Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (6): 1807-1820.doi: 10.13229/j.cnki.jdxbgxb.20220860

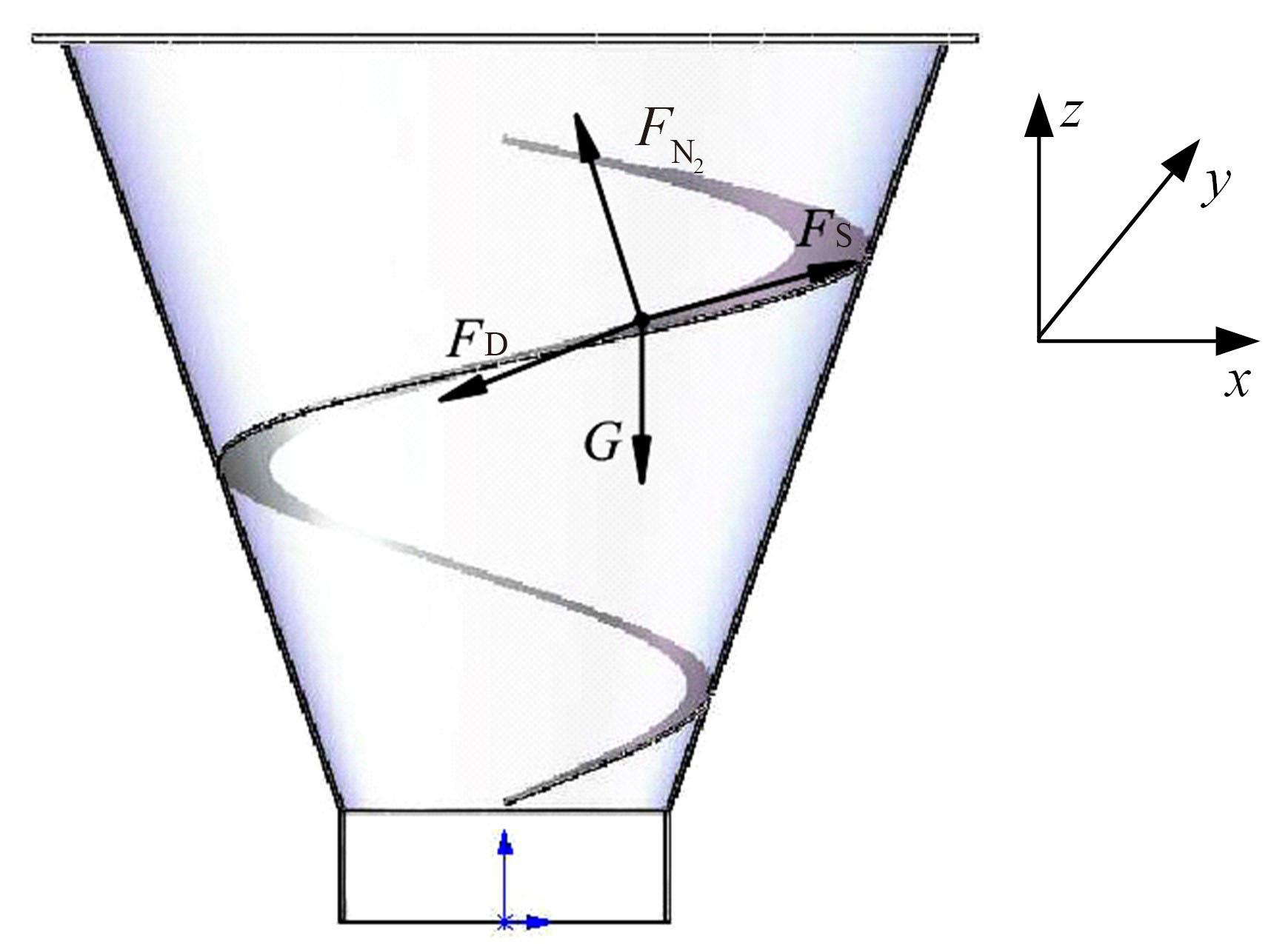

Design and experiment of diversion type double-cylinder cyclone separation system for rapeseed combine harvester

