Journal of Jilin University(Engineering and Technology Edition) ›› 2020, Vol. 50 ›› Issue (5): 1574-1583.doi: 10.13229/j.cnki.jdxbgxb20190458

Influence of coupling of elevated temperature and state of charge on mechanical response of Li⁃ion battery cells

Fei GAO1,2( ),Yang XIAO3(

),Yang XIAO3( ),Wen-hua ZHANG3,Jin-xuan QI3,Zi-qiao LI3,Xiao-yuan MA3

),Wen-hua ZHANG3,Jin-xuan QI3,Zi-qiao LI3,Xiao-yuan MA3

- 1.State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

2.College of Biological and Agricultural Engineering, Jilin University, Changchun 130022, China

3.College of Automotive Engineering, Jilin University, Changchun 130022, China

CLC Number:

- U41

| 1 | 呙晓兵, 范小平, 刘新军, 等. 磷酸铁锂正极锂离子电池的高温循环性能[J]. 电池, 2013, 43(1): 35-37. |

| Guo Xiao-bing, Fan Xiao-ping, Liu Xin-jun, et al. High temperature cycle performance of lithium iron phosphate cathode Li-ion battery[J]. Battery Bimonthly, 2013, 43(1): 35-37. | |

| 2 | 何鹏林. 锂离子电池高温使用安全测试研究[J]. 安全与电磁兼容, 2012(3): 18-20. |

| He Peng-lin. Research on safety test of high temperature for Li-ion battery[J]. Safety & EMC, 2012(3): 18-20. | |

| 3 | Andersson A M, Edstrom K, Rao N, et al. Temperature dependence of the passivation layer on graphite[J]. Journal of Power Sources, 1999, 81/82: 286-290. |

| 4 | Sloop S E, Pugh J K, Kerr J B, et al. Chemical reactivity of PF5 and LiPF6 in ethylene carbonate/dimethyl carbonate solutions[J]. Electrochemical and Solid State Letters, 2001, 4(4): 357-364. |

| 5 | Lin X R, Salari M, Arava L M R, et al. High temperature electrical energy storage: advances, challenges, and frontiers[J]. Chemical Society Reviews, 2016, 45(21): 5848-5887. |

| 6 | 邢海霞. 锂离子电池高温存储性能的影响因素和机理研究[D]. 上海: 上海复旦大学化学系, 2014. |

| Xin Hai-xia. Study on the influence factors and mechanisms of Li-ion battery during high temperature storage[D]. Shanghai: Department of Chemistry, Fudan University, 2014. | |

| 7 | 范光辉, 余剑武, 罗红, 等. 混合动力汽车电池性能影响因素分析与试验[J]. 吉林大学学报: 工学版, 2019, 49(5): 1451-1458. |

| Fan Guang-hui, Yu Jian-wu, Luo Hong, et al. Influencing factors analysis and experimental study of battery performances in hybrid electric vehicle[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1451-1458. | |

| 8 | 陈吉清, 刘蒙蒙, 兰凤崇. 三元动力电池及其成组后的过充安全性试验[J]. 吉林大学学报: 工学版, 2019, 49(4): 1072-1080. |

| Chen Ji-qing, Liu Meng-meng, Lan Feng-chong. Experiment on overcharge safety of NCM battery and battery pack[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1072-1080. | |

| 9 | Avdeev I V, Martinsen M J, Francis A B. Materials testing of a lithium ion battery separator for use in finite element analysis[C]∥ASME International Mechanical Engineering Congress and Exposition, Houston, Texas, USA, 2012: 475-481. |

| 10 | Lin Y C, Chen X M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working[J]. Materials & Design, 2011, 32(4): 1733-1759. |

| 11 | 刘琨, 祖敏辉. PEBA/PVDF复合膜的溶胀及渗透汽化性能研究[J]. 膜科学与技术, 2010, 30(1): 60-64. |

| Liu Kun, Zu Min-hui. Study on swelling and pervaporation behavior of PEBA/PVDF composite membrane[J]. Membrane Science and Technology, 2010, 30(1): 60-64. | |

