Journal of Jilin University(Engineering and Technology Edition) ›› 2018, Vol. 48 ›› Issue (6): 1806-1810.doi: 10.13229/j.cnki.jdxbgxb20170617

Previous Articles Next Articles

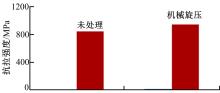

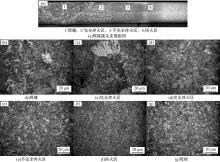

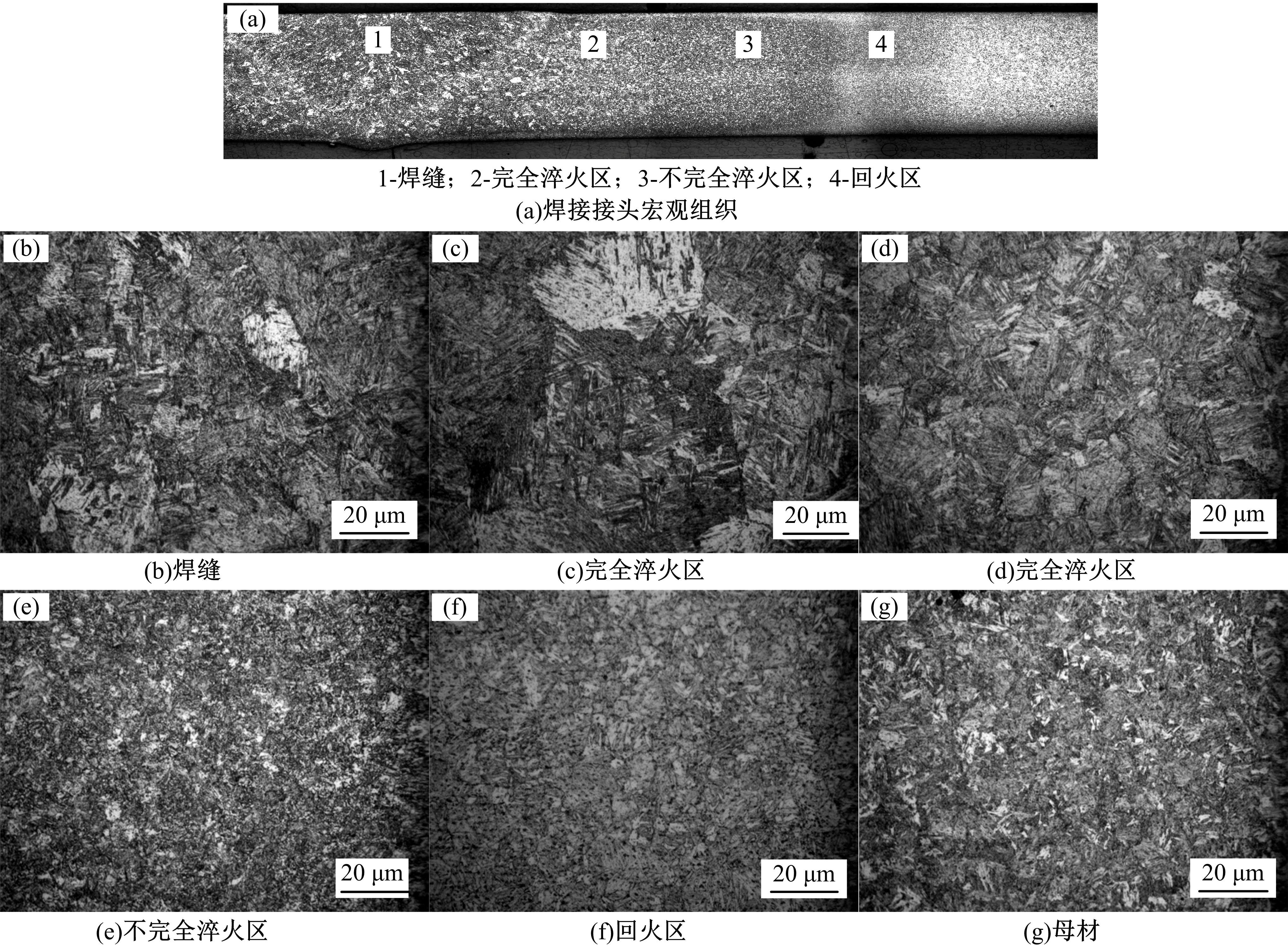

Strengthening properties of welded joints of 22MnB5 super high strength steel

JIANG Qiu-yue1( ),YANG Hai-feng2,TAN Cai-wang2

),YANG Hai-feng2,TAN Cai-wang2

- 1. School of Mechanical and Electrical Engineering, Changchun Institute of Technology, Changchun 130012, China

2. School of Materials Science and Engineering, Harbin Institute of Technology at Weihai, Weihai 264209, China

CLC Number:

- TG453

| [1] |

操志博, 贾耿伟, 王连轩 , 等. 热冲压用超高强钢22MnB5性能测试与分析[J]. 河北冶金, 2017(3):9-14.

doi: 10.13630/j.cnki.13-1172.2017.0302 |

|

Cao Zhi-bo, Jia Geng-wei, Wang Lian-xuan , et al. Performance testing and analysis of super high strength steel 22MnB5 for hot stamping[J]. Hebei Metallurgy, 2017(3):9-14.

doi: 10.13630/j.cnki.13-1172.2017.0302 |

|

| [2] |

Min Jun-ying, Lin Jian-ping, Li Jia-yue , et al. Investigation on hot forming limits of high strength steel 22MnB5[J]. Computational Material Science, 2014,49(2):326-332.

doi: 10.1016/j.commatsci.2010.05.018 |

| [3] |

刘如红, 符月虹 . 超高强钢板热冲压成形工艺及装备的研究[J]. 液压气动与密封, 2015(6):54-56.

doi: 10.3969/j.issn.1008-0813.2015.06.019 |

|

Liu Ru-hong, Fu Yue-hong . Research on super-high strong steel plate hot stamping forming technology and equipment[J]. Hydraulic and Pneumatic Seals, 2015(6):54-56.

doi: 10.3969/j.issn.1008-0813.2015.06.019 |

|

| [4] |

