Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (6): 1677-1685.doi: 10.13229/j.cnki.jdxbgxb.20221343

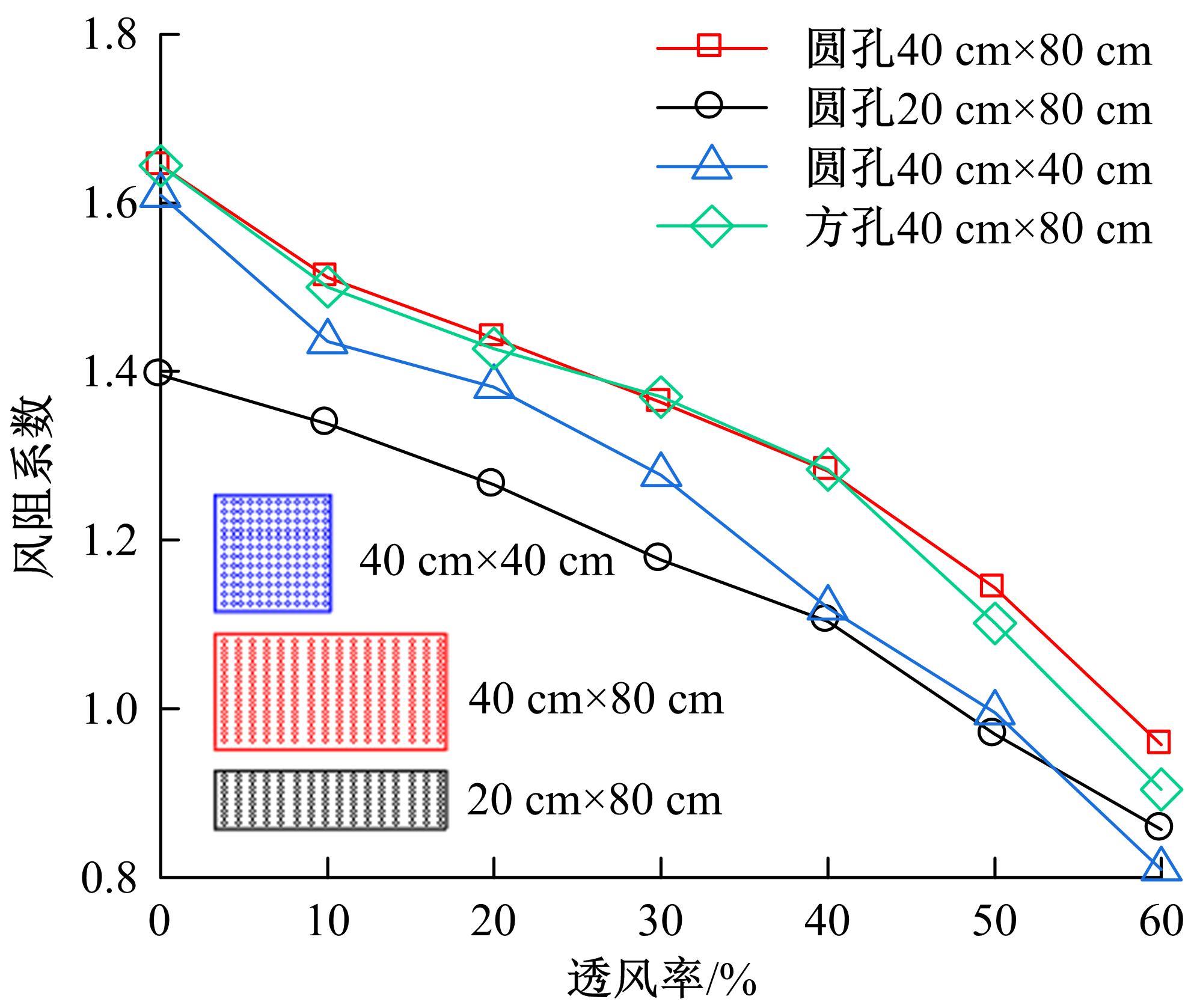

Size and shape effects of wind drag coefficients for porous structures

Feng WANG1( ),Shuang-rui LIU1,Jia-ying WANG1,Jia-ling SONG2,Jun WANG1,Jiu-peng ZHANG1,Xiao-ming HUANG3

