Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (5): 1196-1204.doi: 10.13229/j.cnki.jdxbgxb.20220757

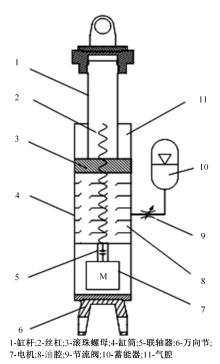

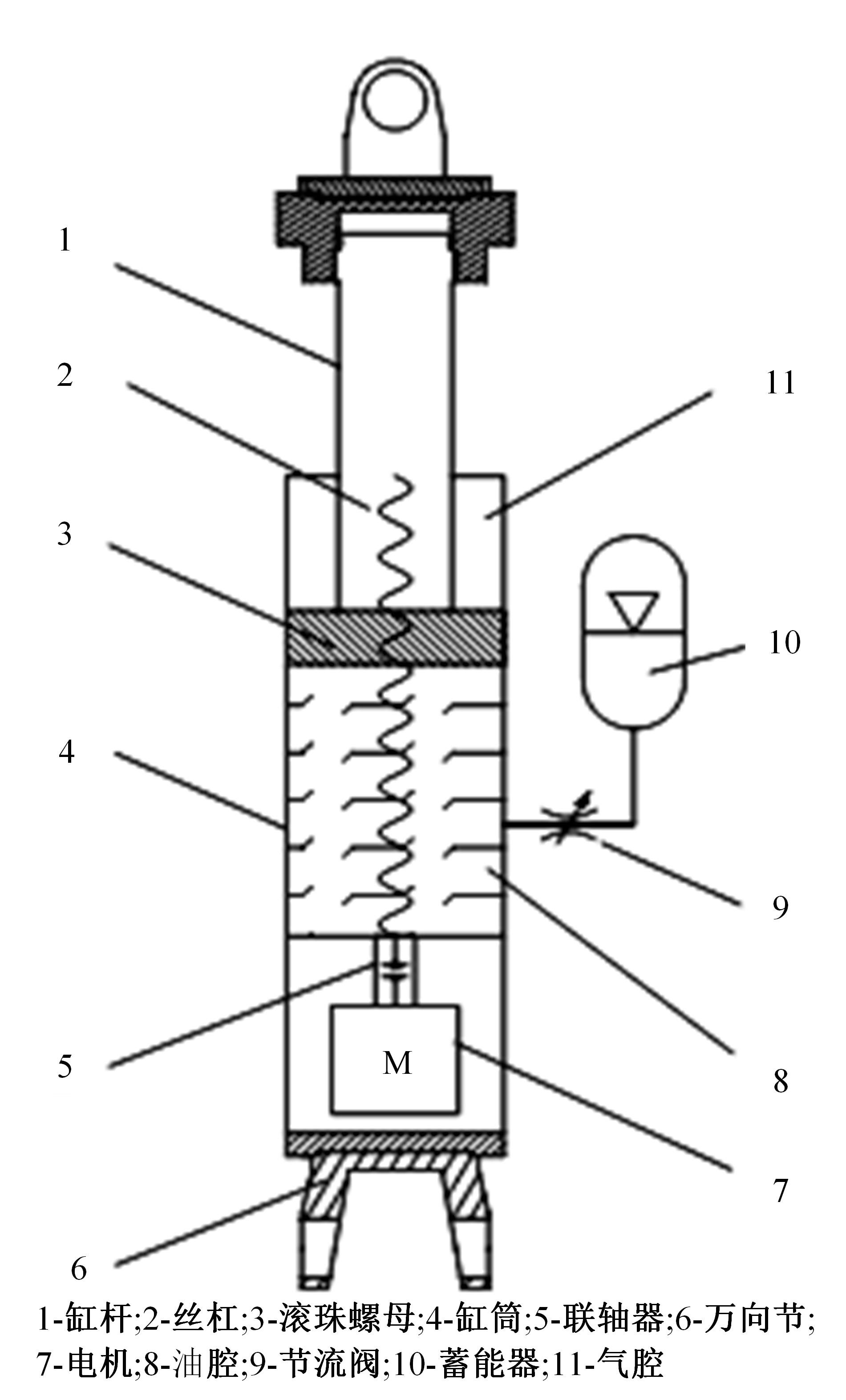

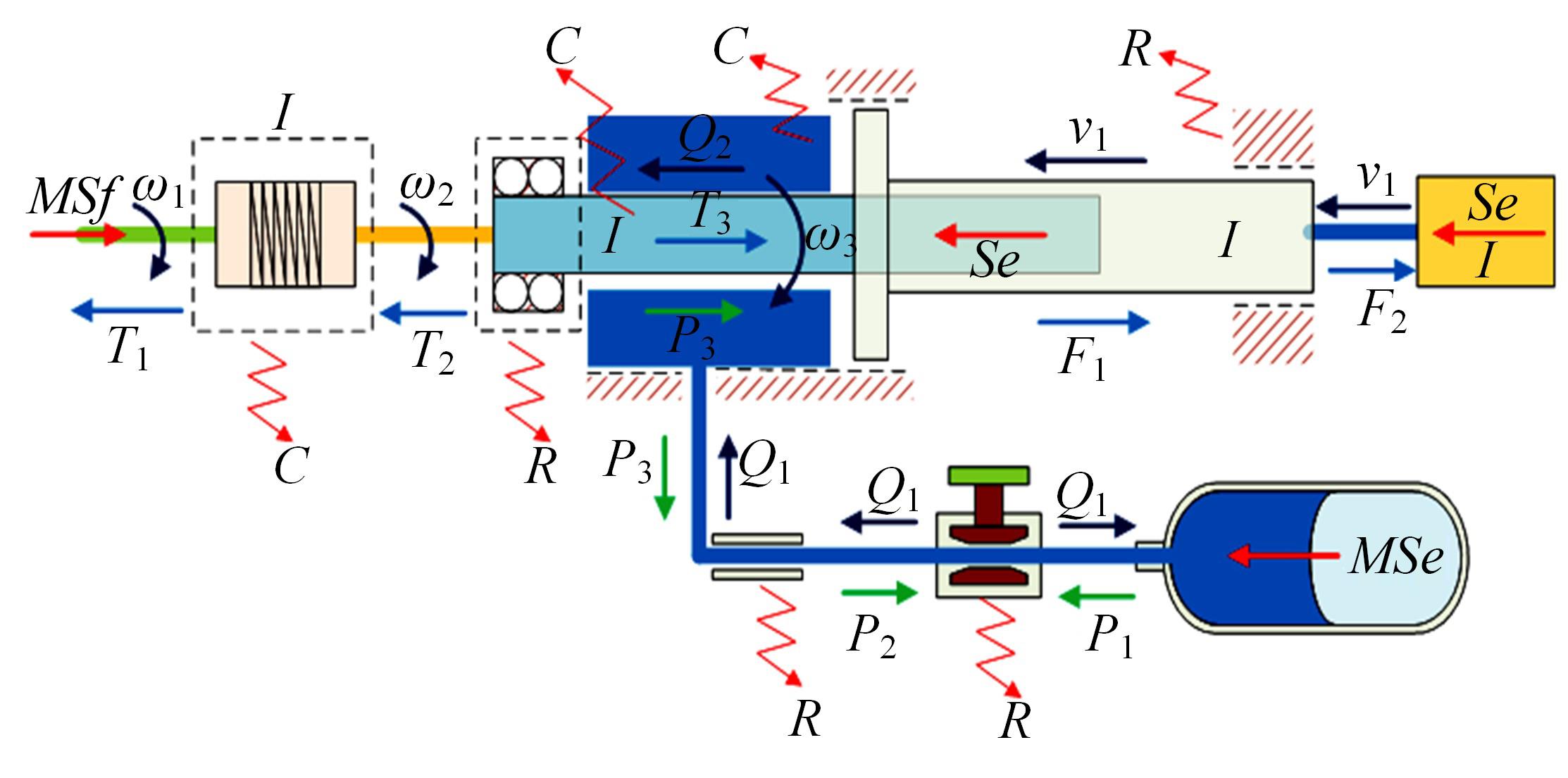

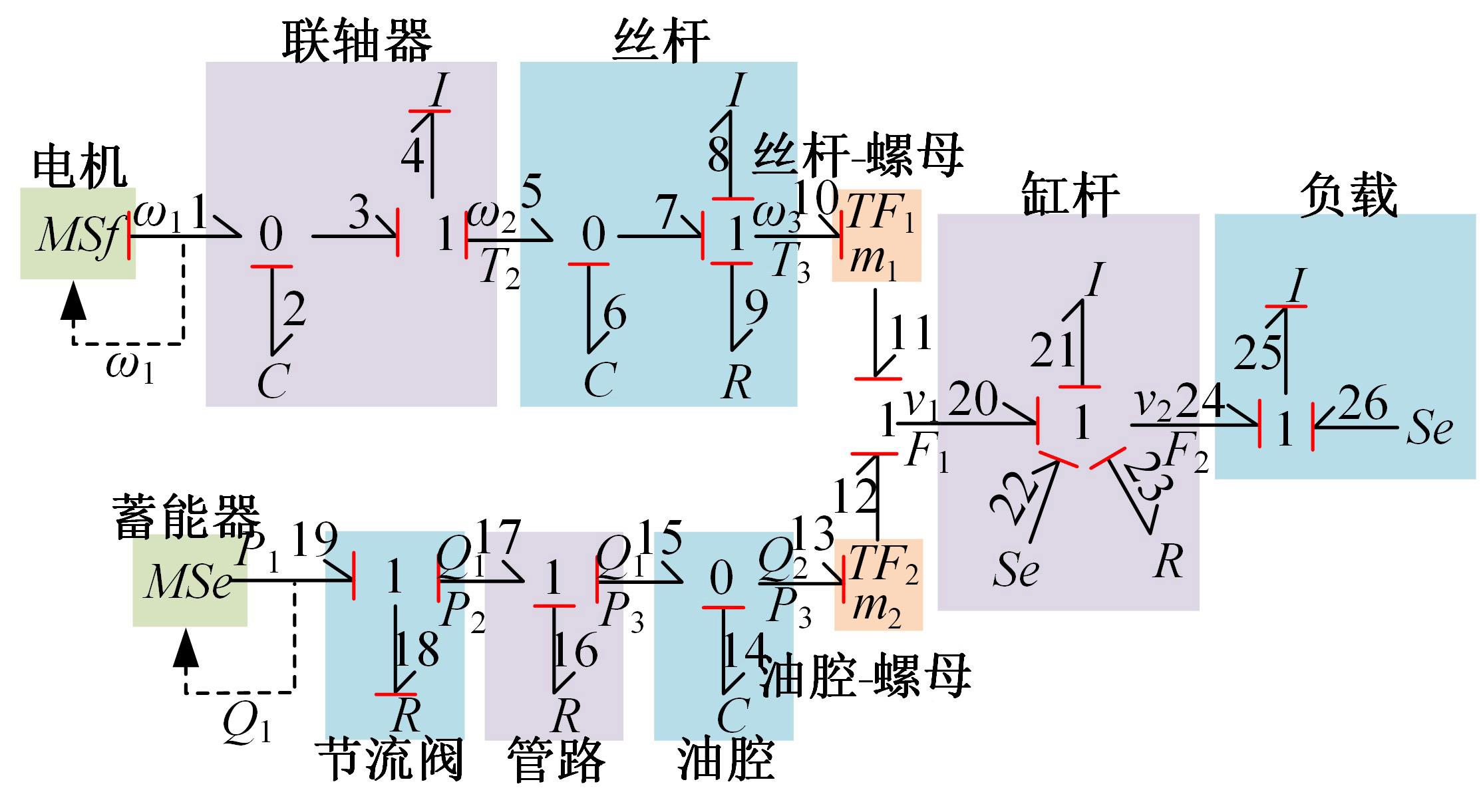

A new electric servo actuator based on energy recovery and its dynamic energy consumption analysis

Qian LIU1( ),Zhu-xin ZHANG2(

),Zhu-xin ZHANG2( ),Ding-xuan ZHAO1,Li-xin WANG1,Ya-fei WANG3

),Ding-xuan ZHAO1,Li-xin WANG1,Ya-fei WANG3

- 1.School of Mechanical Engineering,Yanshan University,Qinhuangdao 066000,China

2.School of Vehicle and Energy,Yanshan University,Qinhuangdao 066000,China

3.Systems Engineering Research Institute,China State Shipbuilding Corporation Limited,Beijing 100094,China

