Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (2): 385-393.doi: 10.13229/j.cnki.jdxbgxb.20220323

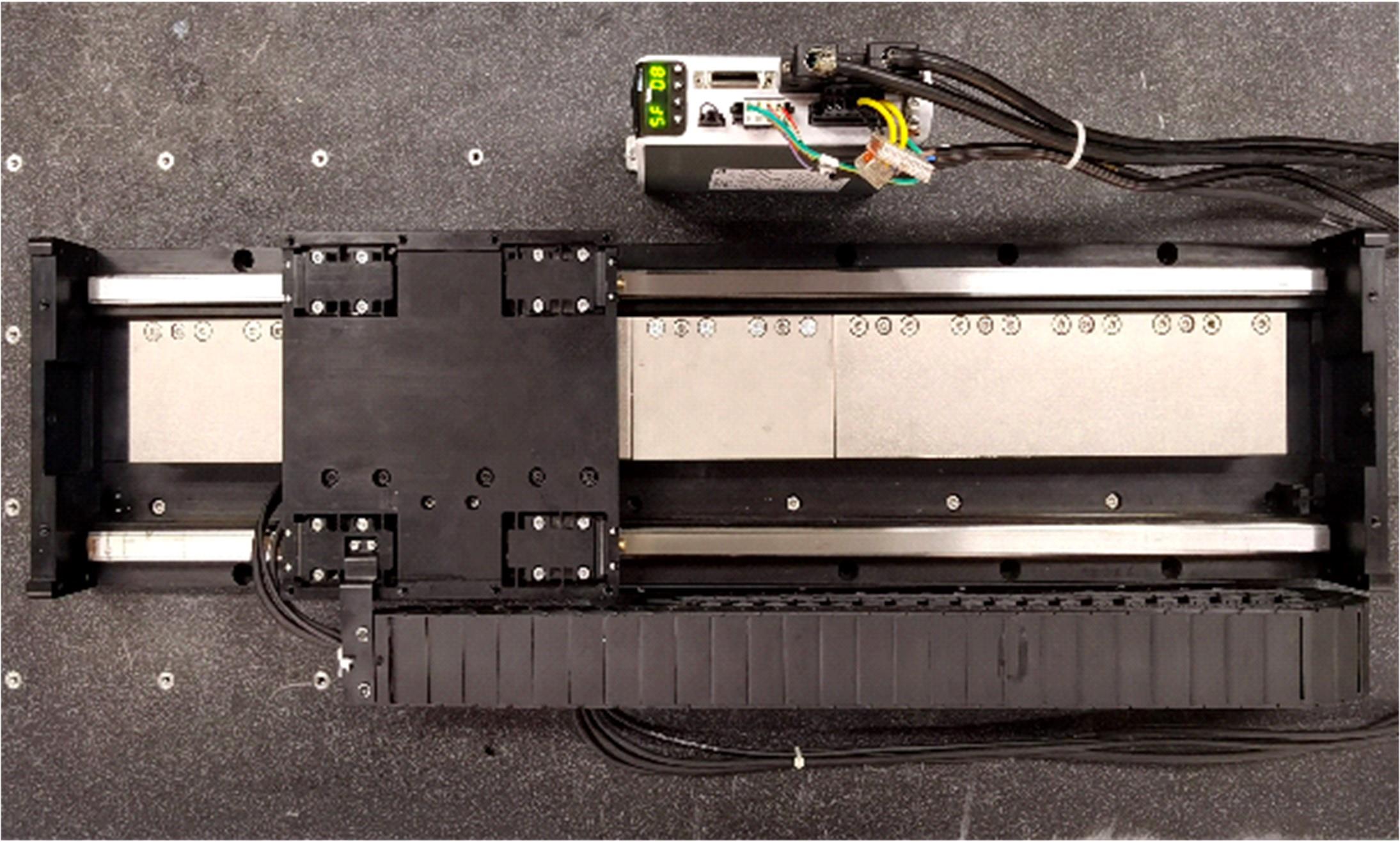

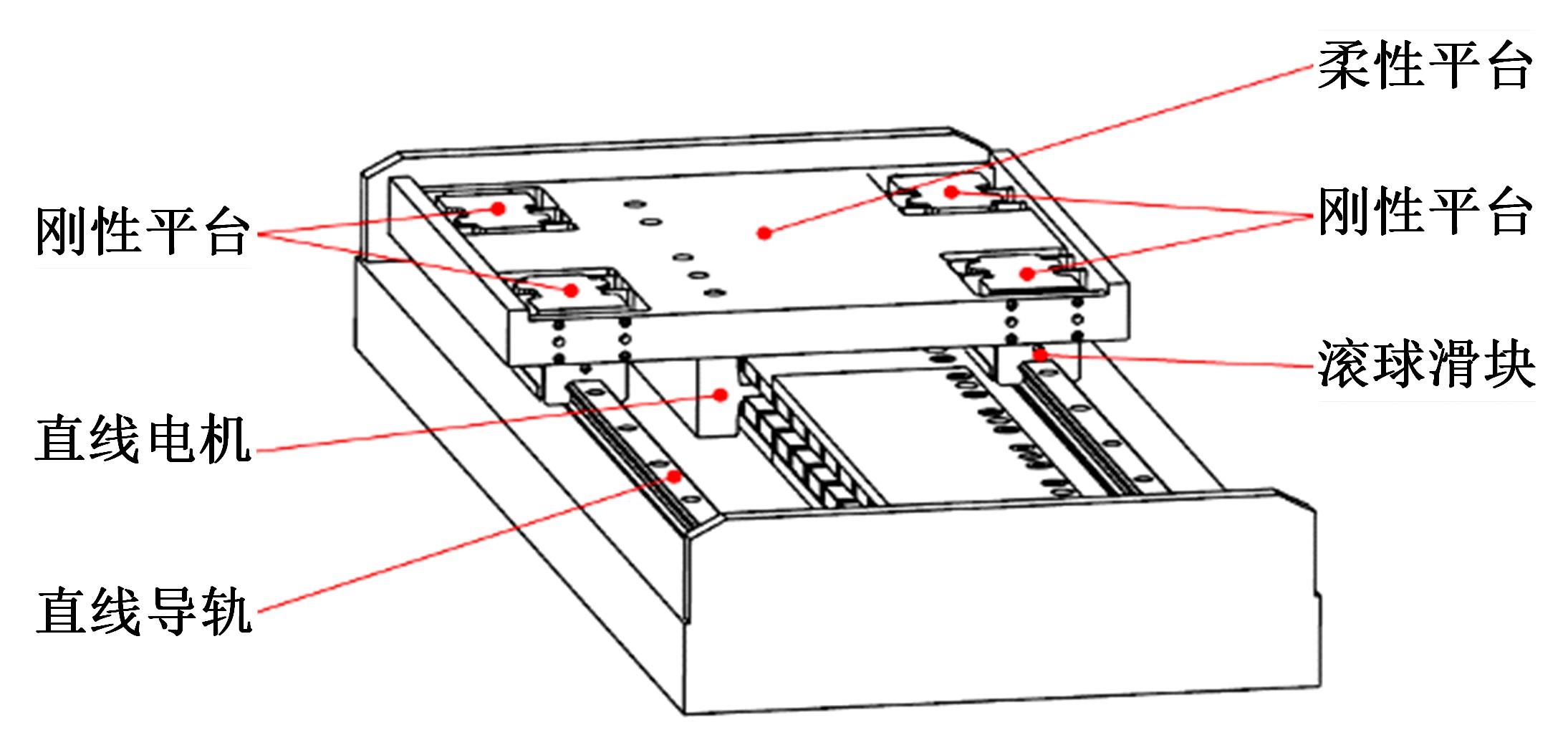

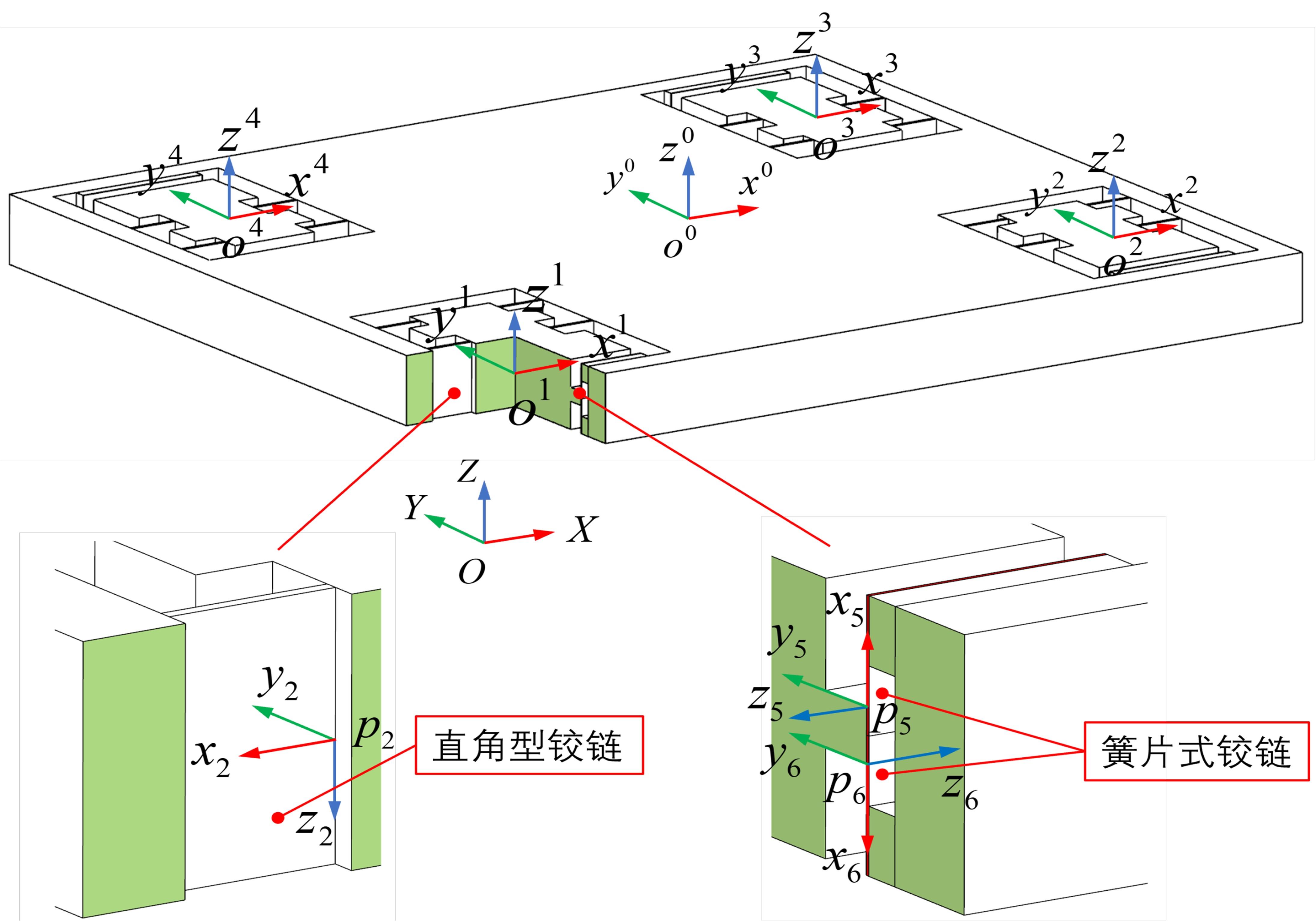

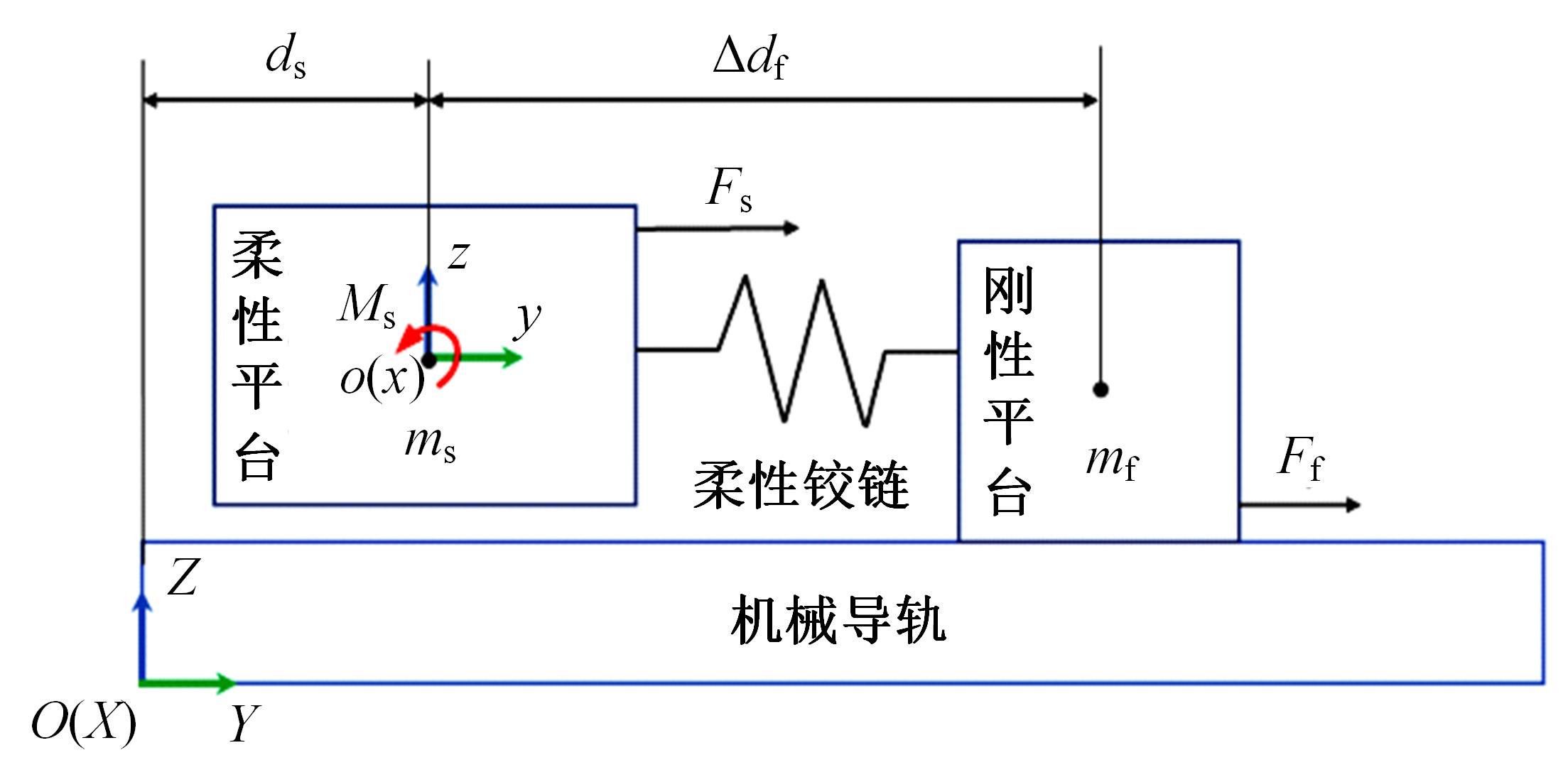

Mechanical model of rigid⁃flexible coupling positioning stage based on floating coordinate method

