Journal of Jilin University(Engineering and Technology Edition) ›› 2020, Vol. 50 ›› Issue (5): 1728-1738.doi: 10.13229/j.cnki.jdxbgxb20190674

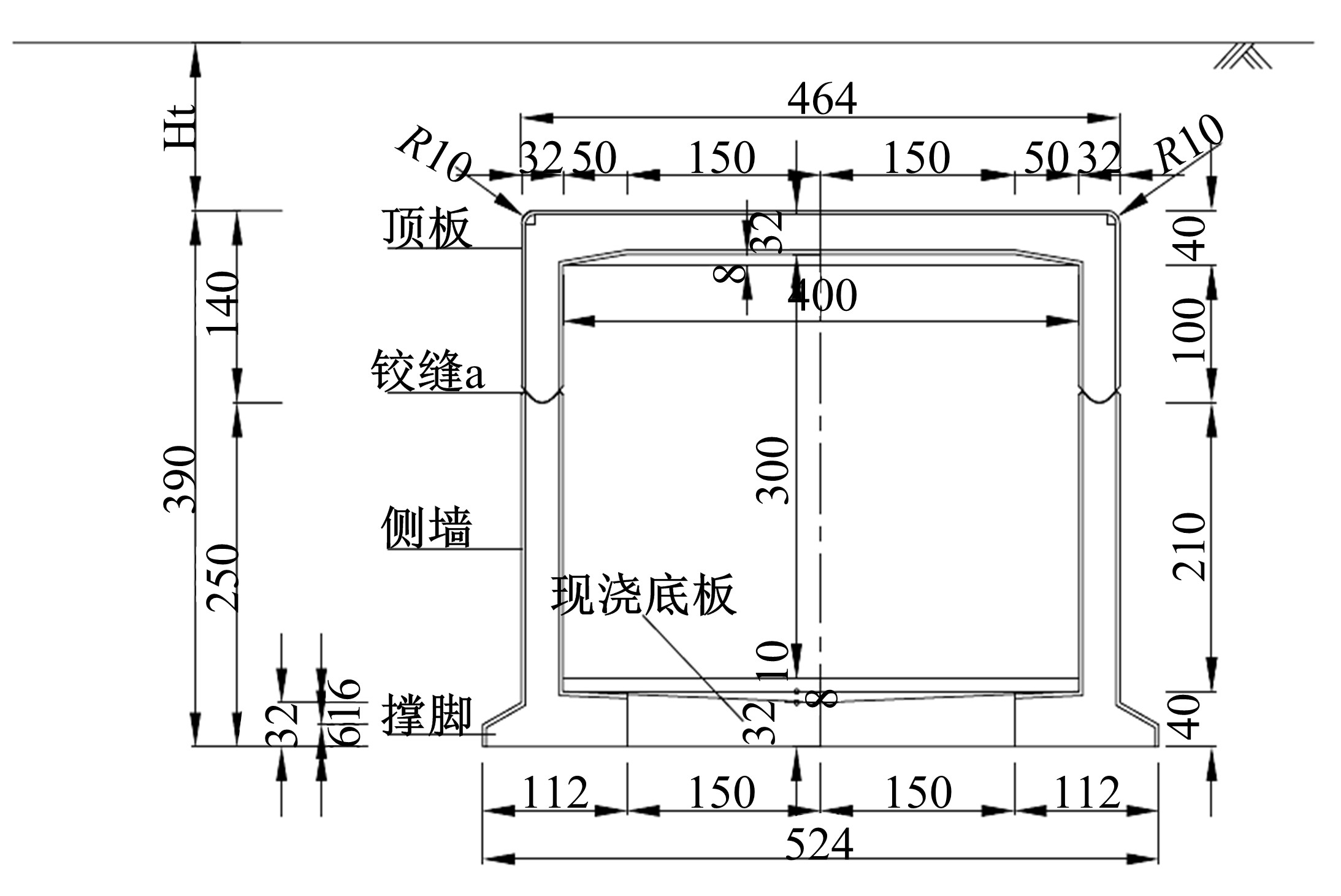

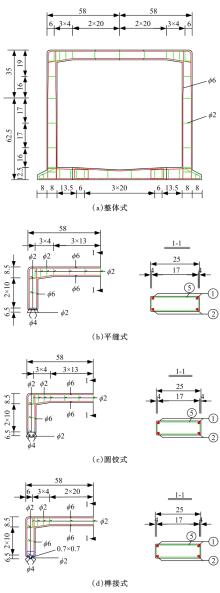

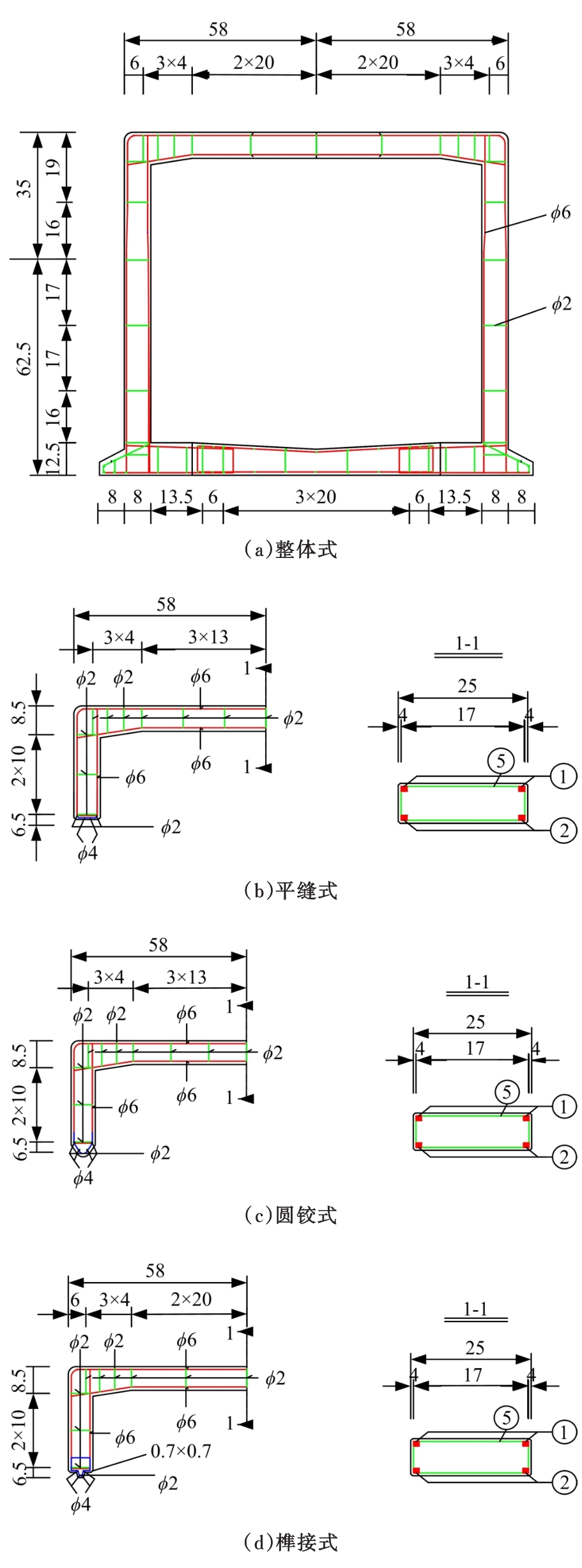

