吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (1): 105-113.doi: 10.13229/j.cnki.jdxbgxb.20220188

• 材料科学与工程 • 上一篇

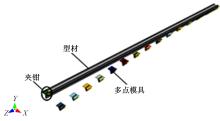

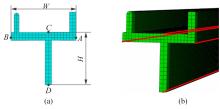

不规则Y形铝型材多点拉弯成形截面变形分析

- 1.吉林大学 材料科学与工程学院,长春 130022

2.吉林大学 汽车材料教育部重点实验室,长春 130022

3.吉林大学 重庆研究院,重庆 401123

Section deformation analysis of irregular Y-shaped aluminum profile of multi-point stretch-bending process

Yi LI1,2( ),Chen-yang LYU1,2,Ji-cai LIANG1,3,Ce LIANG1,2(

),Chen-yang LYU1,2,Ji-cai LIANG1,3,Ce LIANG1,2( )

)

- 1.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

2.Key Laboratory of Automobile Materials,Ministry of Education,Jilin University,Changchun 130022,China

3.Chongqing Research Institute,Jilin University,Chongqing 401123,China

摘要:

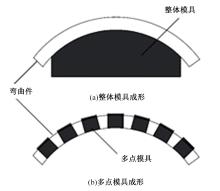

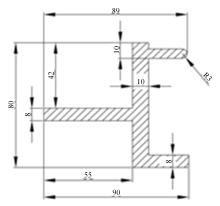

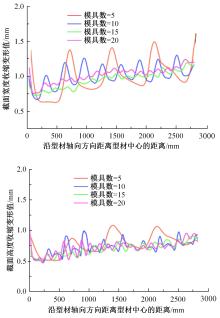

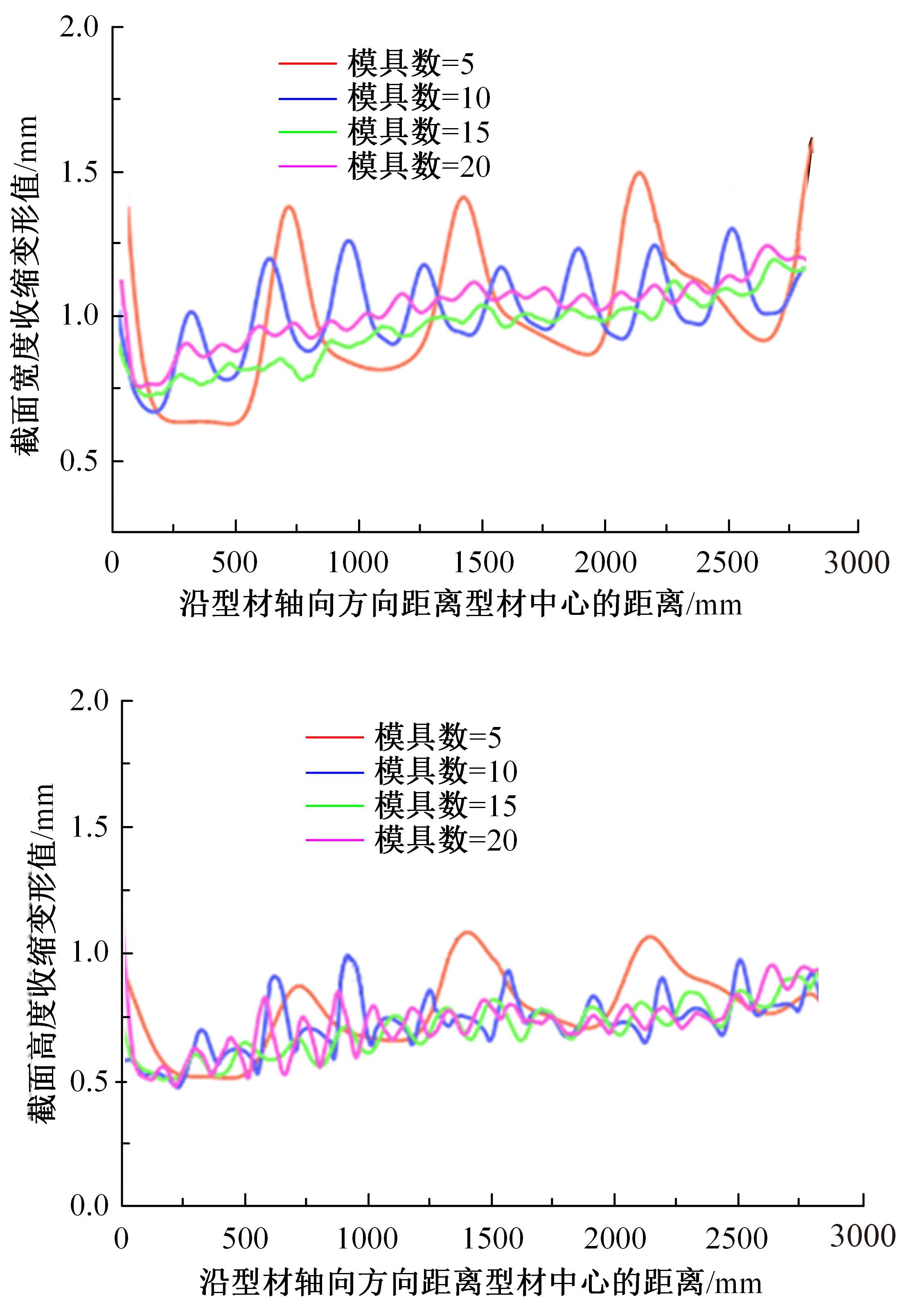

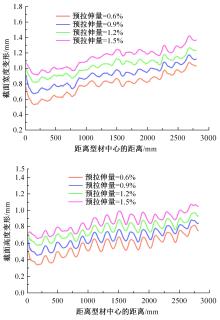

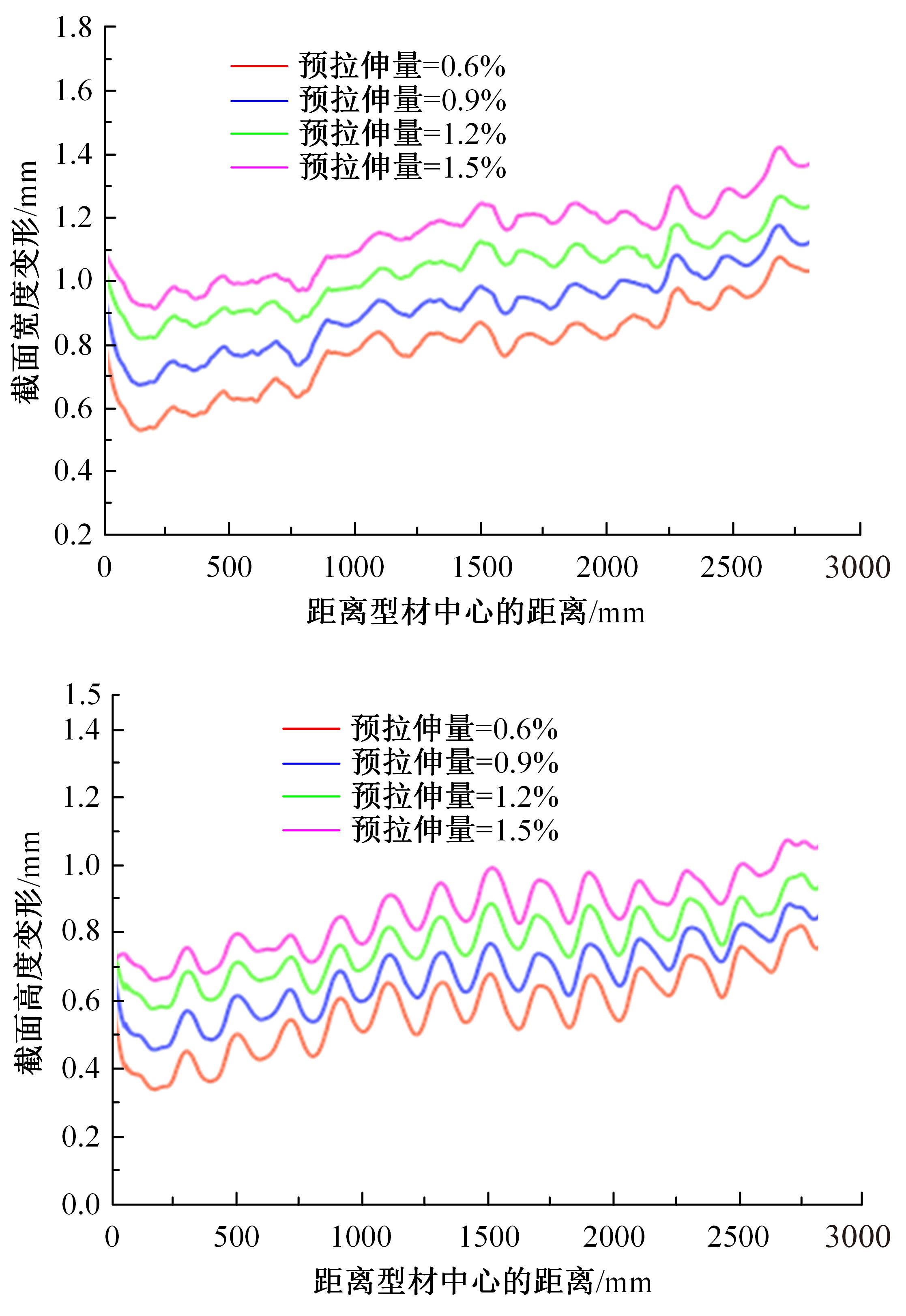

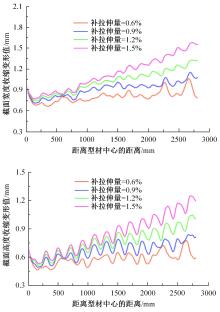

