Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (4): 1063-1071.doi: 10.13229/j.cnki.jdxbgxb20180530

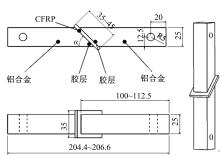

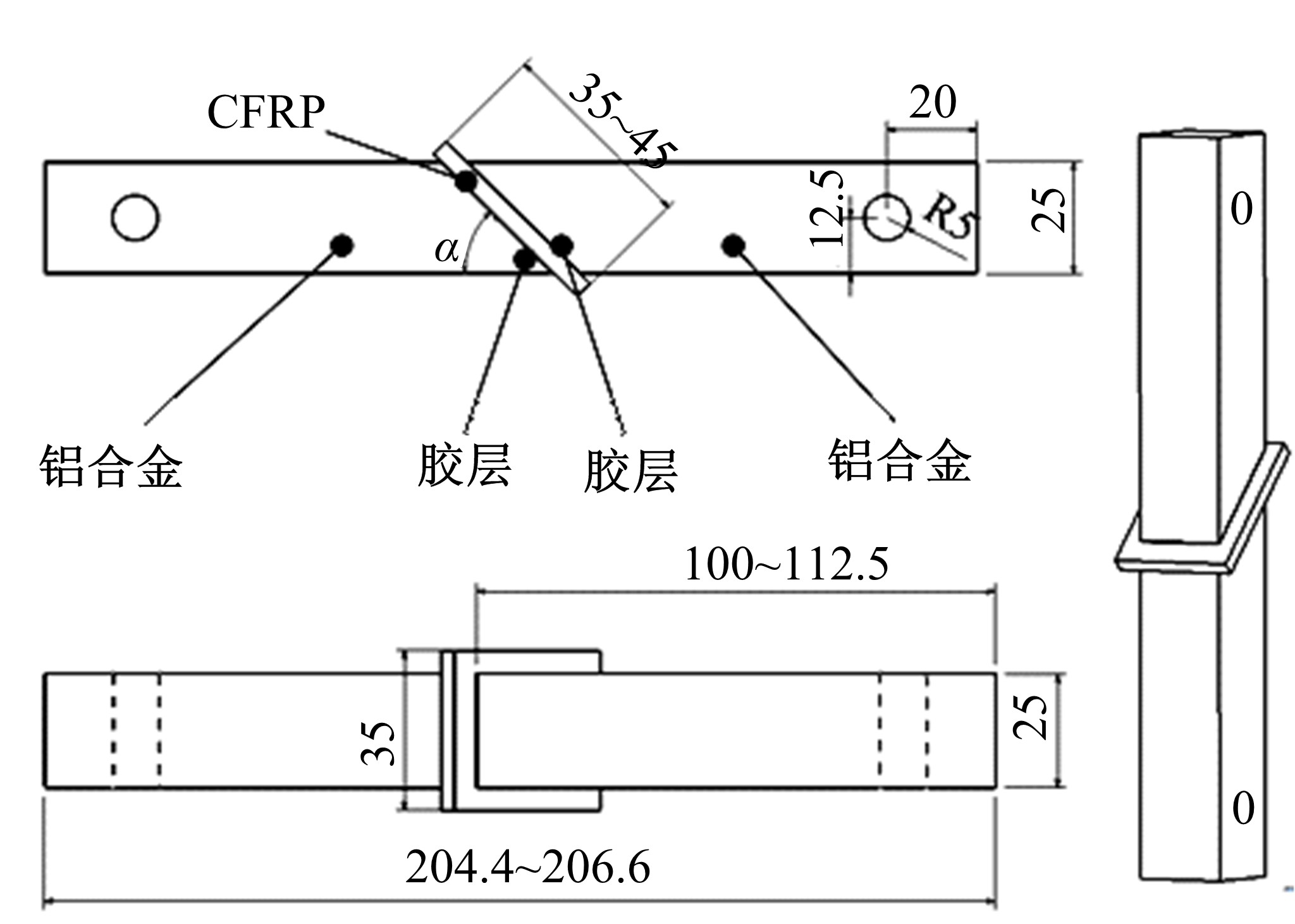

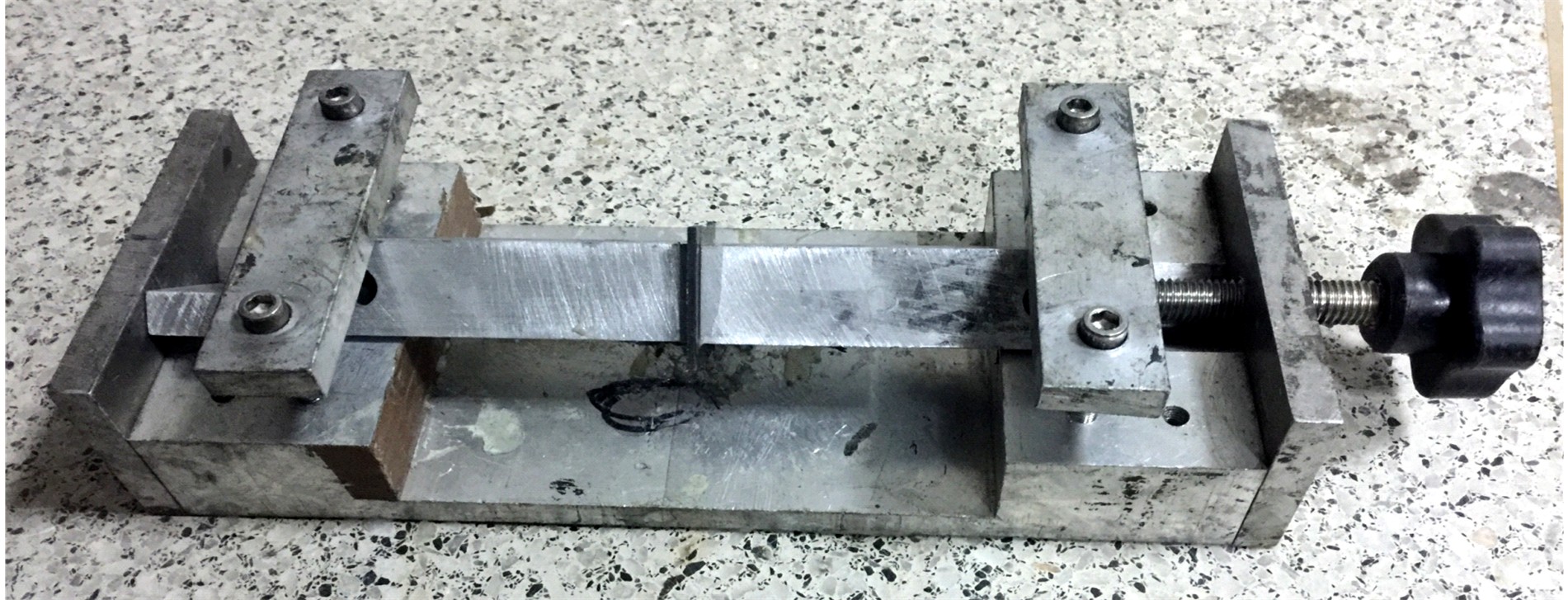

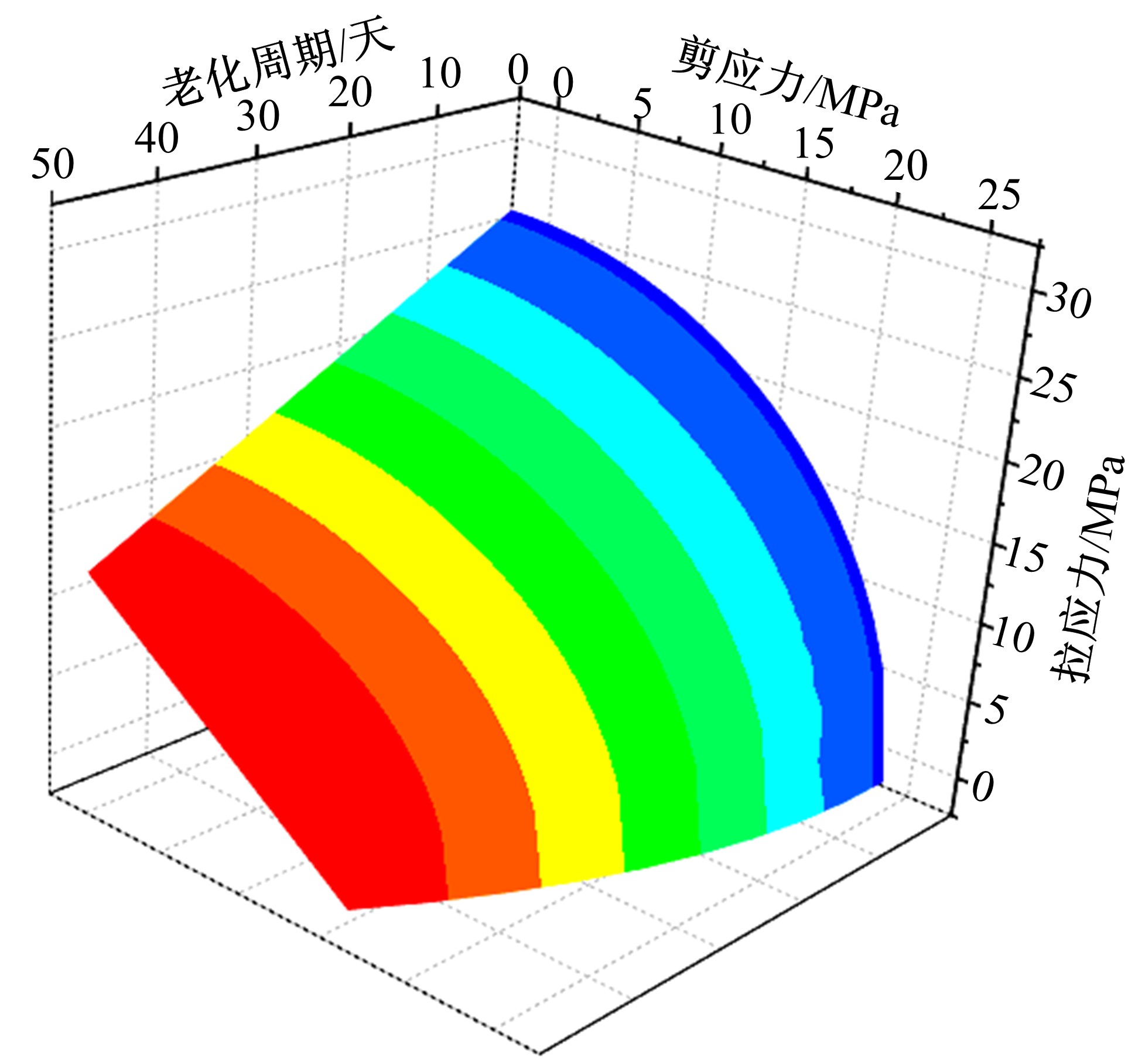

Degradation failure of adhesively bonded CFRP/aluminum alloy subjected to high temperature environment

Guo⁃feng QIN1,2( ),Jing⁃xin NA1(

),Jing⁃xin NA1( ),Wen⁃long MU1,Wei TAN1,Jian⁃ze LUAN1,Hao SHEN1

),Wen⁃long MU1,Wei TAN1,Jian⁃ze LUAN1,Hao SHEN1