Cai-xia SHU1,2( ),Jia YANG1,Qing-xi LIAO1,2,Xing-yu WAN1,Jia-cheng YUAN1

),Jia YANG1,Qing-xi LIAO1,2,Xing-yu WAN1,Jia-cheng YUAN1

- 1.College of Engineering,Huazhong Agricultural University,Wuhan 430070,China

2.Key Laboratory of Agricultural Equipment in Mid-lower Yangtze River,Ministry of Agriculture and Rural Affairs,Wuhan 430070,China

CLC Number:

- S225.99

| 1 | 陈慧,高丽萍,廖庆喜,等. 肥料减量深施对土壤N2O排放和冬油菜产量的影响[J]. 农业工程学报, 2020, 36(21): 80-87. |

| Chen Hui, Gao Li-ping, Liao Qing-xi, et al. Effects of reduced and deep fertilizer on soil N2O emission and yield of winter rapeseed[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(21): 80-87. | |

| 2 | 罗海峰,汤楚宙,官春云,等. 适应机械化收获的田间油菜植株特性研究[J].农业工程学报, 2010, 26():61-66. |

| Luo Hai-feng, Tang Chu-zhou, Guan Chun-yun, et al. Plant characteristic research on field rape based on mechanized harvesting adaptability[J]. Transactions of the Chinese Society of Agricultural Engineering, 2010, 26(Sup.1): 61-66. | |

| 3 | 万星宇,廖庆喜,廖宜涛,等. 油菜全产业链机械化智能化关键技术装备研究现状及发展趋势[J].华中农业大学学报, 2021, 40(2): 24-44. |

| Wan Xing-yu, Liao Qing-xi, Liao Yi-tao, et al. Situation and prospect of key technology and equipment in mechanization and intelligentization of rapeseed whole industry chain[J]. Journal of Huazhong Agricultural University, 2021, 40(2): 24-44. | |

| 4 | 徐立章,李洋,李耀明,等. 谷物联合收获机清选技术与装置研究进展[J]. 农业机械学报, 2019, 50(10):1-16. |

| Xu Li-zhang, Li Yang, Li Yao-ming, et al. Research progress on cleaning technology and device of grain combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(10): 1-16. | |

| 5 | Evangelista R L, Hojilla-Evangelista M P, Cermak S C,et al. Dehulling of coriander fruit before oil extraction[J].Industrial Crops and Products, 2015, 69: 378-384. |

| 6 | Innocentini M D M, Barizan W S, Alves M N O, et al. Pneumatic separation of hulls and meats from cracked soybeans[J]. Food and Bioproducts Processing, 2009, 87(4): 237-246. |

| 7 | Dai F, Song X F, Guo W J, et al. Simulation and test on separating cleaning process of flax threshing material based on gas-solid coupling theory[J]. International Journal of Agricultural and Biological Engineering, 2020, 13(1): 73-81. |

| 8 | Wan Xing-yu, Liao Qing-xi, Xu Yang,et al. Design and evaluation of cyclone separation cleaning devices using a conical sieve for rape combine harvesters[J]. Applied Engineering in Agriculture, 2018, 34(4): 677-686. |

| 9 | 王荣东,杜海鸥,王国芝,等. 旋风组钠气溶胶去除系统性能验证[J].原子能科学技术, 2022, 56(6):1078-1084. |

| Wang Rong-dong, Du Hai-ou, Wang Guo-zhi, et al. Performace verification of sodium aerosol removal system in cyclone group[J]. Atomic Energy Science and Technology, 2022, 56(6): 1078-1084. | |

| 10 | Parvaz F, Hosseini S H, Elsayed K, et al. Numerical investigation of effects of inner cone on flow field, performance and erosion rate of cyclone separators[J]. Separation and Purification Technology, 2018,201: 233-237. |