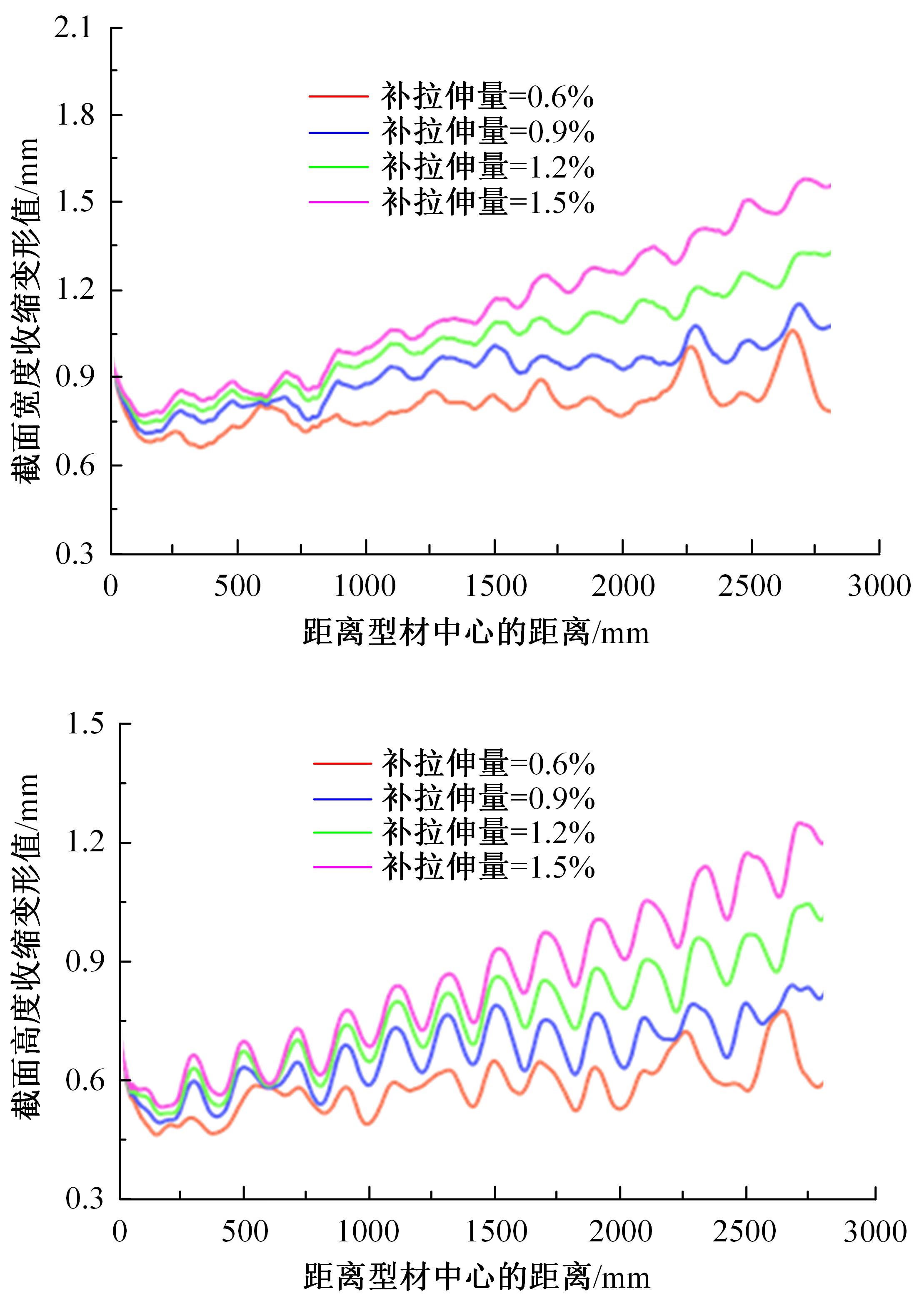

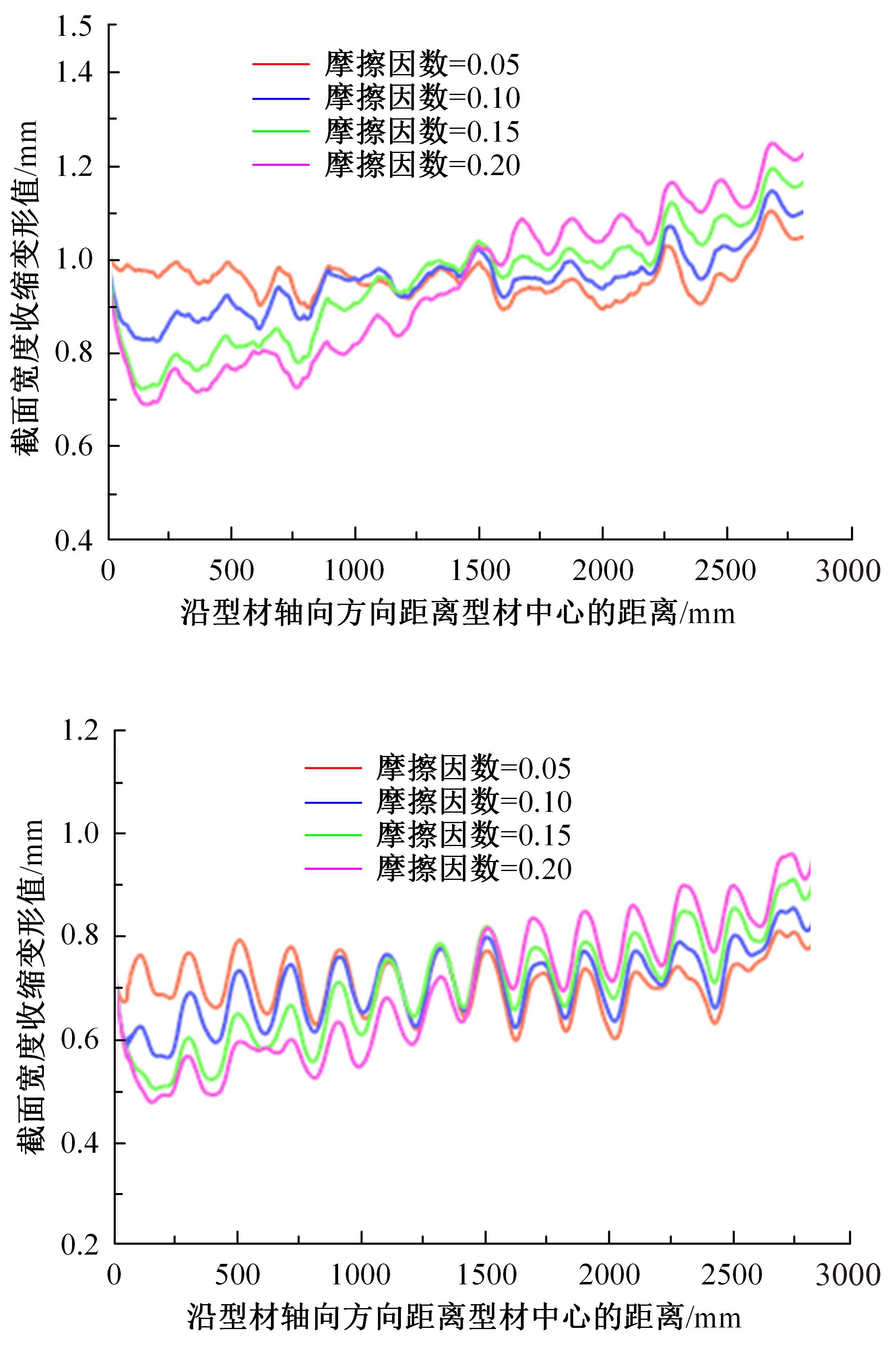

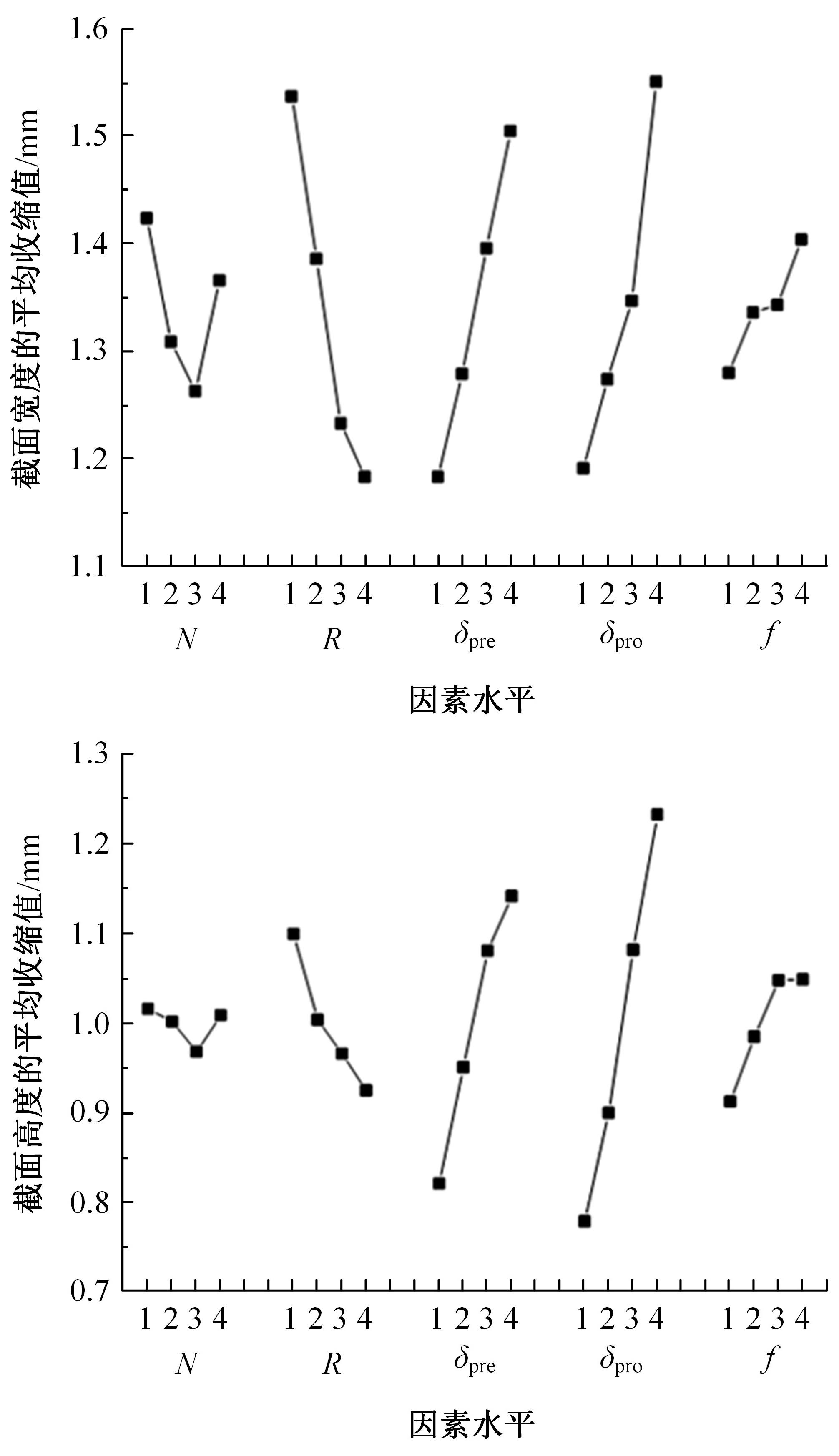

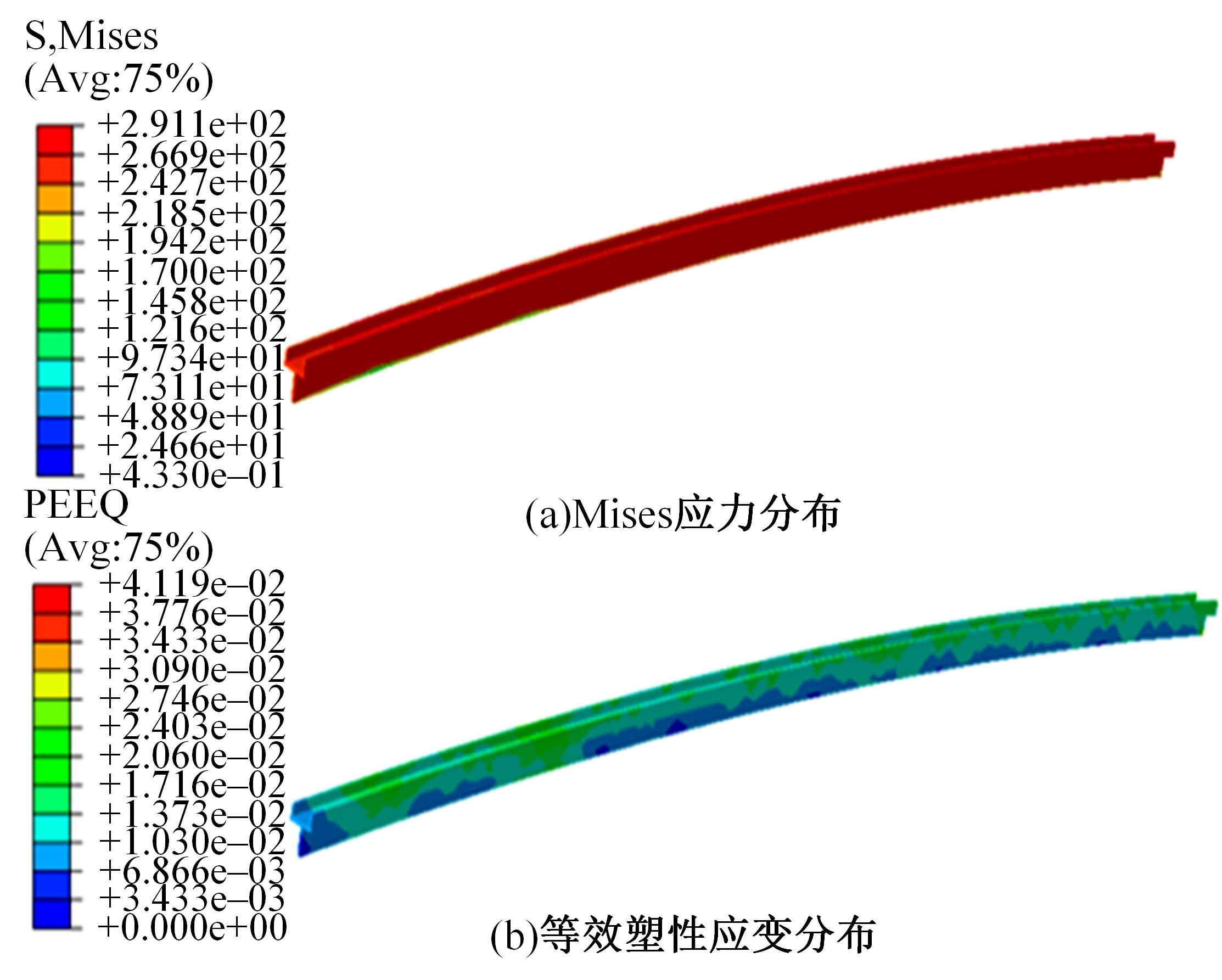

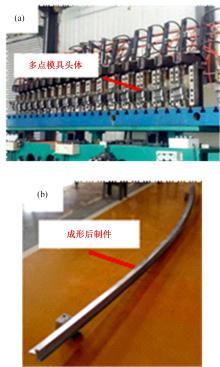

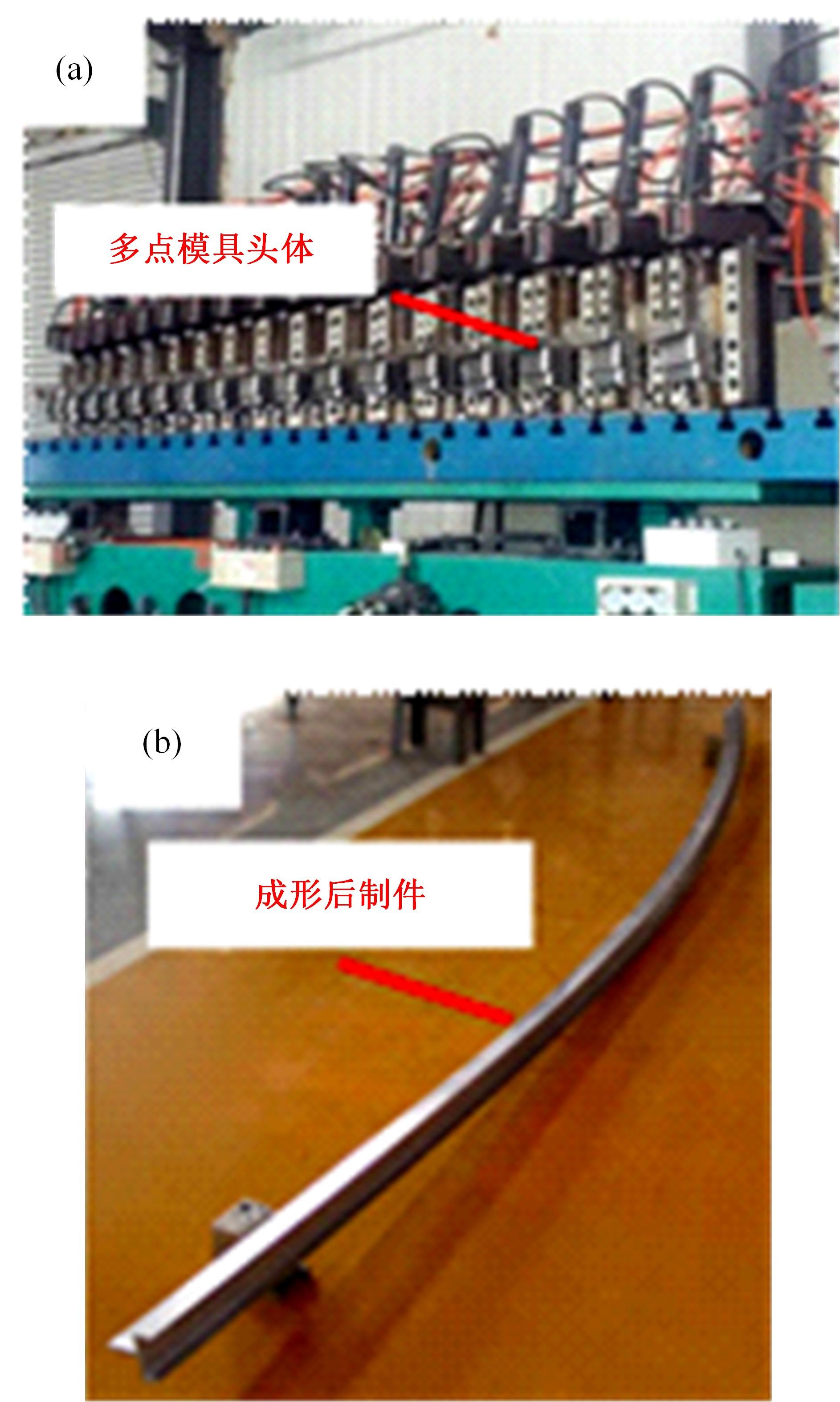

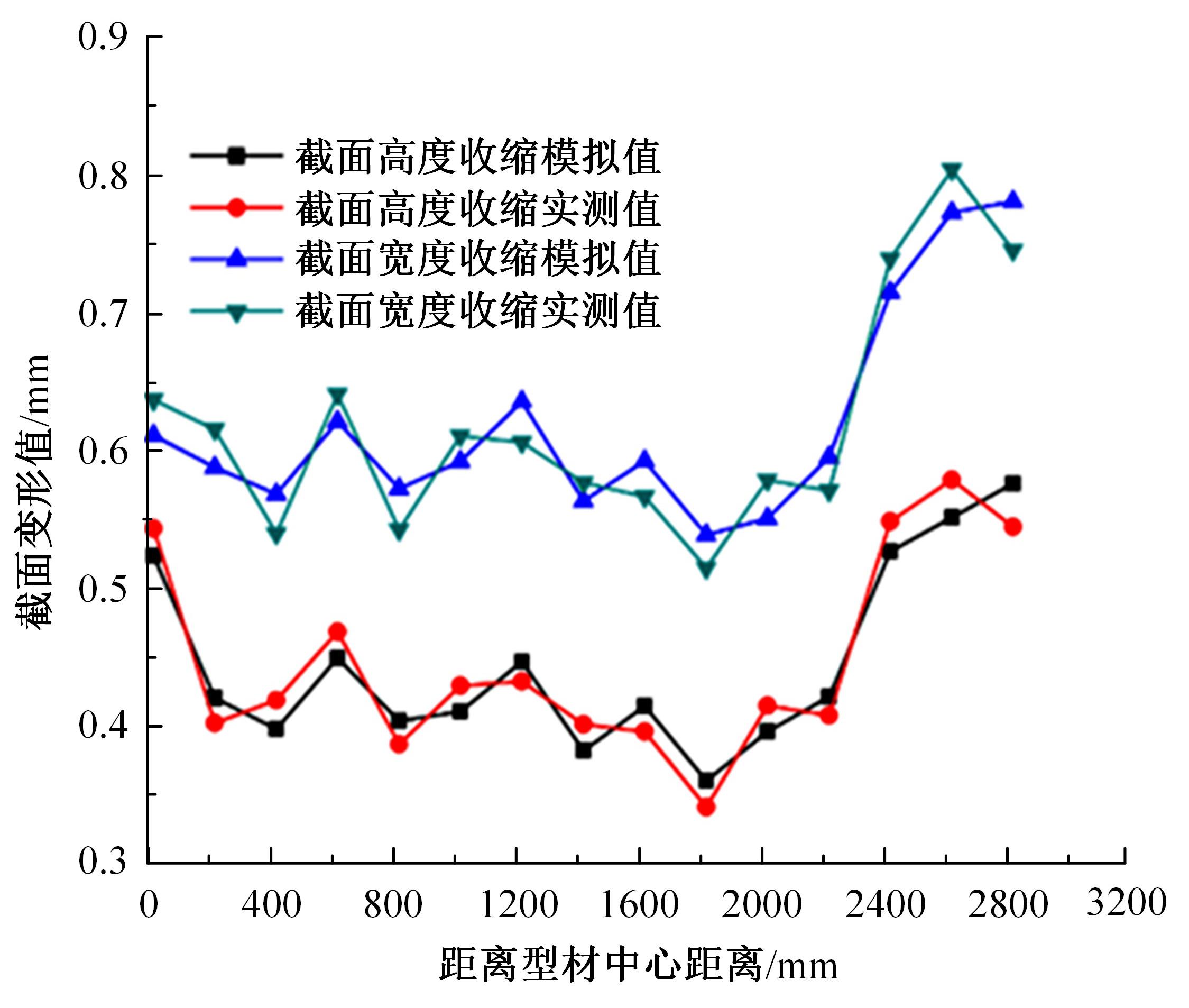

为了提高型材多点拉弯成形后的成形质量,基于ABAQUS有限元模拟了不规则Y形铝型材多点拉弯成形中截面变形规律。首先,通过控制变量法探究了不同工艺参数(模具数、弯曲半径、预拉伸量、补拉伸量和摩擦因数)对制件截面变形分布的影响规律。其次,为了综合考虑各工艺参数间的相互作用,结合正交试验分析进一步探究了各工艺参数对制件最大截面变形的影响程度。