吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (9): 2502-2510.doi: 10.13229/j.cnki.jdxbgxb.20221405

混凝土加强波纹钢组合板抗弯刚度及承载能力

- 1.北京交通大学 土木建筑工程学院,北京 100044

2.山东省交通规划设计院集团有限公司,济南 250031

Flexural stiffness and bearing capacity of corrugated steel plate composite structures reinforced by concrete

Bao-dong LIU1( ),Fang LI1,Xiao-xi WANG1,Meng GAO2

),Fang LI1,Xiao-xi WANG1,Meng GAO2

- 1.School of Civil Engineering,Beijing Jiaotong University,Beijing 100044,China

2.Shandong Provincial Communication Planning and Design Institute Group Co. ,Ltd. ,Jinan 250031,China

摘要:

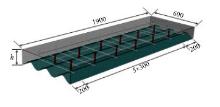

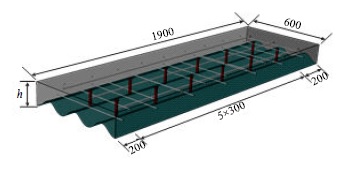

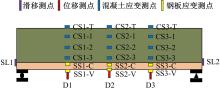

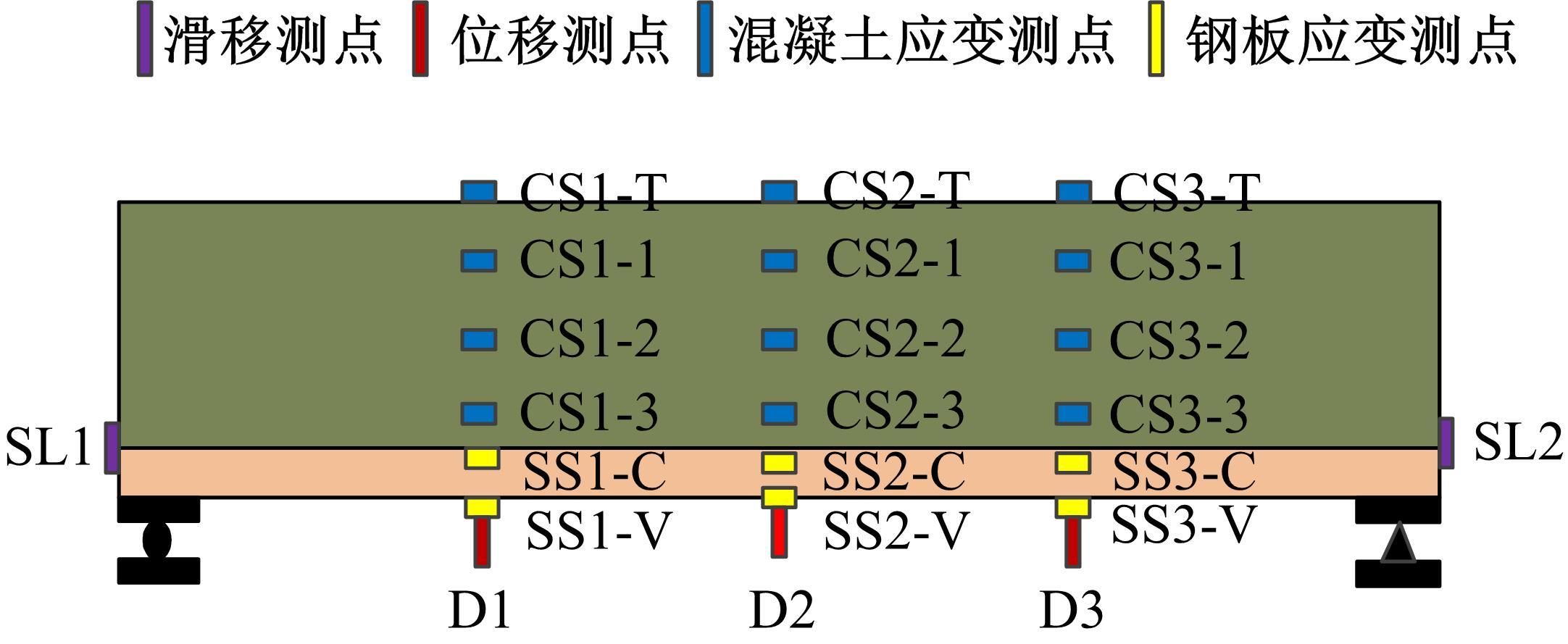

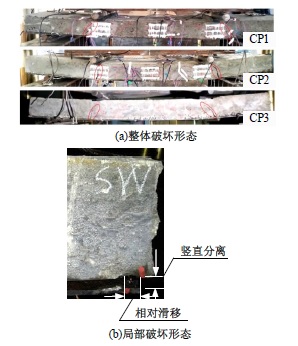

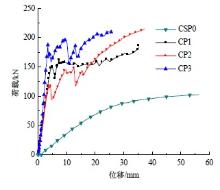