| 11 | 王晨雯. 旋风分离器内短路流的流动特征与形成机理研究[D]. 兰州:兰州大学资源环境学院,2020. |

| Wang Chen-wen. A study on the characteristics and mechanism of short-circuit flow in a gas cyclone[D]. Lanzhou: College of Earth and Enviornmental Science, Lanzhou University, 2020. | |

| 12 | 戴飞. 胡麻脱粒物料分离清选机理与关键技术研究[D].兰州:甘肃农业大学机电工程学院, 2020. |

| Dai Fei. Study on the separating-cleaning mechanism andkey technology of flax threshing material[D]. Lanzhou: Gansu Agricultural University Mechanical and Electrical Engineering college, 2020. | |

| 13 | 谢超,刘大为,李旭,等. 小型水稻联合收割机旋风分离清选装置的结构优化与试验[J].中国农业科技导报,2018, 20(5): 54-63. |

| Xie Chao, Liu Da-wei, Li Xu, et al. Structure optimization and experiment on cyclone separation-purification device for small rice combine harvester[J]. Journal of Agricultural Science and Technology, 2018, 20(5): 54-63. | |

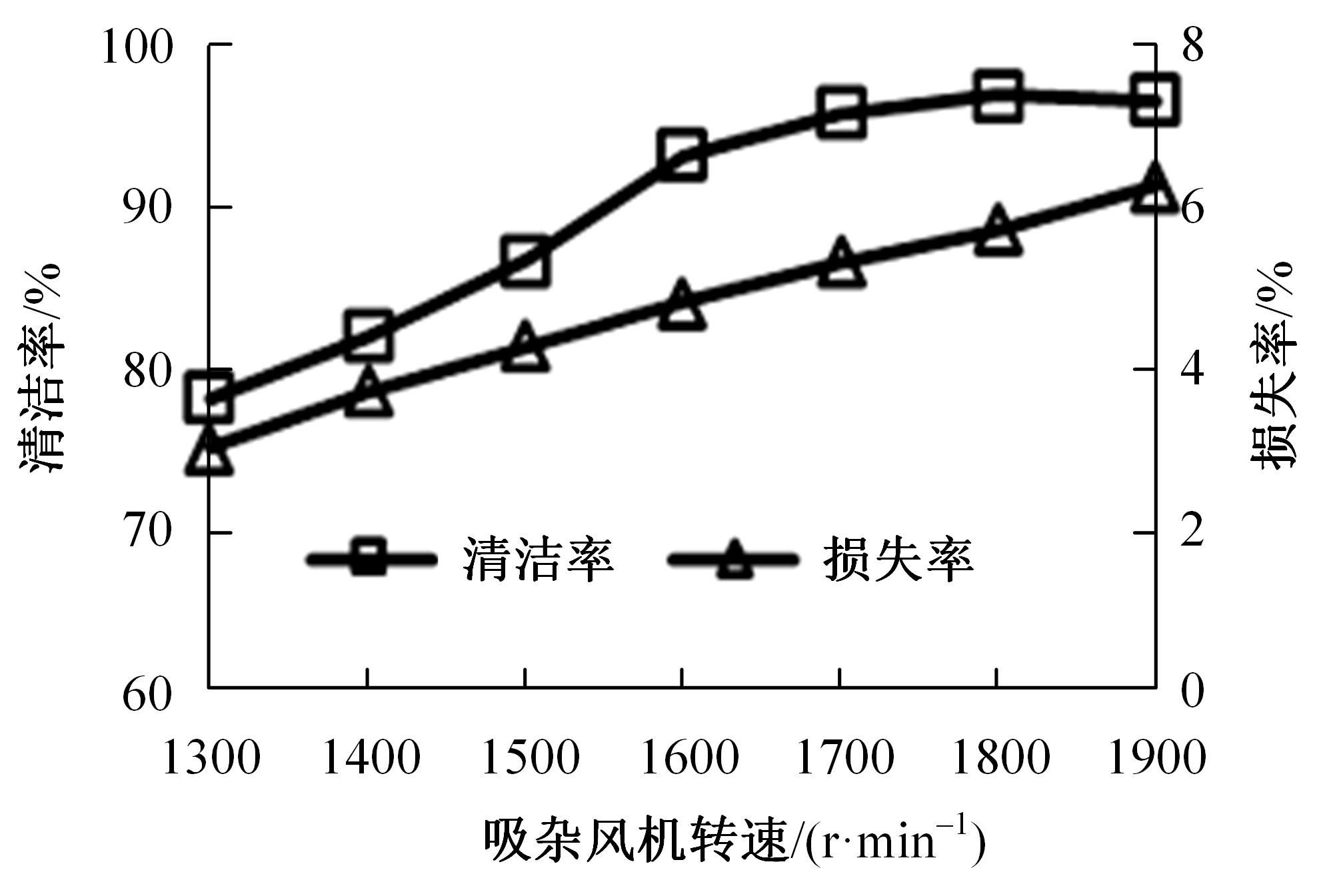

| 14 | 金鑫,杜新武,甘帮兴,等. 小型联合收获机旋风分离系统清选性能试验[J]. 农业机械学报, 2016, 47(5): 99-105. |

| Jin Xin, Du Xin-wu, Gan Bang-xing, et al. Cleaning performance experiment of cyclone separating system in miniature combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(5): 99-105. | |

| 15 | 刘师多,张利娟,师清翔,等. 微型小麦联合收获机旋风分离清选系统研究[J]. 农业机械学报, 2006(6):45-48. |

| Liu Shi-duo, Zhang Li-juan, Shi Qing-xiang, et al. Experimental research on cyclone separating cleaning system used on micro-combine harvester of wheat[J]. Transactions of the Chinese Society for Agricultural Machinery, 2006(6): 45-48. | |

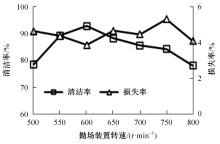

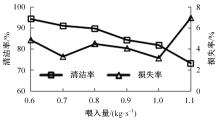

