Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (9): 2733-2740.doi: 10.13229/j.cnki.jdxbgxb.20221407

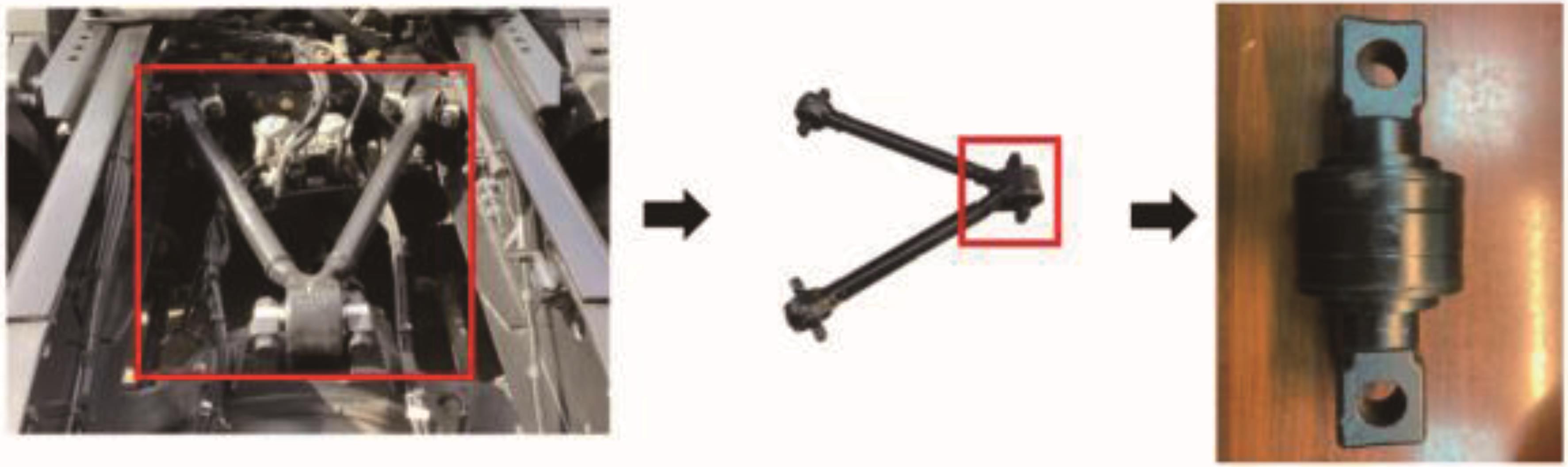

Thrust rod ball hinge bionic surface improvement and finite element analysis

Hua-min LIU( ),Shu-han YANG,Yi LI,Ce LIANG,Qi-gang Han(

),Shu-han YANG,Yi LI,Ce LIANG,Qi-gang Han( )

)

- College of Materials Science and Engineering,Jilin University,Changchun 130022,China

CLC Number:

- TG356

| 1 | Feng G Y, Shi W K, Zhang H, et al. Research on the fatigue life prediction method of thrust rod[J]. Mathematical Problems in Engineering, 2016, 2016:No. 1254037. |

| 2 | Feng G Y, Shi W K, Wang Q, et al. Finite element analysis of static characteristic of rubber spherical joint for commercial vehicle thrust rod[J]. Advanced Materials Research, 2013, 710: 273-276. |

| 3 | 冯国雨. 商用车推力杆性能优化与疲劳寿命预测研究[D]. 长春:吉林大学汽车工程学院, 2016. |

| Feng Guo-yu. Performance optimization and fatigue life prediction of commercial vehicle thrust rod [D]. Changchun:College of Automotive Engineering, Jilin University, 2016. | |

| 4 | 王倩. 重型商用车推力杆结构优化与耐久性研究[D]. 长春:吉林大学汽车工程学院, 2013. |

| Wang Qian. Structure optimization and durability research of heavy commercial vehicle thrust rod[D]. Changchun:College of Automotive Engineering, Jilin University, 2013. | |

| 5 | Li Z, Shi W K, Wang Q, et al. Force and simulation analysis of thrust rod on heavy commercial vehicle balanced suspension[J]. Applied Mechanics and Materials, 2013, 387: 94-99. |

| 6 | 李赞. 商用车推力杆结构改进与性能研究[D]. 长春:吉林大学汽车工程学院, 2015. |

| Li Zan. Structure improvement and performance study of thrust rod on ccmmercial vehicle[D] Changchun:College of Automotive Engineering, Jilin University, 2015. | |

| 7 | 李磊. 重型商用车推力杆橡胶球铰的设计与寿命研究[D]. 长春:吉林大学汽车工程学院, 2017. |

| Li Lei. Structure design and fatigue life study of rubber bushing for commercial vehicle thrust rod [D]. Changchun:College of Automotive Engineering,Jilin University, 2017. | |