CLC Number:

- TP242.2

| 1 | He X, Xiao G, Hu B, et al. The applications of energy regeneration and conversion technologies based on hydraulic transmission systems: a review[J]. Energy Conversion and Management, 2020, 205:No. 112413. |

| 2 | Quan Z, Quan L, Zhang J. Review of energy efficient direct pump controlled cylinder electro-hydraulic technology[J]. Renewable and Sustainable Energy Reviews, 2014, 35: 336-346. |

| 3 | Liu D, Wang J, Wang S, et al. Active disturbance rejection control for electric cylinders with PD-type event-triggering condition[J]. Control Engineering Practice, 2020, 100: No. 104448. |

| 4 | Asswad E M, Alfayad S, Khalil K. Experimental estimation of friction and friction coefficient of a lightweight hydraulic cylinder intended for robotics applications[J]. International Journal of Applied Mechanics, 2018, 10(8):No. 1850080. |

| 5 | 梁涛, 张晓刚, 葛磊, 等. 泵阀双源协同驱动非对称液压缸系统特性[J]. 液压与气动, 2021, 45(12): 58-64. |

| Liang Tao, Zhang Xiao-gang, Ge Lei, et al. Characteristics of valve control and pump control dual source cooperative drive differential cylinder system[J]. Chinese Hydraulics & Pneumatics, 2021, 45(12): 58-64. | |

| 6 | Qu S, Fassbender D, Vacca A, et al. A high-efficient solution for electro-hydraulic actuators with energy regeneration capability[J]. Energy, 2021, 216: No.119291. |

| 7 | 龚中良, 金可. 电动缸传输效率测试系统的设计与试验研究[J]. 机械设计与制造, 2020, 2020: 300-303. |

| Gong Zhong-liang, Jin Ke. Design and test of transmission efficiency test system for electric cylinder[J]. Machinery Design & Manufacture, 2020, 2020: 300-303. | |

| 8 | 娄开成, 徐志鹏. 液压动态加载的伺服电动缸综合性能测试系统设计[J]. 中国计量大学学报, 2017, 28(4): 467-471. |

| Lou Kai-cheng, Xu Zhi-peng. Design of servo electric cylinders comprehensive performance test systems of based on hydraulic dynamic loading[J]. Journal of China University of Metrology, 2017, 28(4):467-471. | |

| 9 | 权龙, 夏连鹏, 赵斌, 等. 液压驱动机械臂势能回收利用研究工作进展[J]. 机械工程学报, 2018, 54(20): 4-13. |

| Quan Long, Xia Lian-peng, Zhao Bin, et al. Innovation progress in research on gravitational potential energy recovery and utilization of hydraulic driven mechanical arm[J]. J Mech Eng, 2018, 54(20): 4-13. | |

| 10 | 李泽鹏, 权龙, 葛磊, 等. 液电混合驱动液压挖掘机动臂特性及能效研究[J]. 机械工程学报, 2018, 54(20): 213-219. |

| Li Ze-peng, Quan Long, Ge Lei, et al. Research on characteristics and energy efficiency of hydraulic-electric combined driving hydraulic excavator boom[J]. J Mech Eng, 2018, 54(20): 213-219. | |

| 11 | 刘昌盛, 何清华, 张大庆, 等. 混合动力挖掘机势能回收系统参数优化与试验[J].吉林大学学报: 工学版, 2014, 44(2): 379-386. |

| Liu Chang-sheng, He Qing-hua, Zhang Da-qing, et al. Parameter optimization and experiment of potential energy recovery system of hybrid excavator[J]. Journal of Jilin University (Engineering and Technology Edition), 2014, 44(2): 379-386. | |

| 12 | 朱建新, 刘复平, 朱俊霖, 等. 电动叉车势能回收液压系统工作效率分析与实验[J]. 机械设计与研究, 2011, 27(6): 101-104. |

