吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (3): 641-649.doi: 10.13229/j.cnki.jdxbgxb.20220563

• 车辆工程·机械工程 • 上一篇

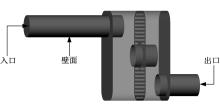

基于喷雾冷却的发动机排气系统减阻

张成春1,2( ),辛振涛1,2,于海3(

),辛振涛1,2,于海3( ),吴玉峰4,孙潇伟1,2,杜天宇1,2

),吴玉峰4,孙潇伟1,2,杜天宇1,2

- 1.吉林大学 工程仿生教育部重点实验室, 长春 130022

2.吉林大学 威海仿生研究院, 山东 威海 264402

3.威海市科技创新与发展中心, 山东 威海 264200

4.中国北方车辆研究所, 北京 100086

Drag reduction of engine exhaust system based on spray cooling

Cheng-chun ZHANG1,2( ),Zhen-tao XIN1,2,Hai YU3(

),Zhen-tao XIN1,2,Hai YU3( ),Yu-feng WU4,Xiao-wei SUN1,2,Tian-yu DU1,2

),Yu-feng WU4,Xiao-wei SUN1,2,Tian-yu DU1,2

- 1.Key Laboratory of Bionic Engineering,Ministry of Education,Jilin University,Changchun 130022,China

2.Weihai Institute for Bionics,Jilin University,Weihai 264402,China

3.WeiHai Science and Technology Innovation and Development Center,Weihai 264200,China

4.China North Vehicle Research Institute,Bejing 100086,China

摘要:

