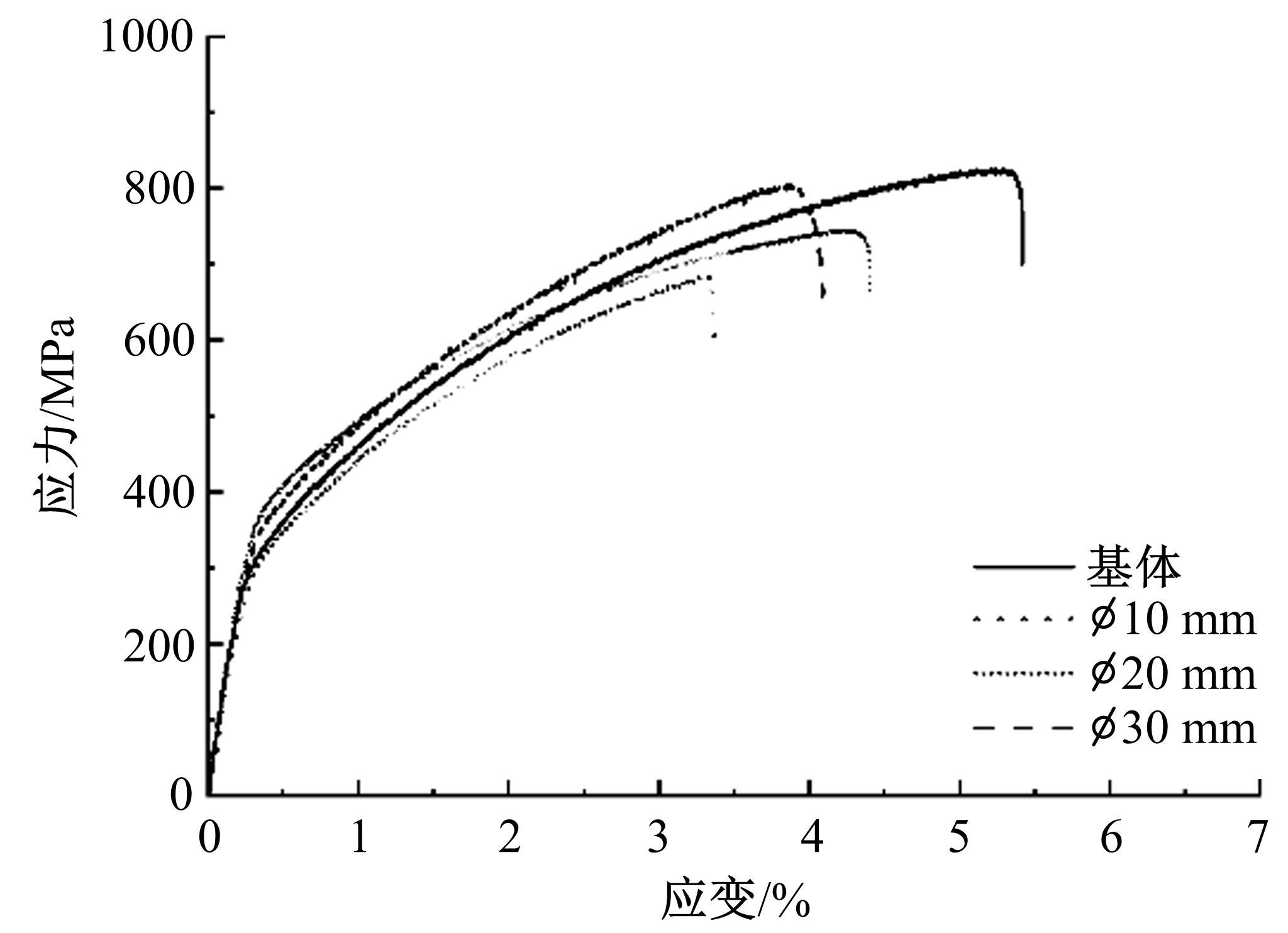

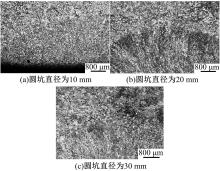

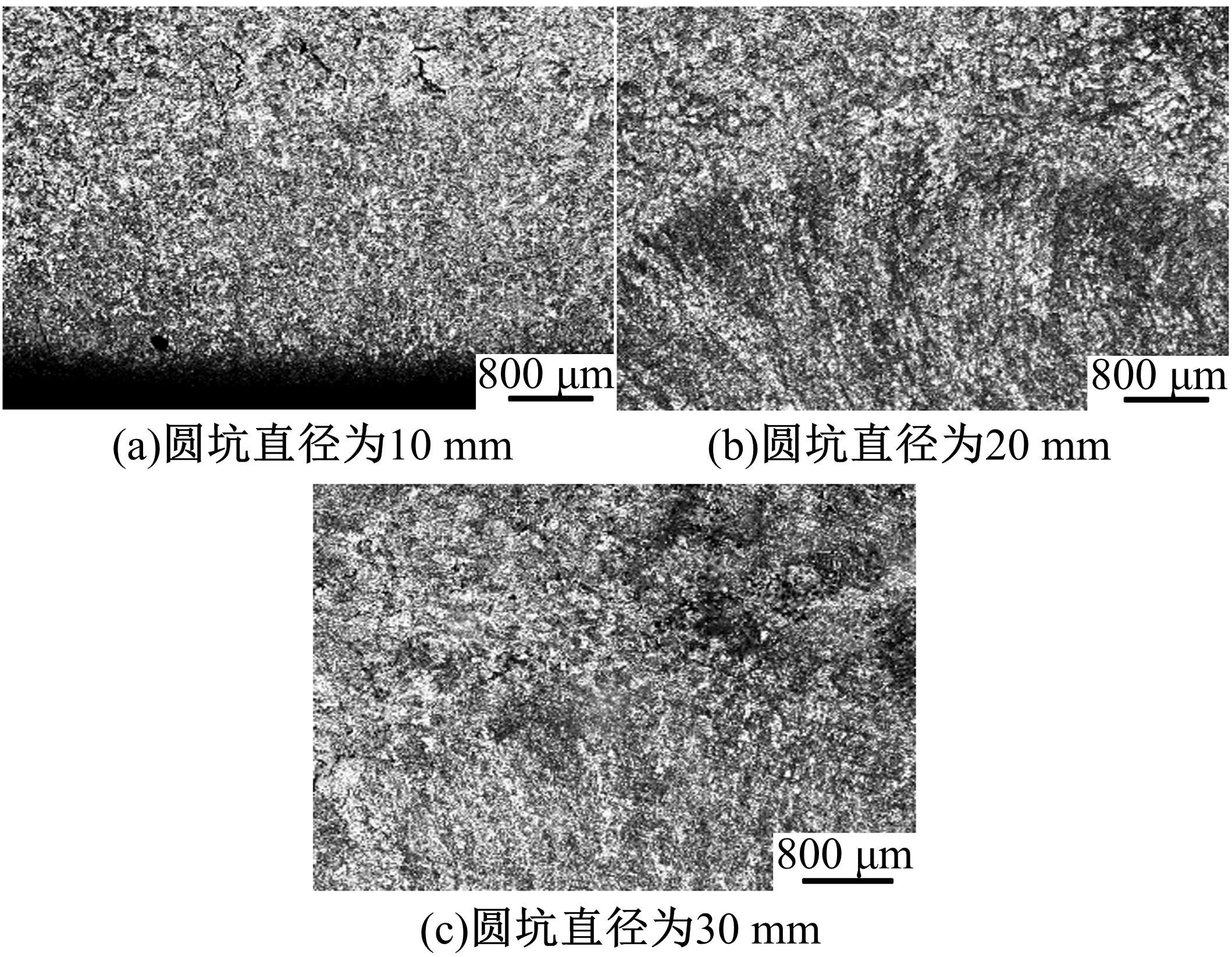

采用新设计的圆坑修复法对5Cr5MoV冷作模具钢开展了修复试验,并采用扫描电子显微镜(SEM)对修复区微观组织进行了表征,绘制了修复区显微硬度分布图。基于修复区最大硬度、最小硬度和基体硬度,提出了铸造模具钢的修复效果评价参数—波动系数n。试验结果表明:圆坑直径为20 mm时,修复效果最佳。