结果显示,补拉伸量变化时,截面宽度变形最大值为1.58 mm,最小值为1.06 mm,其变化幅度为49.1%;截面高度变形最大值为1.25 mm,最小值为0.77 mm,其变化幅度为62.3%,即补拉伸量对截面变形的影响最大。最后,综合分析后确定多点拉弯最优成形方案,并通过模拟和试验验证了该成形方案的可行性,从而极大地提高制件的成形质量。

中图分类号:

- TG356

| 1 | 李军,周佳,王利刚,等. 中国乘用车轻量化水平发展趋势研究[J]. 汽车工程学报, 2021, 11(5): 313-319, 362. |

| Li Jun, Zhou Jia, Wang Li-gang, et al. Research on the development trend of lightweight level of passenger cars in China[J]. Journal of Automotive Engineering, 2021, 11(5): 313-319, 362. | |

| 2 | 郑雪芹. 汽车新材料的应用及发展趋势[J]. 汽车纵横, 2021(11): 73-76. |

| Zheng Xue-qin. Application and development trend of new automotive materials[J]. Automotive Vertical and Horizontal, 2021(11): 73-76. | |

| 3 | 陈文博,屈闯,丁介然,等. 简述汽车用铝合金防护方式[J]. 汽车实用技术, 2021, 46(13): 202-204. |

| Chen Wen-bo, Qu Chuang, Ding Jie-ran,et al. Brief description of aluminum alloy protection methods for automobile[J]. Automobile Practical Technology, 2021, 46(13): 202-204. | |

| 4 | Li M Z, Cai Z Y, Sui Z, et al. Principle and applications of multi-point matched-die forming for sheet metal[J]. Journal of Engineering Manufacture, 2008, 222(5): 581-589. |