| 12 | 吴正国, 张剑波, 李哲, 等. 锂离子电池加速老化温度应力的滥用边界[J]. 汽车安全与节能学报, 2018, 9(1): 99-109. |

| Wu Zheng-guo, Zhang Jian-bo, Li Zhe, et al. Aging abuse boundary of lithium-ion cell above room temperature[J]. Journal of Automotive Safety and Energy, 2018, 9(1): 99-109. | |

| 13 | Taniguchi S, Shironita S, Konakawa K, et al. Thermal characteristics of 80 °C storage-degraded 18650-type lithium-ion secondary cells[J]. Journal of Power Sourses, 2019, 416: 148-154. |

| 14 | Yayathi S, Walker W, Doughty D, et al. Energy distributions exhibited during thermal runaway of commercial lithium ion batteries used for human spaceflight applications[J]. Journal of Power Sources, 2016, 329: 197-206. |

| 15 | 端方勇, 陈亮. 内外饰颜色对车辆暴晒后车内温度影响的研究[J]. 汽车实用技术, 2017(12): 129-131. |

| Duan Fang-yong, Chen Liang. Study on the influence of interior and exterior color on vehicle temperature after exposure[J]. Automobile Applied Technology, 2017(12): 129-131. | |

| 16 | 闵磊, 仲昭佩. 汽车暴晒试验方法的探讨[J]. 吐鲁番科技, 2010(3): 36-39. |

| Min Lei, Zhong Zhao-pei. Discussion on the test method of automobile exposure[J]. Turpan Technology, 2010(3): 36-39. | |

| 17 | Avdeev I, Gilaki M. Structural analysis and experimental characterization of cylindrical lithium-ion battery cells subject to lateral impact[J]. Journal of Power Sources, 2014, 271: 382-391. |

| 18 | Xu J, Liu B, Wang X, et al. Computational model of 18650 lithium-ion battery with coupled strain rate and SOC dependencies[J]. Applied Energy, 2016, 172: 180-189. |

| 19 | Greve L, Fehrenbach C. Mechanical testing and macro-mechanical finite element simulation of the deformation, fracture, and short circuit initiation of cylindrical Lithium ion battery cells[J]. Journal of Power Sources, 2012, 214: 377-385. |

| 20 | Cannarella J, Liu X, Leng C Z, et al. Mechanical properties of a battery separator under compression and tension[J]. Journal of The Electrochemical Society, 2014, 161(11): 3117-3122. |