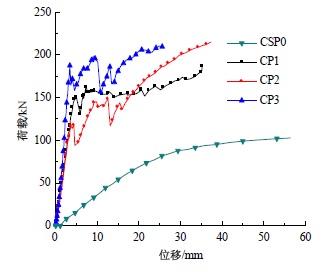

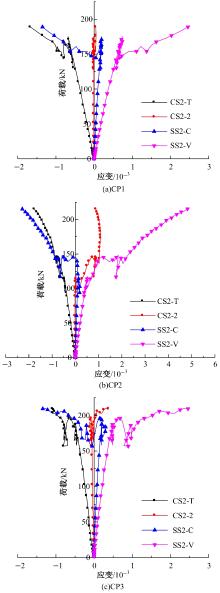

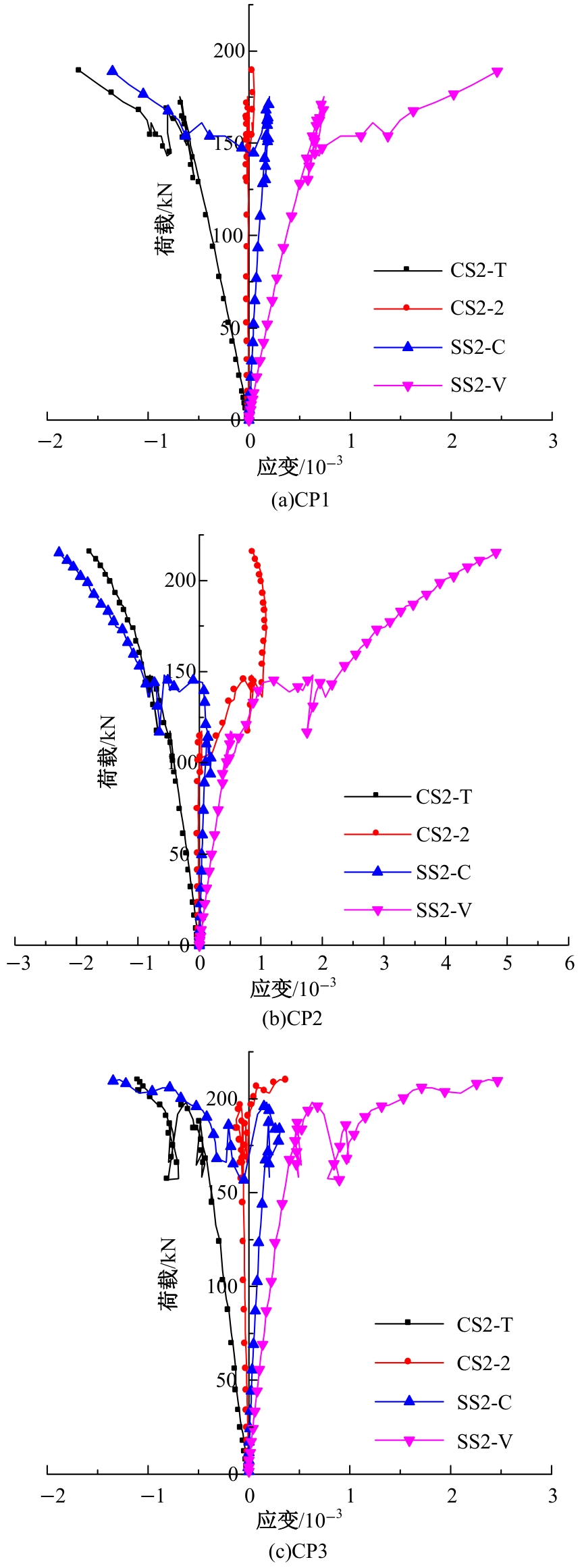

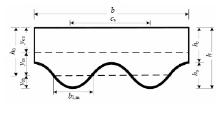

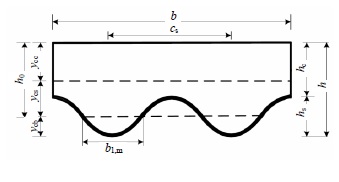

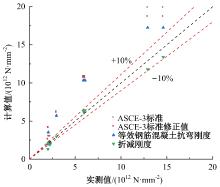

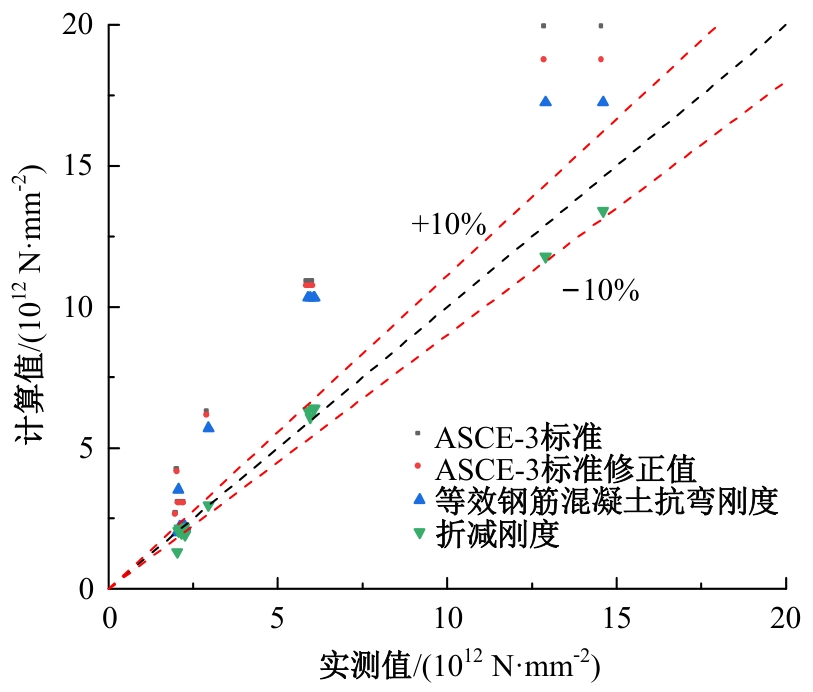

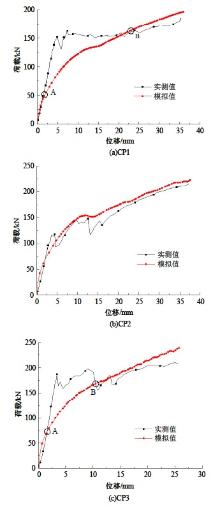

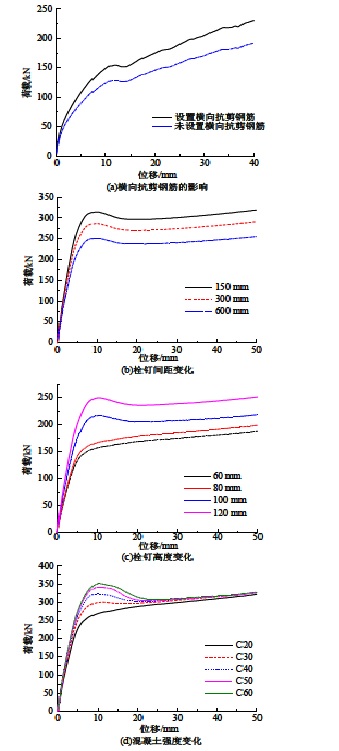

为了增强单层波纹钢板(CSP)的承载能力,在波纹钢板上焊接栓钉作为剪力连接件,然后在波纹钢板上浇筑混凝土层,二者共同受力。对3块混凝土加强波纹钢板组合构件进行了静力加载,分析了不同混凝土厚度对构件受力性能的影响,并验证了焊接栓钉作为剪力连接件的可靠性。试验结果表明:相较于单层波纹钢板,组合板的承载能力提高了60%~111%,并且其抗弯刚度是单层波纹钢板的4倍以上。基于波纹钢板-混凝土(CSPC)组合板的受力性能,提出了适用于波纹钢组合板弯曲刚度的计算方法。随后通过ABAQUS软件建立了数值模型并验证了其可靠性。本文研究结果为混凝土加强波纹钢组合结构在大跨桥涵中的应用提供了设计参考。

中图分类号:

- TU398

| 1 | Maleska T, Beben D. Numerical analysis of a soil-steel bridge during backfilling using various shell models[J]. Engineering Structures, 2019, 196: 1-12. |

| 2 | Gomes N, Shahrooz B, Sanders D, et al. Experimental and analytical evaluation of an innovative strengthening system for long-span deep corrugated buried bridges[J]. Practice Periodical on Structural Design and Construction, 2020, 25(4): No.4020026. |

| 3 | Flener E B, Karoumi R. Dynamic testing of a soil–steel composite railway bridge[J]. Engineering Structures, 2009, 31(12): 2803-2811. |

| 4 | Beben D. Dynamic amplification factors of corrugated steel plate culverts[J]. Engineering Structures, 2013(46): 193-264. |

| 5 | Inc Fixon.Corrugated steel plate[EB/OL]. [2022-09-03]. |

| 6 | Oh H S, Lee J W, Jun B J. An experimental assessment on the structural behavior of bolt connected deep corrugated steel plate[J]. Journal of the Korea Institute for Structural Maintenance & Inspection, 2011, 15(3): 79-87. |