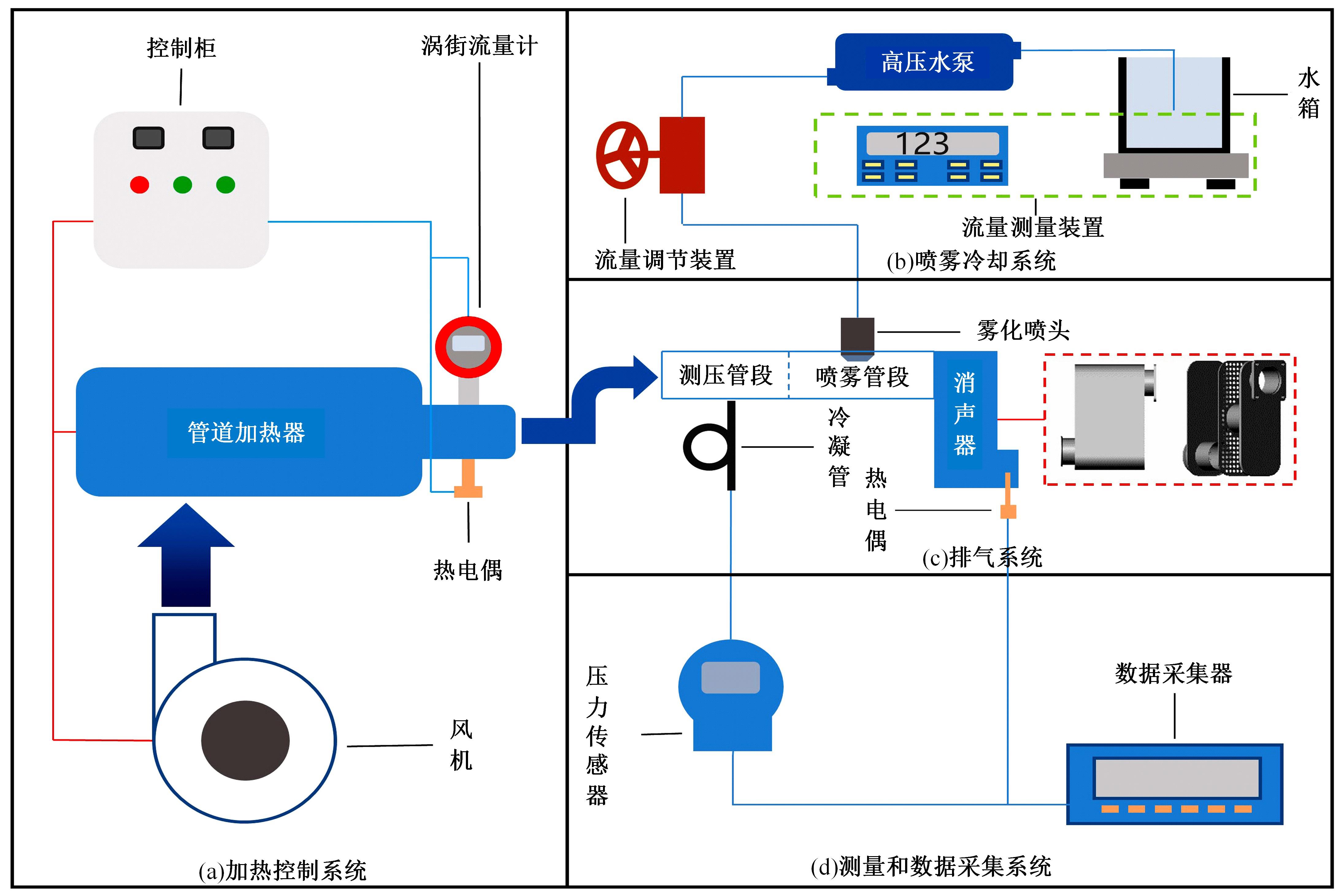

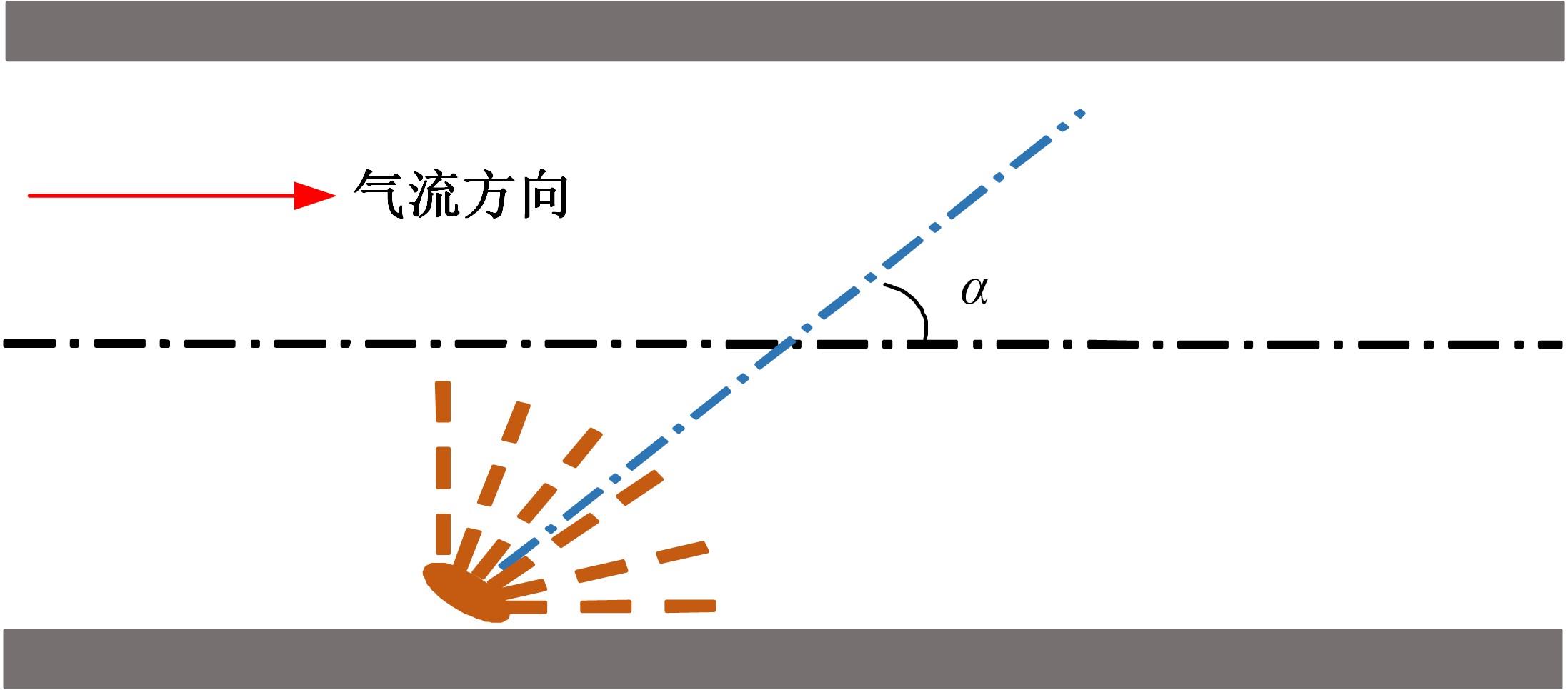

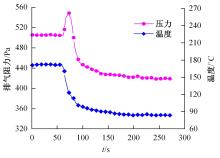

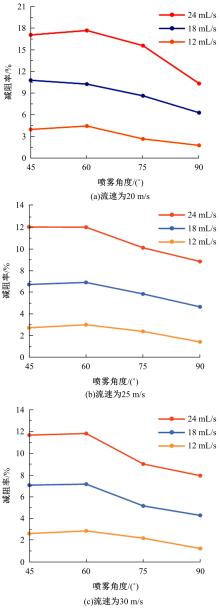

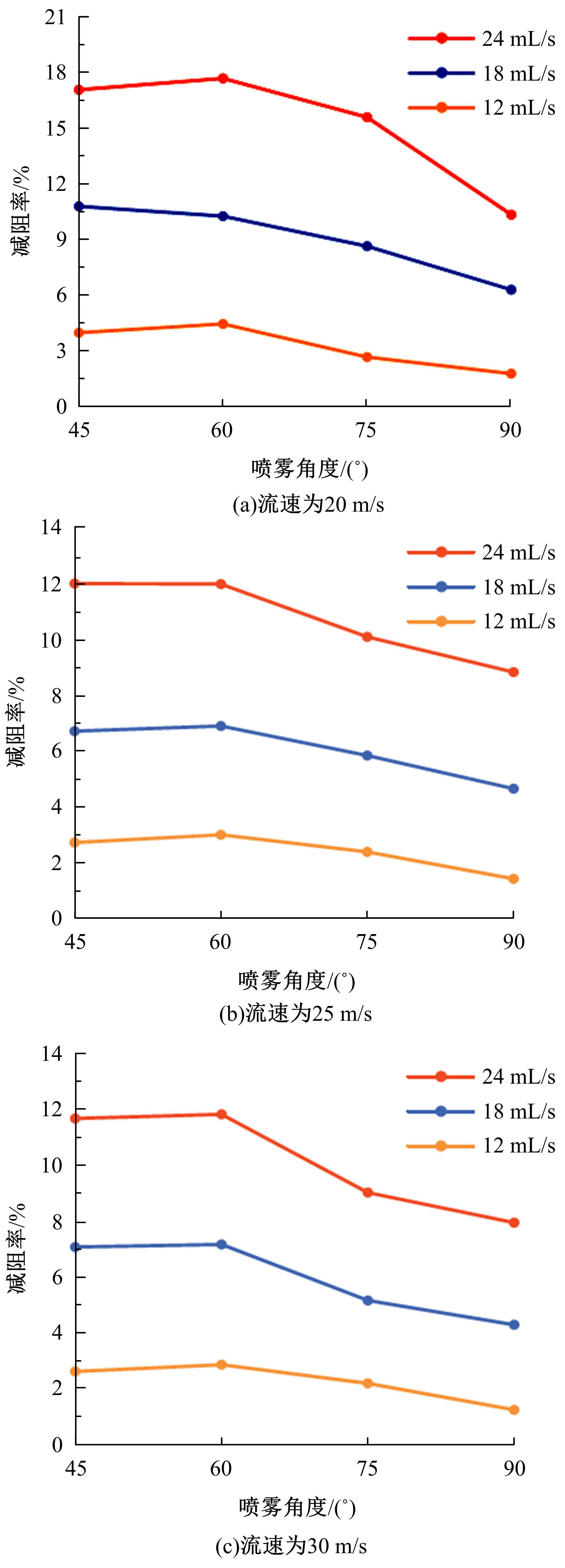