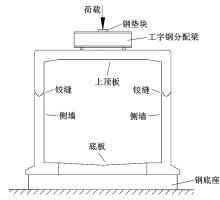

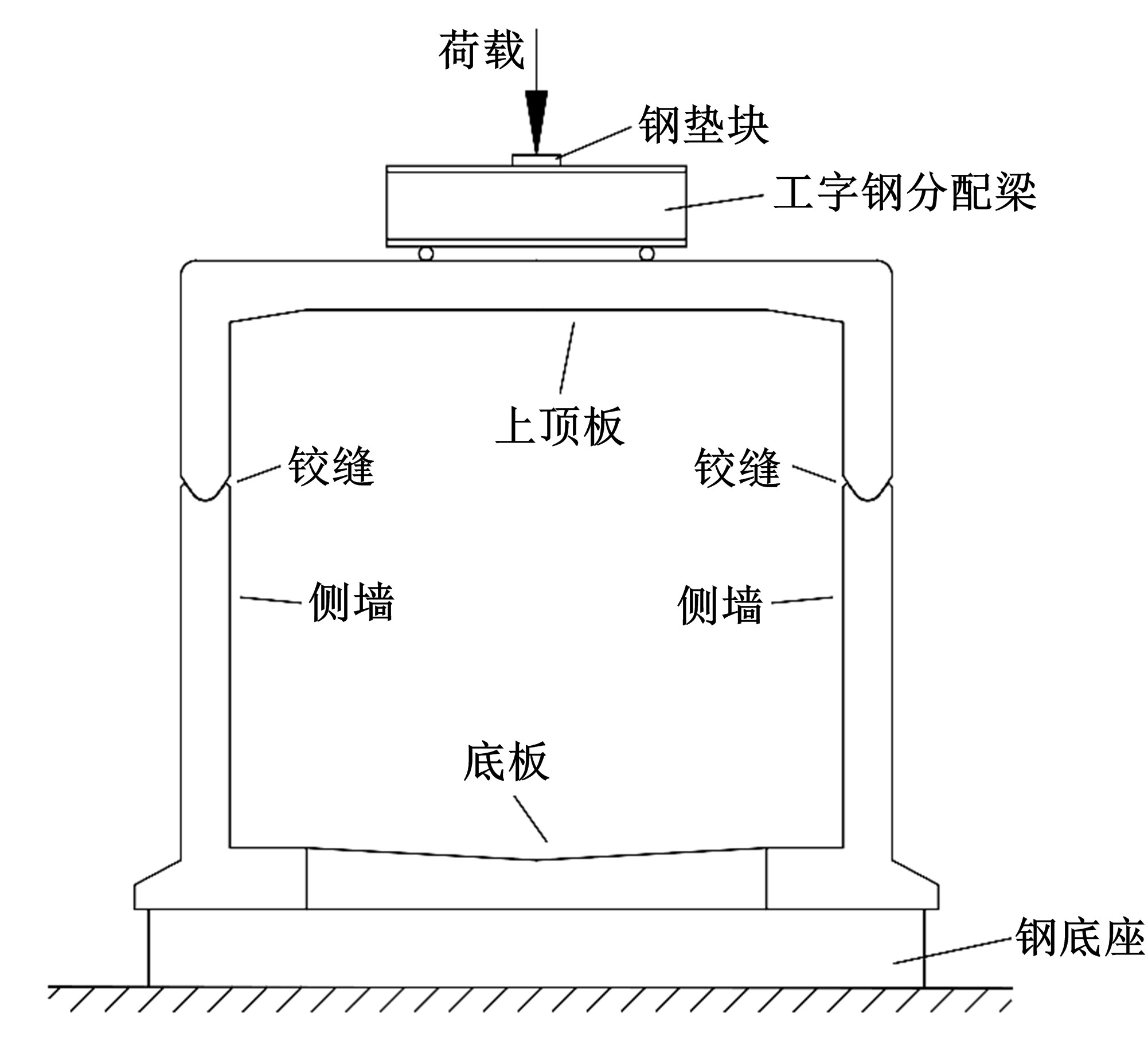

Static test and finite element analysis of scale model of fabricated box culvert

Ya-feng GONG1( ),Jia-xiang SONG1,Hai-peng BI1,Guo-jin TAN1(

),Jia-xiang SONG1,Hai-peng BI1,Guo-jin TAN1( ),Guo-hai HU2,Si-yuan LIN1

),Guo-hai HU2,Si-yuan LIN1

- 1.College of Transportation, Jilin University, Changchun 130022, China

2.Jilin Traffic Planning and Design Institute, Changchun 130022, China

CLC Number:

- U449.1

| 1 | 胡可, 杨晓光, 陈发根, 等. 公路装配式钢筋混凝土通道[M]. 北京: 人民交通出版社, 2018. |

| 2 | 马骞. 朔黄线K549+014涵洞病害原因分析与加固技术[J].铁道建筑, 2017(1): 84-86, 102. |

| Ma Qian. Disease cause analysis and reinforcement technology for culvert at section K549+014 on Shuozhou-Huanghuagang railway[J]. Railway Engineering, 2017(1): 84-86, 102. | |

| 3 | Kim K, Yoo C H. Design loading on deeply buried box culverts[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2005, 131(1): 20-27. |

| 4 | Bennett R M, Wood S M, Drumm E C, et al. Vertical loads on concrete box culverts under high embankments[J]. Journal of Bridge Engineering, 2005, 10(6): 643-649. |

| 5 | 李永刚, 李力. 钢筋混凝土涵洞顶部垂直土压力影响因素研究[J]. 长江科学院院报, 2006, 23(6): 72-74, 79. |

| Li Yong-gang, Li Li. Analysis on influence factors of vertical earth pressure on reinforced concrete culverts[J]. Journal of Yangtze River Scientific Research Institute, 2006, 23(6): 72-74, 79. | |

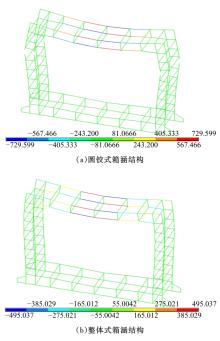

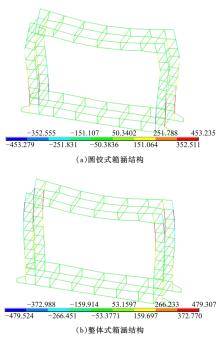

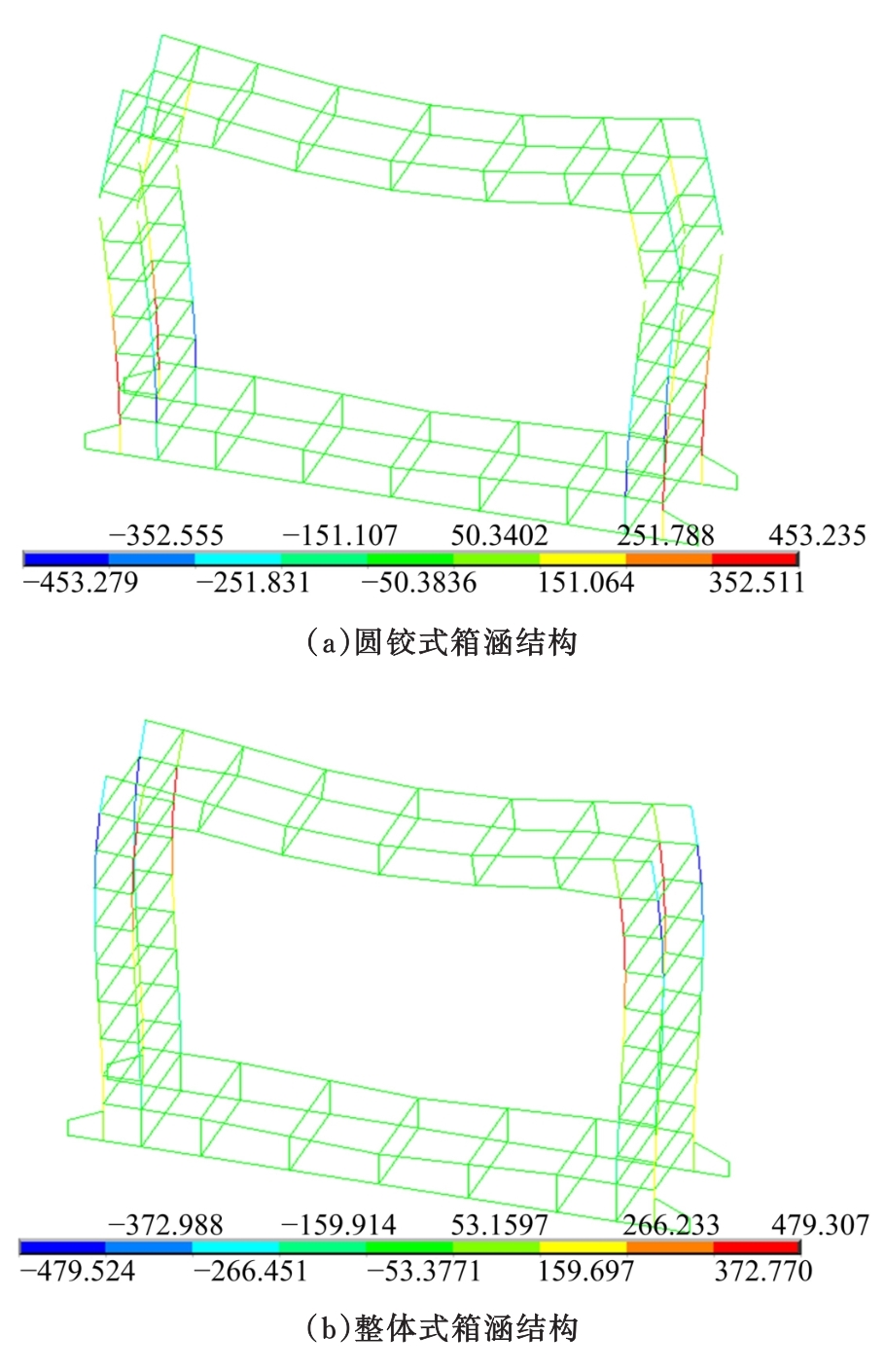

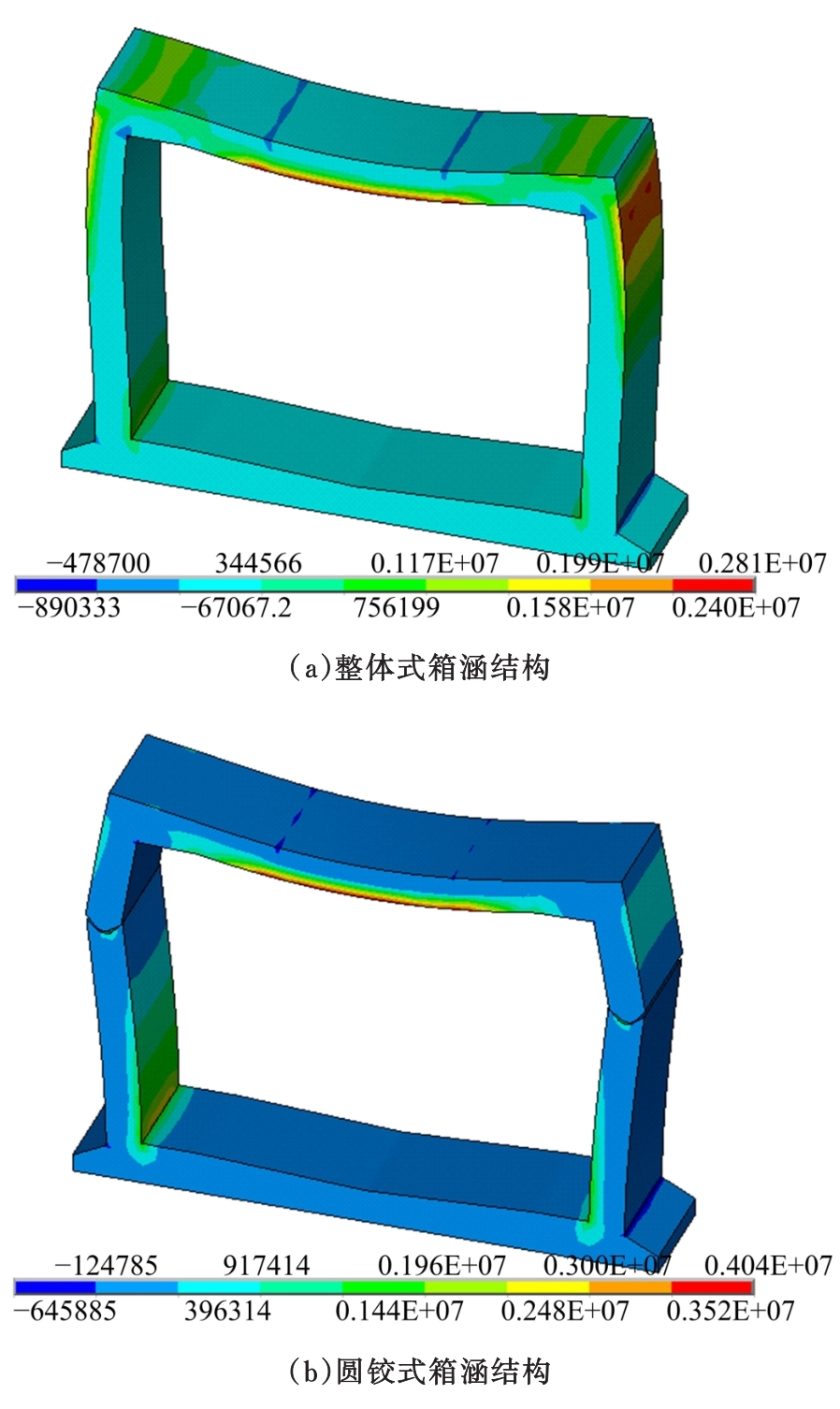