Naderi M, Uthaisangsuk V, Prahl U , et al. Numerical and experimental investigation into hot stamping of boron alloyed heat treated steels[J]. Steel Research International, 2014,79(2):77-84.

doi: 10.1002/srin.200806320 |

| [5] | Altan T . Hot stamping boron-alloyed steels for automotive parts—partII[J]. Stamping Journal, 2014(12):40-41. |

| [6] |

Kerstens N F H, Richardson I M . Heat distribution in resistance upset butt welding[J]. Journal of Materials Processing Technology, 2014,209(5):2715-2722.

doi: 10.1016/j.jmatprotec.2008.06.015 |

| [7] | 吴斌, 曹志福 . 超高强钢板U形件热冲压回弹研究[J]. 热加工工艺, 2016(11):140-143. |

| Wu Bin, Cao Zhi-fu . Study on hot stamping springback of super high strength steel sheet U[J]. Hot Working Technology, 2016(11):140-143. | |

| [8] |

Muccillo R, Muccillo E N S, Kleitz M . Densification and enhancement of the grain boundary conductivity of gadolinium-doped barium cerate by ultra fast flash grain welding[J]. Journal of the European Ceramic Society, 2014,32(10):2311-2316.

doi: 10.1016/j.jeurceramsoc.2012.01.032 |

| [9] | Li Bo, Zhang Zhen-hua, Shen Yi-fu , et al. Dissimilar friction stir welding of Ti-6Al-4V alloy and aluminum alloy employing a modified butt joint configuration: influences of process variables on the weld interfaces and tensile properties[J]. Materials and Design, 2013,53:838-848. |

| [1] | Jin⁃zhong LU,Wan⁃ting ZHOU,Sheng⁃yang ZHANG,Yi⁃kai SHAO,Chang⁃yu WANG,Kai⁃yu LUO. Effect of coverage layer on corrosion resistance of 6061⁃T6 aluminum alloy subjected to laser shock peening [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 842-849. |