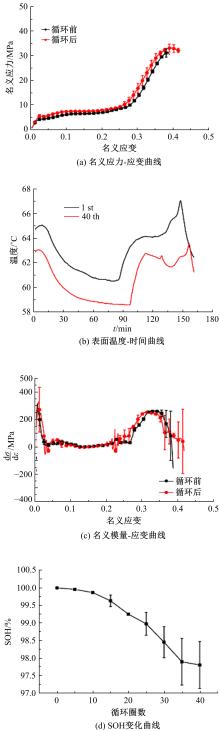

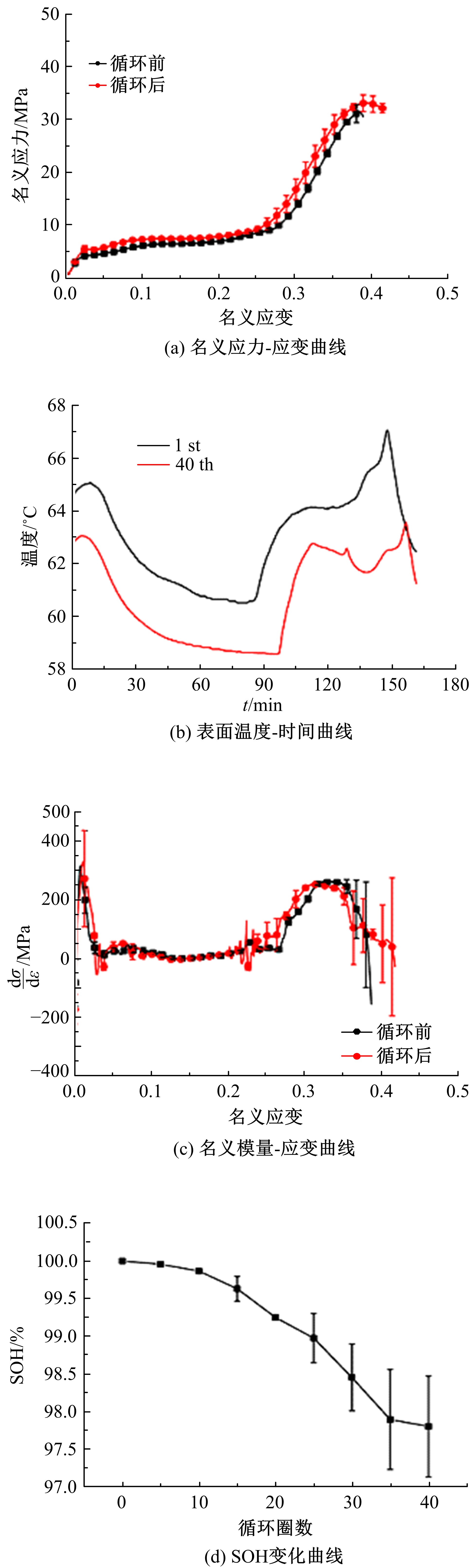

| 21 | Gao Z, Zhang X, Xiao Y, et al. Influence of coupling of overcharge state and short-term cycle on the mechanical integrity behavior of 18650 Li-ion batteries subject to lateral compression[J]. International Journal of Hydrogen Energy, 2018, 43(10): 5261-5271. |

| 22 | Gao Z, Zhang X, Xiao Y, et al. Influence of low-temperature charge on the mechanical integrity behavior of 18650 lithium-ion battery cells subject to lateral compression[J]. Energies, 2019, 12(5): 797-813. |

| 23 | Wierzbicki T, Sahraei E. Homogenized mechanical properties for the jellyroll of cylindrical lithium-ion cells[J]. Journal of Power Sources, 2013, 241: 467-476. |

| 24 | Kisters T, Sahraei E, Wierzbicki T. Dynamic impact tests on lithium-ion cells[J]. International Journal of Impact Engineering, 2017, 108: 205-216. |

| 25 | Leng F, Tan C M, Pecht M. Effect of temperature on the aging rate of Li-ion battery operating above room temperature[J]. Scientific Reports, 2015, 5: 1-12. |

| 26 | Xu J, Liu B H, Hu D Y. State of charge dependent mechanical integrity behavior of 18650 lithium-ion batteries[J]. Scientific Reports, 2016(6): 1-11. |

| 27 | Gao Z H, Zhang X T, Hu H Y, et al. Influencing factors of low-and high-temperature behavior of Co-doped Zn2SnO4-graphene-carbon nanocomposite as anode material for lithium-ion batteries[J]. Journal of Electroanalytical Chemistry, 2017, 791: 56-63. |

| 28 | Andersson A M, Edstrom K. Chemical composition and morphology of the elevated temperature SEI on graphite[J]. Journal of the Electrochemical Society, 2001, 148(10): 1100-1109. |

| 29 | 杜国栋, 努丽燕娜, 冯真真, 等. LiNi0.5Mn1.5O4-xFx高电压电极高温保存下的电化学行为[J]. 物理化学学报, 2008, 24(1): 165-170. |

| Du Guo-dong, Yan-na Nuli, Feng Zhen-zhen, et al. Electrochemical behavior of high-voltage LiNi0.5Mn1.5O4-xFx electrodes at elevated storage temperature[J]. Acta Physico-Chimica Sinica, 2008, 24(1): 165-170. | |