| 6 | 宫亚峰, 王博, 谭国金, 等. 吉林省两种典型装配式箱涵受力特性对比分析[J]. 吉林大学学报: 工学版, 2019, 49(6): 1865-1870. |

| Gong Ya-feng, Wang Bo, Tan Guo-jin, et al. Comparative analysis of mechanical characteristics of two typical fabricated culverts in Jilin[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1865-1870. | |

| 7 | 范鹤, 刘斌, 范泽, 等. 高填土涵洞相似材料模型试验与数值模拟[J]. 吉林大学学报: 工学版, 2008, 38(2): 399-403. |

| Fan He, Liu Bin, Fan Ze, et al. Model test with similar material and numerical simulation of culvert with high fills[J]. Journal of Jilin University(Engineering Editi-on), 2008, 38(2): 399-403. | |

| 8 | 陈保国, 骆瑞萍, 孙金山. 上埋式盖板涵受力特性及影响因素研究[J]. 岩土力学, 2011, 32(1): 199-206. |

| Chen Bao-guo, Luo Rui-ping, Sun Jin-shan. Study of stress characteristics and its influencing factors of embankment installation slab-culverts[J]. Rock and Soil Mechanics, 2011, 32(1): 199-206. | |

| 9 | Garg A K, Abolmaali A. Finite-element modeling and analysis of reinforced concrete box culverts[J]. Journal of Transportation Engineering, 2009, 135(3): 121-128. |

| 10 | Moradi M, Valipour H, Foster S. Reserve of strength in inverted U-shaped RC culverts: effect of backfill on ultimate load capacity and fatigue life[J]. Journal of Bridge Engineering, 2016, 21(2): 1-10. |