),Shuang-rui LIU1,Jia-ying WANG1,Jia-ling SONG2,Jun WANG1,Jiu-peng ZHANG1,Xiao-ming HUANG3

- 1.School of Highway,Chang'an University,Xi'an 710064,China

2.Research Center of Wind Engineering and Engineering Vibration,Guangzhou University,Guangzhou 510006,China

3.School of Transportation,Southeast University,Nanjing 210018,China

CLC Number:

- TU312

| 1 | Allori D, Bartoli G, Mannini C. Wind tunnel tests on macro-porous structural elements: a scaling procedure[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2013, 123: 291-299. |

| 2 | 李春光, 王龙, 韩艳, 等. 风屏障对流线型箱梁涡振性能影响机理试验研究[J]. 湖南大学学报:自然科学版, 2021, 48(11): 12-21. |

| Li Chun-guang, Wang Long, Han Yan, et al. Experimental study on influence of wind barrier permeability on characteristics of main girder vortex-induced vibration[J]. Journal of Hunan University(Natural Sciences), 2021, 48(11): 12-21. | |

| 3 | Buljac A, Kozmar H, Pospíšil S, et al. Flutter and galloping of cable-supported bridges with porous wind barriers[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2017, 171: 304-318. |

| 4 | Dong Z, Luo W, Qian G, et al. A wind tunnel simulation of the mean velocity fields behind upright porous fences[J]. Agricultural and Forest Meteorology, 2007, 146(1/2): 82-93. |

| 5 | Jr P A K, van Winkle M. Discharge coefficients through perforated plates[J]. AIChE Journal, 1957, 3(3): 305-312. |

| 6 | Jr P L S, van Winkle M. Discharge coefficients through perforated plates at Reynolds numbers of 400 to 3,000[J]. AIChE Journal, 1958, 4(3): 266-268. |

| 7 | Huang S, Ma T, Wang D, et al. Study on discharge coefficient of perforated orifices as a new kind of flowmeter[J]. Experimental Thermal and Fluid Science, 2013, 46: 74-83. |

| 8 | 田红, 高旭, 汤珂, 等. 结构参数对多孔板低温流量计性能影响分析[J]. 低温工程, 2015(6): 43-48. |

| Tian Hong, Gao Xu, Tang Ke, et al. Influence of geometric parameters on performance of a cryogenic fluid flowmeter with perforated plate[J]. Cryogenics, 2015(6): 43-48. | |

| 9 | 王慧锋, 凌长玺. 几何特征对多孔板特性的影响[J]. 华东理工大学学报:自然科学版, 2015, 41(5): 677-685. |

| Wang Hui-feng, Ling Chang-xi. Effect of general geometric characteristics for multi-hole orifices'features[J]. Journal of East China University of Science and Technology(Natural Science Edition), 2015, 41(5): 677-685. | |

| 10 | 赵天怡, 张吉礼. 多孔孔板节流特性主效应因素试验[J].哈尔滨工业大学学报, 2007, 39(12): 1878-1881. |

| Zhao Tian-yi, Zhang Ji-li. Experimental study on main factor affecting throttling characteristic for multi-hole orifice[J]. Journal of Harbin Institute of Technology, 2007, 39(12): 1878-1881. | |

| 11 | 韩伟, 董志勇, 邴斌, 等. 多孔板压力特性的试验研究[J].水力发电学报, 2014, 33(6): 126-131. |

| Han Wei, Dong Zhi-yong, Bing Bin, et al. Experimental study of pressure characteristics behind multi-orifice plates[J]. Journal of Hydroelectric Engineering, 2014, 33(6): 126-131. | |

| 12 | 马有福, 王凡, 吕俊复. 孔数与孔厚对多孔板压损系数的影响机理[J]. 化工进展, 2020, 39(2): 446-452. |

| Ma You-fu, Wang Fan, Jun-fu Lü. Influencing mechanism of orifice number and thickness on pressure loss coefficient of multi-orifice plates[J]. Chemical Industry and Engineering Progress, 2020, 39(2): 446-452. | |