| 30 | Gomez J, Nelson R, Kalu E E, et al. Equivalent circuit model parameters of a high-power Li-ion battery: Thermal and state of charge effects[J]. Journal of Power Sources, 2011, 196(10): 4826-4831. |

| 31 | Campion C L, Li W T, Lucht B L. Thermal decomposition of LiPF6-based electrolytes for lithium-ion batteries[J]. Journal of the Electrochemical Society, 2005, 152(12): 2327-2334. |

| 32 | Zinigrad E, Larush-Asraf L, Gnanaraj J S, et al. On the thermal stability of LiPF6[J]. Thermochimica Acta, 2005, 438(1/2): 184-191. |

| 33 | Guan T, Sun S, Gao Y Z, et al. The effect of elevated temperature on the accelerated aging of LiCoO2/mesocarbon microbeads batteries[J]. Applied Energy, 2016, 177: 1-10. |

| [1] | Chang-qing DU,Xi-liang CAO,Biao HE,Wei-qun REN. Parameters optimization of dual clutch transmission based on hybrid particle swarm optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1556-1564. |

| [2] | Jing LI,Qiu-jun SHI,Liang HONG,Peng LIU. Commercial vehicle ESC neural network sliding mode control based on vehicle state estimation [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1545-1555. |

| [3] | Ji-qing CHEN,Qing-sheng LAN,Feng-chong LAN,Zhao-lin LIU. Trajectory tracking control based on tire force prediction and fitting [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1565-1573. |

| [4] | Xin CHEN,Ning WANG,Chuan-liang SHEN,Xiao FENG,Chang-hai YANG. Effect of rearview mirror modeling on aerodynamic noise of front window [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 426-436. |

| [5] | Xiao-yu LI,Nan XU,Tao QIU,Kong-hui GUO. Influence of anisotropic stiffness on tire mechanical properties and vehicle handling characteristics under combined slip situations [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 389-398. |

| [6] | Yin-ping LI,Tian-xu JIN,Li LIU. Design and dynamic characteristic simulation of pantograph⁃catenary continuous energy system for pure electric LHD [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 454-463. |

| [7] | Chen-guang LAI,Qing-yu WANG,Bo HU,Kai-ping WEN,Yan-yu CHEN. Design and optimization of a car empennage with winglet under effect of static aeroelasticity [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 399-407. |

| [8] | Hui YE,Chang LIU,Kang-kang YAN. Application of fiber reinforced composite in auto⁃body panel [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 417-425. |

| [9] | Fang-wu MA,Hong-yu LIANG,Ying ZHAO,Meng YANG,Yong-feng PU. Multi⁃objective crashworthiness optimization design of concave triangles cell structure with negative Poisson′s ratio [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 29-35. |

| [10] | Kong-hui GUO,Shi-qing HUANG,Hai-dong WU. In⁃plane dynamic tire model for high⁃frequency excitation [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 19-28. |

| [11] | Zhe WANG,Yi XIE,Peng-fei ZANG,Yao WANG. Energy management strategy of fuel cell bus based on Pontryagin′s minimum principle [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 36-43. |

| [12] | Wen-ku SHI,Long CHEN,Gui-hui ZHANG,Zhi-yong CHEN. Modeling and tests for torsional characteristics of multi-stage stiffness dual mass flywheel torsional dampers [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 44-52. |

| [13] | Xin GUAN,Hao JIN,Chun-guang DUAN,Ping-ping LU. Estimation of lateral slope of vehicle driving road [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1802-1809. |

| [14] | Xin CHEN,Xin-jian RUAN,Ming LI,Ning WANG,Jia-ning WANG,Kai-xuan PAN. Application of modified discrete scheme based onlarge eddy simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1756-1763. |

| [15] | Fang-wu MA,Li-wei NI,Liang WU,Jia-hong NIE,Guang-jian XU. Position and attitude closed loop control of wheel⁃leggedall terrain mobile robot [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1745-1755. |

|

||