- 1. State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2. Teachers College for Vocational and Technical Education, Guangxi Normal University, Guilin 541004,China

CLC Number:

- U463.82

| 1 | 冯美斌. 汽车轻量化技术中新材料的发展及应用[J]. 汽车工程, 2006, 28(3): 213⁃220. |

| FengMei⁃bin. Development and applications of new materials in automotive light weighting technologies[J]. Automotive Engineering, 2006, 28(3): 66⁃72. | |

| 2 | ElmarakbiA. Advanced Composite Materials for Automotive Applications: Structural Integrity and Crashworthiness[M]. New York: Wiley, 2013. |

| 3 | SakundariniN, TahaZ, Abdul⁃RashidS H, et al. Optimal multi/material selection for lightweight design of automotive body assembly incorporating recyclability[J]. Materials and Design, 2013, 50:846⁃857. |

| 4 | SilvaL F M D, ÖchsnerA, AdamsR D. Handbook of Adhesion Technology NOVA[M]. Newcastle: The University of Newcastle's Digital Repository, 2011. |

| 5 | VianaG, CostaM, BaneaM D, et al. A review on the temperature and moisture degradation of adhesive joints[J]. Journal of Materials: Design and Applications, 2017, 231(5): 488⁃501. |

| 6 | MarquesE A S, Da SilvaL F M, BaneaM D, et al. Adhesive joints for low⁃ and high⁃temperature use: an overview[J]. Journal of Adhesion, 2014, 91(7): 556⁃585. |