| Zhu Jian-xin, Liu Fu-ping, Zhu Jun-lin, et al. Analysisand experimental study on hydraulic system work efficiency for recovering the potential energy of electric forklift[J]. Machine Design and Research, 2011, 27(6): 101-104. | |

| 13 | 赵丁选, 陈明东, 戴群亮, 等. 油液混合动力液压挖掘机动臂势能回收系统[J].吉林大学学报: 工学版, 2011, 41(): 150-154. |

| Zhao Ding-xuan, Chen Ming-dong, Dai Qun-liang, et al. System of arm potential energy recovery in hybrid hydraulic excavators[J]. Journal of Jiin University(Engineering and Technology Edition), 2011, 41(Sup.1): 150-154. | |

| 14 | Lin T, Huang W, Ren H, et al. New compound energy regeneration system and control strategy for hybrid hydraulic excavators[J]. Automation in Construction, 2016, 68: 11-20. |

| 15 | Lin T, Wang Q, Hu B, et al. Research on the energy regeneration systems for hybrid hydraulic excavators[J]. Automation in Construction, 2010, 19(8): 1016-1026. |

| 16 | 樊延都, 张博航, 陈凯. 滚珠丝杠副高密封性组合油封[P]中国: CN2021I2532349.8, 2022-04-12. |

| 17 | 谷玉念, 林新忠. 滚珠丝杠副及密封结构[P].中国:CN202121293380.4,2021-11-26. |

| 18 | Liu W, Li L, Cai W, et al. Dynamic characteristics and energy consumption modelling of machine tools based on bond graph theory[J]. Energy, 2020, 212: No.118767. |

| 19 | Chen Y, Sun Q, Guo Q, et al. Dynamic modeling and experimental validation of a water hydraulic soft manipulator based on an improved Newton-Euler iterative method[J]. Micromachines, 2022, 13(1):No. 13010130. |

| 20 | Ungureanu L M, Petrescu F I T. Dynamics of mechanisms with superior couplings[J]. Applied Sciences, 2021, 11(17): No.11178207. |

| 21 | Tu T W. Dynamic modelling of a railway wheelset based on Kane's method[J]. International Journal of Heavy Vehicle Systems, 2020, 27(1/2): 202-226. |

| 22 | Somu N, Mr G R, Ramamritham K. A hybrid model for building energy consumption forecasting using long short term memory networks[J]. Applied Energy, 2020, 261: No.114131. |

| 23 | Saeedi M, Moradi M, Hosseini M, et al. Robust optimization based optimal chiller loading under cooling demand uncertainty[J]. Applied Thermal Engineering, 2019, 148: 1081-1091. |

| 24 | Su S, Wang X, Cao Y, et al. An energy-efficient train operation approach by integrating the metro timetabling and eco-driving[J]. IEEE Trasactions on Intelligent Transportation Systems, 2019, 21(10): 4252-4268. |

| 25 | KomuZ G, Geitner G H. Systems featuring chain structures⁃a generalized bond graph modelling[J]. International Journal of General Systems, 2019, 48(8): 861-889. |

| 26 | Geinter G H, Komurgoz G. Generic power split modelling for compound epicyclic four-speed gears[J]. Mechanism and Machine Theory, 2017, 116: 50-68. |

| 27 | Zhang Z, Liu Q, Zhao D, et al. Electrical aircraft ship integrated secure and traverse system design and key characteristics analysis[J]. Applied Sciences, 2022, 12(5): No.12052603. |

| 28 | Zhang Z, Liu Q, Zhao D, et al. Research on shipborne helicopter electric rapid secure device: system design, modeling, and simulation[J]. Sensors, 2022, 22(4): No.22041514. |

| 29 | Wang Y, Zhao D, Wang L, et al. Dynamic simulation and analysis of the elevating mechanism of a forklift based on a power bond graph[J]. Journal of Mechanical Science and Technology, 2016, 30(9): 4043-4048. |

| 30 | Kato S, Sasaki S. Effects of hydraulic oil and lubricant additives on dynamic friction properties under various reciprocating sliding conditions[J]. Friction, 2020, 8(2): 471-480. |

| 31 | Yi T, Ma F, Jin C, et al. Investigation on thermal characteristics of the oil-circulating hydraulic energy storage system for hybrid mining trucks[J]. Frontiers in Energy Research, 2021, 9:No. 733919. |

