吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (4): 745-753.doi: 10.13229/j.cnki.jdxbgxb20200931

• 车辆工程·机械工程 • 上一篇

长头重型卡车气动减阻优化

- 吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Optimization of the aerodynamic drag reduction of a cab behind engine vehicle

Ying-chao ZHANG( ),Yun-hang LI,Zi-yu GUO,Guo-hua WANG,Zhe ZHANG(

),Yun-hang LI,Zi-yu GUO,Guo-hua WANG,Zhe ZHANG( ),Chang SU

),Chang SU

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

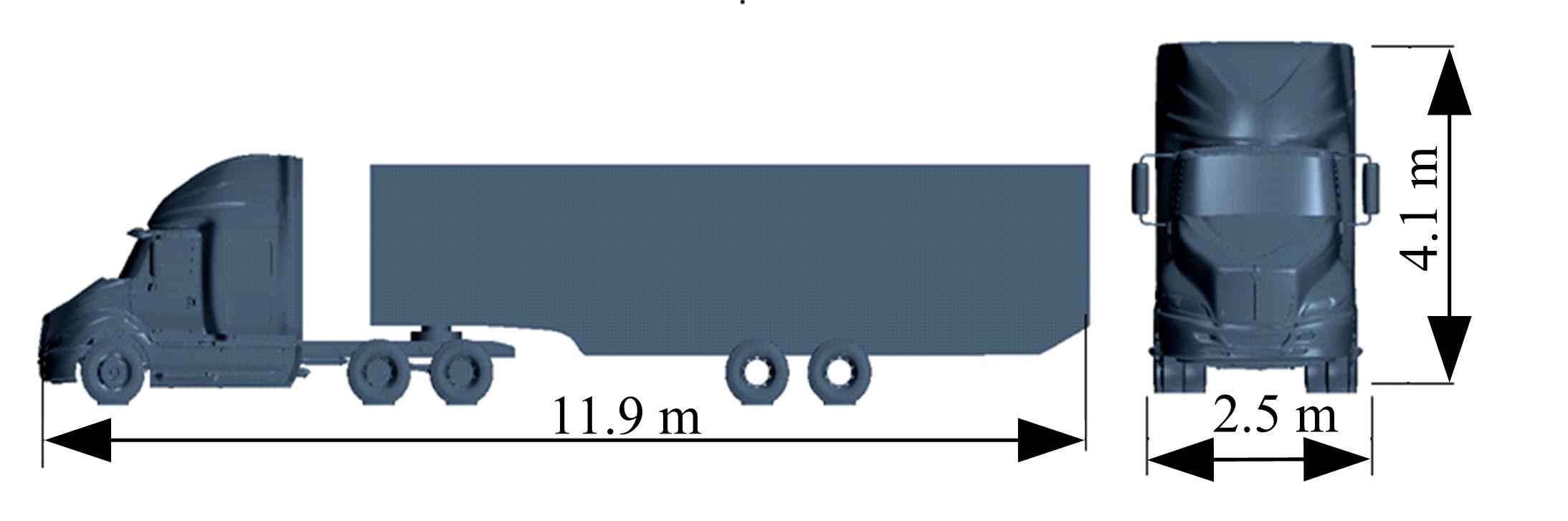

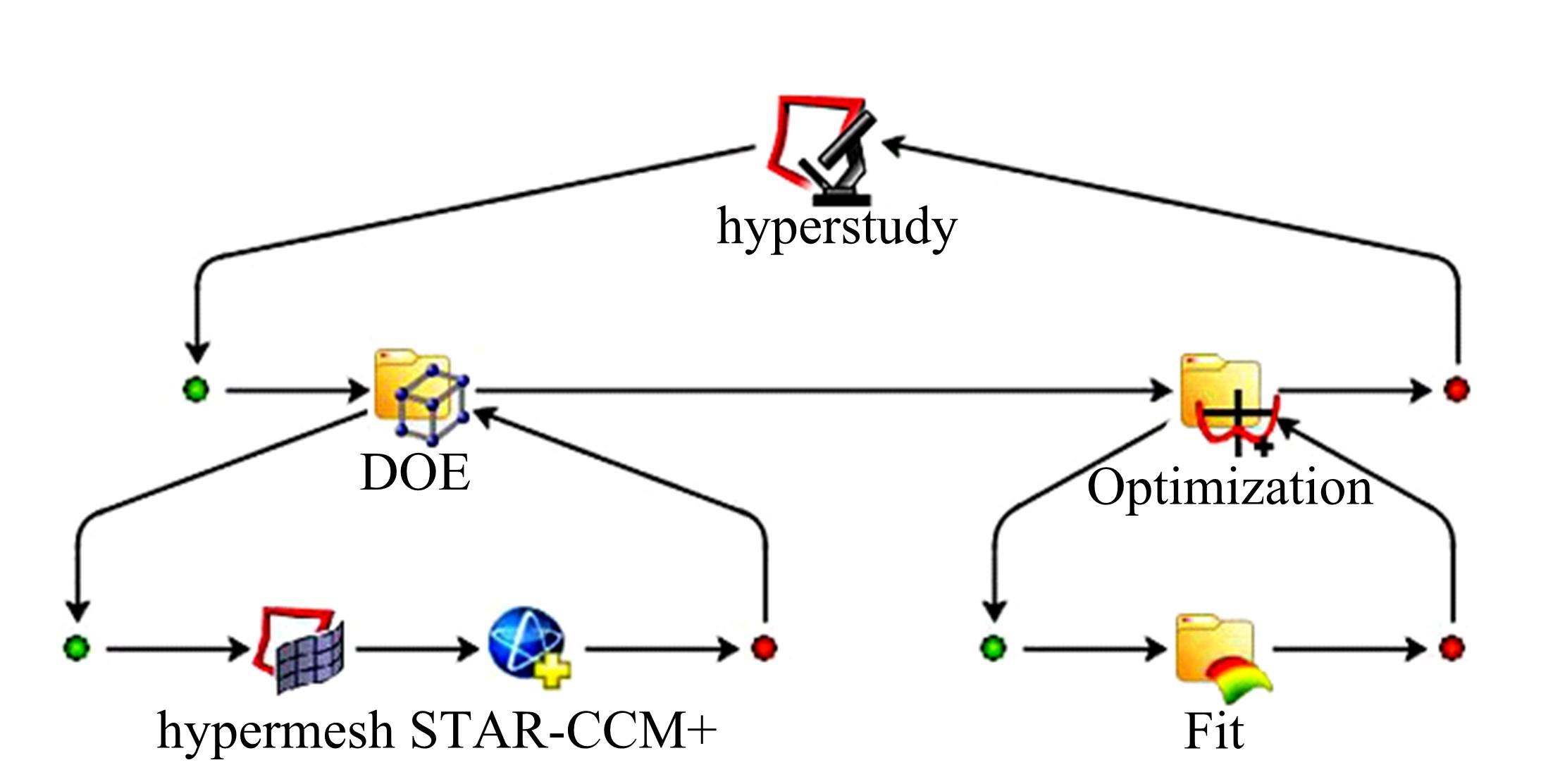

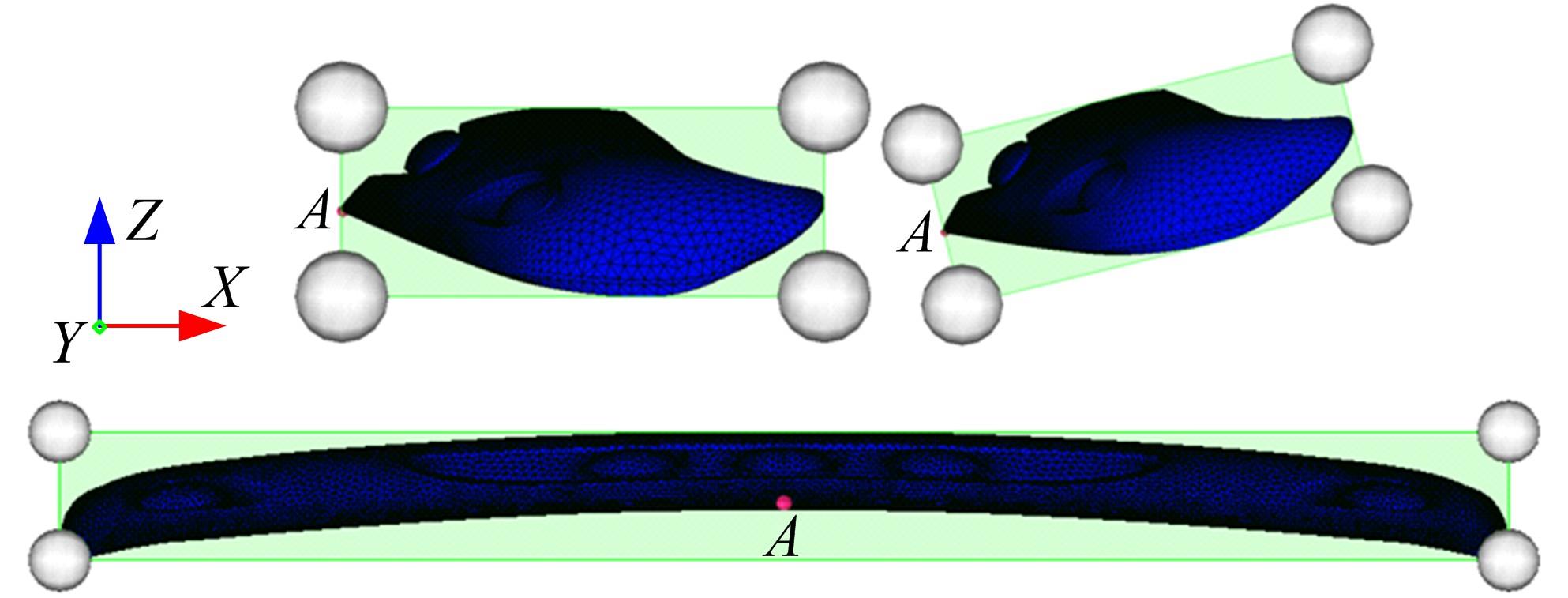

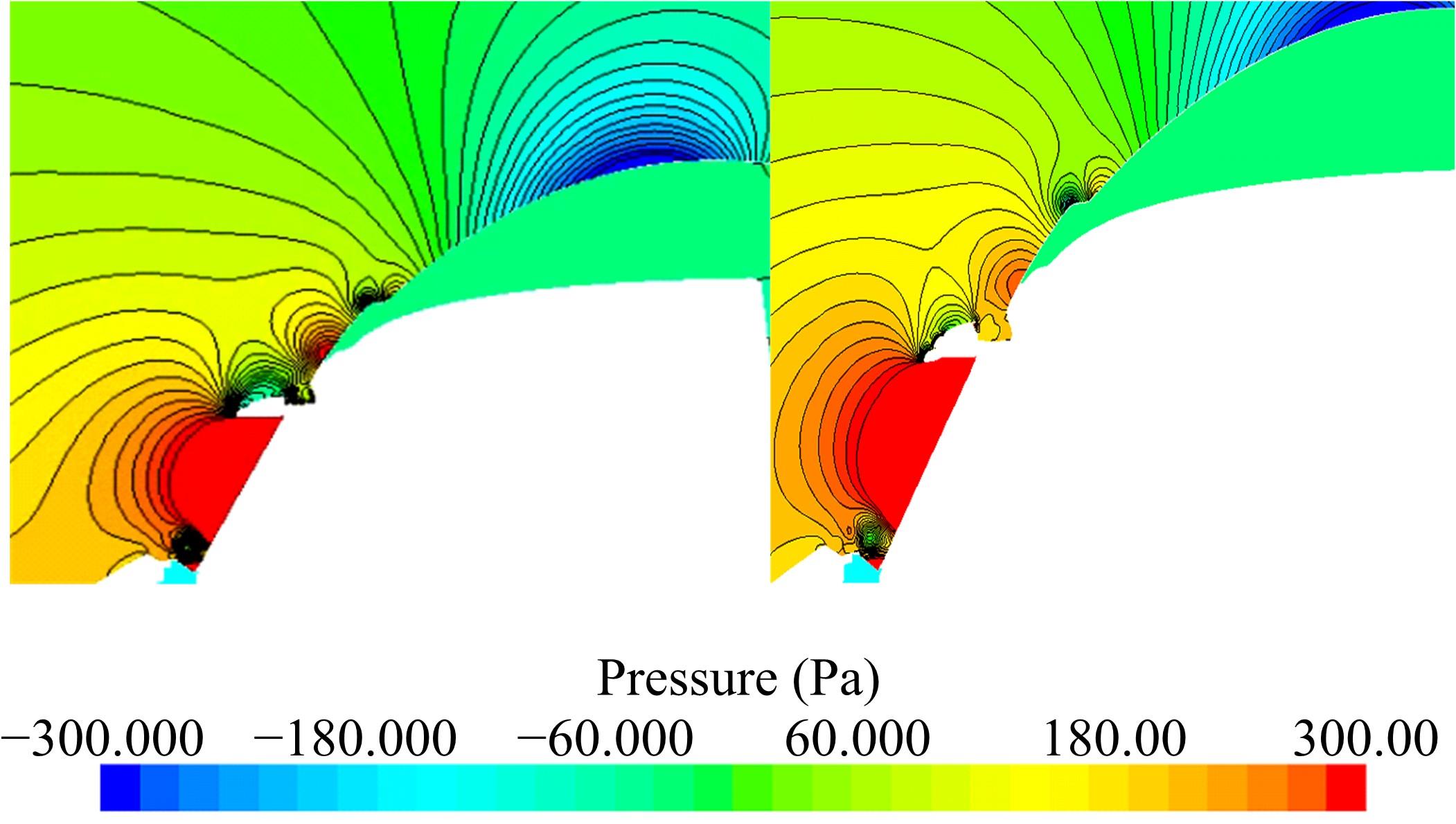

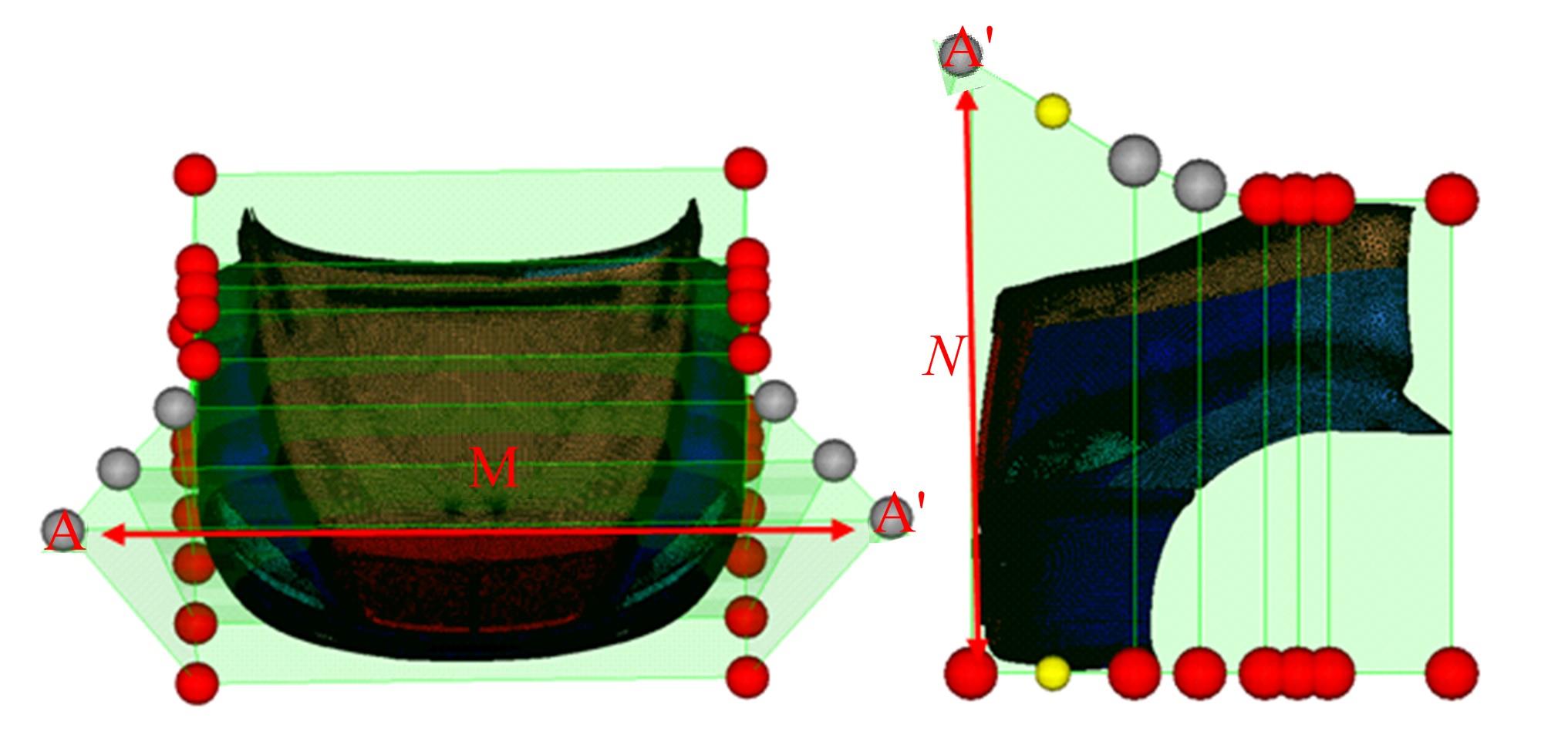