| 7 | PlazekD J, FrundZ N, FrundJ Z N, et al. Epoxy resins (DGEBA): the curing and physical aging process[J]. Journal of Polymer Science Part A: Polymer Chemistry, 1990, 28(4): 431⁃448 |

| 8 | BuchX, ShanahanM E R. Influence of the gaseous environment on the thermal degradation of a structural epoxy adhesive[J]. Journal of Applied Polymer Science, 2000, 76(7): 987⁃992. |

| 9 | HancoxN L. Thermal effects on polymer matrix composites: part 2. thermal degradation[J]. Materials and Design, 1998, 19(3): 93⁃97. |

| 10 | LiM. Temperature and moisture effects on composite materials for wind turbine blades[D]. Bozeman: Montana State University, 2000. |

| 11 | SkourlisT P, McculloughR L. The effect of temperature on the behavior of the interphase in polymeric composites[J]. Composites Science and Technology, 1993, 49(4): 363⁃368. |

| 12 | NgS J, CramerR J, MehrkamP. Characterization of IM 7/8552 polymer composites subjected to heat damage[C]∥International SAMPE Technical Conference, London, UK, 1997, 29: 776⁃786. |

| 13 | WolfrumJ, EiblS, LietchL. Rapid evaluation of long⁃term thermal degradation of carbon fibre epoxy composites[J]. Composites Science and Technology, 2009, 69(3): 523⁃530. |

| 14 | MarquesE A S, Da SilvaL F M, BaneaM D, et al. Adhesive joints for low⁃and high⁃temperature use: an overview[J]. The Journal of Adhesion, 2015, 91(7): 556⁃585. |

| 15 | KhaliliS M R, SharafiM, Eslami⁃FarsaniR, et al. Effect of thermal cycling on tensile properties of degraded FML to metal hybrid joints exposed to sea water[J]. International Journal of Adhesion and Adhesives, 2017, 79(2): 95⁃101. |

| 16 | BaneaM D, DaS L F M. The effect of temperature on the mechanical properties of adhesives for the automotive industry[J]. Journal of Materials: Design and Applications, 2010, 224(2): 51⁃62. |

