吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (11): 3148-3157.doi: 10.13229/j.cnki.jdxbgxb.20230026

• 车辆工程·机械工程 • 上一篇

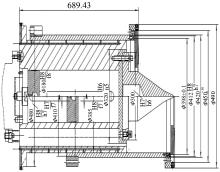

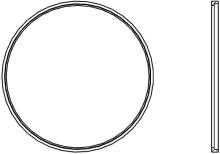

双锥形铜合金药型罩旋压工艺仿真与实验验证

- 1.长春理工大学 机电工程学院,长春 130022

2.长春设备工艺研究所,长春 130012

Simulation and experimental validation of spinning process for double-cone-shaped copper alloy dosage form cover in pharmaceutical applications

Yan-qing LI1( ),Sheng-xu LU1,Yong-zhou LI1,Ming-zhi HUANG1,Tao HUANG2(

),Sheng-xu LU1,Yong-zhou LI1,Ming-zhi HUANG1,Tao HUANG2( )

)

- 1.School of Electromechanical Engineering,Changchun University of Science and Technology,Changchun 130022,China

2.Changchun Institute of Equipment and Technology,Changchun 130012,China

摘要:

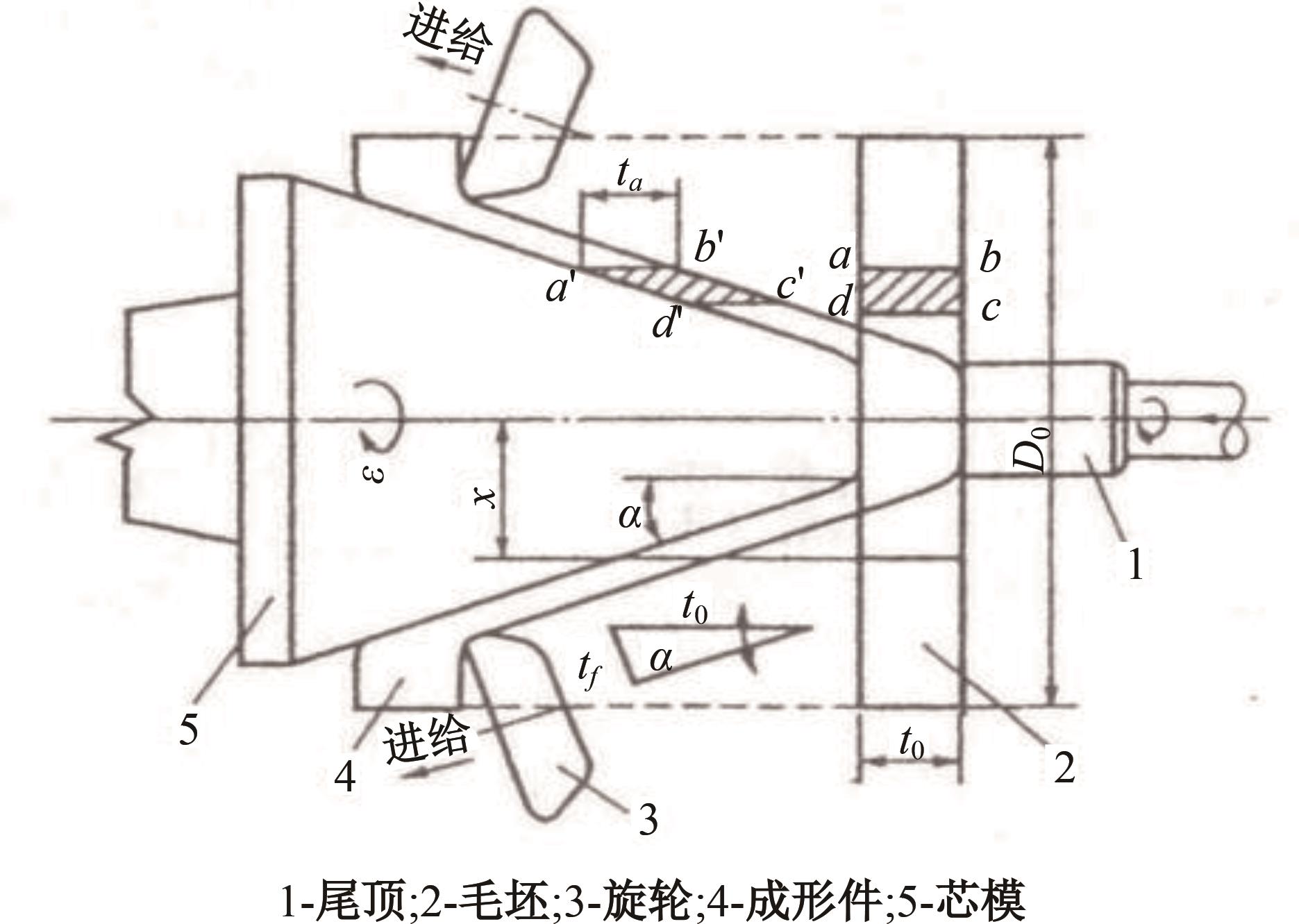

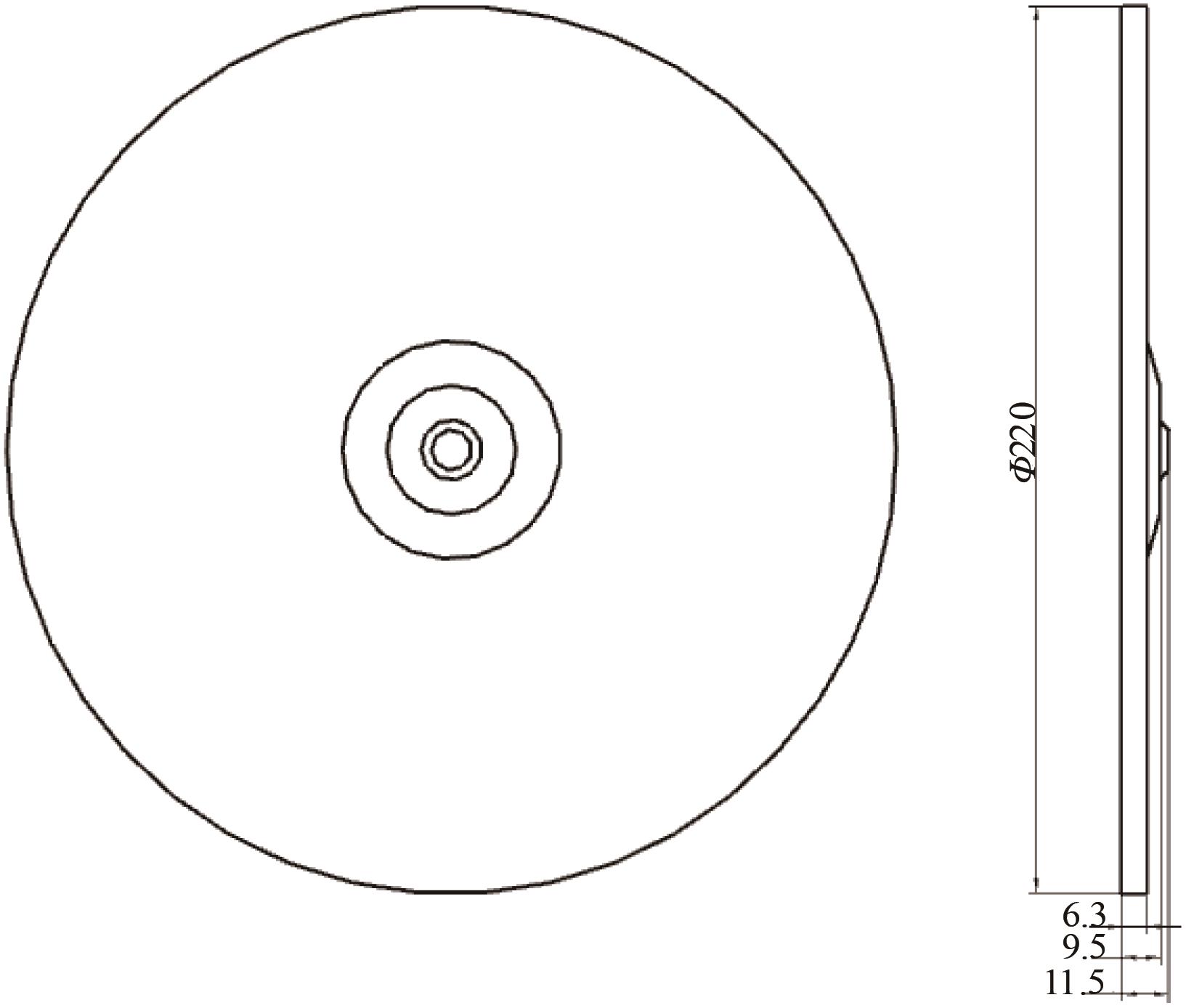

