吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (5): 1509-1520.doi: 10.13229/j.cnki.jdxbgxb20180433

• • 上一篇

带抗剪键叠合板的力学性能

- 沈阳建筑大学 土木工程学院,沈阳 110168

Mechanical properties of laminated slab with shear keys

Ming LI( ),Hao-ran WANG,Wei-jian ZHAO

),Hao-ran WANG,Wei-jian ZHAO

- School of Civil Engineering, Shenyang Jianzhu University, Shenyang 110168, China

摘要:

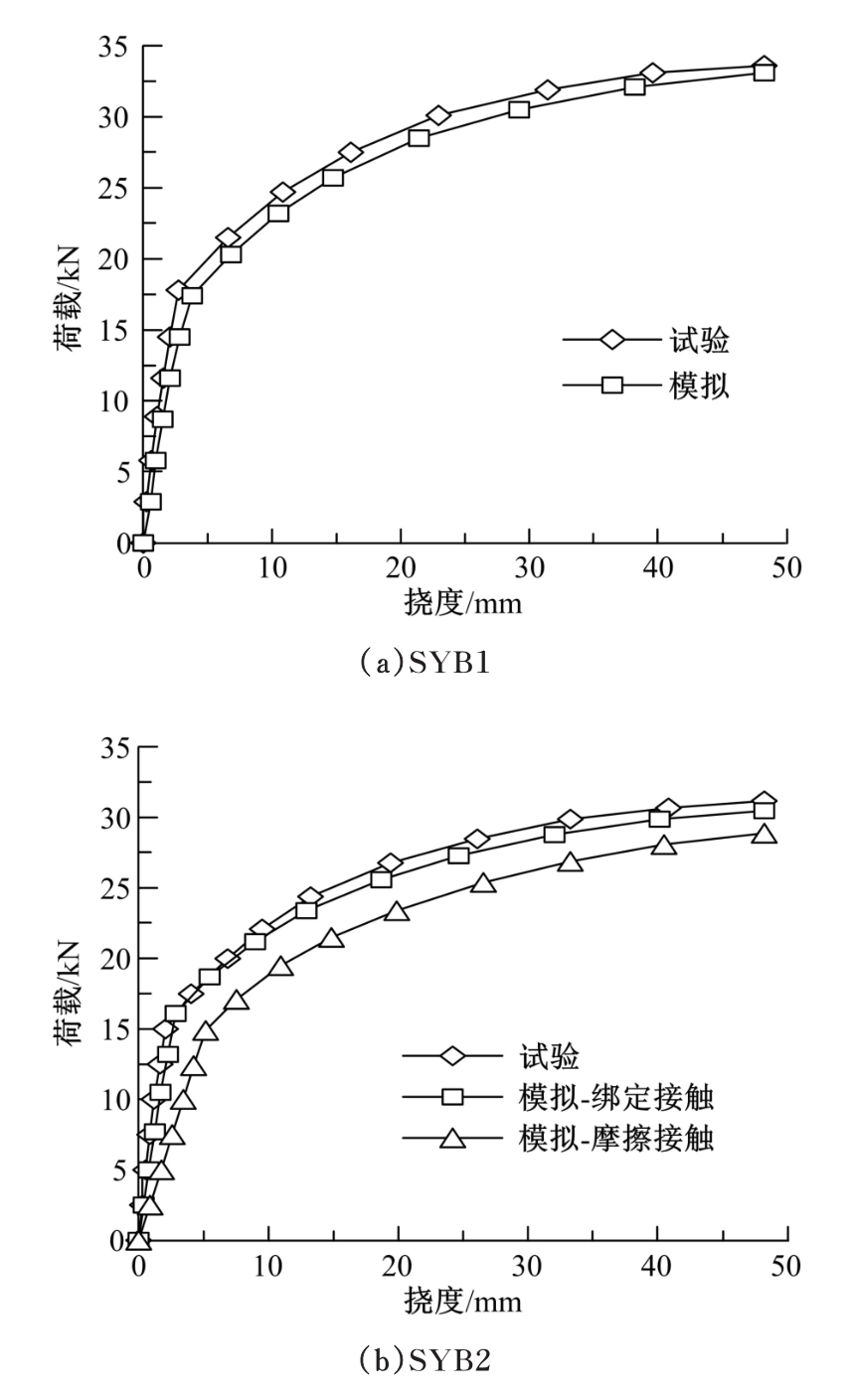

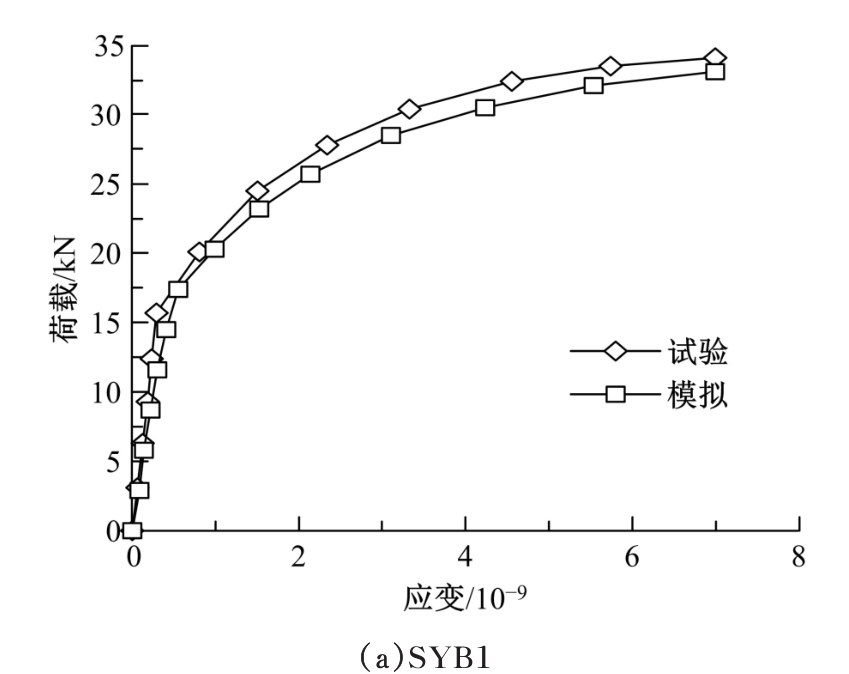