| 13 | 李艺, 苏悦琦. 基于不同孔径范围的碳化作用下纤维混凝土的气体渗透性能和细观结构[J]. 吉林大学学报:工学版, 2021, 51(4): 1287-1295. |

| Li Yi, Su Yue-qi. Gas permeability and meso-structure of fiber reinforced concrete under carbonation based on different pore sizes[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(4): 1287-1295. |

| [1] | Gui-sheng CHEN,Guo-yan LUO,Liang-xue LI,Zhen HUANG,Yi LI. Analysis of diesel particulate filter channel flow field and its noise characteristics in plateau environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 1892-1901. |

| [2] | Zi-yu LIU,Shi-tong CHEN,Mo-mo ZHI,Xiao-ming HUANG,Zhe-xin CHEN. Ultimate bearing capacity of temporary⁃permanent conversion rush⁃repair steel pier for emergency use [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1601-1611. |

| [3] | Yu FENG,Jian-ming HAO,Feng WANF,Jiu-peng ZHANG,Xiao-ming HUANG. Analysis of transient wind⁃induced response of long⁃span bridge under nonstationary wind field [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1638-1649. |

| [4] | Hua WANG,Long-lin WANG,Zi-mo ZHANG,Xin HE. Safety early warning technology of continuous rigid frame bridges based on crack width variation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1650-1657. |

| [5] | Jun WANG,Jia-wu LI,Feng WANG,Jiu-peng ZHANG,Xiao-ming HUANG. Wind speed distribution in simplified U⁃shaped valley and its effect on buffeting response of long⁃span suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1658-1668. |

| [6] | Chun-li WU,Shi-ming HUANG,Kui LI,Zheng-wei GU,Xiao-ming HUANG,Bing-tao ZHANG,Run-chao YANG. Analysis of pier action effect under flood based on numerical simulation and statistical analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1612-1620. |

| [7] | Hui JIANG,Xin LI,Xiao-yu BAI. Review on development of bridge seismic structural systems: from ductility to resilience [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1550-1565. |

| [8] | Guo-jin TAN,Qing-wen KONG,Xin HE,Pan ZHANG,Run-chao YANG,Yang-jun CHAO,Zhong YANG. Bridge scour depth identification based on dynamic characteristics and improved particle swarm optimization algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1592-1600. |

| [9] | Yue ZHANG,Chuan-sen LIU,Fei SONG. Influence of abutment back wall on continuous girder bridge's seismic fragility [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1372-1380. |

| [10] | Hai-bin WEI,Shuan-ye HAN,Hai-peng BI,Qiong-hui LIU,Zi-peng MA. Intelligent sensing road active ice and snow removal system and experimental technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1411-1417. |

| [11] | Shu-wei LAN,Dong-hua ZHOU,Xu CHEN,Nan-ming MO. Practical calculation method for the critical bearing capacity of double column bridge with high piers [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1105-1111. |

| [12] | Jing-fu JIN,Xin-ju DONG,Zhi-cheng JIA,Kang WANG,Lian-bin HE,Meng ZOU,Ying-chun QI. Optimization of the tread plate-spring structure of flexible metal wheel with plate-spring [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 964-972. |

| [13] | Zhuang-zhuang LIU,You-wei ZHANG,Peng-yu JI,Abshir Ismail Yusuf,Lin LI,Ya-zhen HAO. Study on heat transfer characteristics of electric heating snow melting asphalt pavement [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 523-530. |

| [14] | Qi-kai SUN,Nan ZHANG,Xiao LIU,Zi-ji ZHOU. Dynamic reduction coefficients of steel⁃concrete composite beam based on Timoshenko beam theory [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 488-495. |

| [15] | Xiao-hong LU,Jin-hui QIAO,Yu ZHOU,Chong MA,Guo-chuan SUI,Zhuo SUN. Research progress of temperature field in friction stir welding [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 1-17. |

|

||