Zhi-jun YANG( ),Chi ZHANG,Guan-xin HUANG(

),Chi ZHANG,Guan-xin HUANG( )

)

- State Key Laboratory of Precision Electronic Manufacturing Technology and Equipment,Guangdong University of Technology,Guangzhou 510006,China

CLC Number:

- TH113.1

| 1 | Kerschner R K. Differential motor drive for an XY stage[P].USA: |

| 2 | Mao J, Tachikawa H, Shimokohbe A. Precision positioning of a DC-motor-driven aerostatic slide system[J]. Precision Engineering, 2003, 27(1): 32-41. |

| 3 | Shinno H, Hashizume H, Yoshioka H, et al. X-Y-θ nano-positioning table system for a mother machine[J]. CIRP Annals-Manufacturing Technology, 2004, 53(1): 337-340. |

| 4 | 王延风. 磁悬浮精密定位工作台机电一体化CAD/CAE集成研究[D]. 长春: 中国科学院长春光学精密机械与物理研究所, 2004. |

| Wang Yan-feng. Research on the magnetic levitation precision stage with mechachonics CAD/CAE[D]. Changchun: Changchun Institute of Optics, Fine Mechanics and Physics, Chinese Academy of Sciences, 2004. | |

| 5 | Sharon A, Hogan N, Hardt D E. High bandwidth force regulation and inertia reduction using a macro/micro manipulator system[C]∥IEEE International Conference on Robotics & Automation, Pennsylvania, USA, 1988: 3247374. |