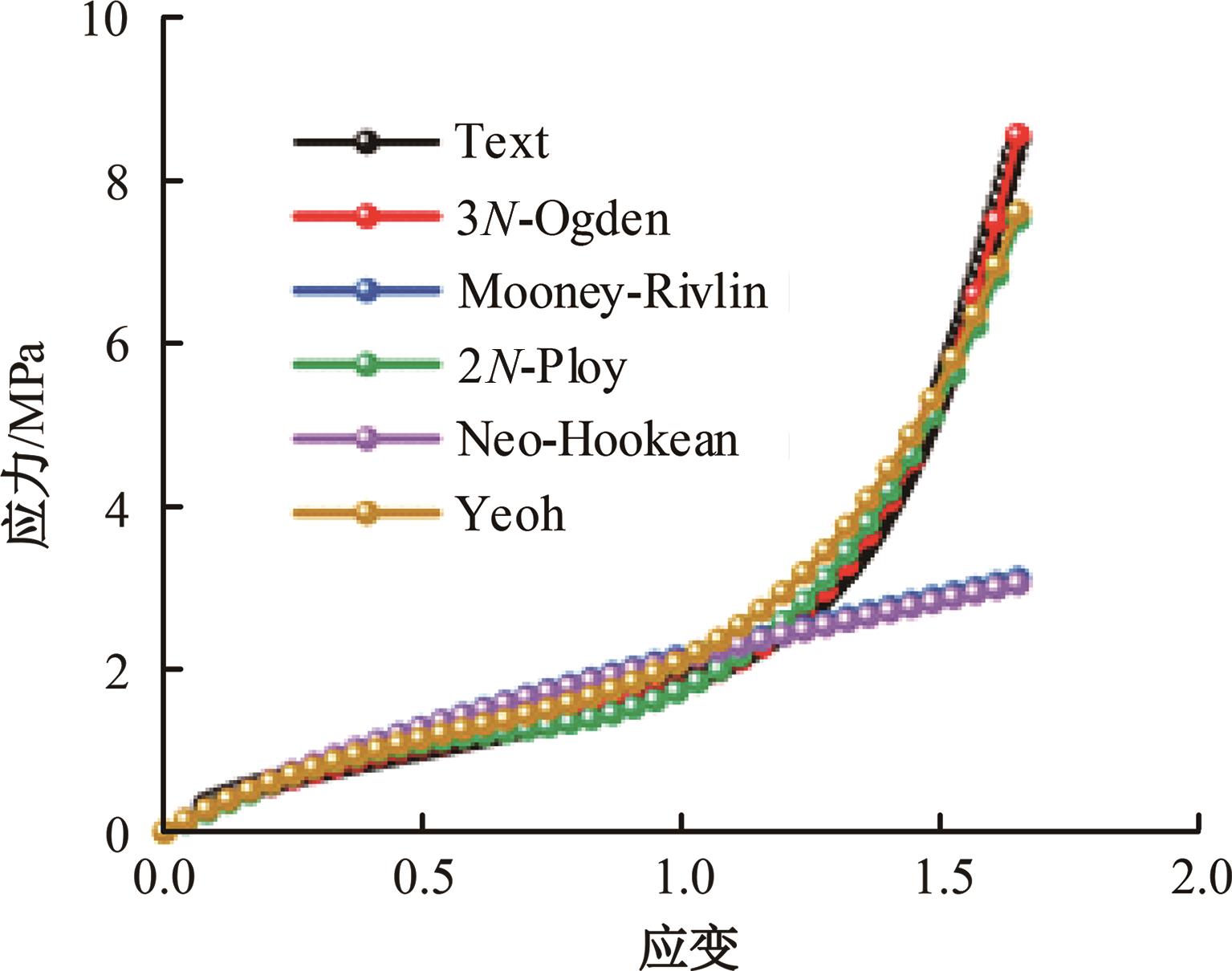

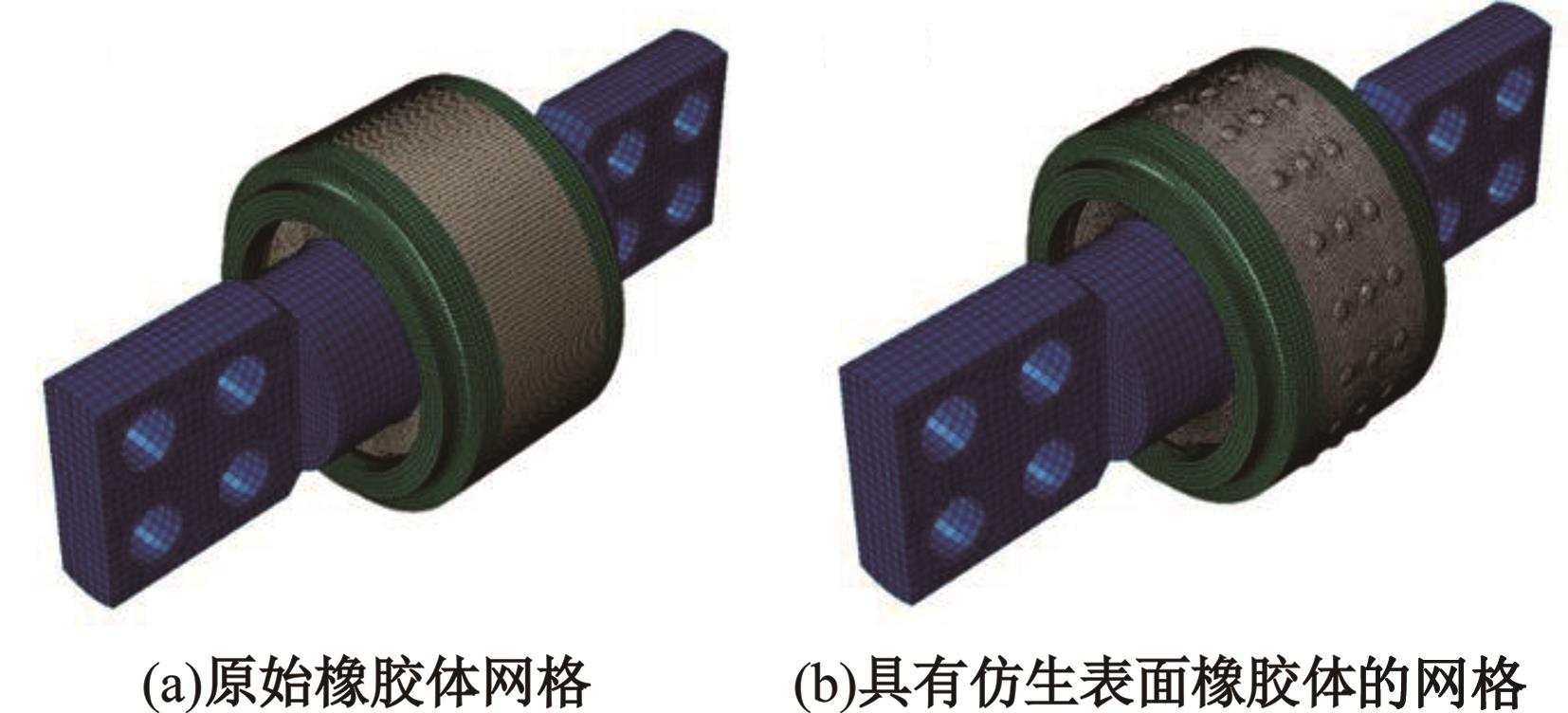

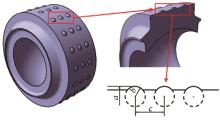

| 8 | 史文库,刘国政, 陈志勇. 橡胶的可压缩性在推力杆球铰有限元分析中的应用[J]. 西安交通大学学报, 2017, 51(9): 63-68, 76. |

| Shi Wen-ku, Liu Guo-zheng, Chen Zhi-yong. Application of rubber compressibility to finite element analysis for thrust rod[J]. Journal of Xi'an Jiaotong University, 2017, 51(9): 63-68, 76. | |