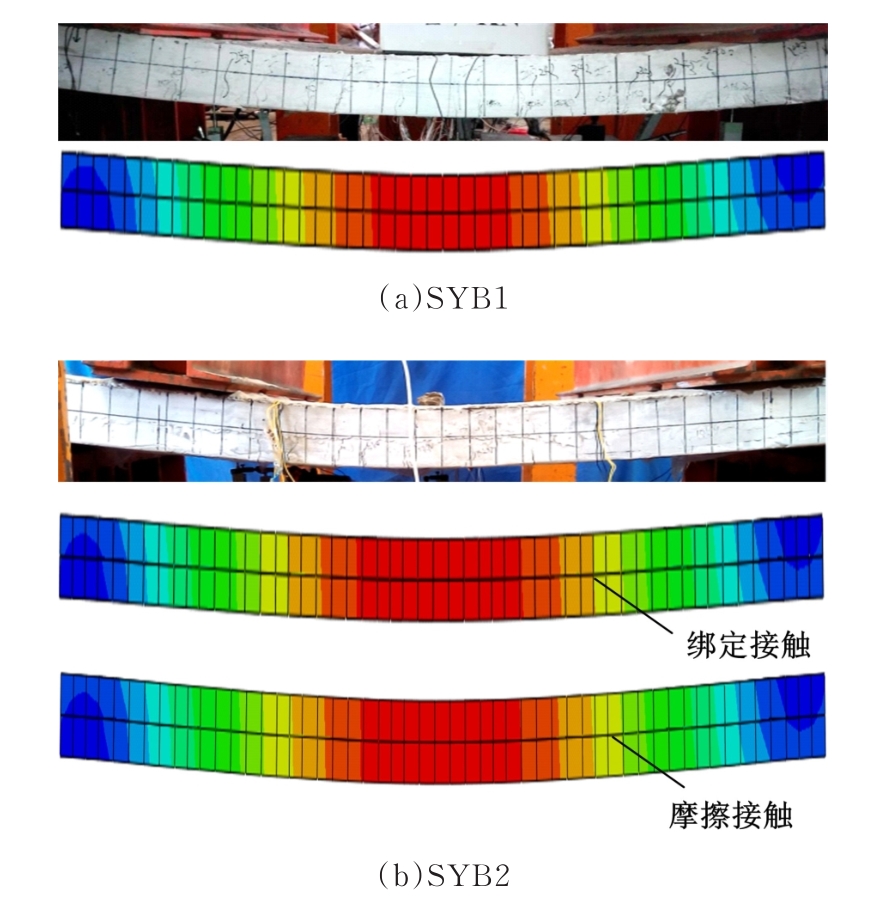

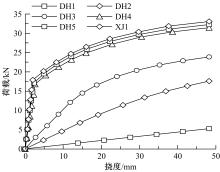

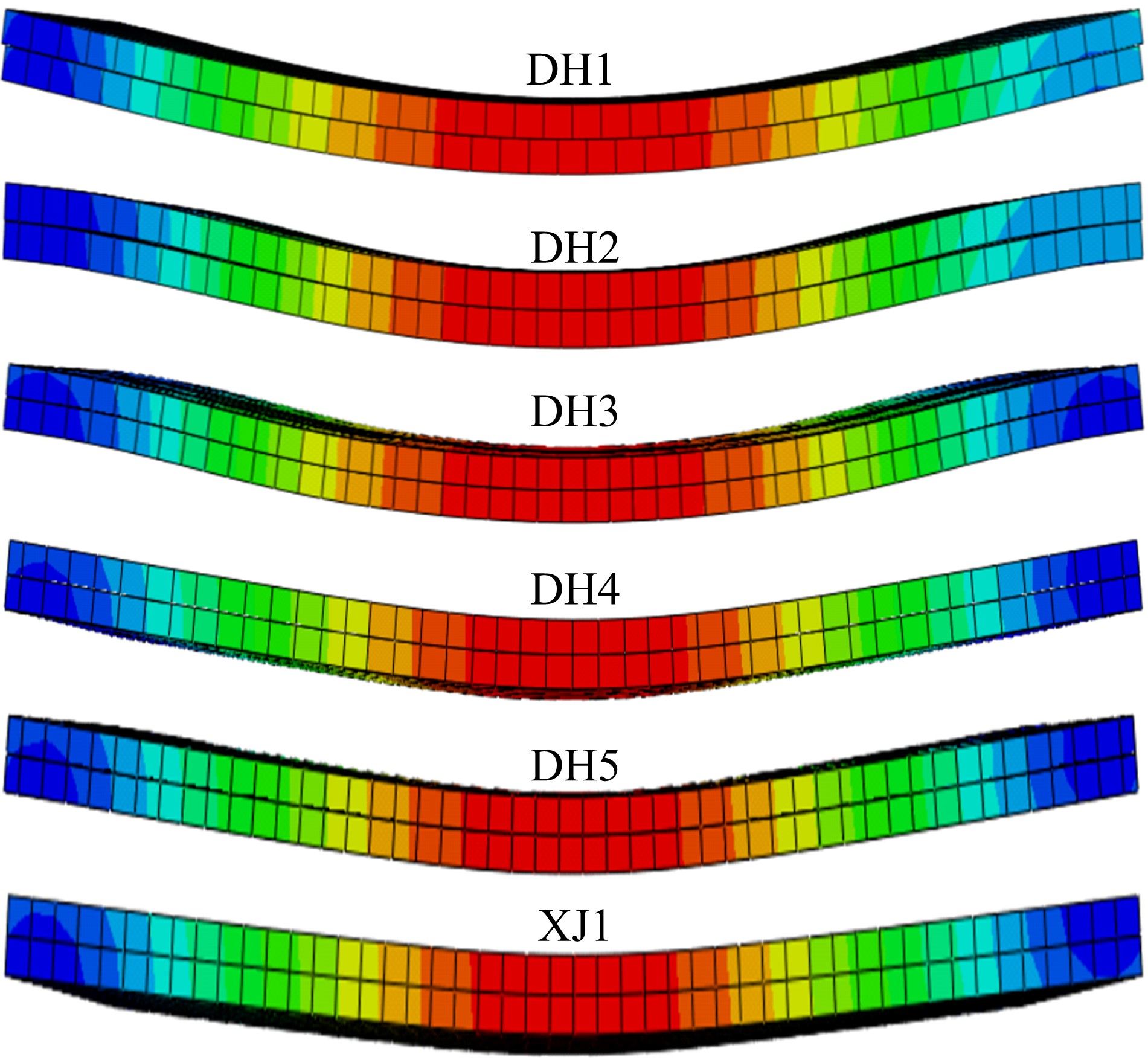

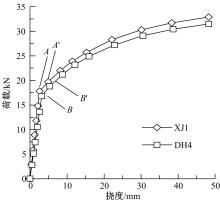

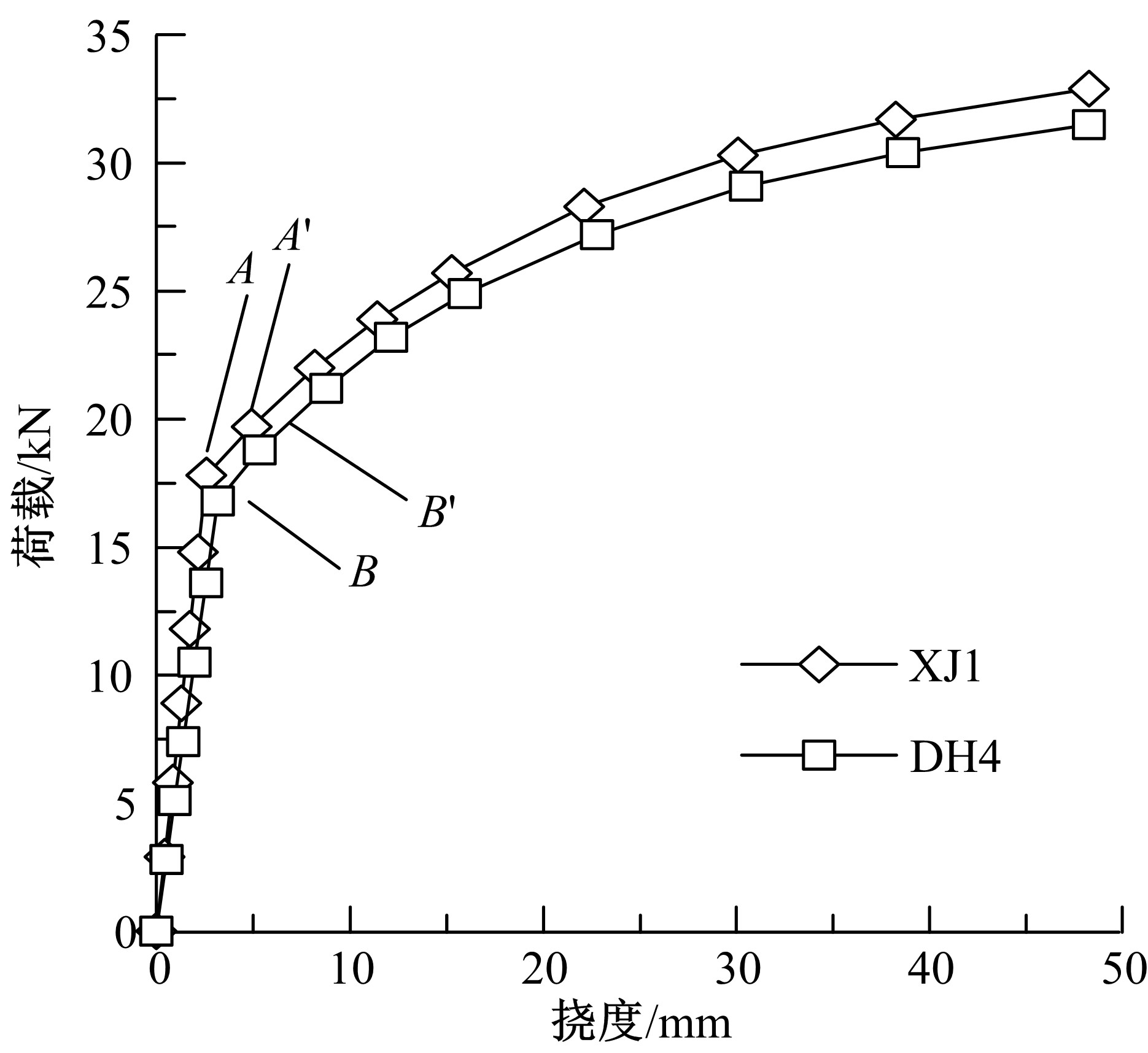

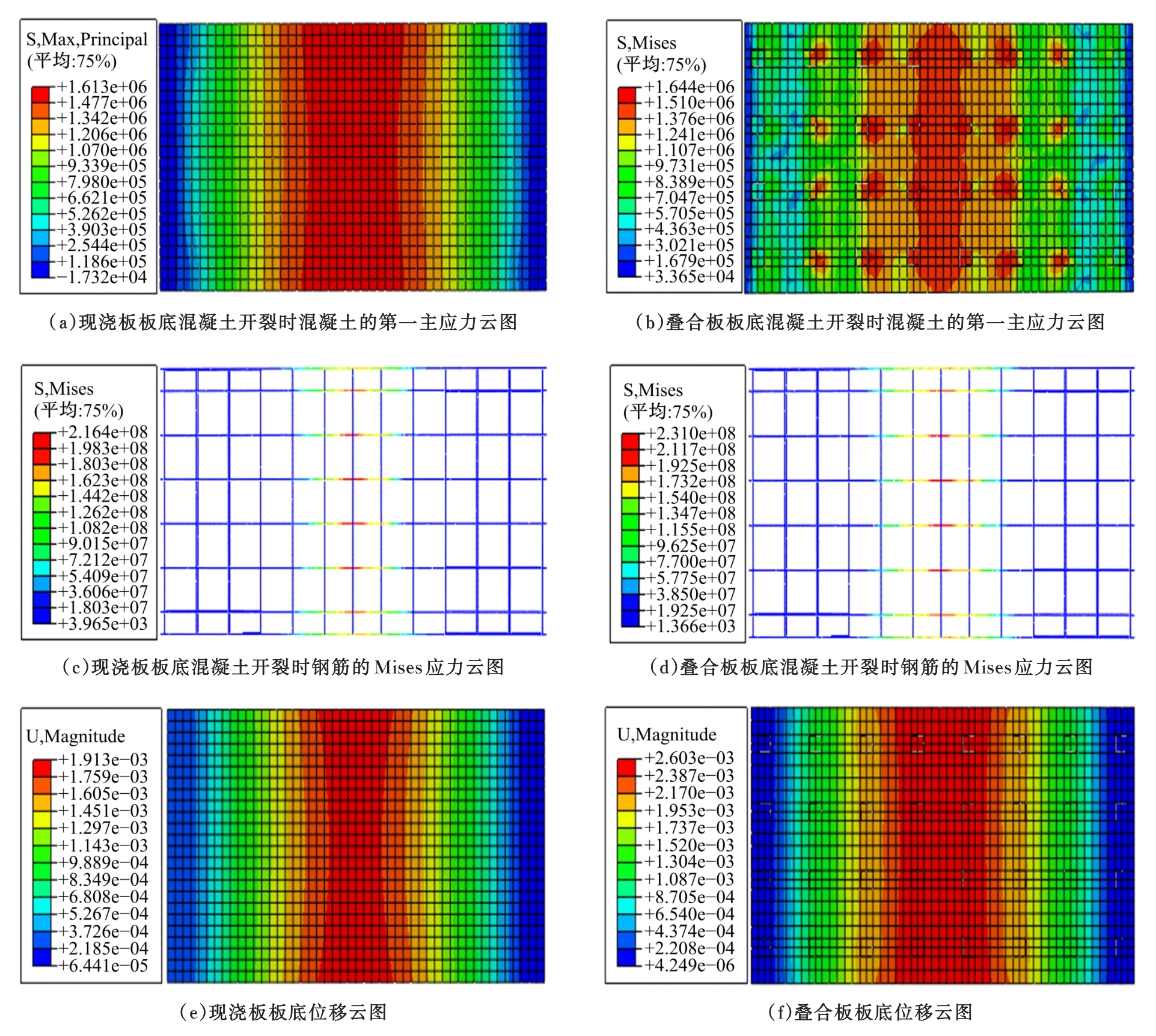

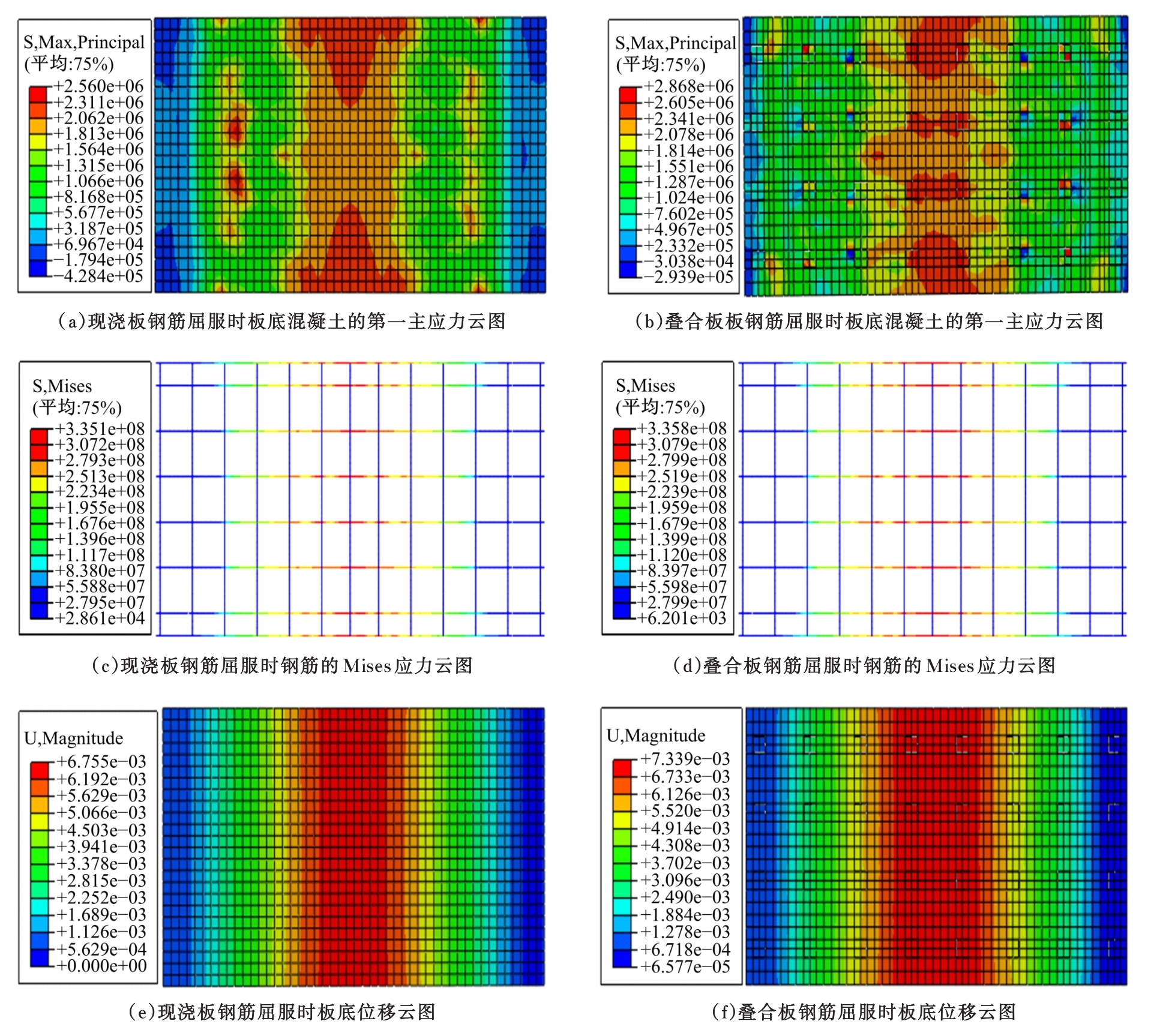

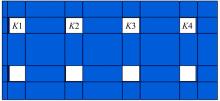

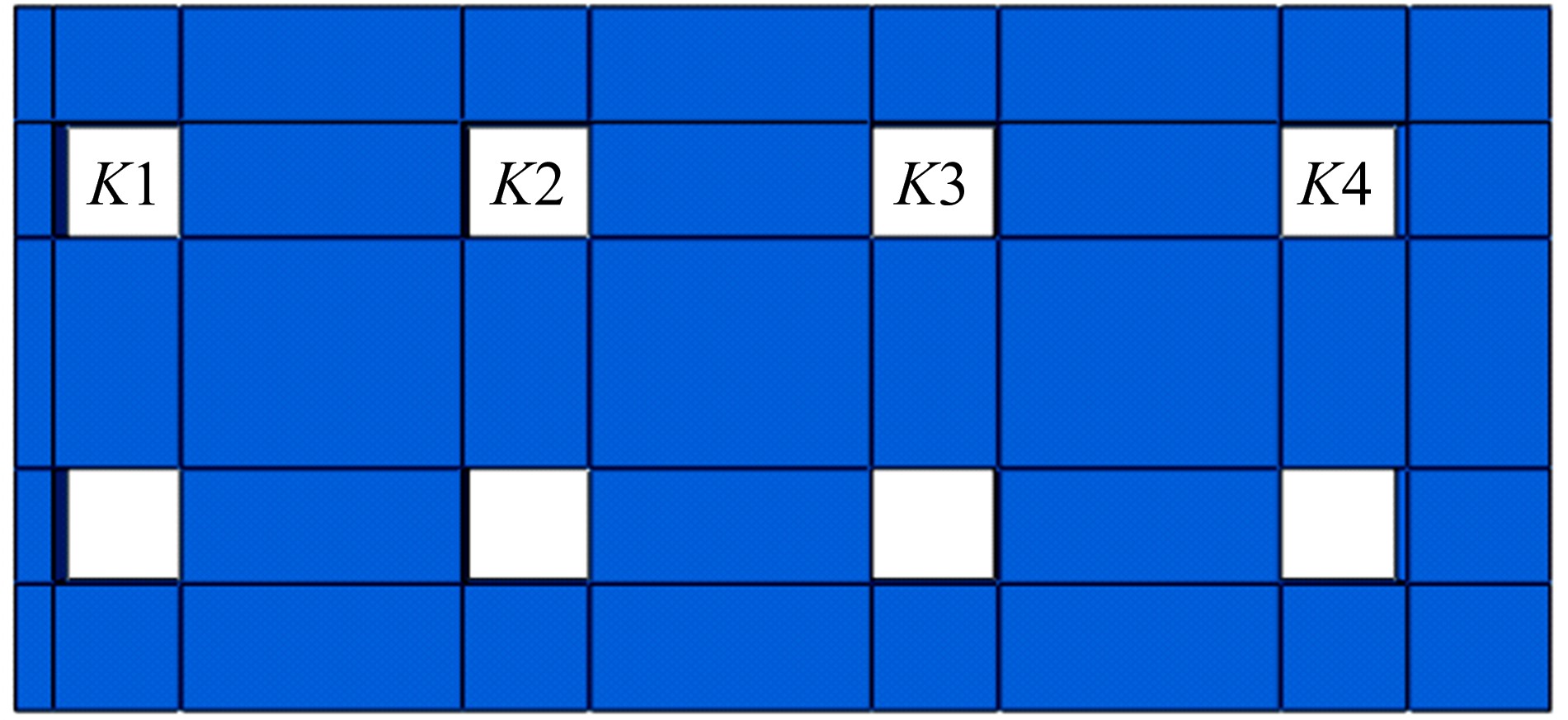

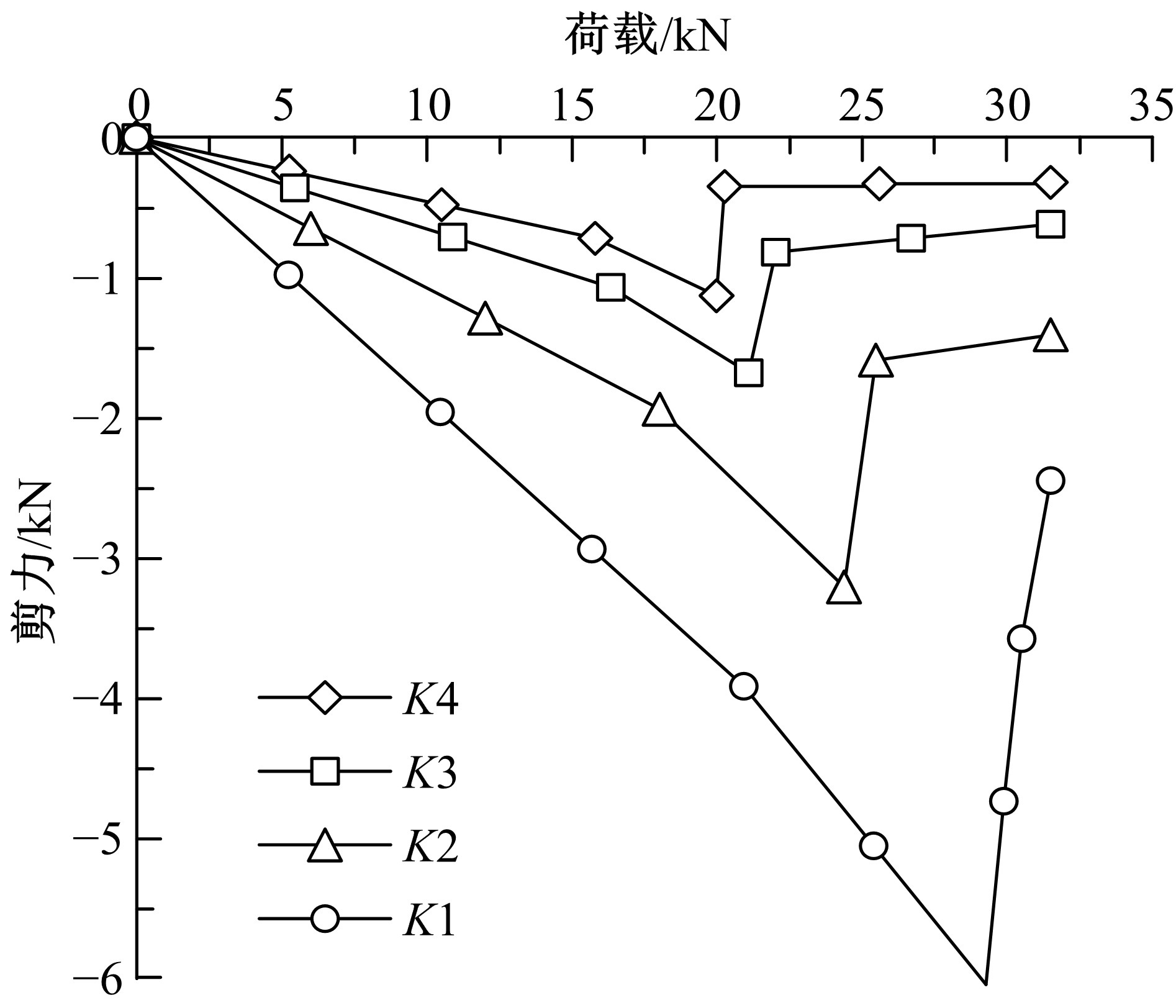