| 6 | 于靖军, 裴旭, 毕树生, 等. 柔性铰链机构设计方法的研究进展[J]. 机械工程学报, 2010, 46(13): 2-13. |

| Yu Jing-jun, Pei Xu, Bi Shu-sheng, et al. State-of-arts of design method for flexure mechanisms[J]. Journal of Mechanical Engineering, 2010, 46(13): 2-13. | |

| 7 | 曲兴田, 董景石, 郭俊臣, 等. 基于柔性铰链放大的压电叠堆泵[J]. 吉林大学学报:工学版, 2008, 38(3): 552-556. |

| Qu Xing-tian, Dong Jing-shi, Guo Jun-chen, et al. Piezoelectric stack pump based on flexure hinge magnification[J]. Journal of Jilin University (Engineering and Technology Edition), 2008, 38(3): 552-556. | |

| 8 | Uchino K. Ceramic actuators: principles and applications[J]. MRS Bulletin, 1993, 18(4): 42-48. |

| 9 | 朱军辉. 全压电驱动的二维大行程纳米定位平台研究[D]. 苏州: 苏州大学机电工程学院, 2015. |

| Zhu Jun-hui. Research on 2-DOF long stroke nano-positioning stage driven by hybrid piezoelectric actuators[D]. Suzhou: College of Mechanical and Electrical Engineering, Suzhou University, 2015. | |

| 10 | Juhász L, Maas J, Borovac B. Parameter identification and hysteresis compensation of embedded piezoelectric stack actuators[J]. Mechatronics, 2011, 21(1): 329-338. |

| 11 | 张涛, 孙立宁, 蔡鹤皋. 压电陶瓷基本特性研究[J]. 光学精密工程, 1998, 6(5): 27-31. |

| Zhang Tao, Sun Li-ning, Cai He-gao. Study on the fundamental characteristics of piezoelectric element[J]. Optics and Precision Engineering, 1998, 6(5): 27-31. | |

| 12 | Kawashima K, Arai T, Tadano K, et al. Development of coarse/fine dual stage using pneumatically driven bellows actuator and cylinder with air bearings[J]. Precision Engineering, 2010, 34(3):526-533. |

| 13 | Shinno H, Yoshioka H, Sawano H. A newly developed long range positioning table system with a sub-nanometer resolution[J]. CIRP Annals-Manufacturing Technology, 2011, 60(1): 403-406. |

| 14 | 杨志军, 高忠义, 王丽君, 等. 面向刚柔耦合定位平台的模型预测控制算法[J]. 吉林大学学报: 工学版, 2022, 52(12): 2806-2815. |

| Yang Zhi-jun, Gao Zhong-yi, Wang Li-jun, et al. Model predictive control algorithm for rigid-flexible coupling positioning stage[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(12): 2806-2815. | |

| 15 | 胡俊峰, 徐贵阳. 四种不同柔性铰链的三自由度微定位平台性能比较[J]. 机械设计与制造, 2014(2): 127-129. |

| Hu Jun-feng, Xu Gui-yang. Characteristics comparison of a 3-DOF micro positioning stage with four different flexible hinges[J]. Machinery Design & Manufacture, 2014(2): 127-129. | |

| 16 | Li R, Yang Z, Cai B, et al. A compliant guiding mechanism utilizing orthogonally oriented flexures with enhanced stiffness in degrees-of-constraint[J]. Mechanism and Machine Theory, 2022, 167: 104555. |

| 17 | 吴胜宝, 章定国. 大范围运动刚体-柔性梁刚柔耦合动力学分析[J]. 振动工程学报, 2011, 24(1):1- 7. |

| Wu Sheng-bao, Zhang Ding-guo. Rigid-flexible coupling dynamic analysis of hub-flexible beam with large overall motion[J]. Journal of Vibration Engineering, 2011, 24(1): 1-7. | |

| 18 | 刘铸永. 刚-柔耦合系统动力学建模理论与仿真技术研究[D]. 上海: 上海交通大学船舶海洋与建筑工程学院, 2008. |

| Liu Zhu-yong. Study on modeling theory and simulation technique for rigid-flexible coupling systems dynamics[D]. Shanghai: School of Naval Architecture, Ocean and Civil Engineering, Shanghai Jiao Tong University, 2008. | |

