吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (12): 3358-3366.doi: 10.13229/j.cnki.jdxbgxb.20220050

• 车辆工程·机械工程 • 上一篇

基于线结构光视觉的平面度误差测量方法

刘思远1( ),侯跃谦2,寇莹1(

),侯跃谦2,寇莹1( ),任真2,胡正乙3,4,赵雪微2,葛云鹏1

),任真2,胡正乙3,4,赵雪微2,葛云鹏1

- 1.吉林大学 机械与航空航天工程学院,长春 130022

2.长春大学 机械工程学院,长春 130022

3.华南理工大学 机械与汽车工程学院,广州 510641

4.长春汽车工业高等专科学校 产教融合发展中心,长春 130010

Flatness error measurement method based on line structured light vision

Si-yuan LIU1( ),Yue-qian HOU2,Ying KOU1(

),Yue-qian HOU2,Ying KOU1( ),Zhen REN2,Zheng-yi HU3,4,Xue-wei ZHAO2,Yu-peng GE1

),Zhen REN2,Zheng-yi HU3,4,Xue-wei ZHAO2,Yu-peng GE1

- 1.School of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

2.School of Mechanical Engineering,Changchun University,Changchun 130022,China

3.School of Mechanical and Automotive Engineering,South China University of Technology,Guangzhou 510641,China

4.Production and Education Integration Development Center,Changchun Automobile Industry College,Changchun 130010,China

摘要:

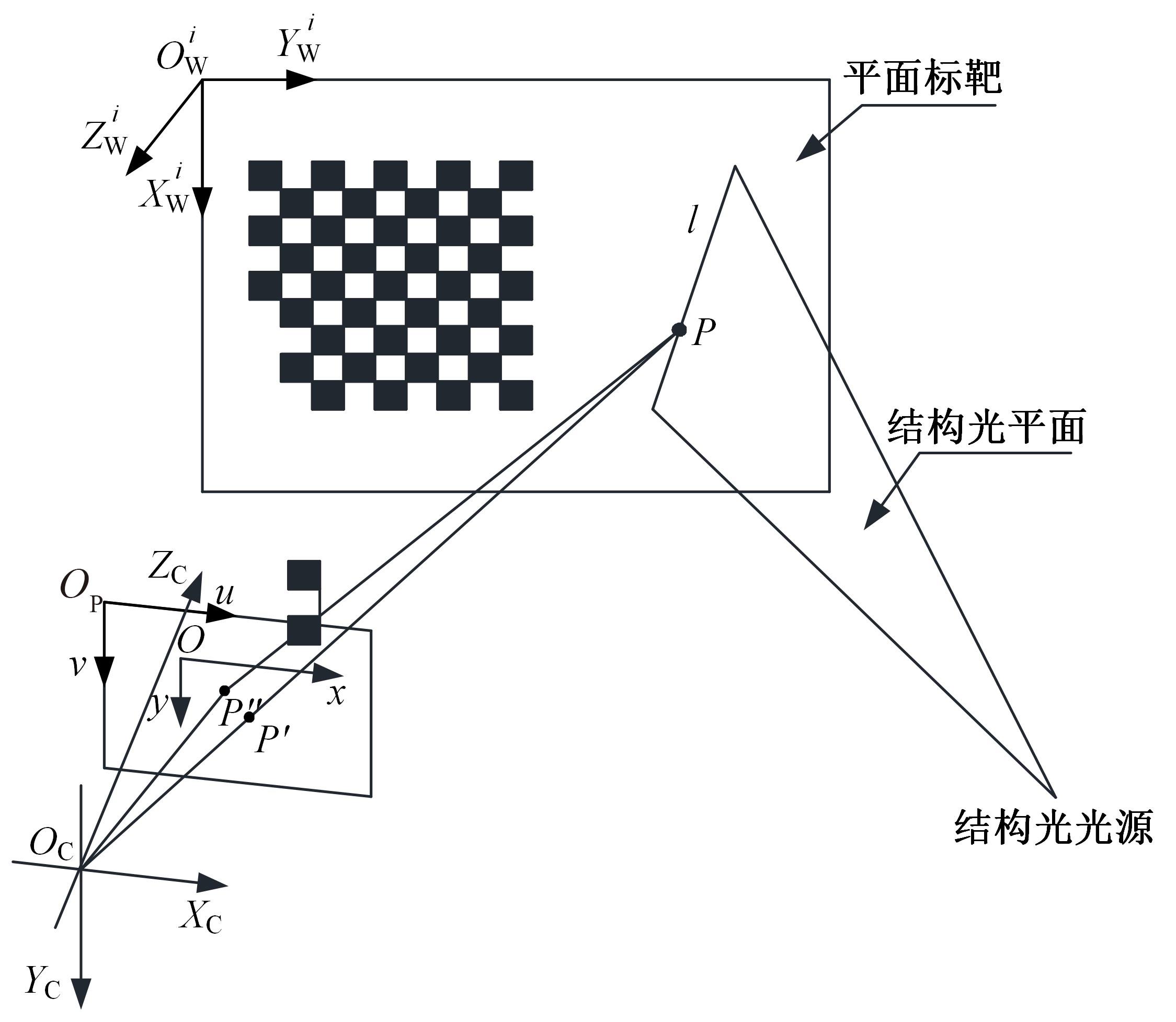

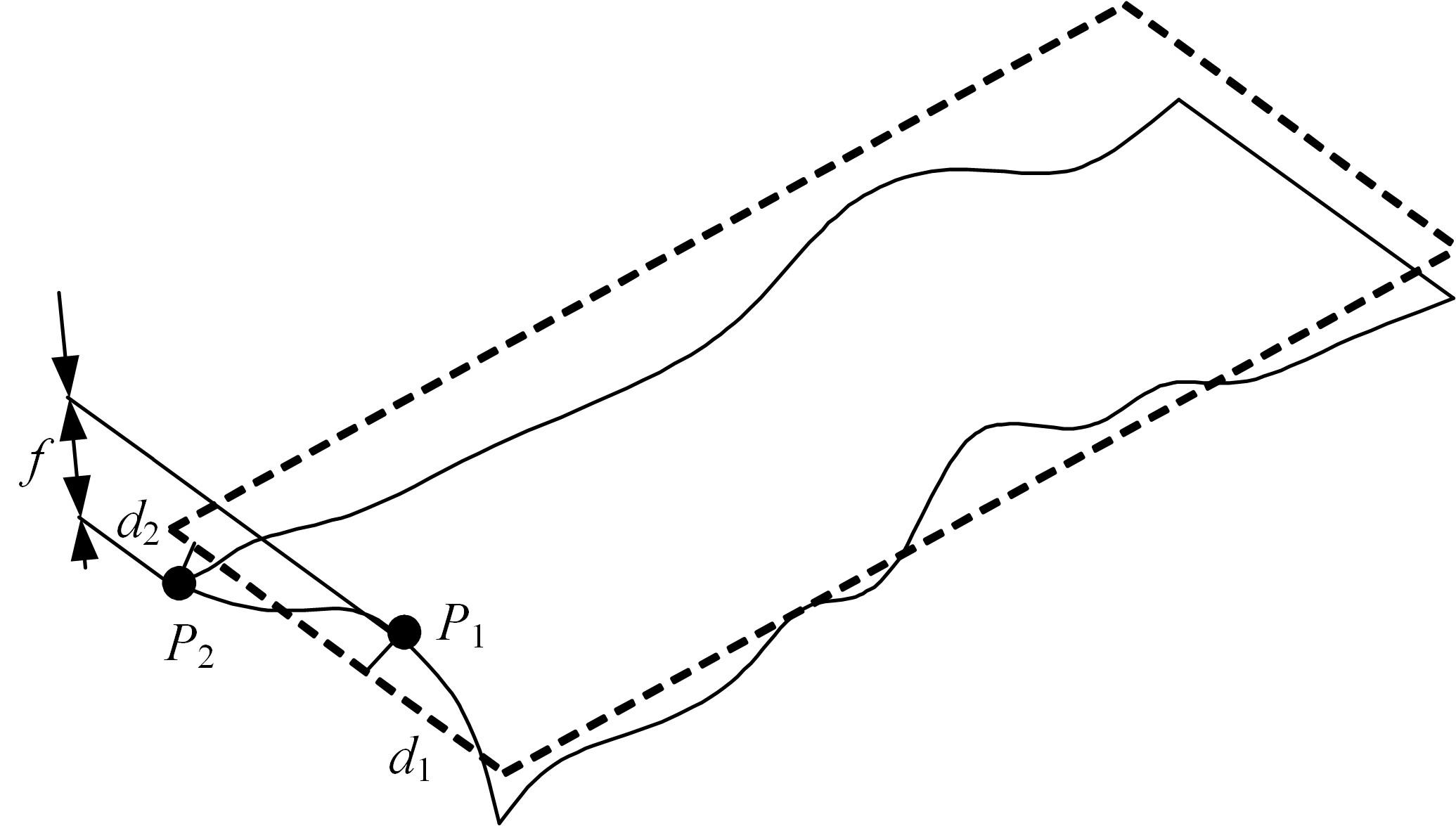

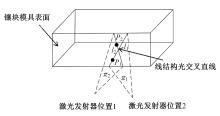

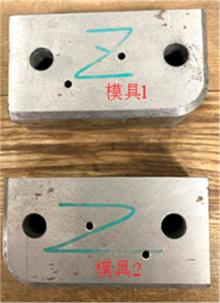

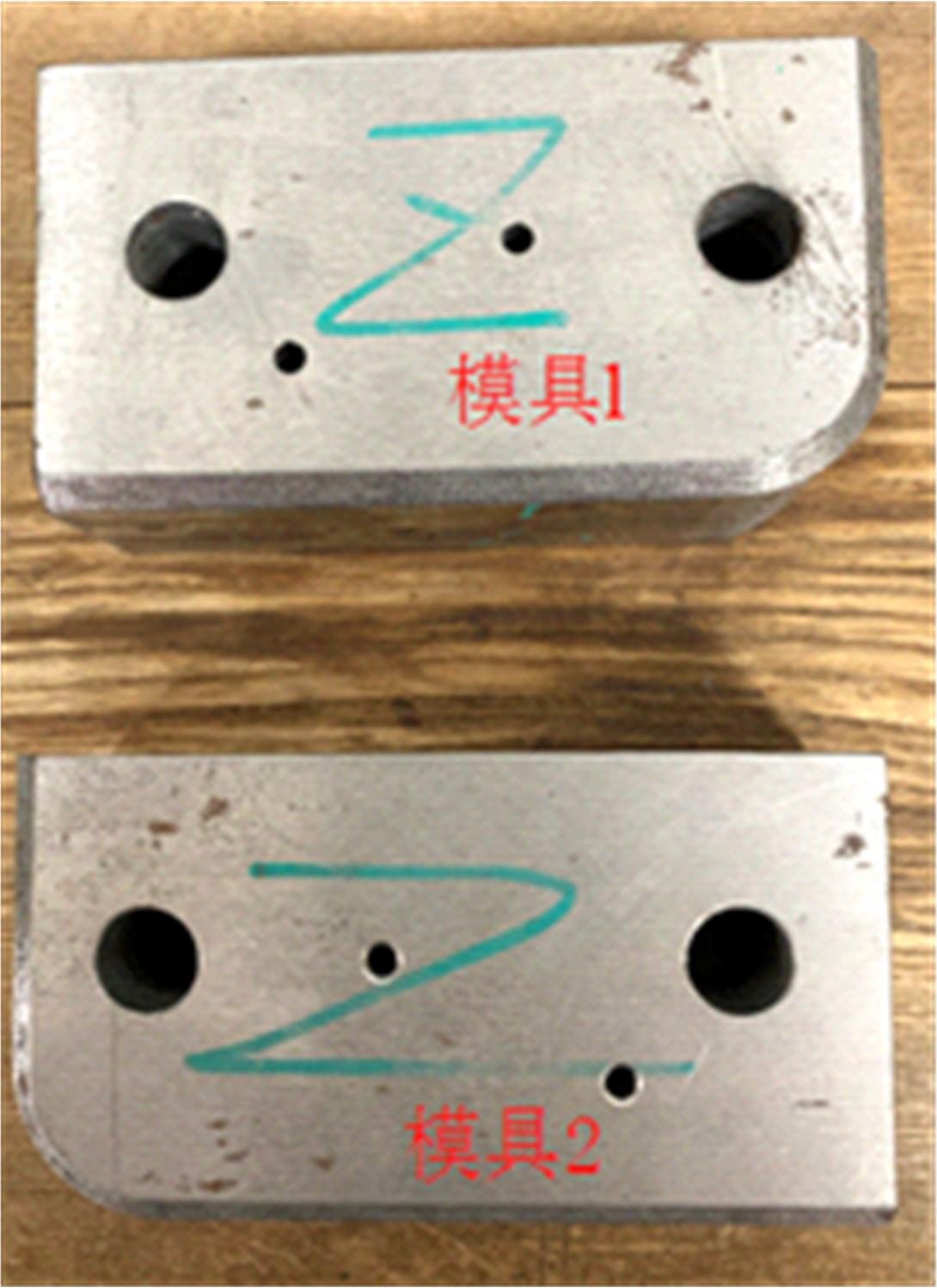

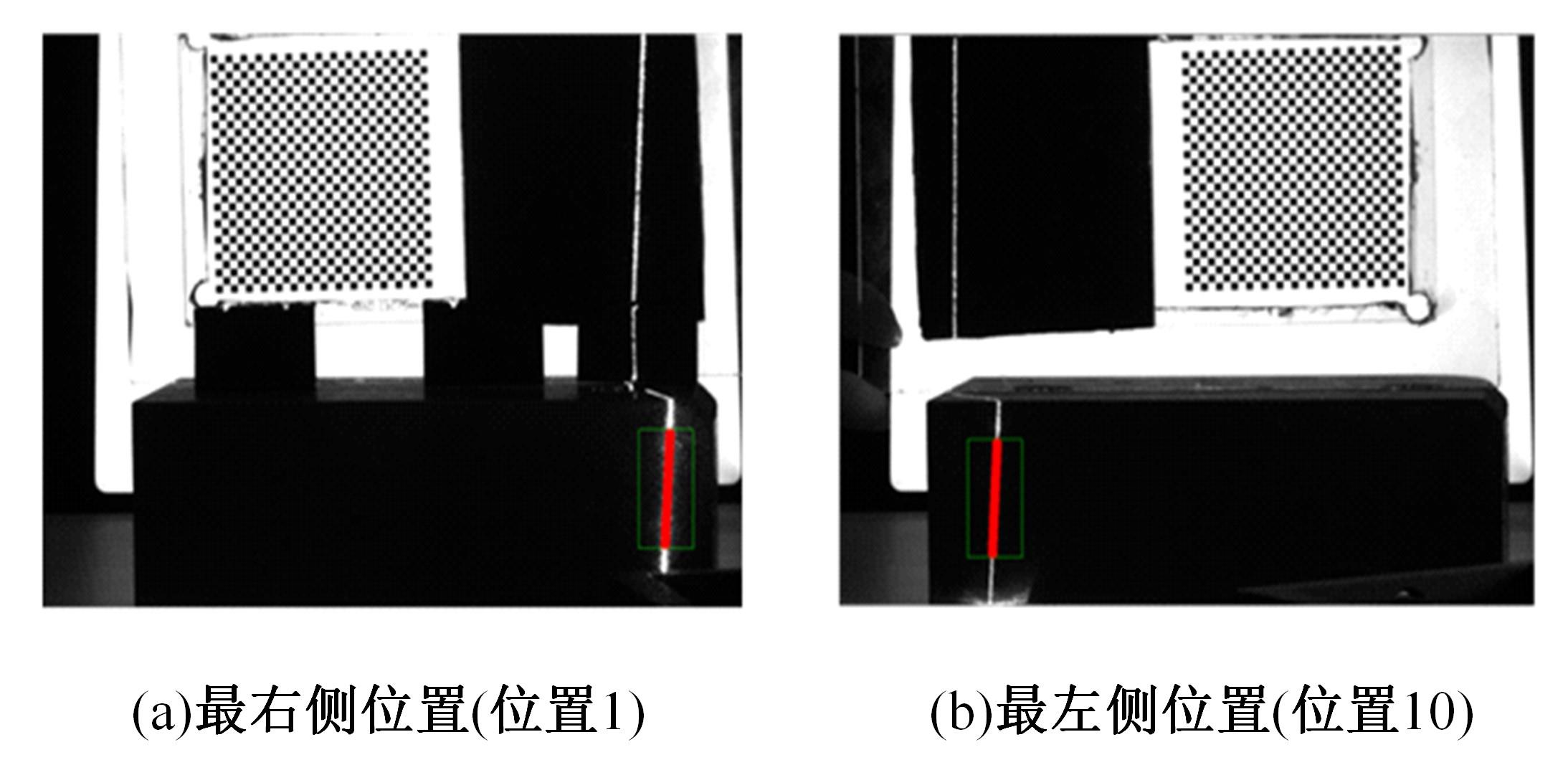

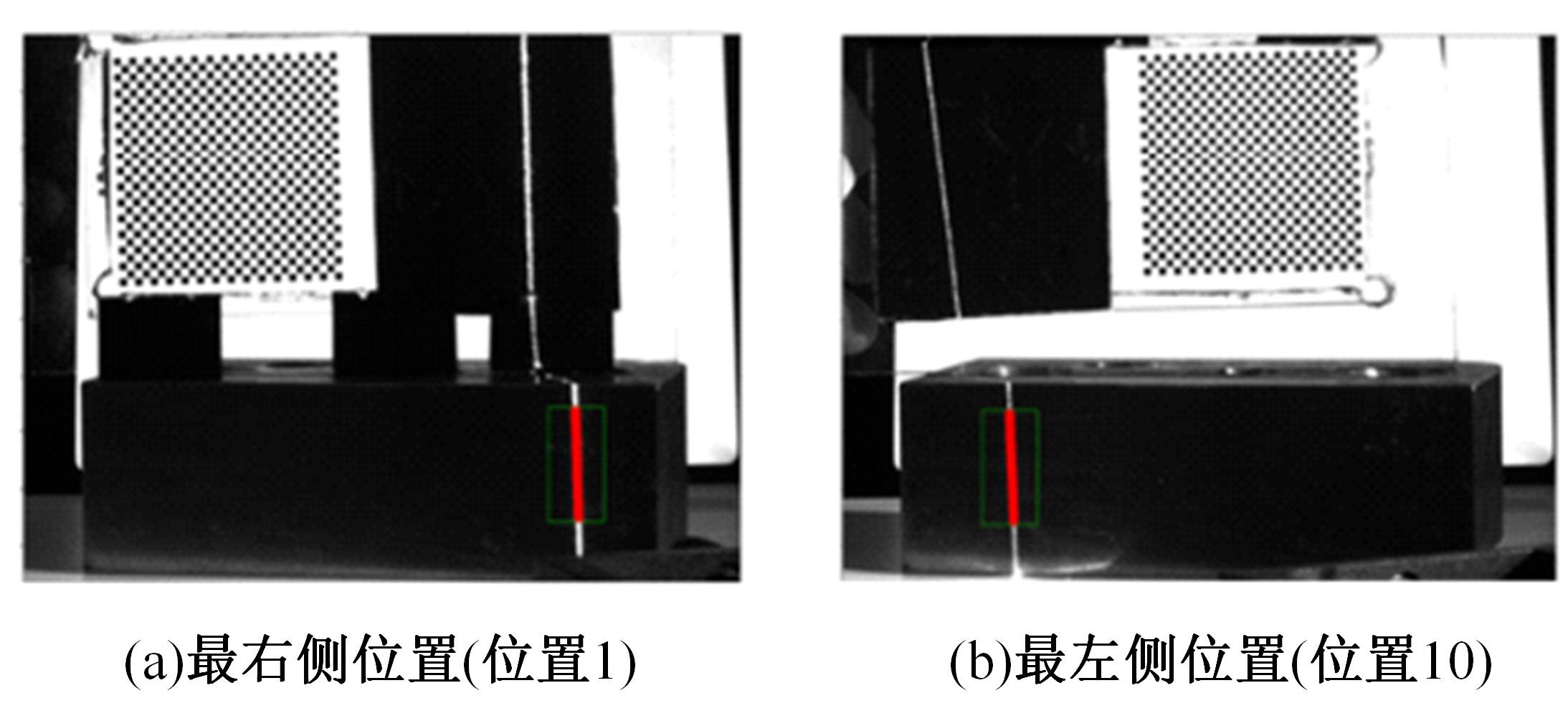

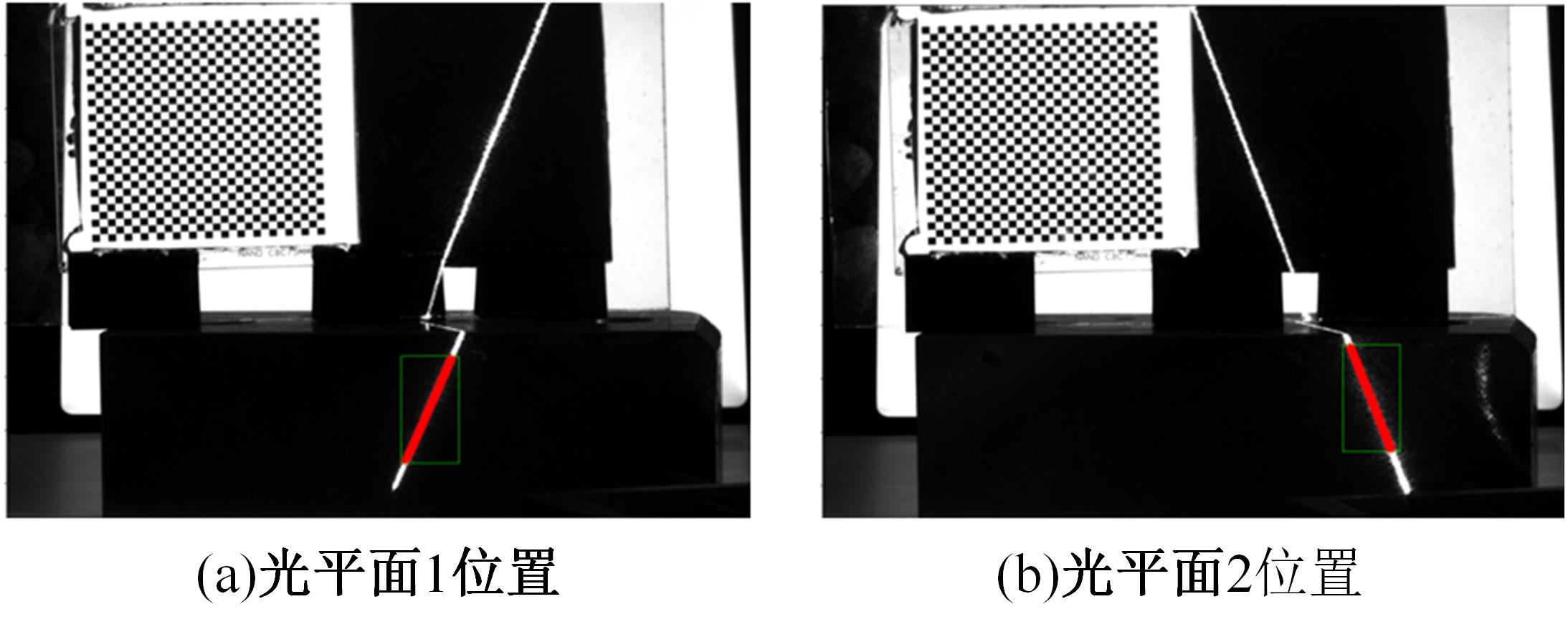

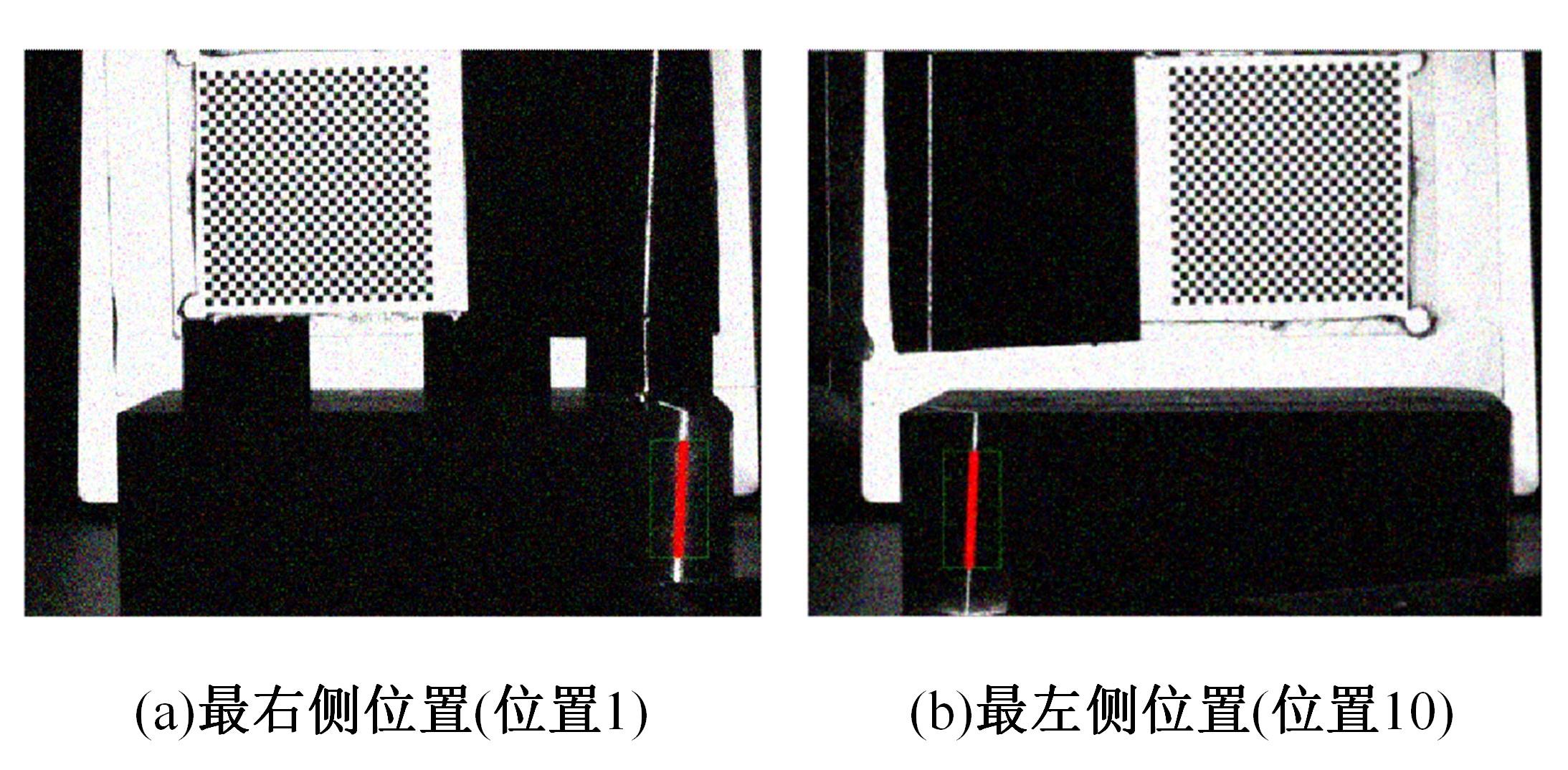

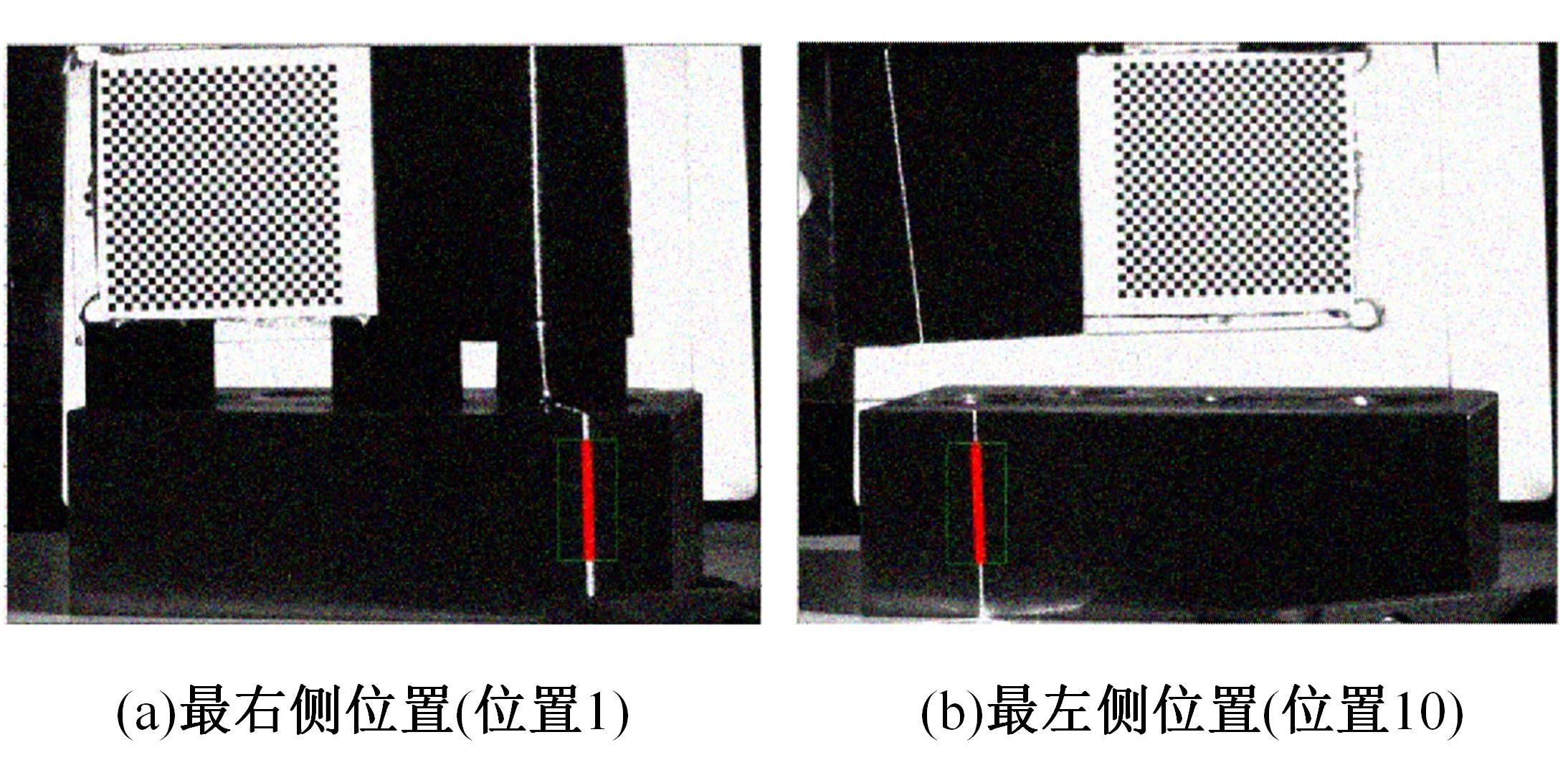