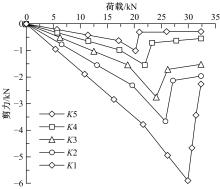

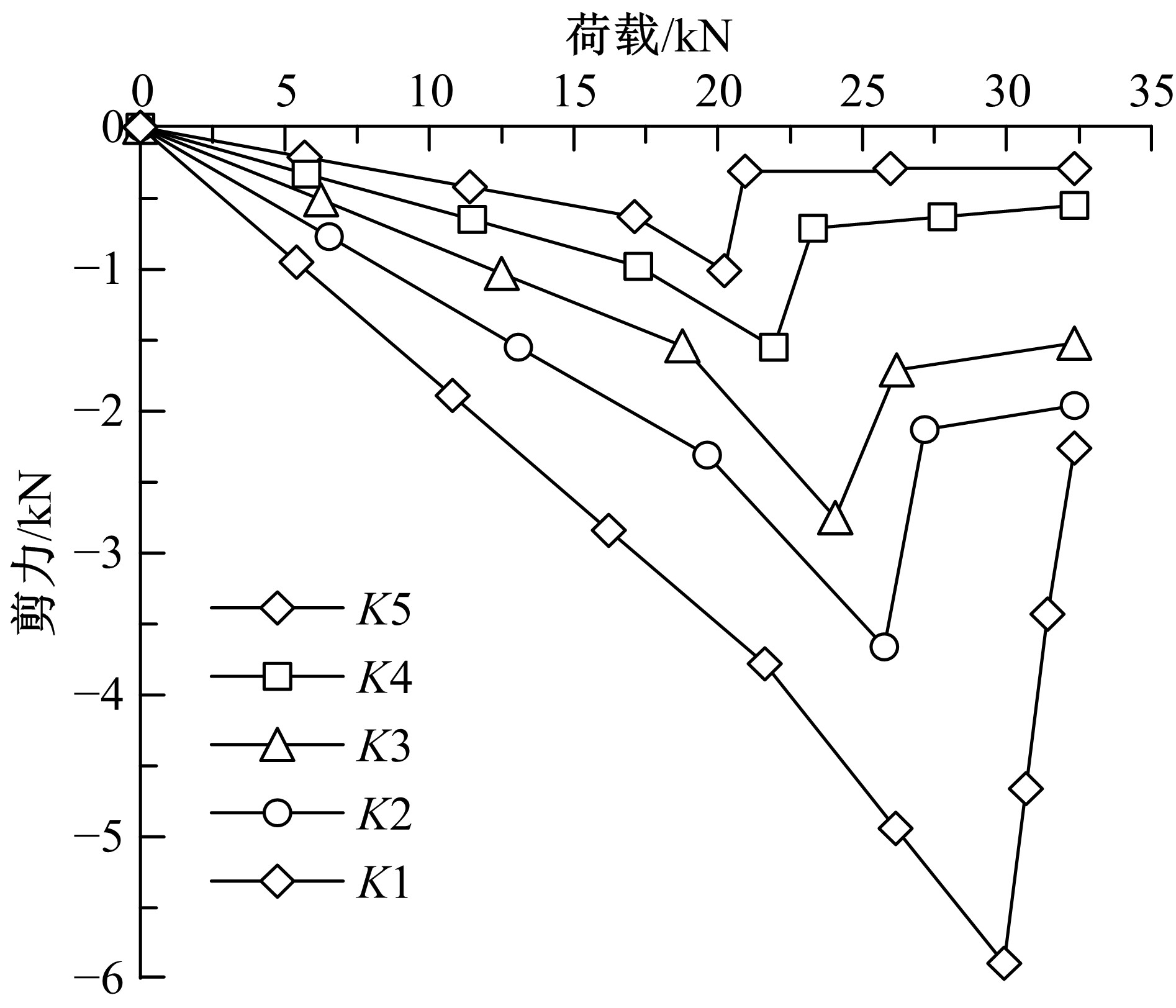

为研究带抗剪键叠合板的力学性能,基于试验和有限元模拟方法,通过对比抗剪键数量不同的叠合板荷载-挠度曲线,分析了设置抗剪键的必要性。通过对比带抗剪键叠合板与现浇板的受力过程,分析了叠合板的受力特点。提取了抗剪键剪力,分析了抗剪键破坏过程及剪力分布规律,并建立了剪力简化计算式。结果表明:抗剪键能明显提高叠合板的刚度和承载力;与现浇板相比,叠合板板底混凝土开裂和钢筋屈服时,板底混凝土第一主应力分布规律明显不同,而板底钢筋应力和位移分布规律相近;叠合板内各抗剪键剪力随荷载增加,先呈线性增加,后突然下降,抗剪键剪力值越靠近支座越大。最后,提出了抗剪键的布置方法。

中图分类号:

- TU375.2

| 1 | 曹万林, 张洁, 董宏英, 等 . 带钢筋桁架高强再生混凝土板受弯性能试验研究[J]. 建筑结构学报, 2014, 35(10): 31-38. |