| 19 | 丁楠. 柔性多体系统动力学建模方法研究[D]. 长春: 吉林大学数学学院, 2013. |

| Ding Nan. Studies on modeling of flexible multi-body system dynamics[D]. Changchun: School of Mathematics, Jilin University, 2013. | |

| 20 | 李彬, 刘锦阳, 洪嘉振. 计及剪切变形的Timoshenko梁的刚-柔耦合动力学[J]. 计算力学学报, 2006, 23(4): 419-422. |

| Li Bin, Liu Jin-yang, Hong Jia-zhen. Coupling dynamics of Timoshenko beam with shear deformation[J]. Chinese Journal of Computational Mechanics, 2006, 23(4): 419-422. | |

| 21 | 张军锋, 尹会娜, 孙大勇, 等. 基于形函数推导考虑剪切变形的欧拉梁单元刚度矩阵[J]. 重庆交通大学学报:自然科学版, 2020, 39(9): 59-66. |

| Zhang Jun-feng, Yin Hui-na, Sun Da-yong, et al. Euler beam element stiffness matrix considering shear deformation based on shape function derivation[J]. Journal of Chongqing Jiaotong University (Natural Science), 2020, 39(9): 59-66. |

| [1] | Lin-rong SHI,Wu-yun ZHAO. Design and test of rolling spoon type flaxes precision hole sower for caraway in northwest cold and arid agricultural region [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2706-2717. |

| [2] | Bo-sen CHAI,Guang-yi WANG,Dong YAN,Guo-ren ZHU,Jin ZHANG,Heng-sheng LYU. Numerical simulation of cavitation in torque converter and analysis of its influence on performance [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2236-2244. |

| [3] | Guo-hui CHEN,Ye-yin XU,Ying-hou JIAO. Meshing stiffness calculation and vibration analysis of helical gear considering deflection [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 1902-1910. |

| [4] | Sheng LI,Jia ZHU,De-hui HUANG,Cun-fu CHEN,Hong-qing FEI,Wei FENG,Xing-jun HU. Structural parameters optimization of louver fins of air⁃cooled charge air cooler [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 998-1006. |

| [5] | Jian WANG,Wei YU,Bin WANG. Effects of methanol substitution percent on combustion and emission of diesel engines under plateau condition [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 954-963. |

| [6] | Li-juan YU,Yang AN,Jia-long HE,Guo-fa LI,Sheng-xu WANG. Research progress and development trend of extrapolation method in electromechanical equipment load spectrum [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 941-953. |

| [7] | Bo-sen CHAI,Dong YAN,Guang-yi WANG,Wen-jie ZUO. Three-dimensional vortex characteristic analysis and simulation evaluation of peach cavity hydrodynamic coupling under braking condition [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(11): 3045-3055. |

| [8] | Yang XIAO,Jie WANG,Meng-jun LIU,Fa-qing YANG,Tian-yao ZHANG,Wei LAN. Improved mechanical model of gas diffusion layer in proton exchange membrane fuel cell [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(9): 2147-2155. |

| [9] | Zhen SONG,Jie LIU. Time series prediction algorithm of vibration frequency of rotating machinery [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1764-1769. |

| [10] | Ling ZHU,Qiu-cheng WANG. New energy vehicle drive system coordinated control method under spatial geometric constraints [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1509-1514. |

| [11] | Zhao-hui JIN,Le-qi GU,Wei HONG,Fang-xi XIE,Tian YOU. Analysis on pressure fluctuation of hydraulic variable valve actuation [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 773-780. |

| [12] | Guo-fa LI,Yan-bo WANG,Jia-long HE,Ji-li WANG. Research progress and development trend of health assessment of electromechanical equipment [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 267-279. |

| [13] | Zhi-jun YANG,Zhong-yi GAO,Li-jun WANG,Guan-xin HUANG,Yu-tai WEI. Model predictive control algorithm for rigid⁃flexible coupling positioning stage [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 2806-2815. |

| [14] | Lei WANG,Bing-han HUANG,Jia-hui CONG,Li HUI,Song ZHOU,Yong-zhen XU. Effect of ultrasonic impact on fatigue performance of friction stir weld [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2542-2548. |

| [15] | Jian-lin ZUO,En-bo LIU,Zheng-bin JIA,Sheng-hao XU,Jian-lin XIAO. Finite element analysis of bionic prosthesis based on design of medial meniscus structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 2319-2324. |

|

||