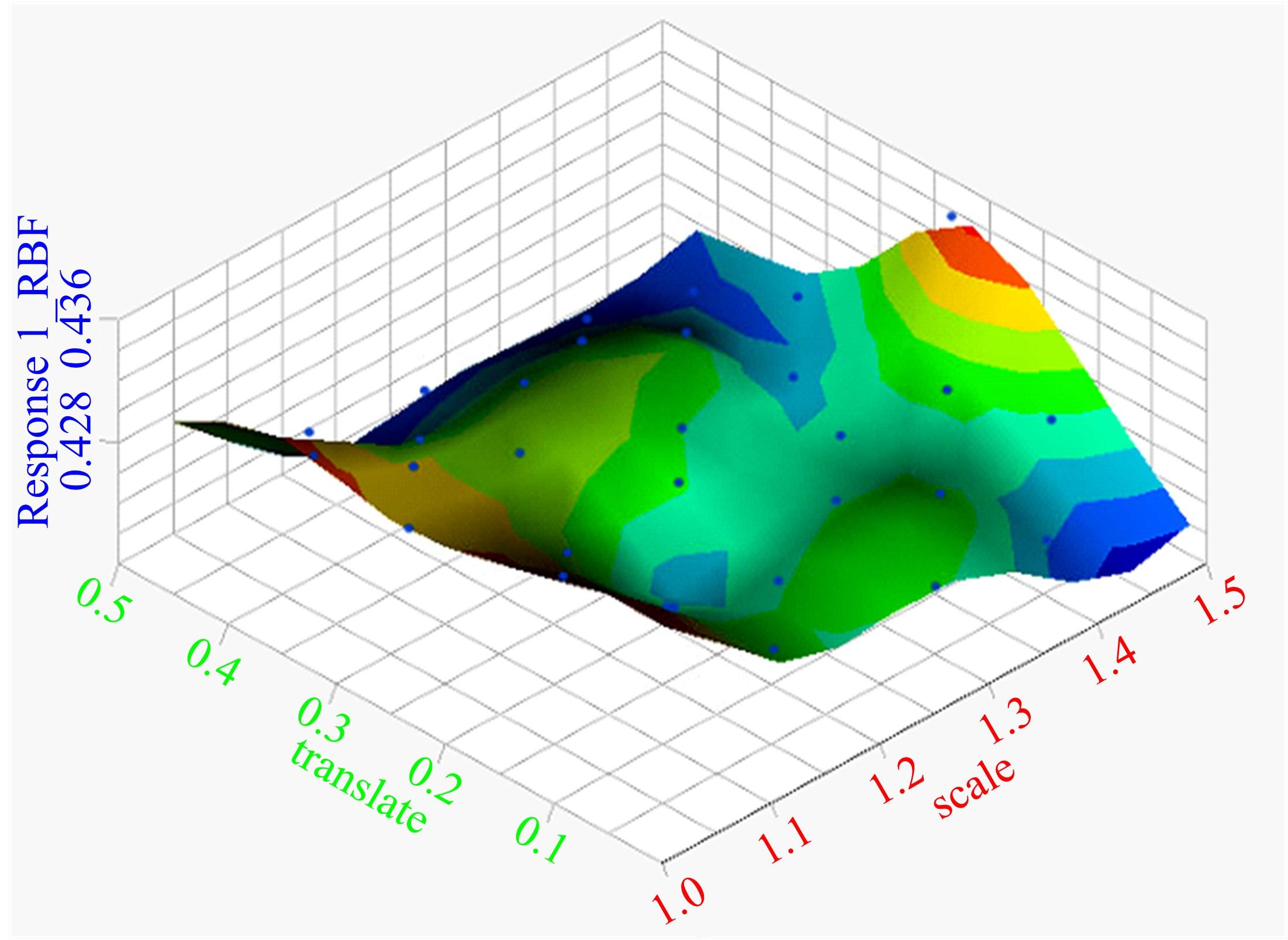

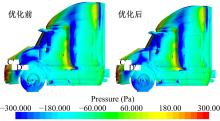

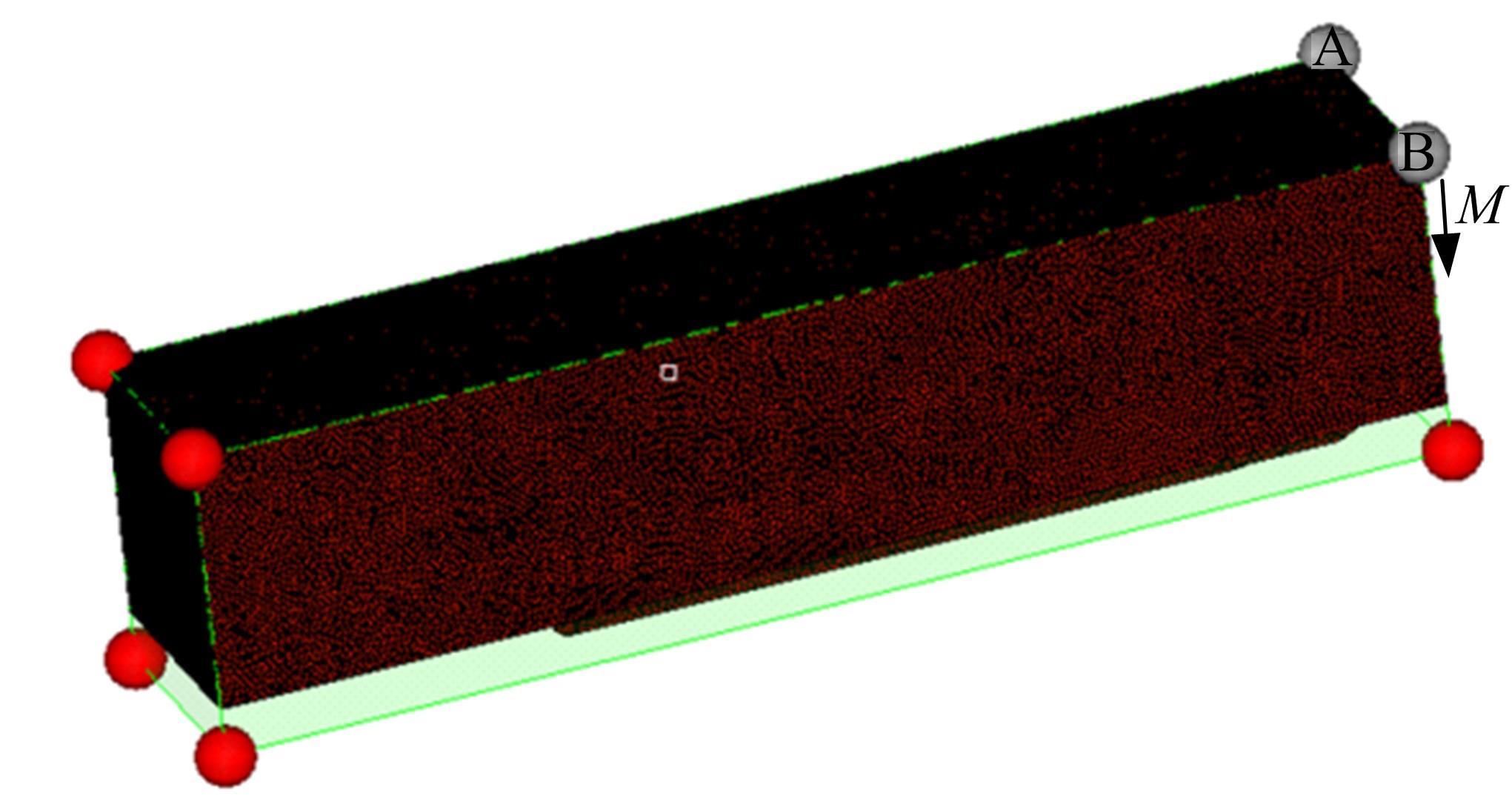

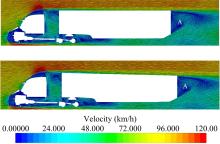

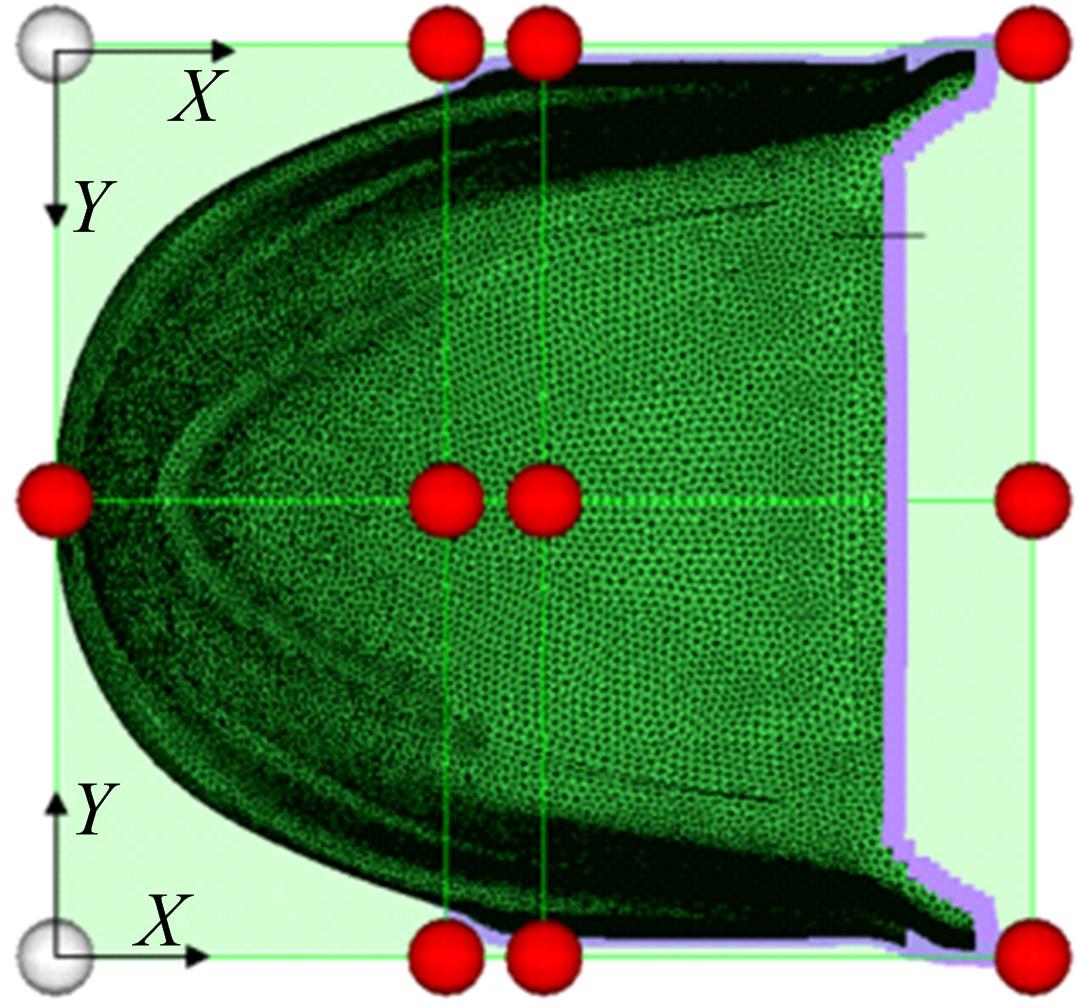

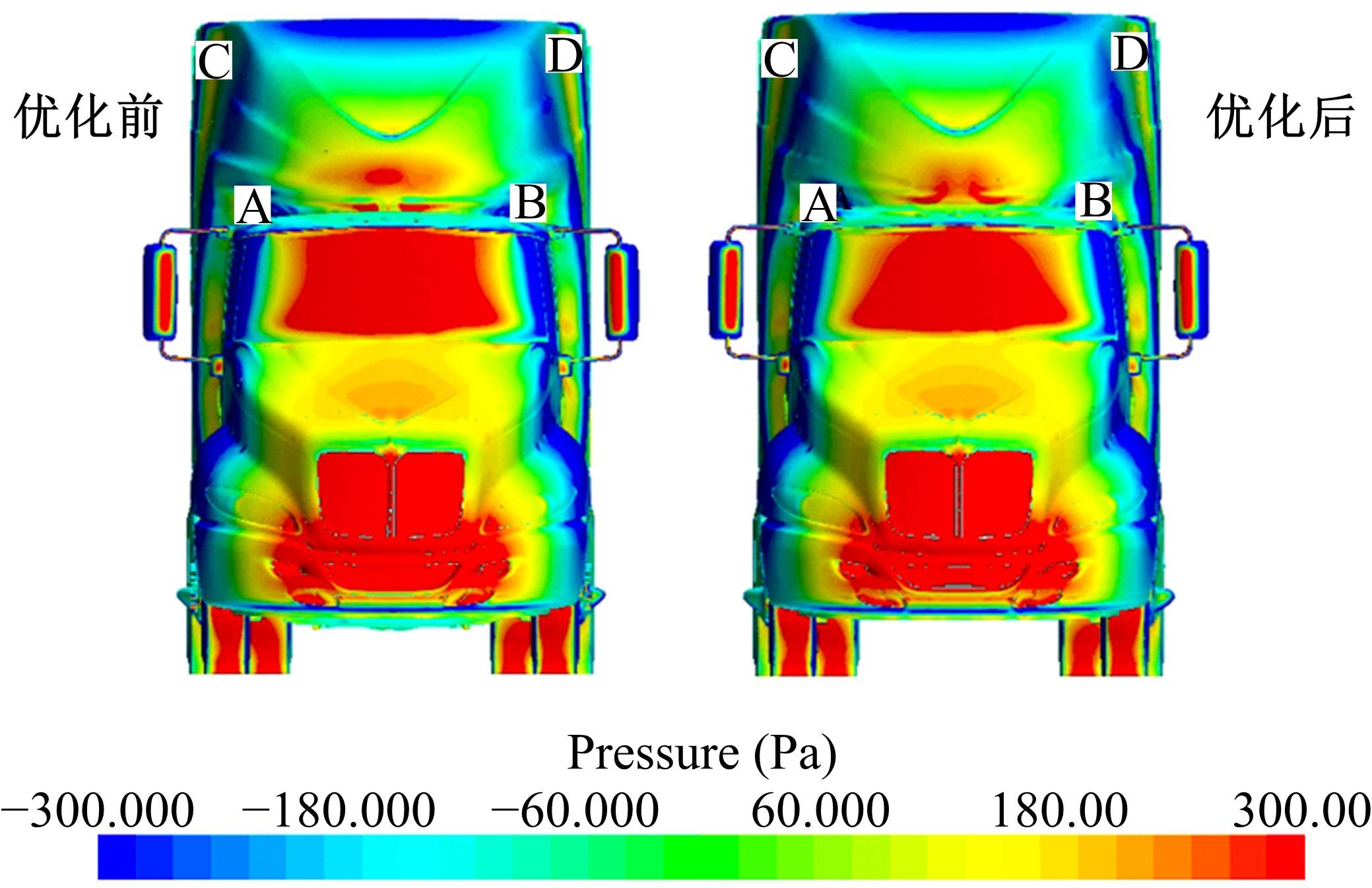

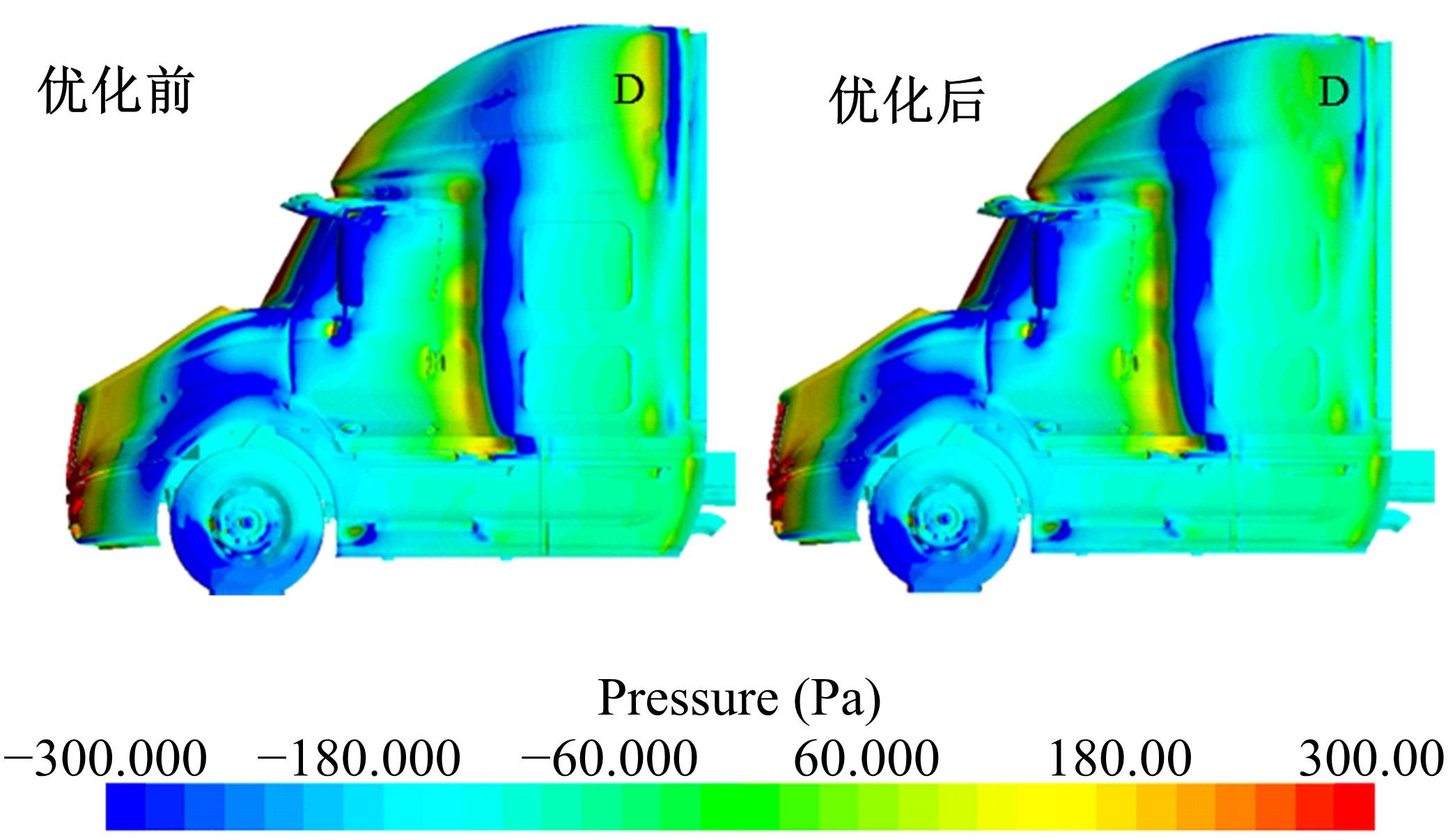

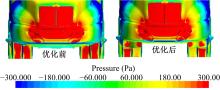

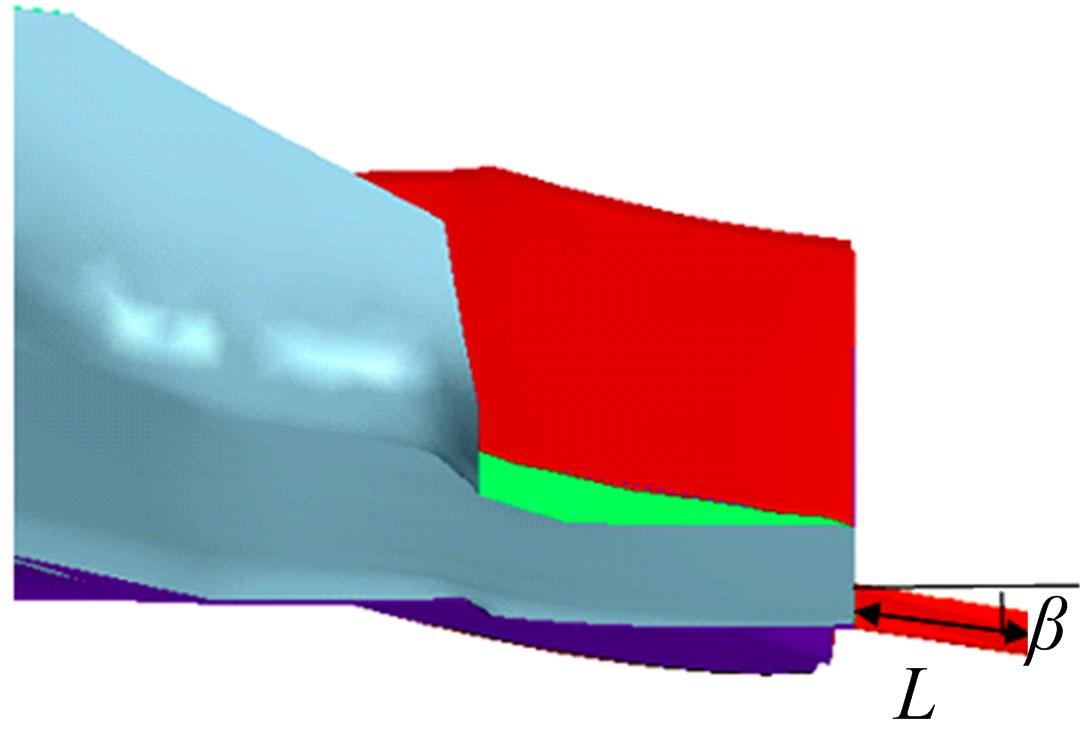

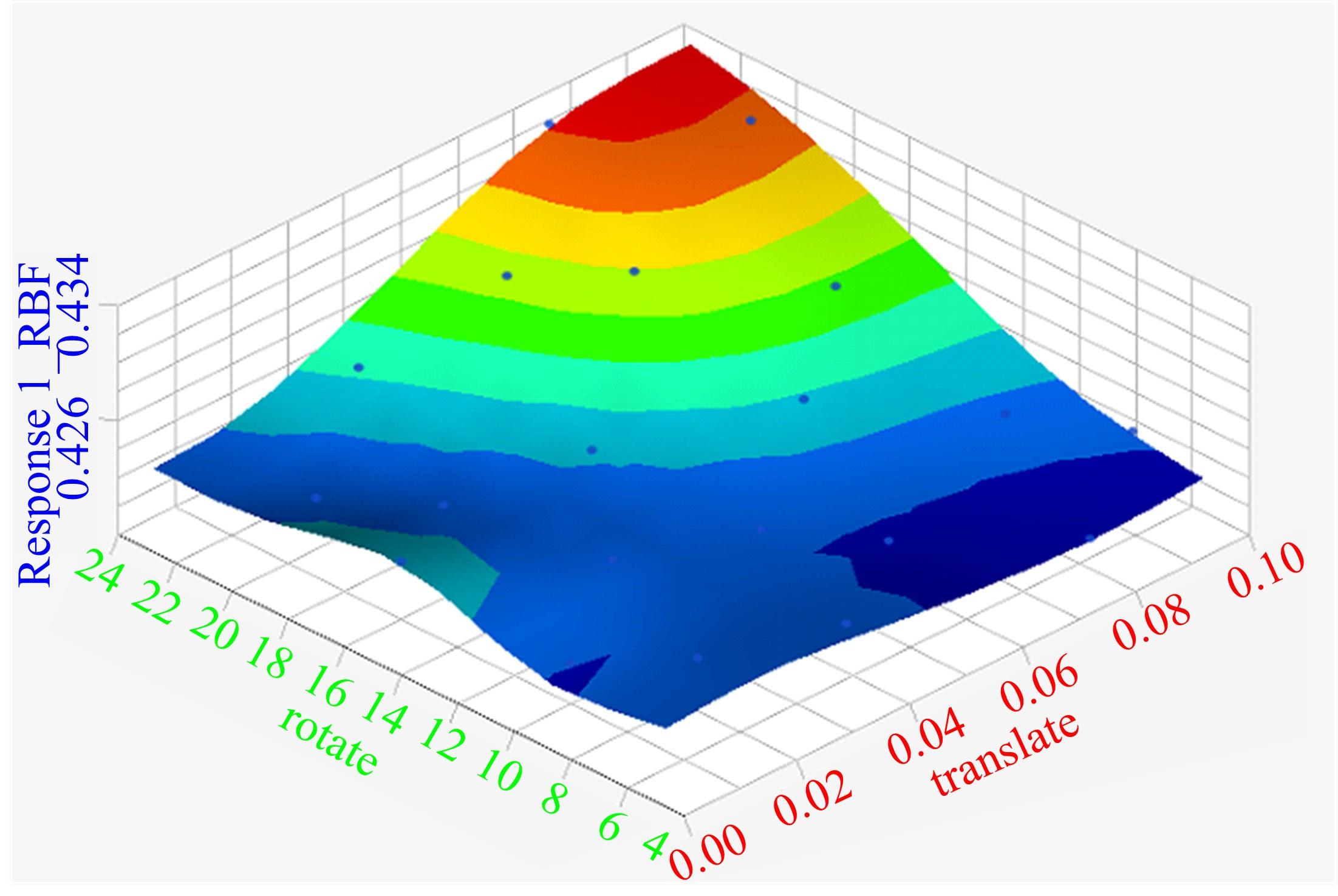

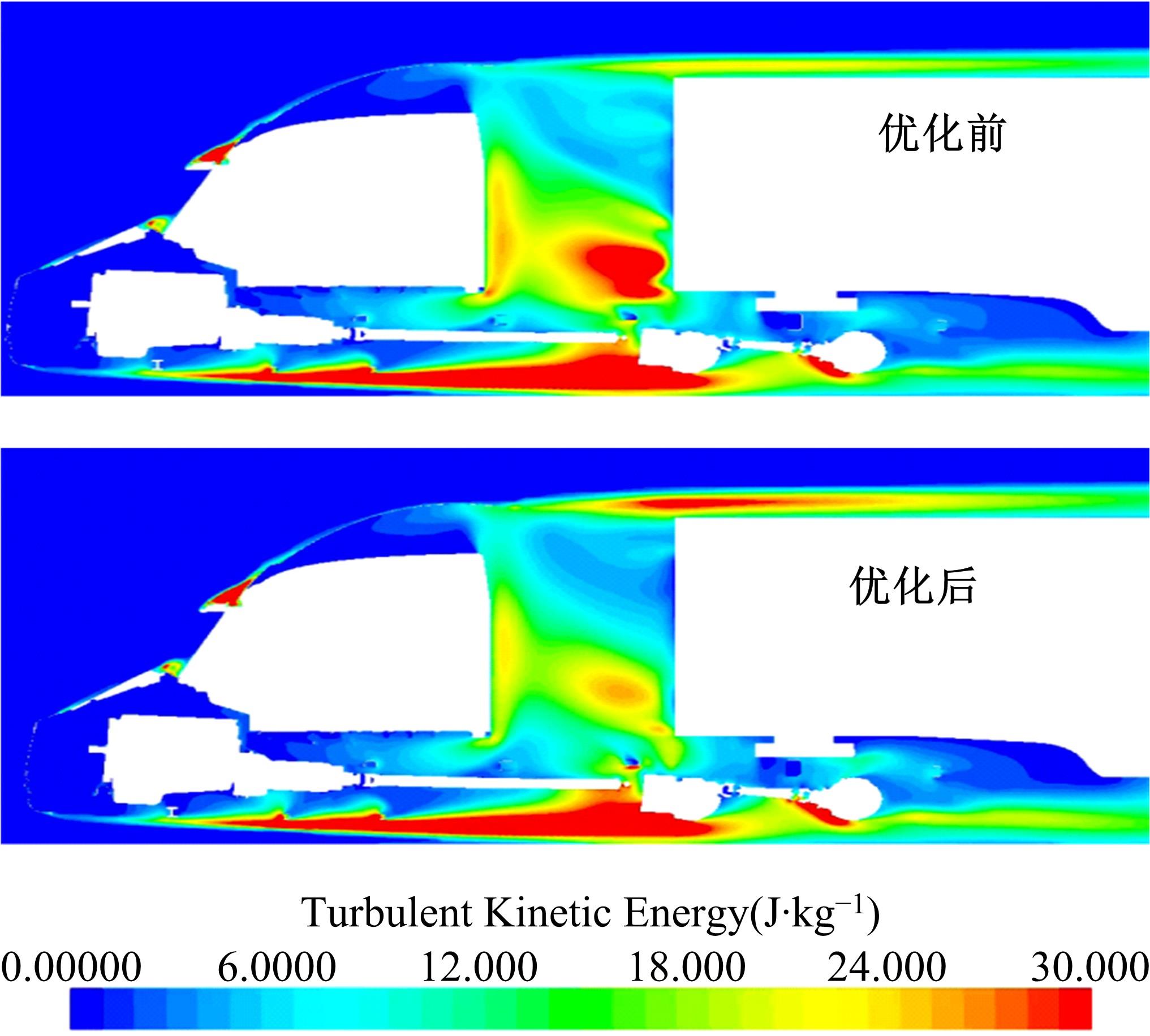

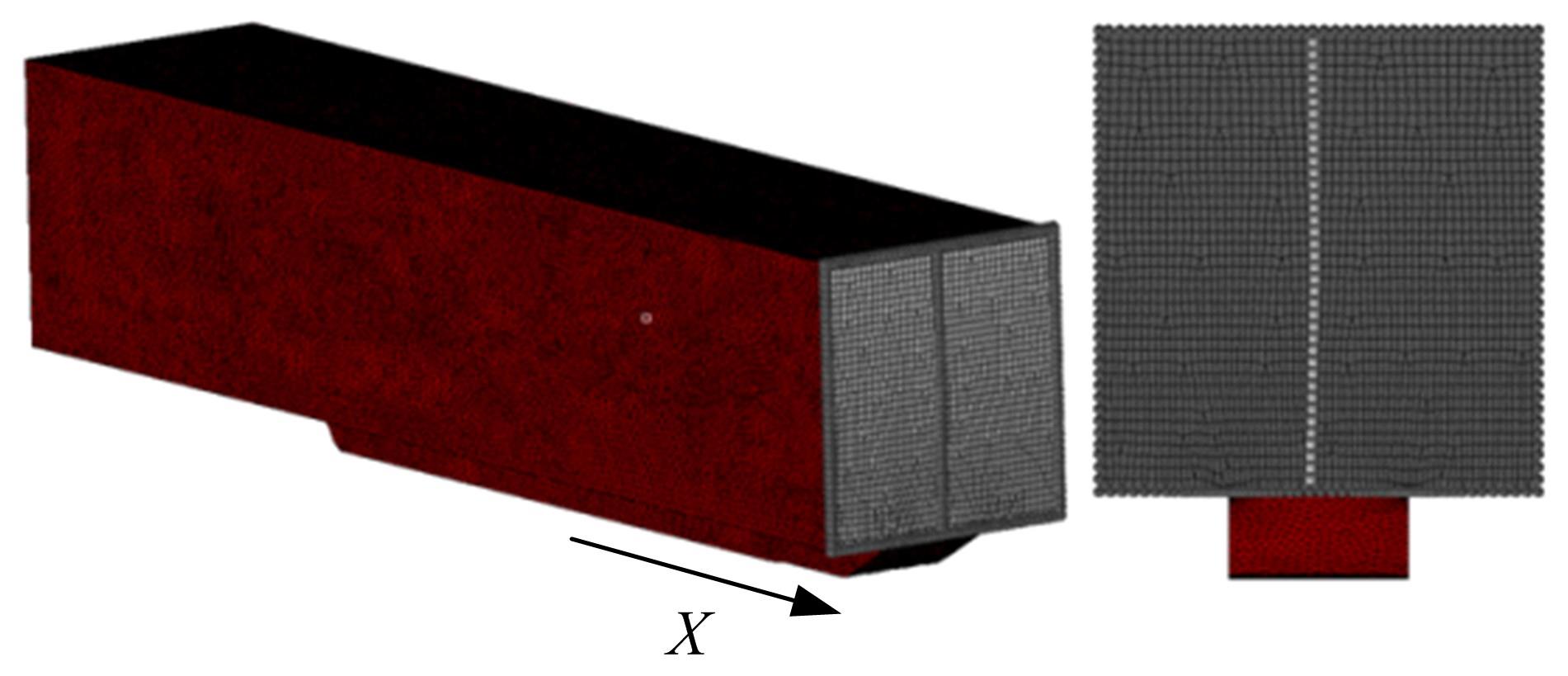

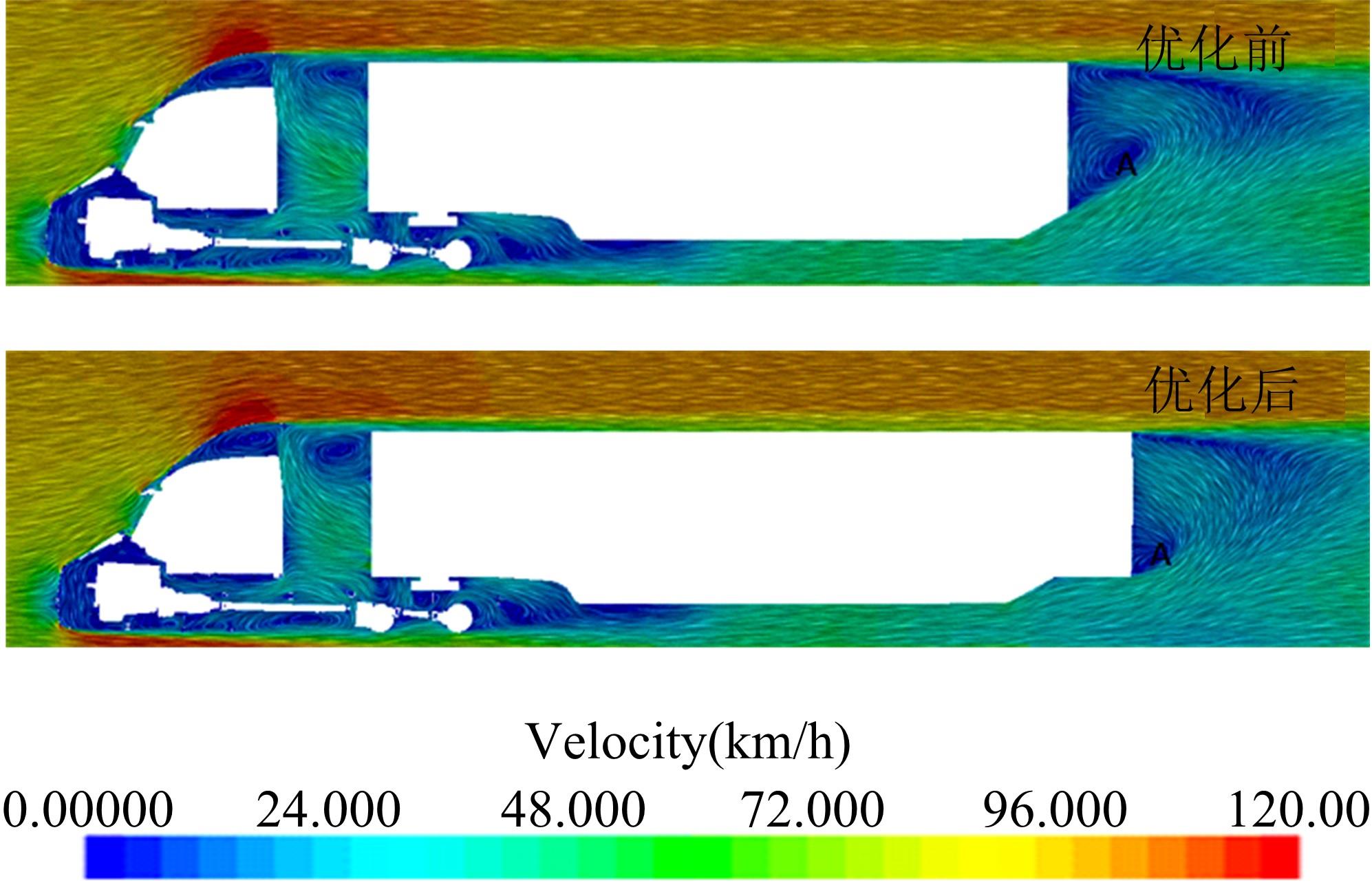

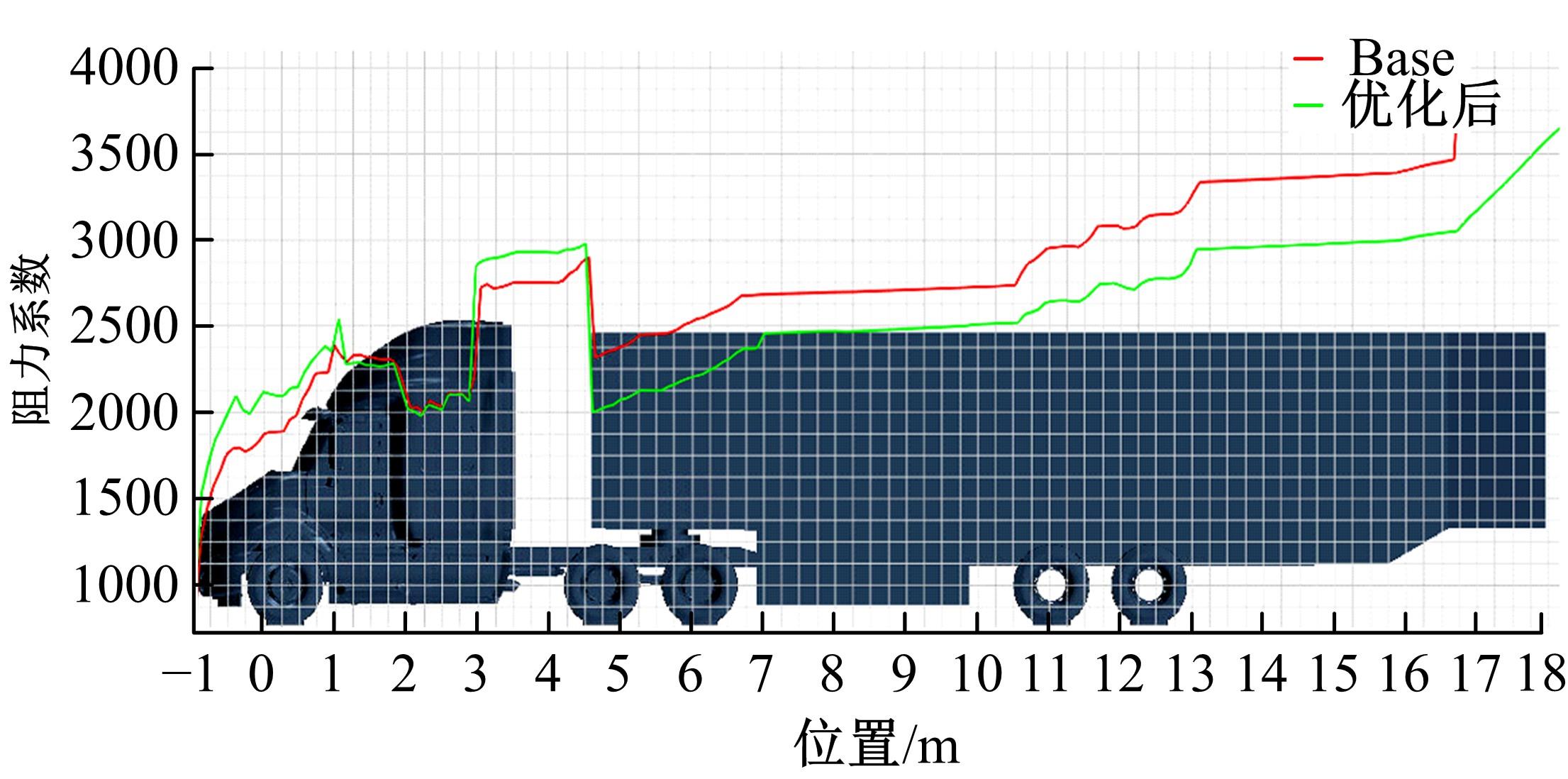

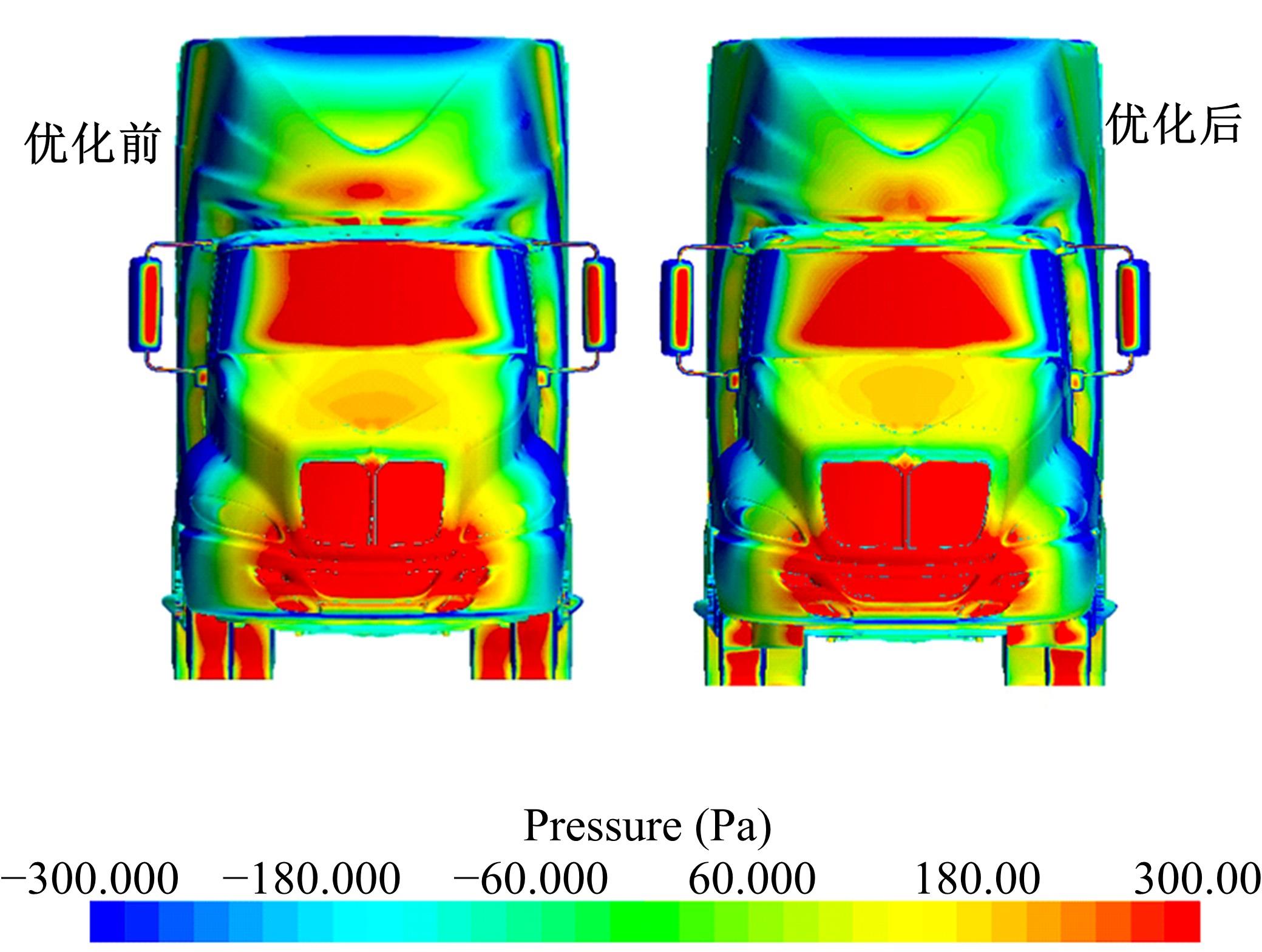