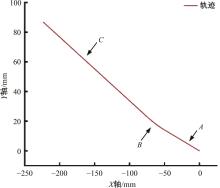

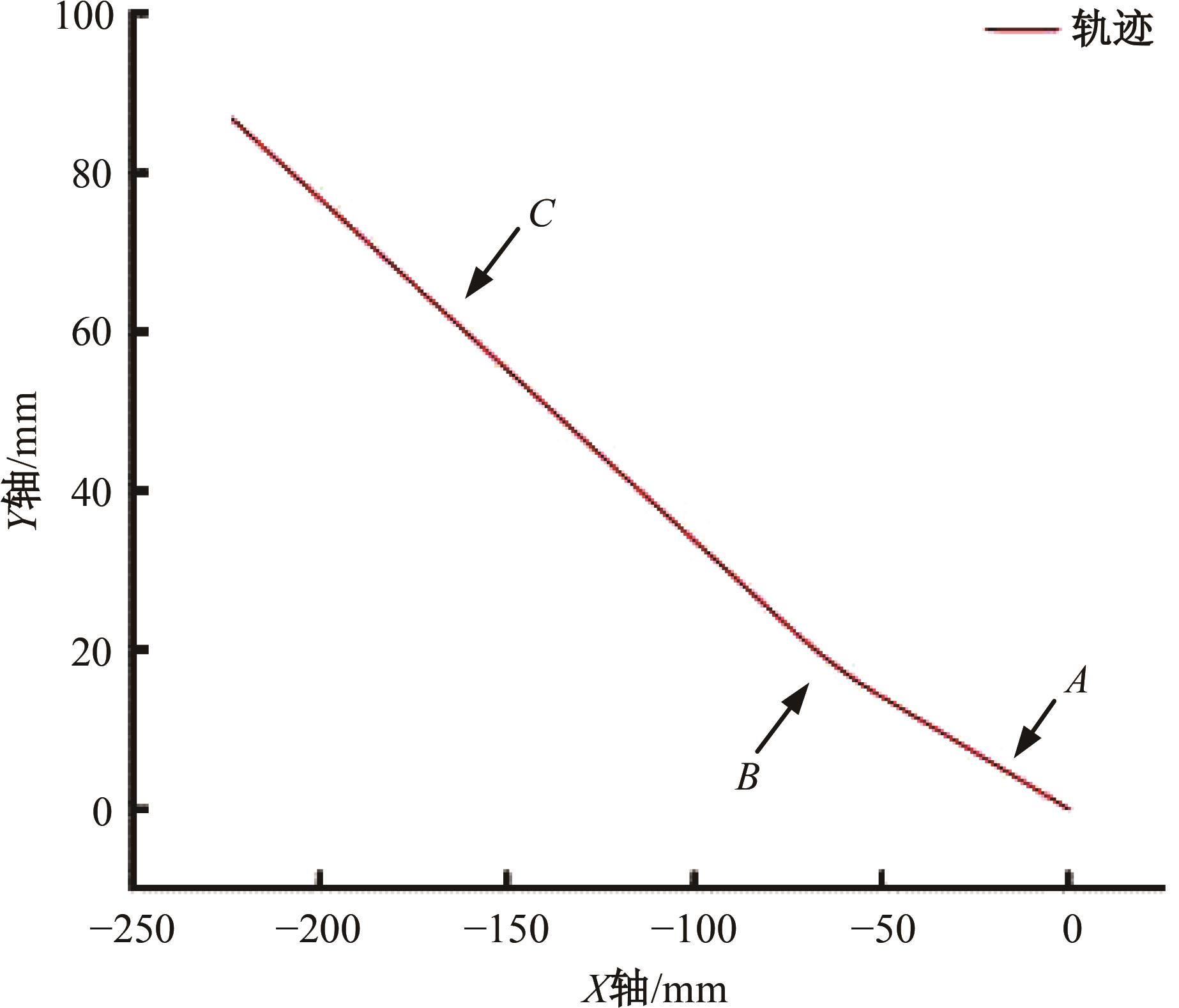

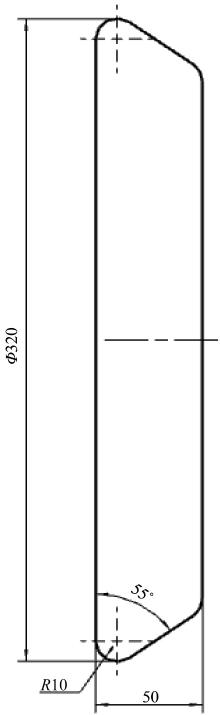

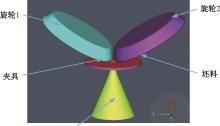

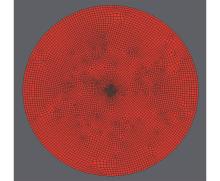

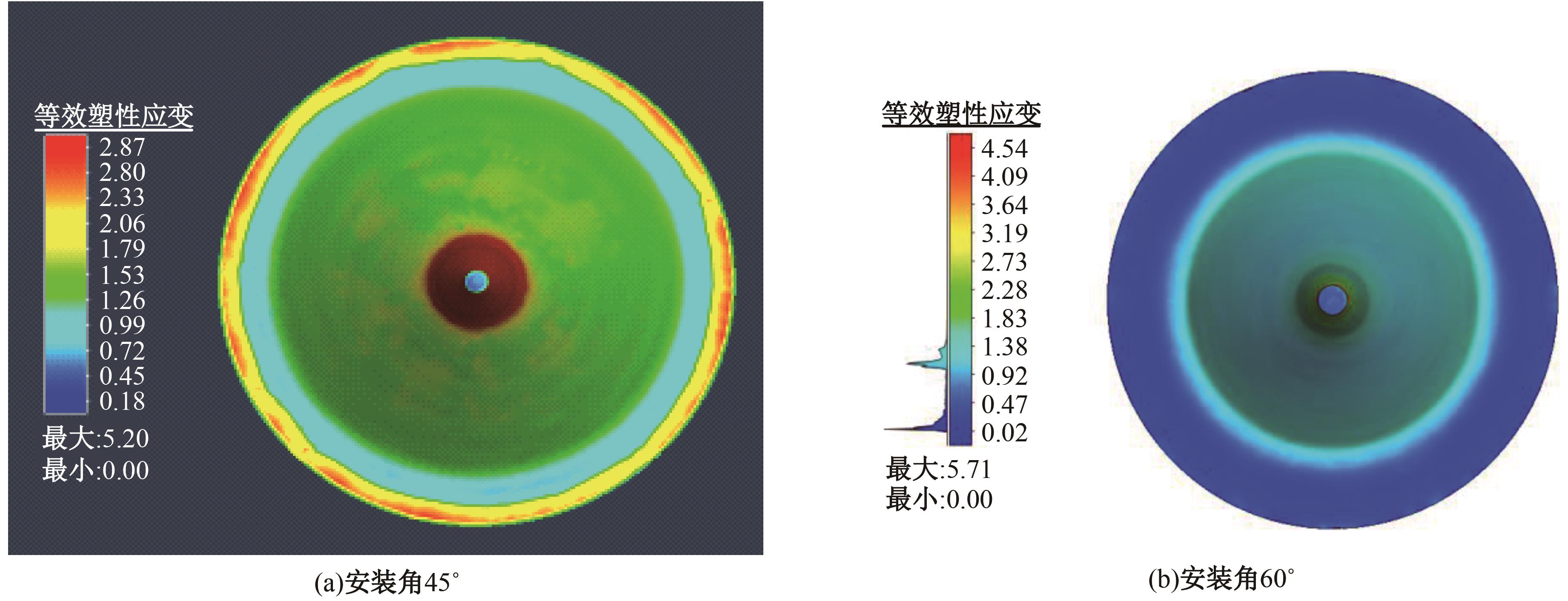

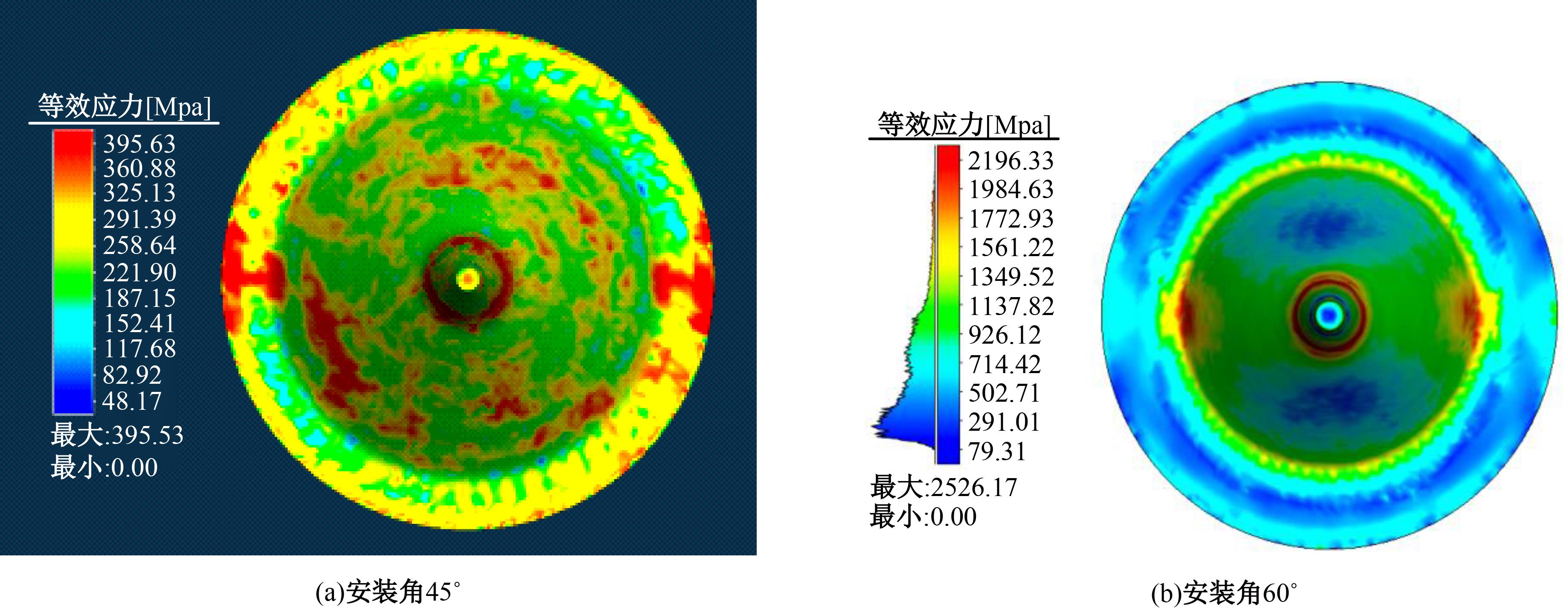

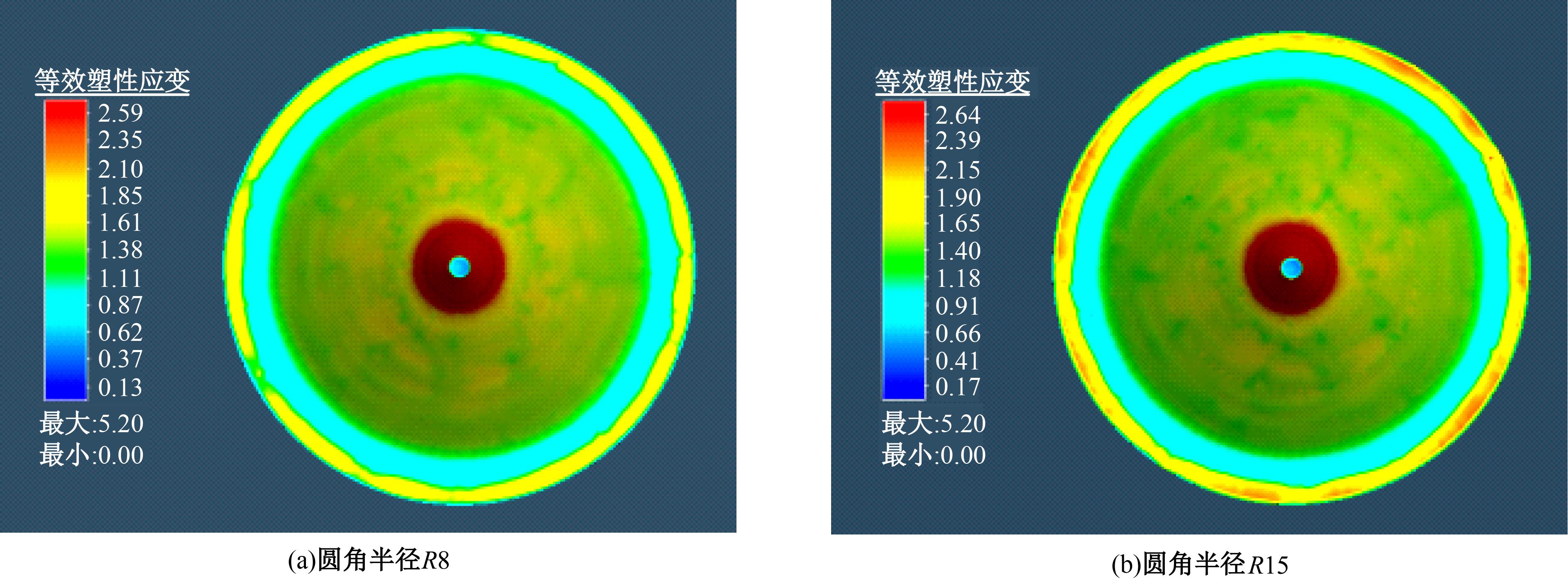

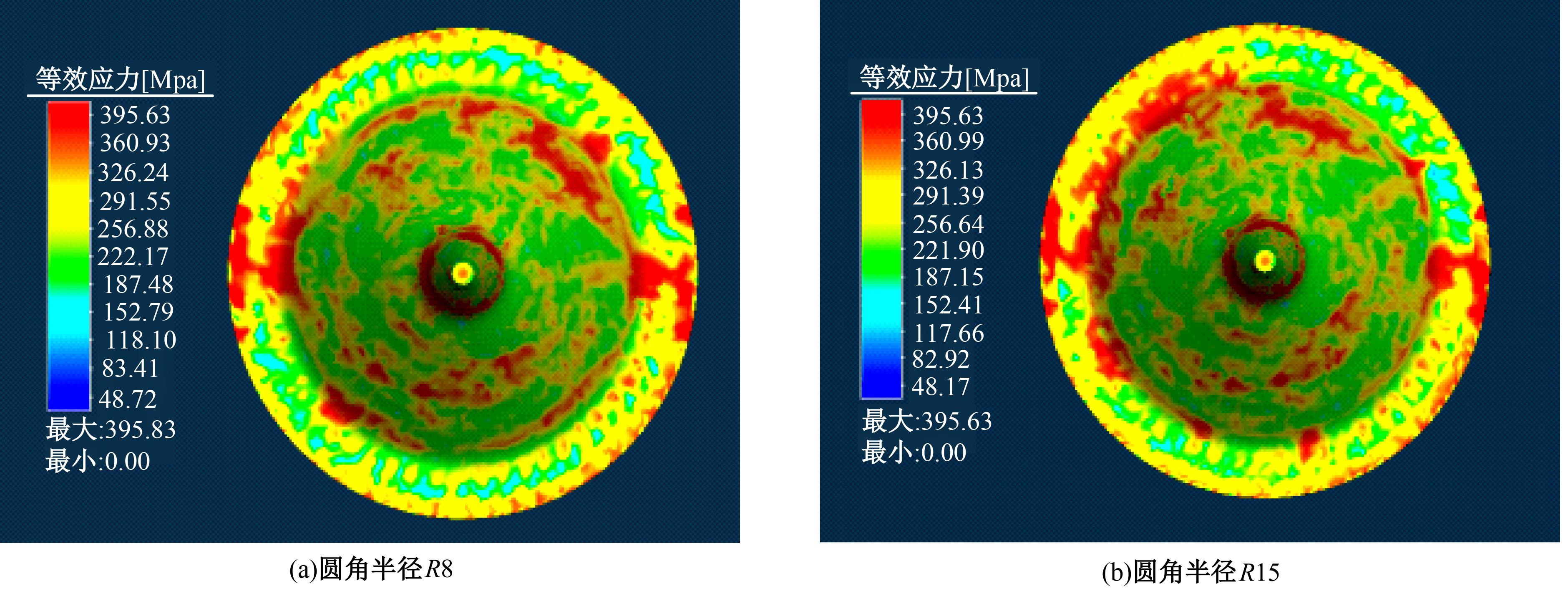

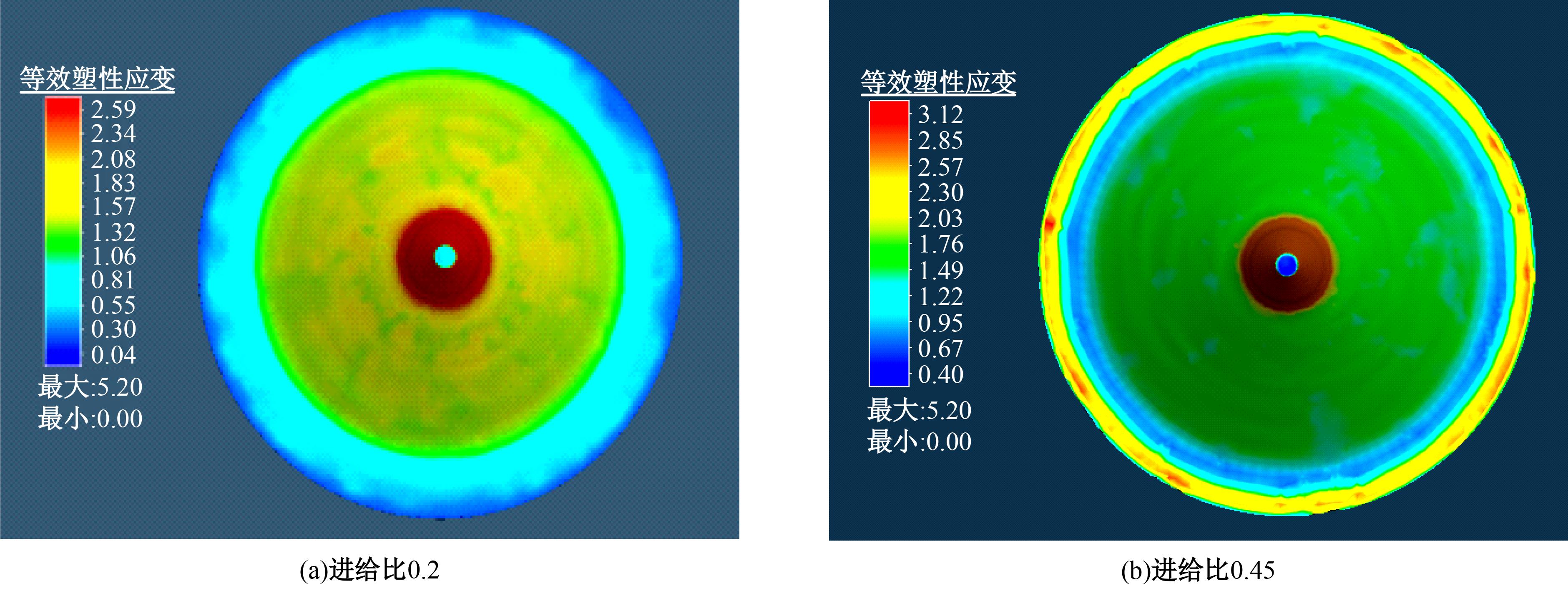