| Cao Wan-lin , Zhang Jie , Dong Hong-ying , et al . Experimental research on flexural performance of high strength recycled aggregate concrete slabs with steel bar truss[J]. Journal of Building Structures, 2014, 35(10): 31-38. | |

| 2 | Orta L , Bartlett F M . Restrained concrete shrinkage in composite trusses[J]. Canadian Journal of Civil Engineering, 2012, 39(7): 779-788. |

| 3 | Josef M , Martin C . Study on shear connection of bridge steel truss and concrete slab deck[J]. Journal of Civil Engineering and Management, 2017, 23(1): 105-112. |

| 4 | 侯和涛, 蓝如海, 冯明远, 等 . 灌浆钢管桁架混凝土叠合板抗弯性能试验研究[J]. 工业建筑, 2017, 47(7): 29-33. |

| Hou He-tao , Lan Ru-hai , Feng Ming-yuan , et al . Experimental research on flexural behavior of concrete composite slab with grouted-round-steel tube truss[J]. Industrial Construction, 2017, 47(7): 29-33. | |

| 5 | 侯和涛, 冯明远, 邱灿星, 等 . 预应力混凝土钢肋叠合板受弯性能试验与理论研究[J]. 建筑结构学报, 2018, 39(3): 103-110. |

| Hou He-tao , Feng Ming-yuan , Qiu Can-xing , et al . Experimental and theoretical study on flexural behavior of prestressed concrete composite slab with steel rib[J]. Journal of Building Structures, 2018, 39(3): 103-110. | |

| 6 | Bozzo L , Torres L . A proposed semi-prefabricated prestressed composite slab[J]. Structures & Buildings, 2004, 157(5): 309-317. |

| 7 | Wang Y Y , Wang Q H , Geng Y , et al . Long-term behavior of simply supported composite slabs with recycled coarse aggregate[J]. Magazine of Concrete Research, 2016, 68(24): 1278-1293. |

| 8 | 黄超, 古倩, 王朝辉, 等 . 页岩陶粒混凝土叠合板原形堆载试验研究[J]. 武汉理工大学学报, 2016, 38(10): 61-67. |

| Huang Chao , Gu Qian , Wang Chao-hui , et al . Imposed load test of full-scale shale-ceramsite concrete composite slabs[J]. Journal of Wuhan University of Technology, 2016, 38(10): 61-67. | |