以长头重型卡车作为研究对象,进行空气动力学性能的减阻优化。优化分为造型初期的外形优化和后期整车阶段的气动优化,优化过程基于Hyperstudy软件实现形状参数化,通过CFD软件仿真进行气动性能评价,并用两种软件构建出了一个自动化流程,实现长头重型卡车气动外形优化。研究确定了8个需要考虑的设计变量(即遮阳板旋转、发舱盖变形、货箱变形、车头顶部导流罩优化、前轮阻风板优化、侧面导流板优化、货箱处添加侧裙、添加货箱尾部导流装置)进行气动优化设计,最终将该车的气动阻力系数从0.432降低至0.387,相比于Base模型降低了45 counts,降幅达10.4%。

中图分类号:

- U270.1

| 1 | 傅立敏. 汽车空气动力学[M]. 北京:机械工业出版社, 2006. |

| 2 | 傅立敏. 用空气动力学附加装置降低国产货车气动阻力措施的探讨[J]. 汽车工程, 1994(3):144-148. |

| Fu Li-min. An investigation to the effects of add-on devices on reducing aerodynamic drag of domestic trucks[J]. Automotive Engineering, 1994(3):144-148. | |

| 3 | Gong X, Gu Z, Li Z, et al. Aerodynamic shape optimization of a container-truck's wind deflector using approximate model[C]∥ SAE Paper, 2010-01-2035. |