针对机械零部件制造及加工领域的平面度测量问题,提出了一种基于线结构光视觉技术的平面度误差测量方法。首先,采集被测平面上不同位置的光条图像,并根据每个位置所对应的光平面方程获得扫描点的空间坐标。其次,对国家标准中平面度误差评定方法进行分析,建立了基于几何约束的平面度误差视觉测量算法。最后,通过本文算法,利用扫描点空间坐标计算出评定基面及平面度误差。在实验中,选择镶块模具的定位面作为被测平面,并将视觉测量结果与采用接触式测量方法获得的结果进行对比,测量误差小于20 μm。实验结果表明本文提出的平面度误差测量方法具有一定的可行性,提高了平面度误差的测量效率。

中图分类号:

- TH164

| 1 | 薛岩, 于明. 机械加工精度测量与质量控制[M]. 3版. 北京: 化学工业出版社, 2016. |

| 2 | 李影. 光电水平仪设计与平面度误差测量方法的研究[D]. 大连:大连理工大学机械工程学院, 2019. |

| Li Ying. The design of photoelectric level gauge and the study of flatness error measurement method[D]. Dalian: School of Mechanical Engineering, Dalian University of Technology, 2019. | |

| 3 | 谯梁, 冉庆, 龚柯安. 激光平面移相干涉仪示值误差测量结果不确定度评定[J]. 工业计量, 2020, 30(): 66-67. |

| Qiao Liang, Ran Qing, Gong Ke-an. Evaluation of uncertainty in measurement results of indication error of laser planar phase-shifting interferometer[J]. Industrial Metrology, 2020, 30(Sup.1): 66-67. | |