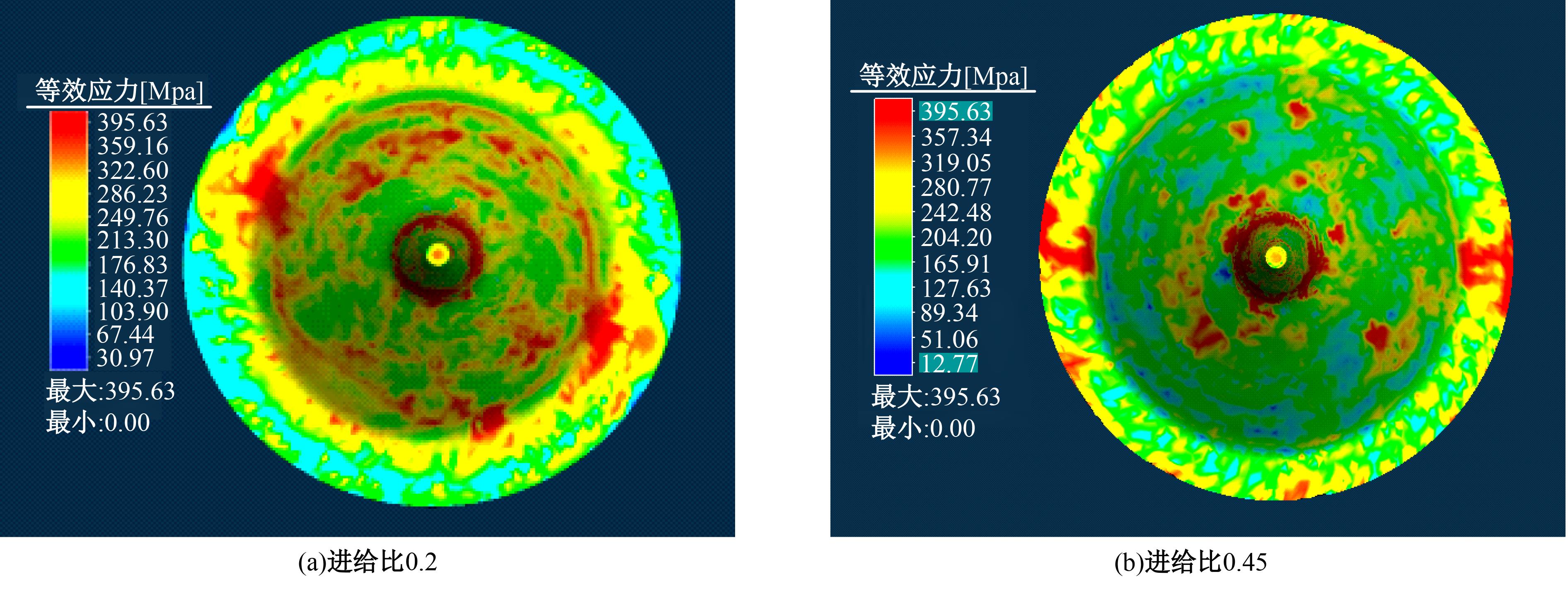

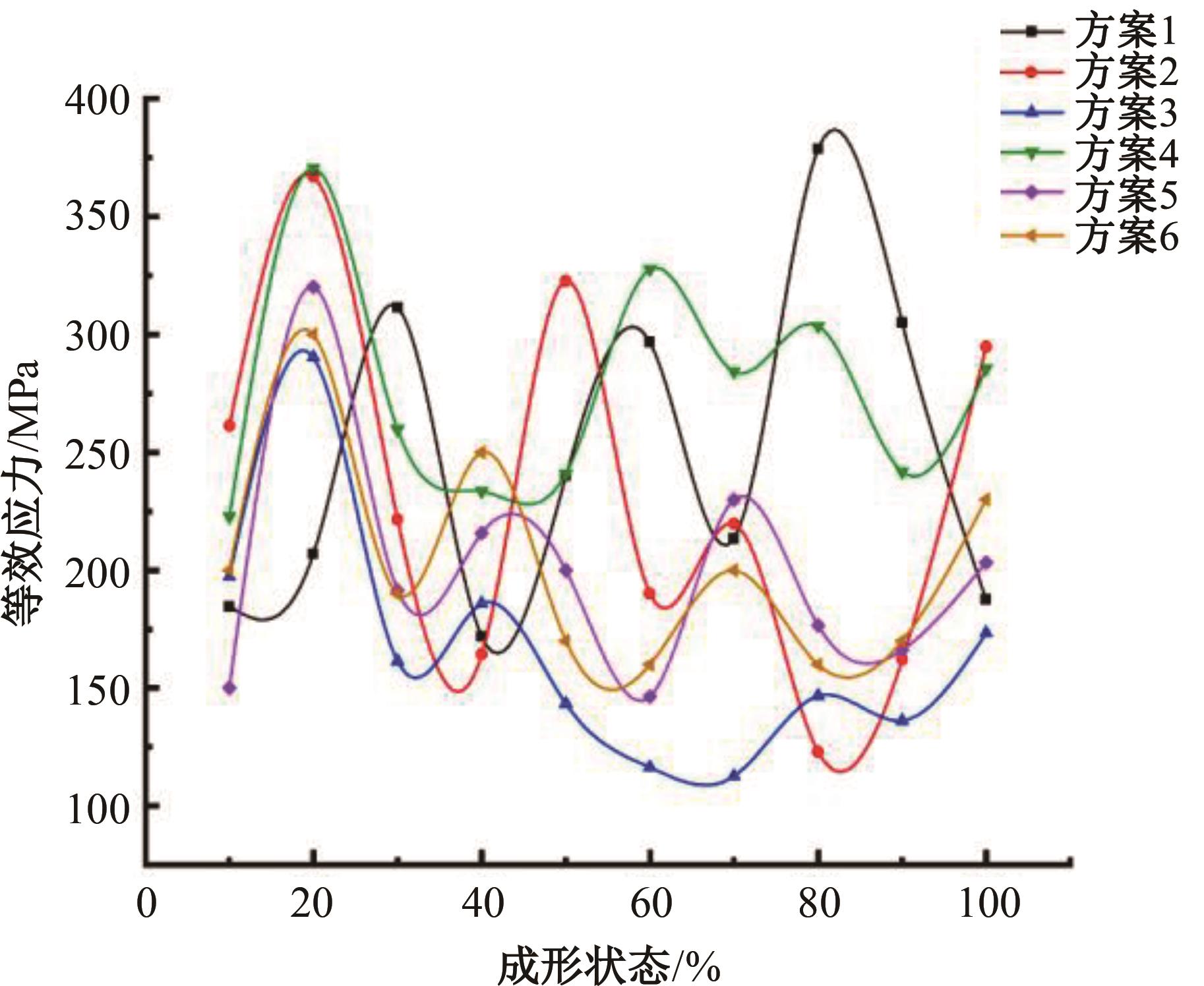

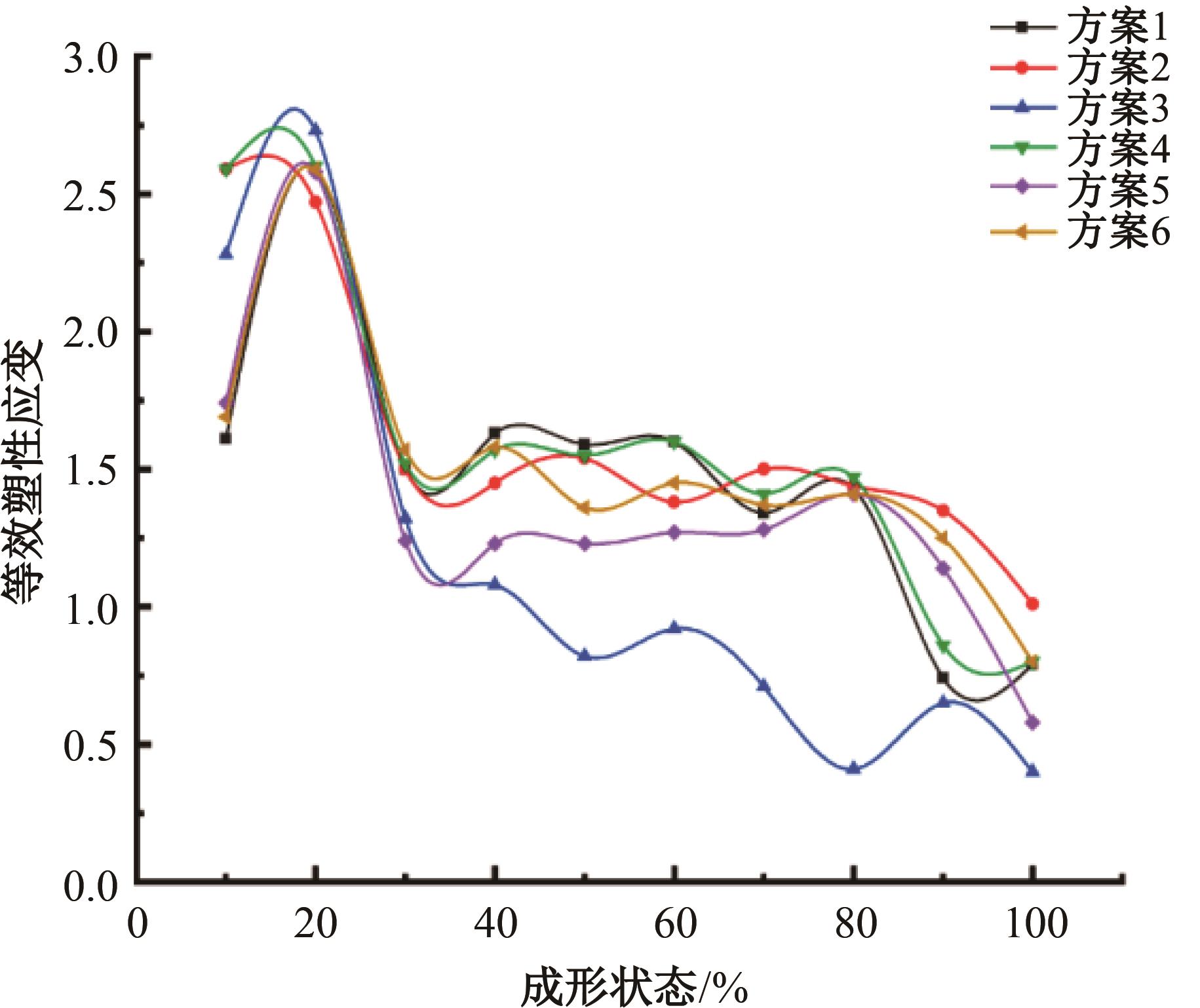

本文主要针对铜合金药型罩零件进行强力旋压成形模拟仿真,基于Simufact/Ansys平台建立双锥形铜合金药型罩旋压三维有限元模型,通过数值模拟对药型罩强力旋压成形过程应力应变的分布规律分析,得出在药型罩的前端区域和双锥角过渡圆弧区域应力较大。以药型罩旋压后的应力应变分布为分析目标,得到旋轮安装角、旋轮半径及进给比对应力应变的影响规律。应用仿真优化的工艺参数进行旋压实验,实验结果表明药型罩满足精度要求,表明采用模拟仿真的方法和手段,能够对实际旋压加工起到指导作用。

中图分类号:

- TG306