| 4 | 许亮. 重型卡车非光滑车身气动减阻特性研究[D]. 长沙:湖南大学机械与运载工程学院, 2014. |

| Xu Liang. Research on non-smooth body aerodynamic drag reduction characteristics of heavy trucks[D]. Changsha: College of Mechanical and Vehicle Engineering, Hunan University, 2014. | |

| 5 | 张凯歌. 重型卡车气动性能优化与实验研究[D]. 长沙:湖南大学机械与运载工程学院,2016. |

| Zhang Kai-ge. The aerodynamic perfomance optimization and experiment study of heavy duty truck[D]. Changsha: College of Mechanical and Vehicle Engineering, Hunan University,2016. | |

| 6 | Cooper K R. Truck aerodynamics reborn - lessons from the past[C]∥ SAE Paper,2003-01-3376. |

| 7 | Englar R J. Development of pneumatic aerodynamic devices to improve the performance, economics, and safety of heavy vehicles[C]∥SAE Paper, 2000-01-2208. |

| 8 | Englar R J. Advanced aerodynamic devices to improve the performance, economics, handling, and safety of heavy vehicles[C]∥SAE Paper, 2001-01-2072. |

| 9 | Englar R J. Improved pneumatic aerodynamics for drag reduction, fuel economy, safety and stability increase for heavy vehicles[C]∥SAE Paper, 2005-01-3627. |

| 10 | Salati L, Cheli F, Schito P. Heavy truck drag reduction obtained from devices installed on the trailer[C]∥SAE Paper,2015-01-2898. |