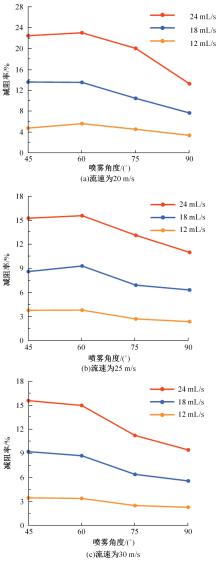

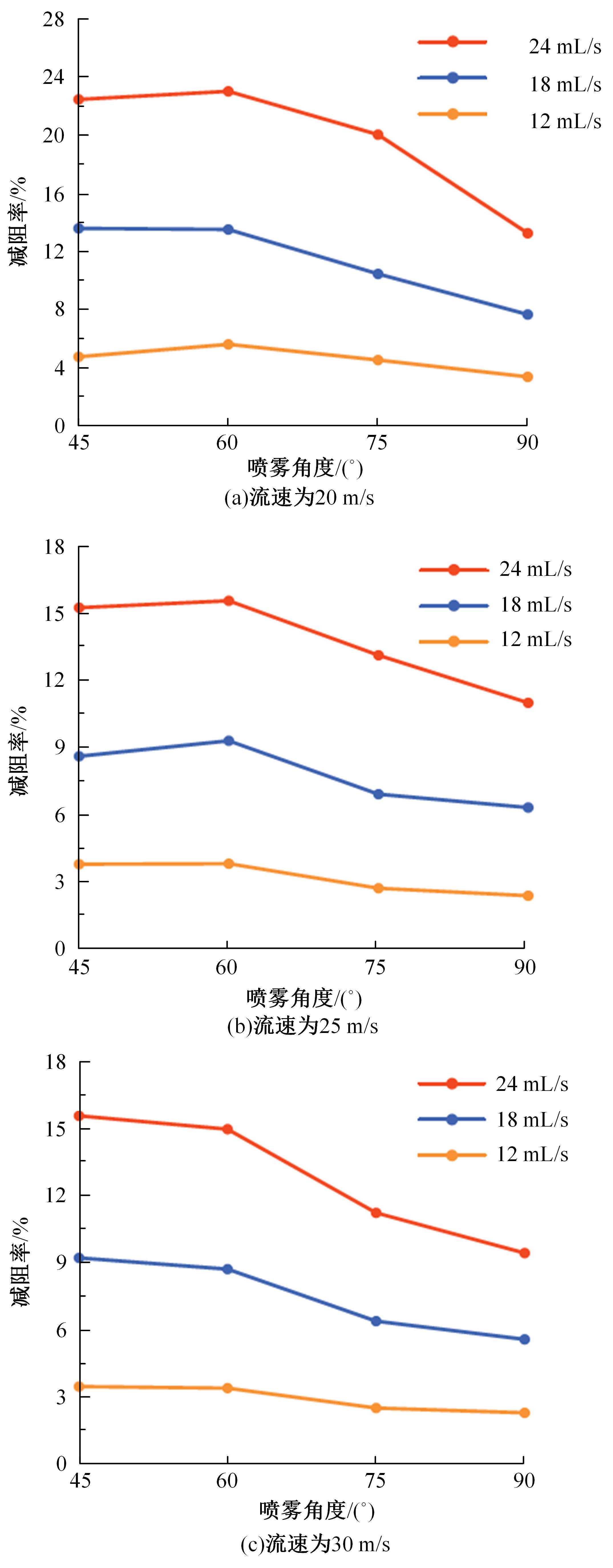

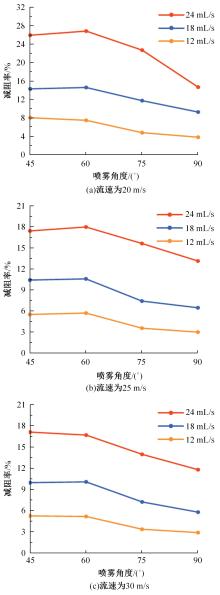

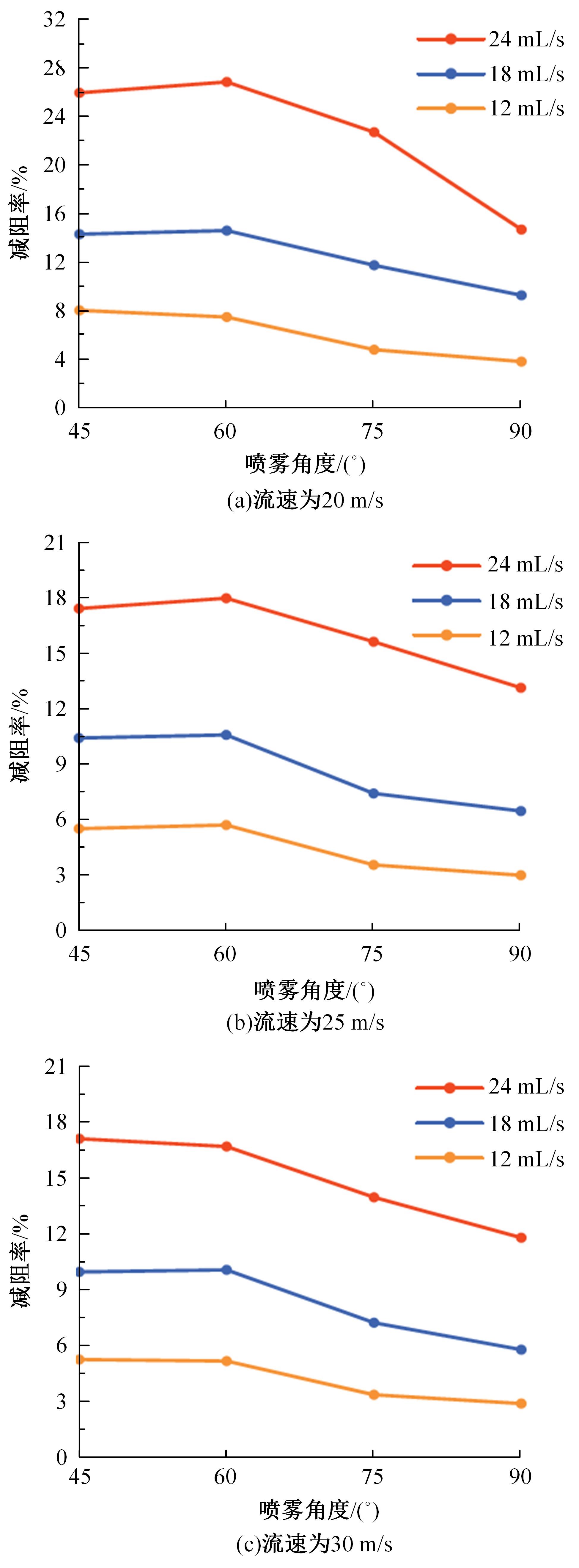

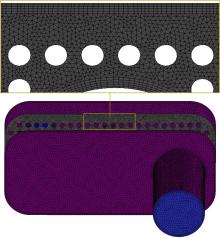

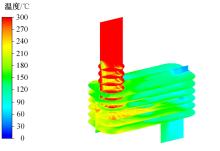

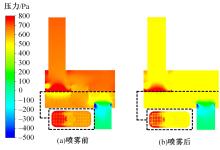

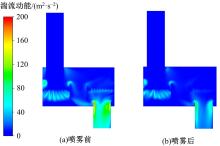

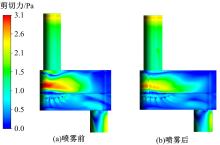

采用电加热喷雾冷却减阻试验台,系统研究了喷雾流量、喷雾倾角、气流温度、气流速度影响发动机排气系统减阻性能的规律;采用基于离散相模型(DPM)的数值模拟,阐释了喷雾冷却大幅降低排气阻力的原因。研究结果表明:喷雾流量为12~24 mL/s时,减阻率随喷雾流量的增加而增大;喷雾倾角由45°增加至90°时,减阻率先保持不变后减小,45°和60°喷雾倾角时的减阻效果均为最佳;气流温度为200~300 ℃时,随着气流温度的升高,减阻率呈增大趋势;气流速度由20 m/s增大至30 m/s时,减阻率逐渐下降。排气系统喷雾后阻力大幅度减小的原因是喷雾后气流速度降低,湍流强度降低,局部阻力和摩擦阻力显著减小。

中图分类号:

- V228.7

| 1 | Ma Ze-tai, Gu Yun-cheng, Zhu Si-peng, et al. Analysis on capability of power recovery of marine diesel engine at high backpressure conditions[J]. Applied Thermal Engineering, 2022, 204: No. 117933. |

| 2 | Ebrahimnataj M R, Tiji A E, Eisapour M, et al. The effect of soot accumulation and backpressure of an integrated after-treatment system on diesel engine performance[J]. Journal of Thermal Analysis and Calorimetry, 2021, 147: 8435-8443. |

| 3 | Sapra H, Godjevac M, Visser K, et al. Experimental and simulation-based investigations of marine diesel engine performance against static back pressure[J]. Applied Energy, 2017, 204: 78-92. |

| 4 | Dziubak T, Boruta G. Experimental and theoretical research on pressure drop changes in a two-stage air filter used in tracked vehicle engine[J]. Separations, 2021, 8(6): No.71. |

| 5 | Sivaram A R, Rajavel R, Jayakumar N, et al. Exhaust back pressure effect on the performance features of a diesel engine[J]. ARPN Journal of Engineering and Applied Sciences, 2017, 12: 5353-5356. |

| 6 | Xin Zhe, Wang Shunxi, Zhang Yin, et al. Pressure loss of urea-SCR converter and its influence on diesel engine performance[J]. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27(8): 169-173. |

| 7 | Shabnam R A. Geometry mediated drag reduction using riblets and wrinkled surface textures[D]. Cambridge: Massachusetts Institute of Technology, 2018. |

| 8 | Rong Wan-ting, Zhang Hai-feng, Mao Zhi-gang, et al. Stable drag reduction of anisotropic superhydrophobic/hydrophilic surfaces containing bioinspired micro/nanostructured arrays by laser ablation[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2021, 622: No. 126712. |

| 9 | 许浩然. 形状、结构耦元对排气管减阻性能影响 [D]. 长春:吉林大学材料科学与工程学院,2015. |

| Xu Hao-ran. Influence of shape and structure coupling elements on drag reduction performance of exhaust pipe[D]. Changchun: School of Materials Science and Engineering, Jilin University, 2015. | |

| 10 | Xu Jian-min, Zhou Shui-ting, Li Kun-sheng. Analysis of flow field and pressure loss for fork truck muffler based on the finite volume method[J]. International Journal of Heat and Technology, 2015, 33(3): 85-90. |

| 11 | Pangavhane S D, Ubale A, Tandon V, et al. Experimental and CFD analysis of a perforated inner pipe muffler for the prediction of backpressure[J]. International Journal of Engineering & Technology, 2013, 5(5): 115-119. |

| 12 | Lee S J, Jang Y G. Control of flow around a NACA 0012 airfoil with a micro-riblet film[J]. Journal of Fluids and Structures, 2005, 20(5): 659-672. |

| 13 | Viswanath P R. Aircraft viscous drag reduction using riblets[J]. Progress in Aerospace Sciences, 2002, 38(6/7): 571-600. |

| 14 | 田丽梅, 王养俊, 李子源, 等. 仿生功能表面内流减阻测试系统的研制[J]. 吉林大学学报: 工学版, 2017, 47(4): 1179-1184. |

| Tian Li-mei, Wang Yang-jun, Li Zi-yuan, et al. Development of drag-reduction test system of bionic functional surfaces with internal flow[J]. Journal of Jilin University (Engineering and Technology Edition), 2017, 47(4): 1179-1184. | |

| 15 | Liu Gui-jie, Yuan Zi-chao, Qiu Zhao-zun, et al. A brief review of bio-inspired surface technology and application toward underwater drag reduction[J]. Ocean Engineering, 2020, 199: No. 106962. |

| 16 | Tian Gui-zhong, Zhang Yao-sheng, Feng Xiao-ming, et al. Focus on bioinspired textured surfaces toward fluid drag reduction: recent progresses and challenges[J]. Advanced Engineering Materials, 2022, 24(1): No. 2100696. |

| 17 | Prajapati V D, Desai A J. Design and analysis of automotive muffler[J]. International Journal of Engineering Research & Technology (IJERT), 2016, 5(5): 384-389. |

| 18 | Sayinci B. Effect of strainer type, spray pressure, and orifice size on the discharge coefficient of standard flat-fan nozzles[J]. Turkish Journal of Agriculture and Forestry, 2015, 39(5): 692-704. |

| 19 | Payri R, Bracho G, Gimeno J, et al. Investigation of the urea-water solution atomization process in engine exhaust-like conditions[J]. Experimental Thermal and Fluid Science, 2019, 108: 75-84. |

| 20 | Zhang Hai-bin, Bai Bo-feng, Liu Li, et al. Droplet dispersion characteristics of the hollow cone sprays in crossflow[J]. Experimental Thermal and Fluid Science, 2013, 45: 25-33. |