| 4 | Wang Han-bin. Uncertainty evaluation for the CMM flatness measurement[J]. Metrology & Measurement Technique, 2019, 46(3): 98-99. |

| 5 | 单忠德, 张飞, 聂军刚, 等. 非接触式缸盖平面度误差检测方法与测量系统研究[J]. 机械工程学报, 2016, 52(20): 1-7. |

| Shan Zhong-de, Zhang Fei, Nie Jun-gang, et al. Study on the detection method and measurement system of head flatness error on non-contact detection[J]. Journal of Mechanical Engineering, 2016, 52(20): 1-7. | |

| 6 | Tan Qing-chang, Kou Ying, Miao Jian-wei, et al. A model of diameter measurement based on the machine vision[J]. Symmetry, 2021, 13(2): No. 187. |

| 7 | Liu Rui-yuan, Wang Ze-yuan, Liu Xiao-min, et al. Research on Visual Inspection of Appearance Defects of Automotive Precision Parts, 2020, 41(3): 192-196. |

| 8 | Mikko Makela, Marja Rissanen, Herbert Sixta. Machine vision estimates the polyester content in recyclable waste textiles[J]. Resources Conservation and Recycling, 2020, 161: No. 105007. |

| 9 | 张广军. 机器视觉[M]. 北京:科学出版社, 2005. |

| 10 | Liu Bin, Wang Peng, Zeng Yong, et al. Measuring method for micro-diameter based on structured-light vision technology[J]. Chinese Optics Letters, 2010, 8(7): 666-669. |

| 11 | Liu Si-yuan, Tan Qing-chang, Zhang Ya-chao. Shaft diameter measurement of using the structured light vision[J]. Sensors, 2015, 15(8): 19750-19767. |