| 9 | 刘巧斌,史文库,高承明,等. 采用灰色Savitzky-Golay滤波的商用车推力杆橡胶球铰非对称迟滞建模[J]. 西安交通大学学报, 2019, 53(5): 82-91, 99. |

| Liu Qiao-bin, Shi Wen-ku, Gao Cheng-ming, et al. Asymmetrical hysteresis modelling basedd on Savitzky-Golay filter for rubber hinge on thrust rod of commercial vehicle[J]. Journal of Xi'an Jiaotong University, 2019, 53(5): 82-91, 99. | |

| 10 | 柯俊,祖洪飞, 史文库. 基于有限元法及遗传算法的推力杆球铰多目标优化方法[J]. 汽车工程, 2020, 42(2): 178-183. |

| Ke Jun, Zu Hong-fei, Shi Wen-ku. A multi-objective optimization method for the spherical hinge of a thrust rod based on the finite elemnet method and genetic algorithm [J]. Automotive Engineering, 2020, 42(2):178-183. | |

| 11 | 杨银辉, 晁鹏翔, 申国伟,等. 重卡推力杆载荷分析及结构优化[J]. 汽车实用技术,2018(19): 39-41. |

| Yang Yin-hui, Chao Peng-xiang, Shen Guo-wei,et al. Load analysis and structure optimization for truck thrust rod[J]. Automobile Applied Technology, 2018 (19):39-41. | |

| 12 | 翁明武, 刘飞, 李杨欢, 等. 自卸车推力杆的失效改进[J]. 汽车实用技术, 2018(18): 79-81. |

| Weng Ming-wu, Liu Fei, Li Yang-huan,et al. Dump truck thrust bar failure improvement [J]. Automobile Applied Technology, 2018 (18):79-81. | |

| 13 | 卜继玲, 周炜, 李建林, 等. 带橡胶球铰的车用推力杆稳定性分析[J]. 湘潭大学自然科学学报, 2016, 38(1): 39-41, 46. |

| Bu Ji-ling, Zhou Wei, Li Jian-lin, et al. Stability analysis of vehicle torque rod based on the rubber[J]. Natural Science Journal of Xiangtan University, 2016, 38(1): 39-41, 46. | |

| 14 | 曹洲, 王印, 梁津,等. 商用车V型推力杆失效分析[J]. 汽车实用技术. 2021, 46(14): 69-72. |

| Cao Zhou, Wang Yin, Liang Jin, et al. Failure analysis of V-type thrust bar of commercial vehicle[J]. Automobile Applied Techonlogy, 2021, 46(14):69-72. | |

| 15 | 潘博. 重卡用推力杆挡圈脱落机理分析及其结构优化设计[D]. 北京: 清华大学车辆与运载学院, 2017. |

| Pan Bo. Failure analysis of the thrust rod retaining ring for heavy duty truck and the structural optimization design [D]. Beijing:School of Vehicle and Mobility,Tsinghua University, 2017. | |

| 16 | 张俊荣, 张排排, 唐春红,等. 轻量化铝合金推力杆结构设计及其性能研究[J]. 汽车工艺与材料, 2021(8): 13-17. |

| Zhang Jun-rong, Zhang Pai-pai, Tang Chun-hong,et al. Structural design and performance research on lightweight aluminum alloy thrust rod[J]. Automobile Technology& Material, 2021(8):13-17. | |

| 17 | 张子尧. 基于Kriging模型的球铰芯轴预成形多目标优化[D]. 镇江:江苏大学材料科学与工程学院, 2016. |

| Zhang Zi-yao. Multi-target preform optimization for spherical hinge mandrel based on Kriging model methodology [D]. Zhenjiang:School of Materials Science & Engineering,Jiangsu University, 2016. | |

| 18 | 刘峰. 基于有限元分析的推力杆球铰硫化模具设计[D]. 长沙:湖南大学机械与运载工程学院, 2016. |

| Liu Feng. Design of vulcanization mould of torque rod bushing based on FEA[D]. Changsha:College of Mechanical and Vehicle Engineering, Hunan University, 2016. | |