| 5 | Cai Z Y, Li M Z. Principle and theoretical analysis of continuous roll forming for three-dimensional surface parts[J]. Science China Technological Sciences, 2013, 56(2): 351-358. |

| 6 | 彭赫力,于亚平,李明哲,等. 大尺寸三维曲面件多点分段成形技术[J]. 锻压技术, 2018, 43(2): 29-33. |

| Peng He-li, Yu Ya-ping, Li Ming-zhe, et al. Multi-point segmented forming technology for large-size 3D curved parts[J]. Forging Technology, 2018, 43(2): 29-33. | |

| 7 | Li Y, Li R, Liang C, et al. Influence of the curvature of the multipoint die for flexible multipoint stretch bending on the quality of aluminum profile[J]. Mathematical Problems in Engineering, 2020(1):1-9. |

| 8 | 郝涛涛. 非对称截面型材拉弯成形数值模拟研究[J]. 机械制造, 2014, 52(6): 40-42. |

| Hao Tao-tao. Numerical simulation of stretch bending of asymmetric section profiles[J]. Mechanical Manufacturing, 2014, 52(6): 40-42. | |

| 9 | Gu Z W, Lv M M, Li X, et al. Stretch bending defects control of L-section aluminum components with variable curvatures[J]. The International Journal of Advanced Manufacturing Technology, 2016, 85(5-8): 1053-1061. |