| [2] | Na WU,Jian ZHUANG,Ke⁃song ZHANG,Hui⁃xin WANG,Yun⁃hai MA. Compression mechanical properties and fracture mechanism of Scapharca Subcrenata shell [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 897-902. |

| [3] | HU Zhi-qing, YAN Ting-xu, LI Hong-jie, LYU Zhen-hua, LIAO Wei, LIU Geng. Effect of cryogenic treatment on punch-shearing performance of aluminum alloy sheet [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1524-1530. |

| [4] | ZHENG Xiao-yi, SUN Da-qian, LI Xin, DU Gui-gang, XIN Wei-da, REN Zhen-an. Microstructure and properties of cladded Al-Nb layers reinforced by NbAl3 [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1531-1536. |

| [5] | QIU Xiao-ming, WANG Yin-xue, YAO Han-wei, FANG Xue-qing, XING Fei. Multi-objective optimization of resistance spot welding parameters for DP1180/DP590 using grey relational analysis based Taguchi [J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [6] | CHEN Jun-fu, GUAN Zhi-ping, YANG Chang-hai, NIU Xiao-ling, JIANG Zhen-tao, Song Yu-quan. Comparison of strain ranges and mechanical properties of metal rods under tension and torsion tests [J]. 吉林大学学报(工学版), 2018, 48(4): 1153-1160. |

| [7] | LIANG Xiao-bo, CAI Zhong-yi, GAO Peng-fei. Numerical simulation and experiment of cylindrical forming of sandwich composite panel [J]. 吉林大学学报(工学版), 2018, 48(3): 828-834. |

| [8] | LIU Zi-wu, LI Jian-feng. Erosion damage and evaluation of remanufacturing cladding layer for impeller metals FV520B [J]. 吉林大学学报(工学版), 2018, 48(3): 835-844. |

| [9] | ZHAO Yu-guang, YANG Xue-hui, XU Xiao-feng, ZHANG Yang-yang, NING Yu-heng. Effects of Al-10Sr modifiers with different states, modification temperature and holding time on microstructure of ZL114A alloy [J]. 吉林大学学报(工学版), 2018, 48(1): 212-220. |

| [10] | LIU Chun-guo, LIU Wei-dong, DENG Yu-shan. Effect of multi-point punch active loading path on the stretch-forming of sheet [J]. 吉林大学学报(工学版), 2018, 48(1): 221-228. |

| [11] | ZHANG Zhi-qiang, LIU Cong-hao, HE Dong-ye, LI Xiang-ji, LI Ji-xuan. Effect of hot stamping process of boron steel on shape precision based on performance gradient distribution [J]. 吉林大学学报(工学版), 2017, 47(6): 1829-1833. |

| [12] | LYU Meng-meng, GU Zheng-wei, XU Hong, LI Xin. Process optimization of hot stamping for anti-collision beam with ultra high strength [J]. 吉林大学学报(工学版), 2017, 47(6): 1834-1841. |

| [13] | XING Hai-yan, GE Hua, LI Si-qi, YANG Wen-guang, SUN Xiao-jun. Hidden defect metal magnetic memory identification for welded joints based on fuzzy membership and maximum likelihood estimation [J]. 吉林大学学报(工学版), 2017, 47(6): 1854-1860. |

| [14] | GU Xiao-yan, LIU Ya-jun, SUN Da-qian, XU Feng, MENG Ling-shan, GAO Shuai. Microstructures and mechanical properties of transient liquid phase diffusion bonded S355 steel/6005A aluminum alloy joint [J]. 吉林大学学报(工学版), 2017, 47(5): 1534-1541. |

| [15] | GU Zheng-wei, ZHANG Wen-xue, LYU Meng-meng, WANG Wei, XU Hong, LI Xin. Stretch bending defect control of U-section stainless steel profile with wide flange [J]. 吉林大学学报(工学版), 2017, 47(4): 1165-1170. |

|