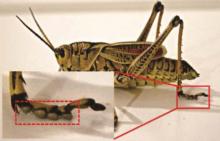

| 19 | van Den Boogaart L M, Langowski J K A, Amador G J. Studying stickiness: methods, trade-offs, and perspectives in measuring reversible biological adhesion and friction [J]. Biomimetics, 2022, 7(3): 1-19. |

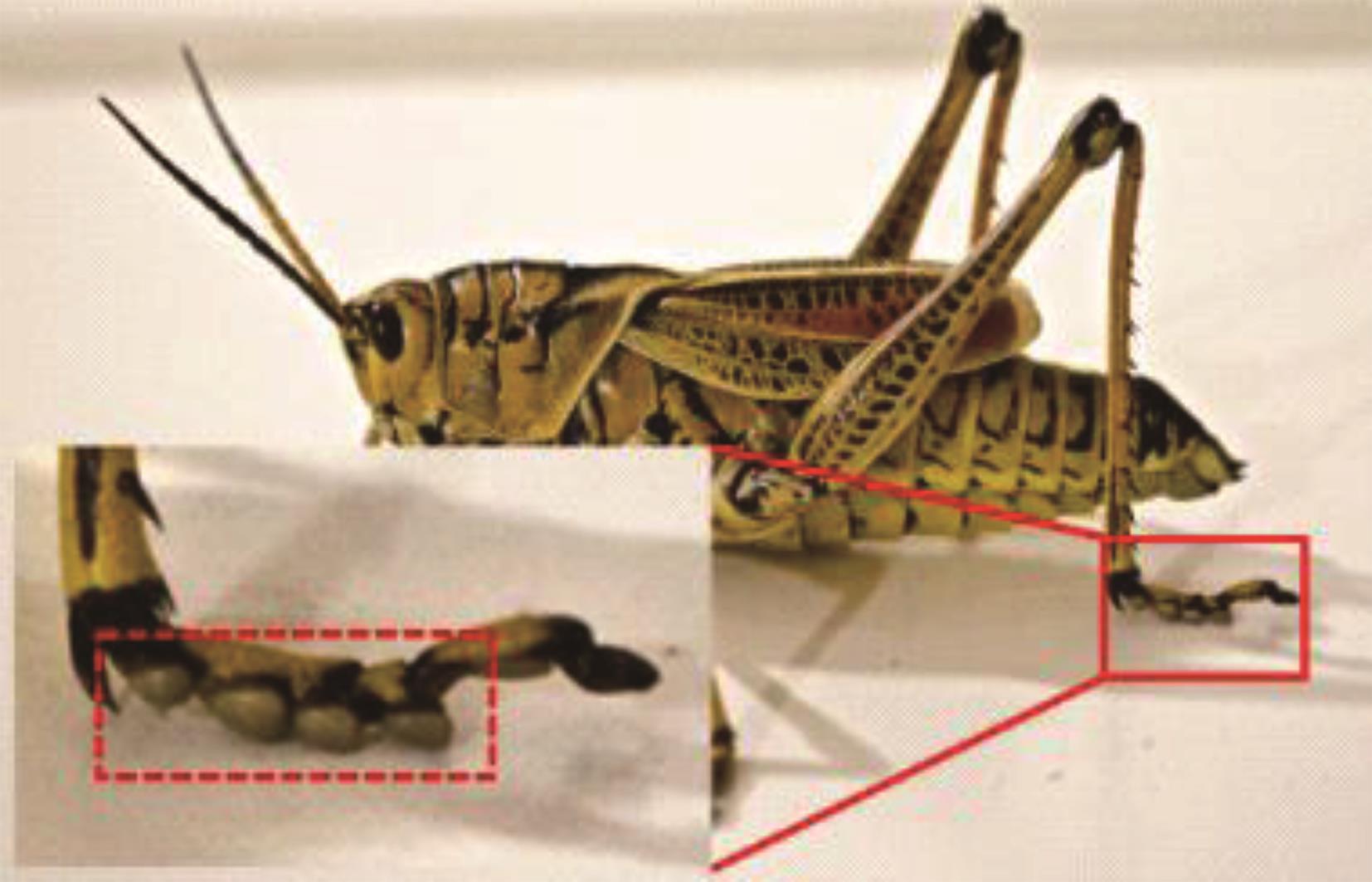

| 20 | Wang L X, Zhou Q, Xu S Y, et al. Investigation of the sliding friction behaviors of locust on slippery plates[J]. Chinese Science Bulletin, 2009, 54(24): 4549-4554. |