| 21 | Sun Y B, Guan Z Q, Hal G, et al. Investigation on the influence of injection direction on the spray cooling performance in natural draft dry cooling tower[J]. International Journal of Heat and Mass Transfer, 2017, 110: 113-131. |

| 22 | Gao Ran, Liu Kai-kai, Li An-gui, et al. Biomimetic duct tee for reducing the local resistance of a ventilation and air-conditioning system[J]. Building and Environment, 2018, 129: 130-141. |

| 23 | Eggels J G M, Unger F, Weiss M H, et al. Fully developed turbulent pipe flow: a comparison between direct numerical simulation and experiment[J]. Journal of Fluid Mechanics, 1994, 268: 175-210. |

| 24 | Paul D. Advanced Approaches in Turbulence[M]. Netherlands: Elsevier, 2021: 161-241. |

| [1] | 张英朝,李昀航,郭子瑜,王国华,张喆,苏畅. 长头重型卡车气动减阻优化[J]. 吉林大学学报(工学版), 2022, 52(4): 745-753. |

| [2] | 胡兴军,张靖龙,罗雨霏,辛俐,李胜,胡金蕊,兰巍. 冷却管结构及进气方向对空冷中冷器性能的影响[J]. 吉林大学学报(工学版), 2021, 51(6): 1933-1942. |

| [3] | 张斌,程国赞,洪昊岑,赵春晓,杨华勇. 基于计算流体仿真的双作用叶片泵气蚀机理分析[J]. 吉林大学学报(工学版), 2021, 51(3): 831-839. |

| [4] | 陈鑫,阮新建,李铭,王宁,王佳宁,潘凯旋. 基于大涡模拟的离散格式改进方法及应用[J]. 吉林大学学报(工学版), 2019, 49(6): 1756-1763. |

| [5] | 施卫平,赵旭,胡兴军,余天明,柳博文,段彦. 天然气开采阻水装置AICD的设计和数值模拟[J]. 吉林大学学报(工学版), 2019, 49(6): 1986-1991. |

| [6] | 胡兴军,惠政,郭鹏,张扬辉,张靖龙,王靖宇,刘飞. 基于流固耦合的汽车气动特性[J]. 吉林大学学报(工学版), 2019, 49(5): 1414-1419. |

| [7] | 孙正, 黄钰期, 俞小莉. 径向滑动轴承润滑油膜流动-传热过程仿真[J]. 吉林大学学报(工学版), 2018, 48(3): 744-751. |

| [8] | 田丽梅, 王养俊, 李子源, 商延赓. 仿生功能表面内流减阻测试系统的研制[J]. 吉林大学学报(工学版), 2017, 47(4): 1179-1184. |

| [9] | 赵刚, 李照远, 赵华兴, 饶宇, 李芳, 刘文博. 外旋立式射流减阻测试平台研制及实验[J]. 吉林大学学报(工学版), 2016, 46(4): 1175-1181. |

| [10] | 李芳, 赵刚, 刘维新, 孙壮志. 多孔仿生射流表面减阻特性数值模拟[J]. 吉林大学学报(工学版), 2014, 44(6): 1698-1703. |

| [11] | 韦甘, 杨志刚, 李启良. 基于分步遗传算法的车身气动优化[J]. 吉林大学学报(工学版), 2014, 44(6): 1578-1582. |

| [12] | 田丽梅, 商震, 胡国梁, 李楠. 基于形态仿生的轿车升阻特性的数值模拟[J]. 吉林大学学报(工学版), 2014, 44(5): 1283-1289. |

| [13] | 刘光洁, 徐涛, 李俊楼, 于征磊, 修航, 程飞. 燃气轮机过渡段双腔室模型设计及优化[J]. 吉林大学学报(工学版), 2014, 44(5): 1360-1365. |

| [14] | 王骥月,丛茜,齐欣,张琰. 基于蝉口针形态的仿生针头结构优化设计及减阻机理分析[J]. 吉林大学学报(工学版), 2014, 44(3): 696-700. |

| [15] | 田丽梅, 高志桦, 王银慈, 任露泉, 商震. 形态/柔性材料二元仿生耦合增效减阻功能表面的设计与试验[J]. 吉林大学学报(工学版), 2013, 43(04): 970-975. |

|

||