| 16 | 万星宇,廖宜涛,袁佳诚,等. 油菜联合收获机组合式旋风分离清选参数分析与试验[J].农业机械学报, 2020, 51(): 202-211. |

| Wan Xing-yu, Liao Yi-tao, Yuan Jia-cheng, et al. Parameters analysis and experiment of cyclone separation cleaning system with replaceable parts for rapeseed combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(Sup.2): 202-211. | |

| 17 | 万星宇.油菜联合收获机旋风分离清选系统设计及其工作机理[D]. 武汉:华中农业大学工学院, 2019. |

| Wan Xing-yu. Design and working mechanical study on the cyclone separation cleaning system for rapeseed combine harvester[D].Wuhan:College Of Engineering, Huazhong Agricultural University, 2019. | |

| 18 | 刘正怀,郑一平,王志明,等. 微型稻麦联合收获机气流式清选装置研究[J].农业机械学报, 2015, 46(7): 102-108. |

| Liu Zheng-huai, Zheng Yi-ping, Wang Zhi-ming, et al. Design on air-flowing cleaning unit of micro rice-wheat combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(7):102-108. | |

| 19 | 迟媛,李蒙福,杨月斌,等. 禽蛋壳膜旋风式气流清选装置研究[J].农业机械学报, 2019, 50(8): 339-350. |

| Chi Yuan, Li Meng-fu, Yang Yue-bin, et al. Cyclone device collecting eggshell membranes and eggshells separately from eggshells mixture[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(8): 339-350. | |

| 20 | El-Batsh H M. Improving cyclone performance by proper selection of the exit pipe[J]. Applied Mathematical Modelling, 2013, 37(7): 5286-5303. |

| 21 | 侯华铭,崔清亮,郭玉明,等. 气吹式粮油作物脱出物清选悬浮速度测量装置设计与试验[J]. 农业工程学报,2018,34(16):43-49. |

| Hou Hua-ming, Cui Qing-liang, Guo Yu-ming, et al. Design and test of air-sweeping suspension velocity testing device for cleaning threshed materials of grain and oil crops[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(16): 43-49. | |