| 12 | Zhong Chu-qian, Gao Zhan, Wang Xu, et al. Structured light three-dimensional measurement based on machine learning[J]. Sensors, 2019, 19(14): No. 3229. |

| 13 | 何文彦, 曹学东, 匡龙. 结构光检测大型止推环止推面平面度探究[J]. 光电工程, 2016, 43(11): 7-12. |

| He Wen-yan, Cao Xue-dong, Kuang Long, et al. A preliminary based on structured-light for flatness measurement of large annular planes[J]. Opto-Electronic Engineering, 2016, 43(11): 7-12. | |

| 14 | Miao Hui-si, Xiao Chang-yan, Li Yu-cheng, et al. Machine vision system for key-cap flatness measurement of computer keyboards[J]. Optical Engineering, 2020, 59(3): No.1. |

| 15 | 谭文, 方淼, 段峰, 等. 基于机器视觉的3D激光平面度测量系统的研究与应用[J]. 仪器仪表学报, 2020, 41(1): 241-249. |

| Tan Wen, Fang Miao, Duan Feng, et al. Research and application of 3D laser flatness measurement system based on machine vision[J]. Chinese Journal of Scientific Instrument, 2020, 41(1): 241-249. | |

| 16 | Chen Sheng-feng, Su Chong-yang, Liu Jian, et al. Flatness measurement of platform screen system welding assembly using stereo vision and grid pattern projector[J]. IEEE Sensors Journal, 2022, 22(1): 948-958. |

| 17 | . 产品几何量技术规范(GPS)平面度误差检测 [S]. |

| 18 | Zhang Z. A flexible new technique for camera calibration[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2000, 22(11): 1330-1334. |

| 19 | Steger C. An unbiased detector of curvilinear structures[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 1998, 20(2): 113-125. |

| [1] | 包昊菁,刘思远,任真,张云辉,胡正乙,葛宇鹏. 基于机器视觉的链轮尺寸测量方法[J]. 吉林大学学报(工学版), 2023, 53(10): 2795-2806. |

| [2] | 李景彬,杨禹锟,温宝琴,坎杂,孙雯,杨朔. 基于根茬检测的秋后残膜回收导航路径提取方法[J]. 吉林大学学报(工学版), 2021, 51(4): 1528-1539. |

| [3] | 刘恩泽,吴文福. 基于机器视觉的农作物表面多特征决策融合病变判断算法[J]. 吉林大学学报(工学版), 2018, 48(6): 1873-1878. |

| [4] | 林金花, 王延杰, 王璐, 姚禹. 全局相机姿态优化下的快速表面重建[J]. 吉林大学学报(工学版), 2018, 48(3): 909-918. |

| [5] | 张飞, 单忠德, 任永新, 聂军刚, 刘丰. 缸盖缺陷检测系统线阵相机现场标定方法[J]. 吉林大学学报(工学版), 2017, 47(2): 540-545. |

| [6] | 周晓东, 张雅超, 谭庆昌, 张维君. 基于结构光视觉技术的圆柱度测量新方法[J]. 吉林大学学报(工学版), 2017, 47(2): 524-529. |

| [7] | 张波,王文军,魏民国,成波. 基于机器视觉的驾驶人使用手持电话行为检测[J]. 吉林大学学报(工学版), 2015, 45(5): 1688-1695. |

| [8] | 张保华, 黄文倩, 李江波, 赵春江, 刘成良, 黄丹枫. 基于I-RELIEF和SVM的畸形马铃薯在线分选[J]. 吉林大学学报(工学版), 2014, 44(6): 1811-1817. |

| [9] | 刘长英1, 蔡文静1, 王天皓2, 李机智1, 贾艳梅1, 宋玉河1. 汽车连杆裂解槽视觉检测技术[J]. 吉林大学学报(工学版), 2014, 44(4): 1076-1080. |

| [10] | 万川, 田彦涛, 刘帅师, 陈宏伟. 基于主动机器视觉的人脸跟踪与表情识别系统[J]. 吉林大学学报(工学版), 2013, 43(02): 459-465. |

| [11] | 赵丁选, 崔玉鑫, 龚捷, 倪涛, 侯敬巍, 赵颖, 王超飞. 基于机器视觉的运动目标跟踪及位置检测方法[J]. 吉林大学学报(工学版), 2010, 40(增刊): 257-0261. |

| [12] | 孟祥艳, 孙永海, 王笑丹, 李志, 胡铁军, 何兵. 牛胴体眼肌切面分级特征的提取与分析[J]. 吉林大学学报(工学版), 2010, 40(02): 485-0490. |

| [13] | 王红睿, 田彦涛, 顾庆. 变光照环境中的数字摄像机参数自适应调整算法[J]. 吉林大学学报(工学版), 2009, 39(05): 1262-1267. |

| [14] | 李伟,康晴晴,张俊雄,荀一 . 基于机器视觉的苹果表面纹理检测方法[J]. 吉林大学学报(工学版), 2008, 38(05): 1110-1113. |

| [15] | 刘庆民,王龙山,陈向伟,李国发. 滚珠螺母的机器视觉检测[J]. 吉林大学学报(工学版), 2006, 36(04): 534-538. |

|

||