| 11 | Woodiga S, Salazar D M, Wewengkang P, et al. Skin-friction topology on tail plate for tractor—trailer truck drag reduction[J]. Journal of Visualization, 2018,21(6):1017-1029. |

| 12 | 金希东. 遗传算法及其应用[D]. 成都:西南交通大学电气工程学院, 1996. |

| Jin Xi-dong. Genetic algorithm and its application[D]. Chengdu: School of Electrical Engineering,Southwest Jiaotong University, 1996. | |

| 13 | Deb K, Pratap A, Agarwal S, et al. A fast and elitist multi-objective genetic algorithm: NSGA-II[J]. IEEE Transactions on Evolutionary Computation, 2002, 6(2):182-197. |

| 14 | Kleijnen J P C. Simulation Optimization[M]. New York: Elsevier, 2015:101-138. |

| [1] | 李杰,陈涛,郭文翠,赵旗. 汽车非平稳随机振动空间域虚拟激励法及应用[J]. 吉林大学学报(工学版), 2022, 52(4): 738-744. |

| [2] | 姚玉权,仰建岗,高杰,宋亮. 基于性能-费用模型的厂拌再生沥青混合料优化设计[J]. 吉林大学学报(工学版), 2022, 52(3): 585-595. |

| [3] | 张立杰,阿喜塔,田笑,李稳. 基于Gamma过程的加速退化试验多目标优化设计[J]. 吉林大学学报(工学版), 2022, 52(2): 361-367. |

| [4] | 赵泓荀,杨兆军,陈传海,田海龙,王立平. 考虑参数权重的数控机床电主轴加速试验优化设计[J]. 吉林大学学报(工学版), 2022, 52(2): 409-416. |

| [5] | 段亮,宋春元,刘超,魏苇,吕成吉. 基于机器学习的高速列车轴承温度状态识别[J]. 吉林大学学报(工学版), 2022, 52(1): 53-62. |

| [6] | 庄蔚敏,陈沈,王楠. 温度对车身钢铝胶铆连接结构热应力变化的影响[J]. 吉林大学学报(工学版), 2022, 52(1): 70-78. |

| [7] | 陈剑斌,周宋泽,费峰永,陈永龙,凌国平. 过盈量及滚花方式对装配式凸轮轴压装失效的影响[J]. 吉林大学学报(工学版), 2021, 51(6): 1959-1966. |

| [8] | 胡兴军,张靖龙,罗雨霏,辛俐,李胜,胡金蕊,兰巍. 冷却管结构及进气方向对空冷中冷器性能的影响[J]. 吉林大学学报(工学版), 2021, 51(6): 1933-1942. |