中图分类号:

- TG455

| 1 | Aslan E. Experimental investigation of cutting tool performance in high speed cutting of hardened X210 Cr12 cold-work tool steel (62 HRC)[J]. Materials & Design, 2005, 26(1): 21-27. |

| 2 | Li S S, Liu Y H, Song Y L, et al. Microstructure, mechanical properties and strengthening mechanisms of 5Cr5MoV modified by aluminum[J]. Materials & Design, 2015, 83: 483-492. |

| 3 | Elghazaly S A, Gyula K, Elghazaly W. Optimizing Morphology of primary carbides and mechanical properties during processing of Cast-Cold work AISI D2-Steel press forming dies[J]. International Journal of Metalcasting, 2019, 13: 337-344. |

| 4 | Baka T, Kroupa T, Hanzl P, et al. Durability of cutting tools during machining of very hard and solid materials[J]. Procedia Engineering, 2015, 100: 1414-1423. |

| 5 | Čamek L, Lich P, Kroupov I, et al. Effect of cast steel production metallurgy on the emergence of casting defects[J]. Metalurgija, 2016, 55(4): 701-704. |

| 6 | Sarkar A D. Casting Defects[M]. United States, Pennsylvania: Elsevier Ltd, 1967. |

| 7 | Ono K. Non-destructive Testing[M]. Korea: Wiley‐VCH Verlag GmbH & Co., 2000. |

| 8 | Mičian M, Koň R R, Hlavat I, et al. The repair of foundry defects in steel castings using welding technology[J]. Archives of Foundry Engineering, 2018, 18(2): 177-180. |

| 9 | Tuek J, Kosec L, Lenjak A, et al. Electrospark deposition for die repair[J]. Metalurgija: Sisak then Zagreb, 2012, 51(1): 17-20. |

| 10 | Leunda J, Soriano C, Sanz C, et al. Laser cladding of vanadium-carbide tool steels for die repair[J]. Physics Procedia, 2011, 12(A): 345-352. |

| 11 | Junkes R, Howarth J L L, Becker D, et al. Properties evaluation of semi-crystalline and amorphous polymers injected in AISI P20 molds repaired by welding[J/OL].[2021-01-05]. |

| 12 | Gouveia R M, Silva F J, Paiva O C, et al. Study of the heat-treatments effect on high strength ductile cast iron welded joints[J]. Metals, 2017, 7(9): No.382. |

| 13 | Jhavar S, Paul C, Jain N. Causes of failure and repairing options for dies and molds: a review[J]. Engineering Failure Analysis, 2013, 34: 519-535. |

| 14 | Thompson S. Handbook of Mould, Tool and Die Repair Welding[M]. Abington, England: Abington Publishing, 1999. |

| 15 | Peças P, Henriques E, Pereira B, et al. Fostering the use of welding technology in the mould repair[J/OL].[2021-01-15]. |

| 16 | Tušek J, Taljat B, Klobčar D. How to extend the life of die-casting tools[J]. Metalurgija: Sisak then Zagreb, 2006, 46(1): 67-71. |

| [1] | 关庆丰, 董书恒, 郑欢欢, 李晨, 张从林, 吕鹏. 强流脉冲电子束作用下45#钢表面Cr合金化[J]. 吉林大学学报(工学版), 2018, 48(4): 1161-1168. |

| [2] | 关庆丰, 李艳, 侯秀丽, 杨盛志, 王晓彤. 固溶态Mg-Gd-Y-Nd合金强流脉冲电子束表面改性[J]. 吉林大学学报(工学版), 2015, 45(4): 1200-1205. |

| [3] | 谷诤巍, 于思彬, 韩立军, 孟佳, 沈永波, 徐虹. 激光焊接速度对超高强度钢焊缝微观组织和显微硬度的影响 [J]. , 2012, (03): 656-659. |

| [4] | 孔德军,周朝政,胡爱萍. 激光冲击处理对X70管线钢焊接接头力学性能的影响[J]. 吉林大学学报(工学版), 2011, 41(05): 1507-1512. |

|

||