| 9 | 刘运林, 叶献国, 胡昊 . 带格构钢筋混凝土叠合板的数值模拟和格构钢筋作用分析[J]. 合肥工业大学学报: 自然科学版, 2014, 37(9): 1093-1096. |

| Liu Yun-lin , Ye Xian-guo , Hu Hao . Numerical simulation of superimposed slabs with lattice gird and analysis of the function of lattice gird[J]. Journal of Hefei University of Technology (Natural Science), 2014, 37(9): 1093-1096. | |

| 10 | 王立国 . 带抗剪键叠合板的力学性能及影响因素研究[D]. 沈阳: 沈阳建筑大学土木工程学院, 2016. |

| Wang Li-guo . Study on mechanical behavior of laminated Slab with shear connectors[D]. Shenyang: College of Civil Engineering, Shenyang Jianzhu University, 2016. | |

| 11 | GB 50010—2010. 混凝土结构设计规范[S]. |

| 12 | 王强, 朱丽丽, 李哲, 等 . 用于ABAQUS显示分析梁单元的钢筋本构模型研究[J]. 土木工程学报, 2013, 46(增刊2): 100-105. |

| Wang Qiang , Zhu Li-li , Li Zhe , et al . Study on constitutive model of steel for explicit dynamic beam elements of ABAUQS[J]. China Civil Engineering Journal, 2013, 46(Sup.2): 100-105. | |

| 13 | 高欣, 吴晓伟, 田俊 . 轻骨料混凝土剪力墙非线性有限元模型的构成及影响其抗震性能的因素[J]. 吉林大学学报: 工学版, 2015, 45(5): 1428-1435. |

| Gao Xin , Wu Xiao-wei , Tian Jun . Structure of nonlinear finite element model of lightweight aggregate concrete share wall and the factors affecting seismic performance[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(5): 1428-1435. | |

| 14 | 陈富强, 田唯, 刘占国, 等 . 匹配浇筑混凝土接触面摩擦系数试验研究[J]. 中国港湾建设, 2014, 12: 34-38. |

| Cheng Fu-qiang , Tian Wei , Liu Zhan-guo , et al . Experiment study on friction coefficient of concrete with matching pouring surface[J]. China Harbor Engineering, 2014, 12: 34-38. | |

| 15 | 季文玉, 李旺旺, 过民龙, 等 . 预应力叠合梁RPC-NC叠合梁挠度试验及计算方法[J]. 吉林大学学报: 工学版, 2018, 48(1): 129-136. |

| Ji Wen-yu , Li Wang-wang , Guo Min-long , et al . Experimental and calculation methods of prestressed RPC-NC composite beam deflection[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(1): 129-136. |

| [1] | 梁宁慧,缪庆旭,刘新荣,代继飞,钟祖良. 聚丙烯纤维增强混凝土断裂韧度及软化本构曲线确定[J]. 吉林大学学报(工学版), 2019, 49(4): 1144-1152. |

| [2] | 张军,钱诚,郭春燕,钱玉君. 基于多源时空数据的建筑宜居性动态设计[J]. 吉林大学学报(工学版), 2019, 49(4): 1169-1173. |

| [3] | 张磊,刘保国,储昭飞. 深厚孔隙砂岩含水层疏干排水对盾构斜井的 影响模型试验[J]. 吉林大学学报(工学版), 2019, 49(3): 788-797. |

| [4] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [5] | 庄蔚敏, 赵文增, 解东旋, 李兵. 超高强钢/铝合金热铆连接接头性能[J]. 吉林大学学报(工学版), 2018, 48(4): 1016-1022. |

| [6] | 郑一峰, 赵群, 暴伟, 李壮, 于笑非. 大跨径刚构连续梁桥悬臂施工阶段抗风性能[J]. 吉林大学学报(工学版), 2018, 48(2): 466-472. |

| [7] | 王腾, 周茗如, 马连生, 乔宏霞. 基于断裂理论的湿陷性黄土劈裂注浆裂纹扩展[J]. 吉林大学学报(工学版), 2017, 47(5): 1472-1481. |

| [8] | 郭楠, 张平阳, 左煜, 左宏亮. 竹板增强胶合木梁受弯性能[J]. 吉林大学学报(工学版), 2017, 47(3): 778-788. |

| [9] | 刘晓波, 周德坤, 赵宇光. 不同等温热处理条件下半固态挤压Mg2Si/Al复合材料的组织和性能[J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

| [10] | 张静, 刘向东. 混沌粒子群算法优化最小二乘支持向量机的混凝土强度预测[J]. 吉林大学学报(工学版), 2016, 46(4): 1097-1102. |

| [11] | 郭学东, 马立军, 张云龙. 集中力作用下考虑剪切滑移效应的双层结合面组合梁解析解[J]. 吉林大学学报(工学版), 2016, 46(2): 432-438. |

| [12] | 李春玲, 樊丁, 王斌, 余淑荣. 5A06铝合金/镀锌钢预置涂粉对接激光熔钎焊组织与性能[J]. 吉林大学学报(工学版), 2016, 46(2): 516-521. |

| [13] | 赵玉, 李衍赫, 张培, 赵科, 刘伟超. 粘土的动力特性试验[J]. 吉林大学学报(工学版), 2015, 45(6): 1791-1797. |

| [14] | 侯忠明, 王元清, 夏禾, 张天申. 移动荷载作用下的钢-混简支结合梁动力响应[J]. 吉林大学学报(工学版), 2015, 45(5): 1420-1427. |

| [15] | 邓成江,何晓聪,邢保英,王玉奇,曾凯,丁燕芳. 铝与铜异质板材自冲铆搭接接头的力学性能[J]. 吉林大学学报(工学版), 2015, 45(2): 473-480. |

|

||