| 1 | 徐恒秋,樊桂森,张锐,等. 旋压设备及工艺技术的应用与发展[J]. 新技术新工艺, 2007, 230(2): 1, 6-8. |

| Xu Heng-qiu, Fan Gui-sen, Zhang Rui, et al. The application and development of spinning equipment and technology[J]. New Technology&New Process, 2007, 230(2): 1, 6-8. | |

| 2 | Huang C C, Hung J C, Hung C H, et al. Finite element analysis on neck-spinning process of tube at elevated temperature[J]. Int J Adv Manuf Technol, 2011, 56: 1039-1048. |

| 3 | 张全孝,姚懂,曹连忠,等. 钨铜EFP药型罩的制备及成形性能[J]. 稀有金属材料与工程, 2009, 38(3): 154-158. |

| Zhang Quan-xiao, Yao Dong, Cao Lian-zhong, et al. Preparation and formability of tungsten-copper EFP liner[J]. Rare Metal Materials and Engineering, 2009, 38(3): 154-158. | |

| 4 | 张晋辉,牛婷,温凯,等. 铝合金锥形件强旋壁厚与旋压力分布研究[J]. 兵器装备工程学报, 2020, 41(8): 245-249. |

| Zhang Jin-hui, Niu Ting, Wen Kai, et al. Research on distribution of wall thickness and spinning force on power spinning for aluminum alloy conical parts[J]. Journal of Ordnance Equipment Engineering, 2020, 41(8): 245-249. | |

| 5 | 夏琴香,张帅斌,吴小瑜,等. 锥形件单道次拉深旋压成形的数值模拟及试验研究[J]. 锻压技术, 2010, 35(1): 52-56. |

| Xia Qin-xiang, Zhang Shuai-bin, Wu Xiao-yu, et al. Numerical simulation and experimental investigation on one-path deep drawing spinning of conical part[J]. Forging&Stamping Technology, 2010, 35(1): 52-56. | |