| 11 | Abolmaali A, Garg A K. Effect of wheel live load on shear behavior of precast reinforced concrete box culverts[J]. Journal of Bridge Engineering, 2008, 13(1): 93-99. |

| 12 | 李兆平, 苏会锋, 吕书清, 等. 装配式地铁车站结构双榫槽式接头抗弯力学性能试验研究[J]. 土木工程学报, 2017, 50(2): 28-32. |

| Li Zhao-ping, Su Hui-feng, Shu-qing Lyu, et al. Experimental study on flexural mechanical properties of the double tenon groove joints of prefabricated subway station[J]. China Civil Engineering Journal, 2017, 50(2): 28-32. | |

| 13 | 王立超, 李建光. 基于单桩抗压静载实验的桩筏基础协同分析数值模拟研究[J]. 工程建设, 2019, 51(1): 26-31. |

| Wang Li-chao, Li Jian-guang. Study on numerical simulation analysis of settlement under synergistic effect of pile-raft foundation based on static loading test of single pile[J]. Engineering Construction, 2019, 51(1): 26-31. | |

| 14 | 刘丽丽, 李刘峰. 装配式预制箱涵受力及稳定性分析[J]. 福建交通科技, 2019(3): 96-99. |

| Liu Li-li, li Liu-feng, Stress and stability analysis of prefabricated precast box culms[J]. Fujian Traffic Science and Technology, 2019(3): 96-99. | |