| 22 | 陈立,廖庆喜,宗望远,等. 油菜联合收获机脱出物空气动力学特性测定[J]. 农业机械学报, 2012, 43(): 125-130. |

| Chen Li, Liao Qing-xi, Zong Wang-yuan, et al. Aerodynamic characteristics measurement of extraction components for rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(Sup.1): 125-130. | |

| 23 | 马振. 大输量旋风分离器优化设计研究[D].北京:中国石油大学机械与存储工程学院, 2018. |

| Ma Zhen. Study on optimal design of cyclone separator with large mass transmission[D]. Beijing: College of Mechanical and Transportation Engineering, China University of Petroleum, 2018. | |

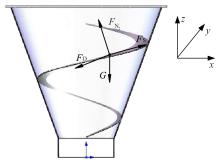

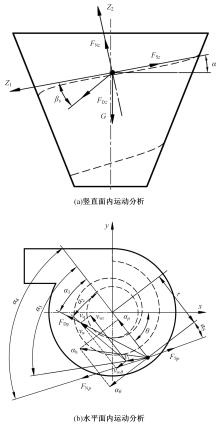

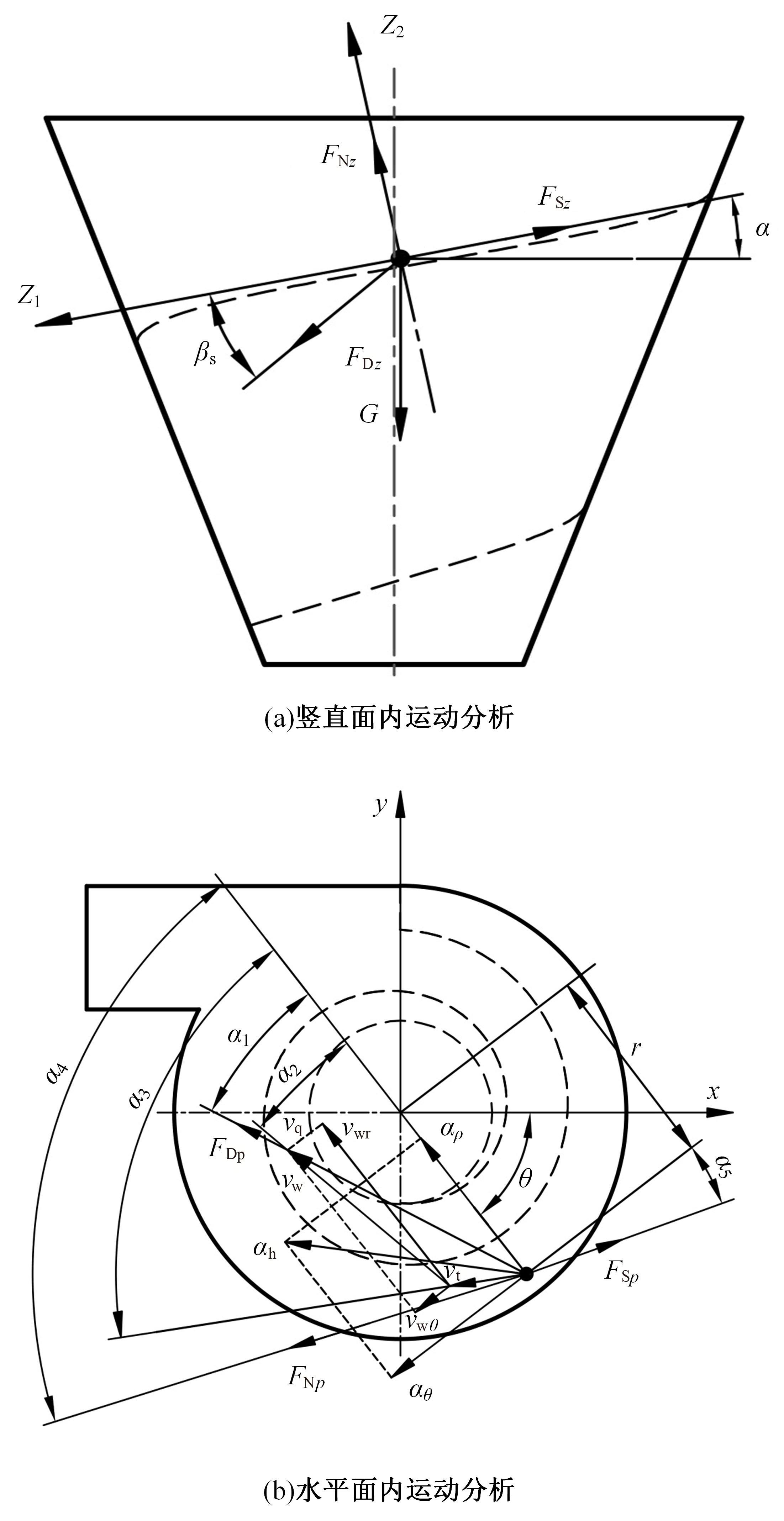

| 24 | 王修善,刘大为,谢方平,等. 旋风清选分离筒中脱出物籽粒的运动分析[J]. 时代农机, 2019, 46(3): 104-108. |

| Wang Xiu-shan, Liu Da-wei, Xie Fang-ping,et al. Motion analysis of the grains of the separated materials in the cyclone cleaning and separating cylinder[J]. Times Agricultural Machinery, 2019, 46(3): 104-108 | |

| 25 | 彭才望,孙松林,贺喜,等. 双向螺旋黑水虻虫沙收集装置设计与试验[J]. 浙江大学学报: 农业与生命科学版, 2020, 46(5): 637-646. |

| Peng Cai-wang, Sun Song-lin, He Xi, et al. Design and experiment of bidirectional spiral collecting device for Hermetia illucens insect sand[J]. Journal of Zhejiang University Agriculture and Life Sciences, 2020, 46(5): 637-646. | |