| 6 | Mori K, Ishiguro M, Isomura Y. Hot shear spinning of cast aluminium alloy parts[J]. Journal of Materials Processing Technology, 2009, 209(7): 3621-3627. |

| 7 | Li Y, Wang J, Lu G D, et al. A numerical study of the effects of roller paths on dimensional precision in die-less spinning of sheet metal[J]. Journal of Zhejiang University Science A, 2014, 15(6): 432-446. |

| 8 | 李灵凤. 变壁厚锥形件强力旋压过程有限元力学模型的建立[J]. 锻压装备与制造技术, 2006(1): 64-66. |

| Li Ling-feng. FEM mechanics modelling of power spinning process of varying thickness conical parts[J]. China Metal Forming Equipment & Manufacturing Technology, 2006(1): 64-66. | |

| 9 | 徐银丽,詹梅,杨合,等. 锥形件变薄旋压回弹的三维有限元分析[J]. 材料科学与工艺, 2008, 16(2): 167-171. |

| Xu Yin-li, Zhan Mei, Yang He, et al. Springback law analysis of cone spinning using 3D FEM[J]. Materials Science and Technology, 2008, 16(2): 167-171. | |

| 10 | 吴统超,詹梅,古创国,等. 大型复杂薄壁壳体第一道次旋压成形质量分析[J]. 材料科学与工艺, 2011, 19(1): 126-131. |

| Wu Tong-Chao, Zhan Mei, Gu Chuang-guo, et al. Forming quality of the first pass spinning of large-sized complicated thin-walled shell[J]. Materials Science and Technology, 2011, 19(1): 126-131. | |

| 11 | Childerhouse T, Long H. Processing maps for wrinkle free and quality enhanced parts by shear spinning[J]. Procedia Manufacturing, 2019, 29: 137-144. |

| 12 | 陆栋,张乐,蒲世翱,等. 304不锈钢锥形件旋压成形工艺参数对损伤的影响[J]. 热加工工艺, 2015, 44(11): 162-165. |

| Lu Dong, Zhang Le, Pu Shi-ao, et al. Effect of process parameters on damage during spinning forming of 304 stainless steel conical parts[J]. Hot Working Technology, 2015, 44(11): 162-165. | |

| 13 | 陈建华,马飞,任顺奎,等. 大直径薄壁铝合金封头剪切旋压成形缺陷分析[J]. 精密成形工程, 2016, 8(2): 64-67. |

| Chen Jian-hua, Ma Fei, Ren Shun-kui, et al. Defect analysis of shear spinning of aluminum alloy thin-walled head with large diameter[J]. Journal of Netshape Forming Engineering, 2016, 8(2): 64-67. |

| [1] | 梁晓波, 蔡中义, 高鹏飞. 夹芯复合板柱面成形的数值模拟及试验[J]. 吉林大学学报(工学版), 2018, 48(3): 828-834. |

| [2] | 吕萌萌, 谷诤巍, 徐虹, 李欣. 超高强度防撞梁热冲压成形工艺优化[J]. 吉林大学学报(工学版), 2017, 47(6): 1834-1841. |

| [3] | 张志强, 刘从豪, 何东野, 李湘吉, 李纪萱. 基于性能梯度分布的硼钢热冲压工艺对形状精度的影响[J]. 吉林大学学报(工学版), 2017, 47(6): 1829-1833. |

| [4] | 谷诤巍, 张文学, 吕萌萌, 王伟, 徐虹, 李欣. 宽翼边U型截面不锈钢型材拉弯成形缺陷控制[J]. 吉林大学学报(工学版), 2017, 47(4): 1165-1170. |

| [5] | 伦凤艳, 付文智, 李明哲, 依卓, 王欣桐, 陈雪. 基于弯曲辊的三维曲面柔性轧制成形[J]. 吉林大学学报(工学版), 2017, 47(3): 876-883. |

| [6] | 谷诤巍, 吕萌萌, 李欣, 徐虹. 数控拉弯工艺中型材变形量的影响因素[J]. 吉林大学学报(工学版), 2016, 46(4): 1190-1196. |

| [7] | 谷诤巍, 吕萌萌, 赵立辉, 徐虹, 李欣, 陆冠含. 超高强钢热成形淬火阶段的工艺参数优化[J]. 吉林大学学报(工学版), 2016, 46(3): 853-858. |

| [8] | 胡平, 张金女, 申国哲, 林发财, 刘立忠. 应力状态对模具分区冷却热成形S-rail硬度分布的影响[J]. 吉林大学学报(工学版), 2016, 46(2): 500-504. |

| [9] | 杨振, 蔡中义, 李明哲. 分布式位移加载方式拉伸成形三维曲面件的数值模拟[J]. 吉林大学学报(工学版), 2016, 46(1): 199-204. |

| [10] | 胡志清,甄娇娇,冯增铭,周淑红. 滚压拉伸成形曲面技术及其数值模拟[J]. 吉林大学学报(工学版), 2014, 44(3): 701-707. |

| [11] | 王蜜, 蔡中义, 李明哲, 王大明. 三维曲面件辊压成形弯曲变形的计算及数值模拟[J]. 吉林大学学报(工学版), 2014, 44(2): 404-408. |

| [12] | 付文智, 朱必章, 张昊晗, 李明哲, 邓玉山. 柔性压辊拉伸成形球形件的解析法[J]. , 2012, 42(04): 930-935. |

| [13] | 彭赫力, 李明哲, 付文智, 冯朋晓. 柔性离散夹钳拉形工艺的数值模拟 [J]. , 2012, (03): 660-664. |

| [14] | 谷诤巍, 孟佳, 李欣, 徐虹, 于思彬, 沈永波. 超高强钢热成形奥氏体化加热参数的优化[J]. 吉林大学学报(工学版), 2011, 41(增刊2): 194-197. |

| [15] | 徐虹, 沈永波, 谷诤巍, 孟佳, 于思彬, 李欣. 汽车超高强钢防撞梁热成形试验[J]. 吉林大学学报(工学版), 2011, 41(增刊1): 111-114. |

|

||