| [9] | 罗勇,韦永恒,黄欢,肖人杰,任淋,崔环宇. 驾驶员意图识别的P2.5插混构型双离合器起步控制[J]. 吉林大学学报(工学版), 2021, 51(5): 1575-1582. |

| [10] | 曾小华,宋美洁,宋大凤,王越. 基于车联网信息的公交客车行驶工况数据处理方法[J]. 吉林大学学报(工学版), 2021, 51(5): 1692-1699. |

| [11] | 马超,高云凯,刘哲,段月星,田林雳. 骨架式车身多材料及梁截面形状和尺寸优化[J]. 吉林大学学报(工学版), 2021, 51(5): 1583-1592. |

| [12] | 兰凤崇,李继文,陈吉清. 面向动态场景复合深度学习与并行计算的DG-SLAM算法[J]. 吉林大学学报(工学版), 2021, 51(4): 1437-1446. |

| [13] | 杨建,夏琦,周海超,王国林. 修正胎体弦轮廓载重子午线轮胎的降噪机理[J]. 吉林大学学报(工学版), 2021, 51(4): 1198-1203. |

| [14] | 龙江启,向锦涛,俞平,王骏骋. 适用于非线性主动悬架滑模控制的线性干扰观测器[J]. 吉林大学学报(工学版), 2021, 51(4): 1230-1240. |

| [15] | 陈鑫,于贵申,张彪,潘凯旋,杨立飞. 搅拌摩擦点焊接头拉伸-剪切行为的等效建模[J]. 吉林大学学报(工学版), 2021, 51(4): 1190-1197. |

|

||