| 10 | Gu Z W, Lv M M, Li X, et al. Stretch bending of Z-section stainless steel profile[J]. Journal of Iron and Steel Research International, 2016, 23(6): 525-530. |

| 11 | Gu Z W, Lv M M, Li X, et al. Stretch bending defect control of L-section SUS301L stainless-steel components with variable contour curvatures[J]. Journal of Iron and Steel Research International, 2019, 26(12): 1376-1384. |

| 12 | Liang K F, Chen Z Z, Wang S M, et al. Finite element simulation and respond surface optimization on stretch bending of square tube aluminum profile[J]. Advanced Materials Research, 2012, 365: 28-32. |

| 13 | 高嵩,梁继才,滕菲,等. 柔性三维拉弯成形零件的形状控制[J]. 华南理工大学学报:自然科学版, 2014, 42(9): 53-58. |

| Gao Song, Liang Ji-cai, Teng Fei,et al. Shape control of flexible 3D stretch bending parts[J]. Journal of South China University of Technology(Natural Science Edition), 2014, 42(9): 53-58. | |

| 14 | Liang J C, Liao Y F, Li Y, et al. Study on the influence of bending angle of multipoint stretch-bending of profiles on section distortion of parts[J]. Mathematical Problems in Engineering, 2020(1):1-11. |

| 15 | Chen C D, Liang J C, Li Y, et al. Effect of discrete roller dies on the contour accuracy of profiles in multi-point flexible stretch-bending forming[J]. The International Journal of Advanced Manufacturing Technology, 2021, 113(7): 1959-1971. |

| 16 | 李义,梁继才,滕菲,等. 型材多点拉弯成形模具型面的分段补偿迭代方法[J]. 吉林大学学报:工学版, 2016,46(6): 1961-1966. |

| Li Yi, Liang Ji-cai, Teng Fei,et al. Sectional compensation iterative method for die surface of profile multi-point stretch bending[J]. Journal of Jilin University(Engineering and Technology Edition), 2016,46(6): 1961-1966. |

| [1] | 梁策,黄富雷,梁继才,李义. 日字形防护梁绕弯成形形变数值模拟[J]. 吉林大学学报(工学版), 2023, 53(12): 3397-3403. |

| [2] | 李建平,边永亮,杨欣,王鹏飞,李昕昊,薛春林. 果园多风机风送喷雾机作业参数优化与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2474-2485. |

| [3] | 金文明,梁田,梁策,李义,李俊涛,梁继才. 工艺参数对汽车防护梁绕弯成形的截面变形影响[J]. 吉林大学学报(工学版), 2021, 51(4): 1182-1189. |

| [4] | 钱志辉, 周亮, 任雷, 任露泉. 具有仿生距下关节和跖趾关节的完全被动步行机[J]. 吉林大学学报(工学版), 2018, 48(1): 205-211. |

| [5] | 孙博华, 邓伟文, 朱冰, 吴坚, 王姗姗. 基于反应式行为的车辆运动意图辨识[J]. 吉林大学学报(工学版), 2018, 48(1): 36-43. |

| [6] | 谷诤巍, 吕萌萌, 张文学, 雷娇娇, 徐虹. 中国标准动车组前端三维蒙皮件冲压成形[J]. 吉林大学学报(工学版), 2017, 47(3): 869-875. |

| [7] | 梁继才, 李义, 高嵩, 滕菲. 型材多点柔性拉弯成形回弹预测[J]. 吉林大学学报(工学版), 2017, 47(1): 185-190. |

| [8] | 李义, 梁继才, 滕菲, 梁策, 于佳奇. 型材多点拉弯成形模具型面的分段补偿迭代方法[J]. 吉林大学学报(工学版), 2016, 46(6): 1961-1966. |

| [9] | 张泽星, 陈国迎, 宗长富. 基于灵敏度分析的EPS转向性能试验客观评价指标[J]. 吉林大学学报(工学版), 2015, 45(4): 1043-1048. |

| [10] | 齐龙, 谭祖庭, 马旭, 陈国锐, 谢俊锋, 邝健霞. 气动振动式匀种装置工作参数的优化及试验[J]. 吉林大学学报(工学版), 2014, 44(6): 1684-1691. |

| [11] | 刘东雷, 申长雨, 刘春太, 辛勇, 孙玲. 工艺参数对高光注射成型制品翘曲的宏观影响 [J]. , 2012, (03): 665-671. |

| [12] | 董立春1,韩志武2,吕尤2,牛士超2,马荣峰2,任露泉2. 凹坑型仿生形态环块样件耐磨性能[J]. 吉林大学学报(工学版), 2011, 41(6): 1659-1663. |

| [13] | 韦大川, 王云鹏, 李世武, 孙文财, 杨志发. 橡胶粉/SBS复合改性沥青吸声系数试验[J]. 吉林大学学报(工学版), 2010, 40(增刊): 199-0203. |

| [14] | 任丽丽, 周江, 佟金. 烯基琥珀酸酐表面改性淀粉膜羟基取代度的影响因素[J]. 吉林大学学报(工学版), 2010, 40(06): 1624-1628. |

| [15] | 高峰;黄河;任露泉 . 新疆岩蜥三元耦合耐冲蚀磨损特性及其仿生试验[J]. 吉林大学学报(工学版), 2008, 38(03): 586-0590. |

|

||