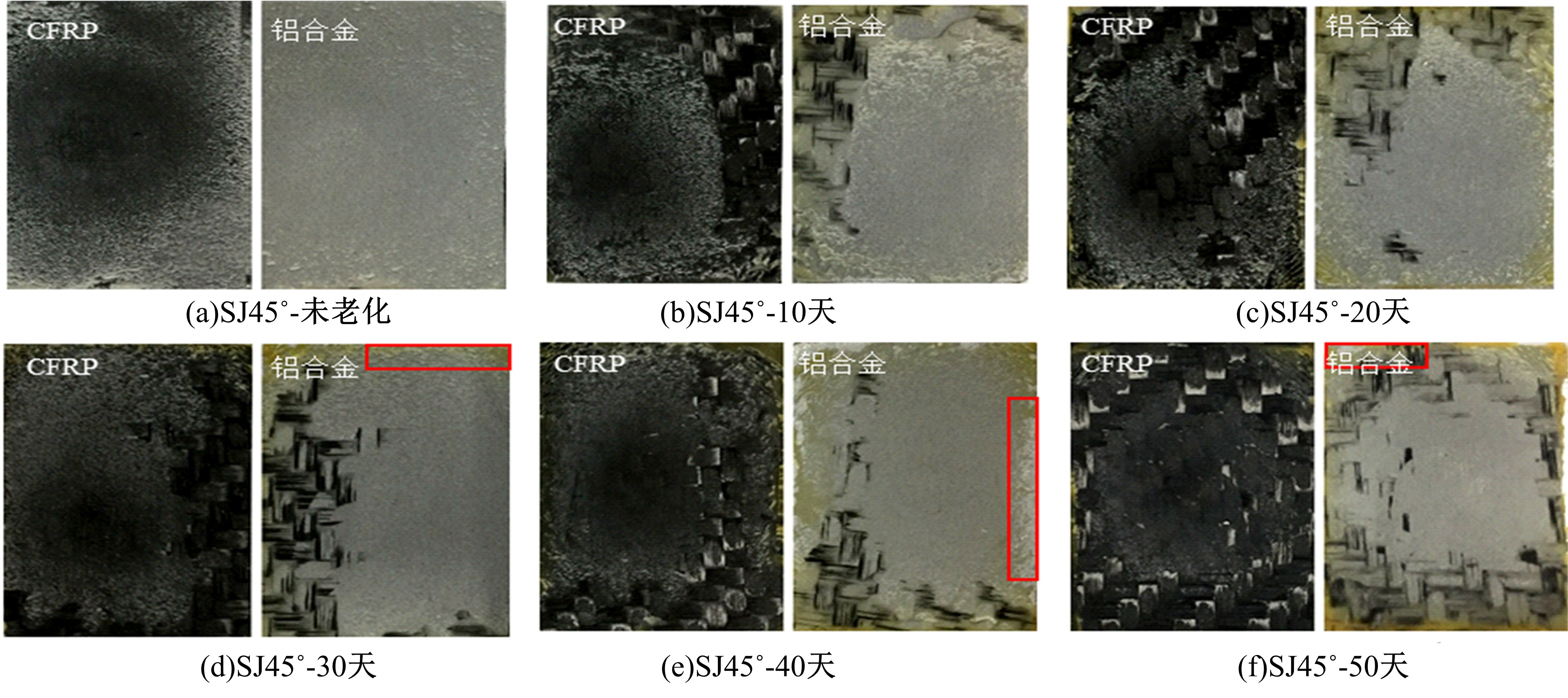

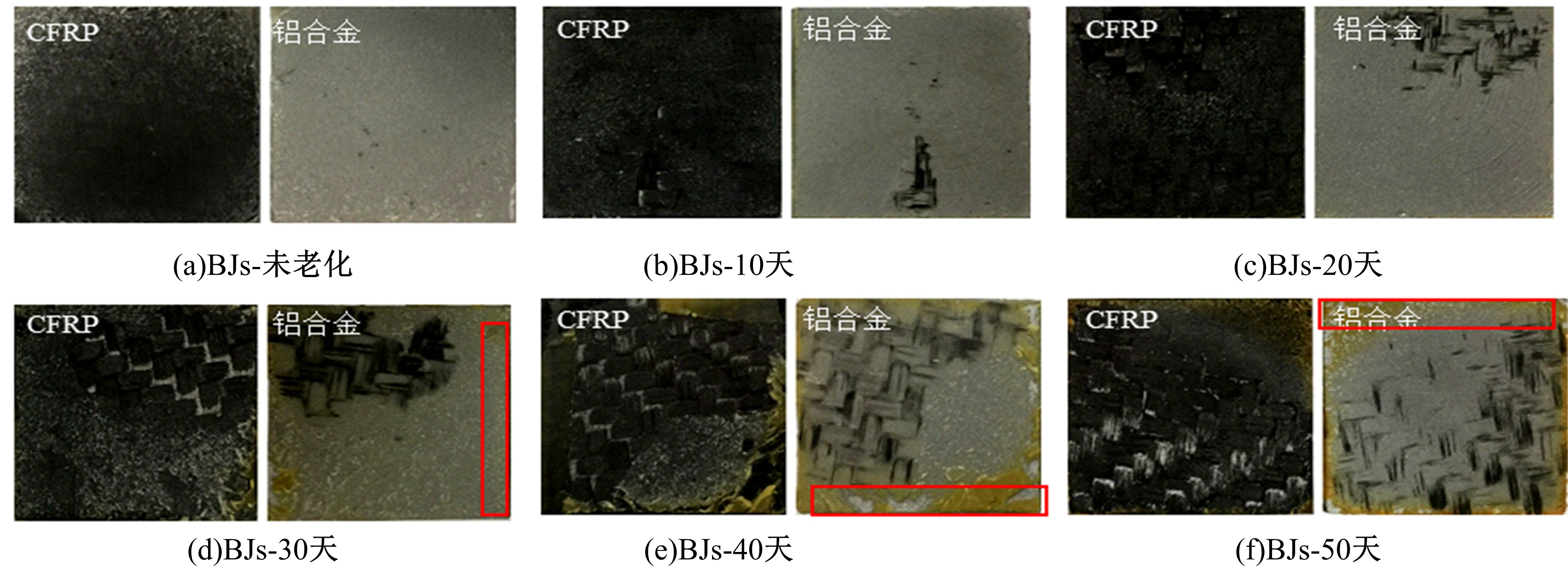

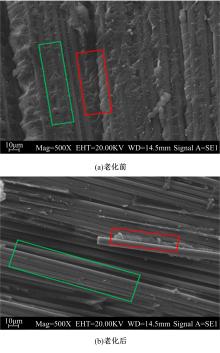

| 17 | QinGuo⁃feng, NaJing⁃xin, MuWen⁃long, et al. Effect of continuous high temperature exposure on the adhesive strength of epoxy adhesive, CFRP and adhesively bonded CFRP⁃aluminum alloy joints[J]. Composites Part B: Engineering, 2018, 154: 43⁃55. |