| 26 | 廖庆喜,王昌,何坤,等. 油菜联合收获后含杂油菜籽复清机设计与试验[J]. 农业机械学报, 2021, 52(10): 175-185, 232. |

| Liao Qing-xi, Wang Chang, He Kun, et al. Design and experiment on re-cleaning machine for rapeseed after combine harvesting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(10): 175-185, 232. | |

| 27 | 黄炎,赵满全. 基于数值模拟与风洞试验的旋风分离式集沙仪优化设计[J].农业工程学报,2015,31(16):50-56. |

| Huang Yan, Zhao Man-quan. Optimization design of performance test of cyclone separator sand sampler based on numerical simulation and wind erosion tunnel experiment[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(16): 50-56. | |

| 28 | 周韬. 旋风分离器的气固两相特性研究与数值模拟[D].上海:上海交通大学机械与动力工程学院,2007. |

| Zhou Tao. Study and numerical simulation on gas-solid two-phase characteristic of cyclone separator[D]. Shanghai:School of Mechanical Echanical Engineering, Shanghai Jiao Tong University, 2007. | |

| 29 | 董玉平,董磊,强宁,等. 旋风分离器内生物质焦油湍流特性的数值模拟[J]. 农业工程学报, 2010, 26(9): 171-175. |

| Dong Yu-ping, Dong Lei, Qiang Ning, et al. Numerical simulation of biomass gas and tar torrential flow characteristics in cyclone separator[J]. Transactions of the Chinese Society of Agricultural Engineering, 2010, 26(9): 171-175. | |