| 15 | 李勇, 赵晓莎, 陈彦江, 等. 钢管混凝土拱桥缩尺模型静动力试验研究[J]. 公路, 2019, 64(3): 99-106. |

| Li Yong, Zhao Xiao-sha, Chen Yan-jiang, al at. Static and dynamic test research of shrinkage model of concrete-filled steel tube arch bridge[J]. Highway, 2019, 64(3): 99-106. | |

| 16 | 颜良. 无腋角综合管廊结构足尺模型静载试验及有限元分析[D]. 长沙: 湖南大学土木工程学院, 2018. |

| Yan Liang. Static test and finite element analysis of full-scale model of utility tunnel structure without axillary angle[D]. Changsha: School of Architecture and Construction, Hunan University, 2018. |

| [1] | Hua CHEN,Yao-jia CHEN,Bin XIE,Peng-kai WANG,Lang-ni DENG. Interface failure mechanism and bonding strength calculation of CFRP tendons bonded anchorage system [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1698-1708. |

| [2] | Hao GAO,Jun-jie WANG,Hui-jie LIU,Jian-ming WANG. Design criterion and applied devices for controlled seismic behavior of continuous girder bridges [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1718-1727. |

| [3] | Qian-hui PU,Jing-wen LIU,Gang-yun ZHAO,Meng YAN,Xiao-bin LI. Theoretical analysis of bearing capacity of concrete eccentric compressive column reinforced by HTRCS [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 606-612. |

| [4] | Yun-long ZHANG,Yang-yang GUO,Jing WANG,Dong LIANG. Natural frequency and mode of vibration of steel⁃concrete composite beam [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 581-588. |

| [5] | Bo-xin WANG,Hai-tao YANG,Qing WANG,Xin GAO,Xiao-xu CHEN. Bridge vibration signal optimization filtering method based on improved CEEMD⁃multi⁃scale permutation entropy analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 216-226. |

| [6] | Miao ZHANG,Yong-jiu QIAN,Fang ZHANG,Shou-qin ZHU. Experimental analysis of spatial force performance of concrete-reinforced stone arch bridge based on enlarged section method [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 210-215. |

| [7] | Yi JIA,Ren-da ZHAO,Yong-bao WANG,Fu-hai LI. Sensitivity analysis of viscous damper parameters for multi⁃span and long⁃unit continuous girder bridges [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1871-1883. |

| [8] | Chun-ling ZHONG,Dong LIANG,Yun-long ZHANG,Jing WANG. Calculation of natural vibration frequency of simply supported beam strengthened by external prestressing [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1884-1890. |

| [9] | Lun-hua BAI,Rui-li SHEN,Xing-biao ZHANG,Lu WANG. In-plane stability of self-anchored suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1500-1508. |

| [10] | Jin⁃gang ZHAO,Ming ZHANG,Yu⁃lin ZHAN,Ming⁃zhi XIE. Damage criterion of reinforced concrete pier based on plastic strain energy density [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1124-1133. |

| [11] | Shi⁃cheng WAN,Qiao HUANG,Jian GUAN,Zhao⁃yuan GUO. Strengthening of continuous steel⁃concrete composite beams in negative moment region using prestressed carbon fiber⁃reinforced polymer plates [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1114-1123. |

| [12] | Wan⁃heng LI,Lin SHEN,Shao⁃peng WANG,Shang⁃chuan ZHAO. Damage assessment of bridge construction based onmulti⁃stage subregion mobile test [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 773-780. |

| [13] | HUI Ying-xin,MAO Ming-jie,LIU Hai-feng,ZHANG Shang-rong. Influence of structural seismic response of bridges crossing active fault [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1725-1734. |

| [14] | GU Hai-dong,LUO Chun-hong. Experiment on soil arching effect of pit supporting structure with scattered row piles and soil nail wall [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1712-1724. |

| [15] | LIU Guo-zheng, SHI Wen-ku, Chen Zhi-yong. Finite element analysis of transmission error for hypoid gears considering installation error [J]. 吉林大学学报(工学版), 2018, 48(4): 984-989. |

|

||