| 7 | Jeong J. Characteristics on composite structure of encased-concrete high strength deep corrugated steel plate[D]. Seoul: Civil and Environmental Engineering, Hanyang University, 2015. |

| 8 | Taesoo K. An experimental study of failue behavior on encased-concrete deep corrugated steel plate structures[D]. Seoul: Civil and Environmental Engineering, Hanyang University, 2009. |

| 9 | Taesung K. Structural behaviour of corrugated steel plate composite structures reinforced by concrete beam[D]. Seoul: Civil and Environmental Engineering,Hanyang University, 2010. |

| 10 | Kim Y, Oh H. An experimental study on flexural strength of deep corrugated steel plate composite members by steel grade and reinforcement method[J]. Journal of the Korea Institute for Structural Maintenance and Inspection, 2017, 21(2): 1-12. |

| 11 | Hongseob O. Verification of compressive and flexural behavior of corrugated steel plates composite section with SFRC[J]. Korean Society of Hazard Mitigation. 2019, 19(1): 231-239. |

| 12 | Hongseob O. Verification on the axial and flexural plastic resistance analysis of unconfined corrugate steel sheet and concrete composite section[J]. Journal of the Korea Institute for Structural Maintenance and Inspection, 2022, 26(3):1-10. |

| 13 | Zhang J L, Liu B D, Zhang P Y, et al. Small-scale test and analysis of corrugated-steel-plate–concrete composite member adopting novel shear connectors[J]. Engineering Structures,2019, 184: 369-383. |

| 14 | Liu B, Zhang Z, Zhang M, et al. Experimental study of the mechanical performance of corrugated steel plate–concrete composite structures[J]. International Journal of Steel Structures, 2019,19(3): 733-746. |

| 15 | 贺文涛.波纹钢-橡胶混凝土组合桥面板力学性能试验研究[D].北京: 北京交通大学土木建筑工程学院,2020. |

| He Wen-tao. Experimental study on mechanical properties of corrugated steel plate and rubber concrete composite deck[D]. Beijing: School of Civil Engineering, Beijing Jiaotong University, 2020. | |

| 16 | 周小淇,黄俊,李海光.波纹钢板-混凝土组合梁的力学性能研究[J].地下空间与工程学报,2020,16(增2): 656-663. |

| Zhou Xiao-qi, Huang Jun, Li Hai-guang. Analysis on the mechanical property of the corrugated steel-concrete composite beam[J]. Chinese Journal of Underground Space and Engineering, 2020, 16(Sup.2): 656-663. | |

| 17 | Holmes N, Dunne K, O'Donnell J. Longitudinal shear resistance of composite slabs containing crumb rubber in concrete toppings[J] Construction and Building Materials, 2014;55: 365-378. |

| 18 | 聂建国,易卫华,雷丽英.闭口型压型钢板-混凝土组合板的刚度计算[J].工业建筑, 2003, 33(12):19-21. |

| Nie Jian-guo, Yi Wei-hua, Lei Li-ying. Rigidity calculation of closed profiled sheeting-concrete composite slabs[J]. Industrial Construction, 2003, 33(12):19-21. | |

| 19 | Yang Y, Liu R, Huo X, et al. Static experiment on mechanical behavior of innovative flat steel plate-concrete composite slabs[J]. International Journal of Steel Structures, 2018, 18: 473-485. |

| 20 | . 钢结构设计标准 [S]. |

| 21 | Zhang J L, Liu B D, Liu R. Behavior of sinusoidal-corrugated-steel-plate-concrete composite slabs: experimental investigation and theoretical model development[J]. Journal of Constructional Steel Research, 2021, 187: No. 106958. |

| [1] | 张艳青,吕宇宣,韩石,尤龙飞,曾俊,侯飞阳. 管幕预筑结构构件受弯性能试验[J]. 吉林大学学报(工学版), 2023, 53(5): 1390-1399. |

| [2] | 陈俊,王韶纤,胥卉,莫端泉,霍静思,邓旭华. 负弯矩作用下可拆卸预制装配式组合梁力学性能试验[J]. 吉林大学学报(工学版), 2022, 52(3): 604-614. |

| [3] | 宫亚峰,王博,谭国金,张立敏,吴文丁,毕海鹏. 吉林省两种典型装配式箱涵受力特性对比分析[J]. 吉林大学学报(工学版), 2019, 49(6): 1865-1870. |

| [4] | 万世成,黄侨,关健,郭赵元. 预应力碳纤维板加固钢⁃混凝土组合连续梁负弯矩区试验[J]. 吉林大学学报(工学版), 2019, 49(4): 1114-1123. |

| [5] | 刘寒冰,刘天明,张云龙. 钢-混凝土组合连续梁抗弯性能[J]. 吉林大学学报(工学版), 2009, 39(06): 1486-1491. |

|