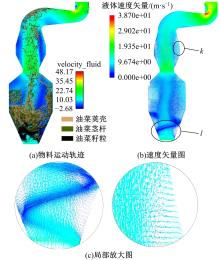

| 30 | 王国伟,夏晓蒙,朱庆辉,等.基于DEM-CFD耦合的辅助充种气吸式大豆高速精密排种器设计与试验[J].吉林大学学报: 工学版, 2022, 52(5): 1208-1221. |

| Wang Guo-wei, Xia Xiao-meng, Zhu Qing-hui, et al. Design and experiment of soybean high⁃speed precision vacuumseed metering with auxiliary filling structure based on DEM⁃CFD[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(5): 1208-1221. | |

| 31 | 刘立意,郝世杨,张萌,等. 基于CFD-DEM的稻谷通风阻力数值模拟与试验[J].农业机械学报, 2015, 46(8): 27-32. |

| Liu Li-yi, Hao Shi-yang, Zhang Meng, et al. Numerical simulation and experiment on paddy ventilation resistance based on CFD-DEM[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(8): 27-32. | |

| 32 | 袁竹林, 朱立平, 耿凡. 气固两相流动与数值模拟[M].南京:东南大学出版社, 2013. |

| 33 | 心男.基于 EDEM-Fluent 耦合的气吹式排种器工作过程仿真分析[D].长春:吉林大学生物与农业工程学院, 2013. |

| Xin Nan. Simulation analysis of working process of air-blowing seed-metering device based on coupled EDEM-Fluent[D]. Changchun: College of Biological and Agricultural Engineering, Jilin University,2013. | |

| 34 | 邢浩男,马少春,王风磊,等. 切段式甘蔗收割机排杂风机结构优化与试验[J]. 农业工程学报,2020,36(20): 67-75. |

| Xing Hao-nan, Ma Shao-chun, Wang Feng-lei, et al. Structure optimization and experiment of sugarcane chopper harvester extractor[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(20): 67-75. | |

| 35 | 袁佳诚,王昌,何坤,等. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报: 工学版, 2021, 51(5): 1897-1907. |

| Yuan Jia-cheng, Wang Chang, He Kun, et al. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(5): 1897-1907. | |

| 36 | 中国农业机械化科学研究院. 农业机械设计手册(下册)[M]. 北京:中国农业科学技术出版社, 2007. |

| [1] | Shuai MA,Li-ming XU,Shu-cai XU,Cong NIU,Cheng-gong YAN,Hao-chao TAN. Design and experiment of grapevine cold⁃proof soil cleaner with combined scraping and brushing [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 294-312. |

| [2] | Lin-rong SHI,Wu-yun ZHAO. Design and test of rolling spoon type flaxes precision hole sower for caraway in northwest cold and arid agricultural region [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2706-2717. |

| [3] | Chao-jian FANG,Xin-rong HU. Privacy-sensitive data filtering algorithm based on fuzzy approximation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1174-1180. |

| [4] | Guo-liang WEI,Qing-song ZHANG,Biao WANG,Kun HE,Qing-xi LIAO. Analysis and experiment on parameters of plough body of rapeseed direct seeder [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1709-1718. |

| [5] | Xing-yu WAN,Qing-xi LIAO,Ya-jun JIANG,Yi-yin SHAN,Yu ZHOU,Yi-tao LIAO. Discrete element simulation and experiment of mechanized harve- sting and chopping process for fodder rape crop harvest [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2735-2745. |

| [6] | Jia-cheng YUAN,Chang WANG,Kun HE,Xing-yu WAN,Qing-xi LIAO. Effect of components mass ratio under sieve on cleaning system performance for rape combine harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1897-1907. |

| [7] | Gang WANG,Hui-li LIU,Hong-lei JIA,Chun-jiang GUO,Yong-jian CONG,Ming-hao QU. Design and experiment of touching-positioning weeding device for inter-row maize (Zea Mays L.) [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1518-1527. |

| [8] | QIN Zheng-kun,HE Fei,LIU Chun-ling,MA Chun-sheng. Effect of reactive ion etching process on simulation of polymeric arrayed waveguide grating multiplexers [J]. 吉林大学学报(工学版), 2011, 41(03): 791-794. |

| [9] | Zhao Ji-yin;Zheng Rui-rui;Liu Yu . Power transformer fault diagnosis based on trapezium gray clustering analysis [J]. 吉林大学学报(工学版), 2008, 38(03): 726-0730. |

|

||