| 21 | Dai Z D, Stanislav G. Contact mechanics of pad of grasshopper (Insecta: Orthoptera) by finite element methods[J]. Chinese Science Bulletin, 2009, 54(4): 549-555. |

| 22 | Woodward M A, Sitti M. Morphological intelligence counters foot slipping in the desert locust and dynamic robots[J]. Proceedings of the National Academy of Sciences of the United States of America, 2018, 115(36): E8358-E8367. |

| [1] | Zhi-jun YANG,Chi ZHANG,Guan-xin HUANG. Mechanical model of rigid⁃flexible coupling positioning stage based on floating coordinate method [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 385-393. |

| [2] | Yang XIAO,Jie WANG,Meng-jun LIU,Fa-qing YANG,Tian-yao ZHANG,Wei LAN. Improved mechanical model of gas diffusion layer in proton exchange membrane fuel cell [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2147-2155. |

| [3] | Jian-lin ZUO,En-bo LIU,Zheng-bin JIA,Sheng-hao XU,Jian-lin XIAO. Finite element analysis of bionic prosthesis based on design of medial meniscus structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2319-2324. |

| [4] | Ya-feng GONG,Jia-xiang SONG,Hai-peng BI,Guo-jin TAN,Guo-hai HU,Si-yuan LIN. Static test and finite element analysis of scale model of fabricated box culvert [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1728-1738. |

| [5] | GU Hai-dong,LUO Chun-hong. Experiment on soil arching effect of pit supporting structure with scattered row piles and soil nail wall [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1712-1724. |

| [6] | LIU Guo-zheng, SHI Wen-ku, Chen Zhi-yong. Finite element analysis of transmission error for hypoid gears considering installation error [J]. 吉林大学学报(工学版), 2018, 48(4): 984-989. |

| [7] | CHEN Dong-hui, LIU Wei, LYU Jian-hua, CHANG Zhi-yong, WU Ting, MU Hai-feng. Bionic design of corn stubble collector based on surface structure of Patinopecten yessoensis [J]. 吉林大学学报(工学版), 2017, 47(4): 1185-1193. |

| [8] | ZHANG Yan-ling, SUN Tong, HOU Zhong-ming, LI Yun-sheng. Bending-torsion characteristics of steel-concrete curved composite beams stiffened with diaphragms [J]. 吉林大学学报(工学版), 2015, 45(4): 1107-1114. |

| [9] | WU Yue, YANG Zhi-gang, CHEN Long, KANG Xiao-tao, ZHANG Dong-wei. Simulation and experiment of piezoelectric cantilever generator with multi-modal [J]. 吉林大学学报(工学版), 2015, 45(4): 1162-1167. |

| [10] | YU Zhen-huan,ZHANG Na,LIU Shun-an. Simulation analysis of dynamic nonlinear characteristics of vehicle shock absorber based on fluid-structure interaction [J]. 吉林大学学报(工学版), 2015, 45(1): 16-21. |

| [11] | LI Cheng, ZHU Hong-hong, TIE Ying, HE Long. Stress distribution and load sharing in single-lap bonded/bolted joints [J]. 吉林大学学报(工学版), 2013, 43(04): 933-938. |

| [12] | CHEN Zhi-yong, SHI Wen-ku, WANG Qing-guo, TENG Teng. Structure parameter of light vehicle cab's hydraulic mount based on fluid-structure interaction finite element analysis [J]. 吉林大学学报(工学版), 2011, 41(增刊2): 98-103. |

| [13] | GUO Kong-hui,QIU En-chaoGUO . Finite element analysis of tire rolling contact based on ring supported on elastic foundation model [J]. 吉林大学学报(工学版), 2011, 41(03): 597-0601. |

| [14] | ZHANG Jun-qiu, HAN Zhi-wu,JIANG Jia-lian,GE Chao, Lü You,WANG Chao-fei. Three dimensional numerical simulation on antierosion of |coupling bionics of flexibility and configuration [J]. 吉林大学学报(工学版), 2011, 41(01): 139-0143. |

| [15] | GUO Li-qun,WANG Deng-feng. Effect of frame stiffness on ride comfort of commercial vehicle [J]. 吉林大学学报(工学版), 2010, 40(04): 911-0914. |

|

||