| 18 | DaS L F M, AdamsR D. Joint strength predictions for adhesive joints to be used over a wide temperature range [J]. International Journal of Adhesion and Adhesives 2007, 27(5): 362⁃379. |

| 19 | LeeM, YeoE, Black LockM, et al. Predicting the strength of adhesively bonded joints of variable thickness using a cohesive element approach[J]. International Journal of Adhesion and Adhesives, 2015, 58(1): 44⁃52. |

| [1] | Jing LI,Qiu⁃jun SHI,Peng LIU,Ya⁃wei HU. Neural network sliding mode control of commercial vehicle ABS based on longitudinal vehicle speed estimation [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1017-1025. |

| [2] | Shun YANG,Yuan⁃de JIANG,Jian WU,Hai⁃zhen LIU. Autonomous driving policy learning based on deep reinforcement learning and multi⁃type sensor data [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1026-1033. |

| [3] | Xin CHEN,Ming LI,Xin⁃jian RUAN,Ning WANG,Jia⁃ning WANG. Investigation of vortical structures in wake of Ahmed body by delayed detached⁃eddy simulation turbulence model using immersed boundary method [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1034-1042. |

| [4] | Hua ZHOU,Zhi⁃gang YANG,Hui ZHU. Aerodynamic calculation of MIRA model correlated with wind tunnel test [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1043-1053. |

| [5] | Run⁃dong LIU,Jun MAO,Yan⁃hong XI,Hong⁃yu ZHANG,Fei PENG. Pressure pulse on windbreak impacting by cross⁃wind coupling with high⁃speed trains passing each other [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1054-1062. |

| [6] | CHANG Cheng,SONG Chuan-xue,ZHANG Ya-ge,SHAO Yu-long,ZHOU Fang. Minimizing inverter capacity of doubly-fed machine driving electric vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1629-1635. |

| [7] | XI Li-he,ZHANG Xin,SUN Chuan-yang,WANG Ze-xing,JIANG Tao. Adaptive energy management strategy for extended range electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1636-1644. |

| [8] | HE Ren,YANG Liu,HU Dong-hai. Design and analysis of refrigeration system supplied by solar auxiliary power of refrigerator car [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1645-1652. |

| [9] | NA Jing-xin,MU Wen-long,FAN Yi-sa,TAN Wei,YANG Jia-zhou. Effect of hygrothermal aging on steel-aluminum adhesive joints for automotive applications [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1653-1660. |

| [10] | LIU Yu-mei,LIU Li,CAO Xiao-ning,XIONG Ming-ye,ZHUANG Jiao-jiao. Construction on collision avoidance model of bogie dynamic simulation test bench [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1661-1668. |

| [11] | ZHAO Wei-qiang, GAO Ke, WANG Wen-bin. Prevention of instability control of commercial vehicle based on electric-hydraulic coupling steering system [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1305-1312. |

| [12] | SONG Da-feng, WU Xi-tao, ZENG Xiao-hua, YANG Nan-nan, LI Wen-yuan. Life cycle cost analysis of mild hybrid heavy truck based on theoretical fuel consumption model [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1313-1323. |

| [13] | ZHU Jian-feng, ZHANG Jun-yuan, CHEN Xiao-kai, HONG Guang-hui, SONG Zheng-chao, CAO Jie. Design modification for automotive body structure based on seat pull safety performance [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1324-1330. |

| [14] | NA Jing-xin, PU Lei-xin, FAN Yi-sa, SHEN Chuan-liang. Effect of temperature and humidity on the failure strength of Sikaflex-265 aluminum adhesive joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1331-1338. |

| [15] | WANG Yan, GAO Qing, WANG Guo-hua, ZHANG Tian-shi, YUAN Meng. Simulation of mixed inner air-flow integrated thermal management with temperature uniformity of Li-ion battery [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1339-1348. |

|

||