| [1] | Jun-cheng WANG,Lin-feng LYU,Jian-min LI,Jie-yu REN. Optimal sliding mode ABS control for electro⁃hydraulic composite braking of distributed driven electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1751-1758. |

| [2] | Peng HU,Jian-xin ZHU,Chang-sheng LIU,Da-qing ZHANG. Characteristics of boom potential energy alternate recovery and utilization system of hydraulic excavator [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2256-2264. |

| [3] | Xin-xin SHI,Jia-cai HUANG,Fang-zheng GAO. Measuring noise rejection of motion control system based on fractional BICO filter [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1873-1878. |

| [4] | QIU Yan-kai, LI Bao-ren, YANG Gang, CAO Bo, LIU Zhen. Characteristics and mechanism reducing pressure ripple of hydraulic system with novel hydraulic muffler [J]. 吉林大学学报(工学版), 2018, 48(4): 1085-1091. |

| [5] | LIU Xiang-yong, LI Wan-li. Electro-hydraulic proportional control model of accumulator [J]. 吉林大学学报(工学版), 2018, 48(4): 1072-1084. |

| [6] | CHU Liang, SUN Cheng-wei, GUO Jian-hua, ZHAO Di, LI Wen-hui. Evaluation method of braking energy recovery based on wheel cylinder pressure [J]. 吉林大学学报(工学版), 2018, 48(2): 349-354. |

| [7] | ZENG Xiao-hua, LI Wen-yuan, SONG Da-feng, LI Gao-zhi, FENG Tao. Driving performance of hub-motor hydraulic driving system for heavy commercial vehicles [J]. 吉林大学学报(工学版), 2017, 47(4): 1009-1016. |

| [8] | DONG Han,LIU Xin-hui,WANG Xin,ZHENG Bo-yuan,LIANG Wei-quan,WANG Jia-yi. Impact of main parameters of accumulator on parallel hydraulic hybrid [J]. 吉林大学学报(工学版), 2015, 45(2): 420-428. |

| [9] | DONG Han, LIU Xin-hui, WANG Xin, ZHENG Bo-yuan, LIANG Wei-quan, WANG Jia-yi. Parallel hydraulic hybrid braking regenerative characteristics [J]. 吉林大学学报(工学版), 2014, 44(6): 1655-1663. |

| [10] | LIU Chang-sheng, HE Qing-hua, ZHANG Da-qing, LI Tie-hui, GONG Jun, ZHAO Yu-ming. Parameter optimization and experiment of potential energy recovery system of hybrid excavator [J]. 吉林大学学报(工学版), 2014, 44(2): 379-386. |

| [11] | DONG Han, LIU Xin-hui, WANG Xin, CHEN Jin-shi, WANG Jia-yi, ZHENG Bo-yuan. Energy saving performance of hydraulic hybrid system with AMESim [J]. 吉林大学学报(工学版), 2013, 43(05): 1264-1270. |

| [12] | YAO Yun-shi, LIU Long, FENG Zhong-xu, SHEN Jian-jun, CHEN Shi-bin. Simulation of hybrid power system for tandem vibratory rollers [J]. 吉林大学学报(工学版), 2013, 43(04): 871-876. |

| [13] | YAO Liang, CHU Liang, ZHOU Fei-kun, LIU Ming-hui, ZHANG Yong-sheng, WEI Wen-ruo. Simulation and analysis of potential of energy-saving from braking energy recovery of electric vehicle [J]. 吉林大学学报(工学版), 2013, 43(01): 6-11. |

| [14] | HUANG Wei-zhong, GUO Li-shu, SHI Zheng-tang, YANG Xiong, HUANG Guo-xing, PAN Zhi-hui. Dynamic response of electric vehicle braking system based on electronically controlled hydraulic braking system [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 13-16. |

| [15] | ZHAO Ding-xuan, CHEN Ming-dong, DAI Qun-liang, ZHANG Er-ping, XU Chun-bo. System of arm potential energy recovery in hybrid hydraulic excavators [J]. 吉林大学学报(工学版), 2011, 41(增刊1): 150-154. |

|

||