Journal of Jilin University(Engineering and Technology Edition) ›› 2020, Vol. 50 ›› Issue (5): 1687-1697.doi: 10.13229/j.cnki.jdxbgxb20190589

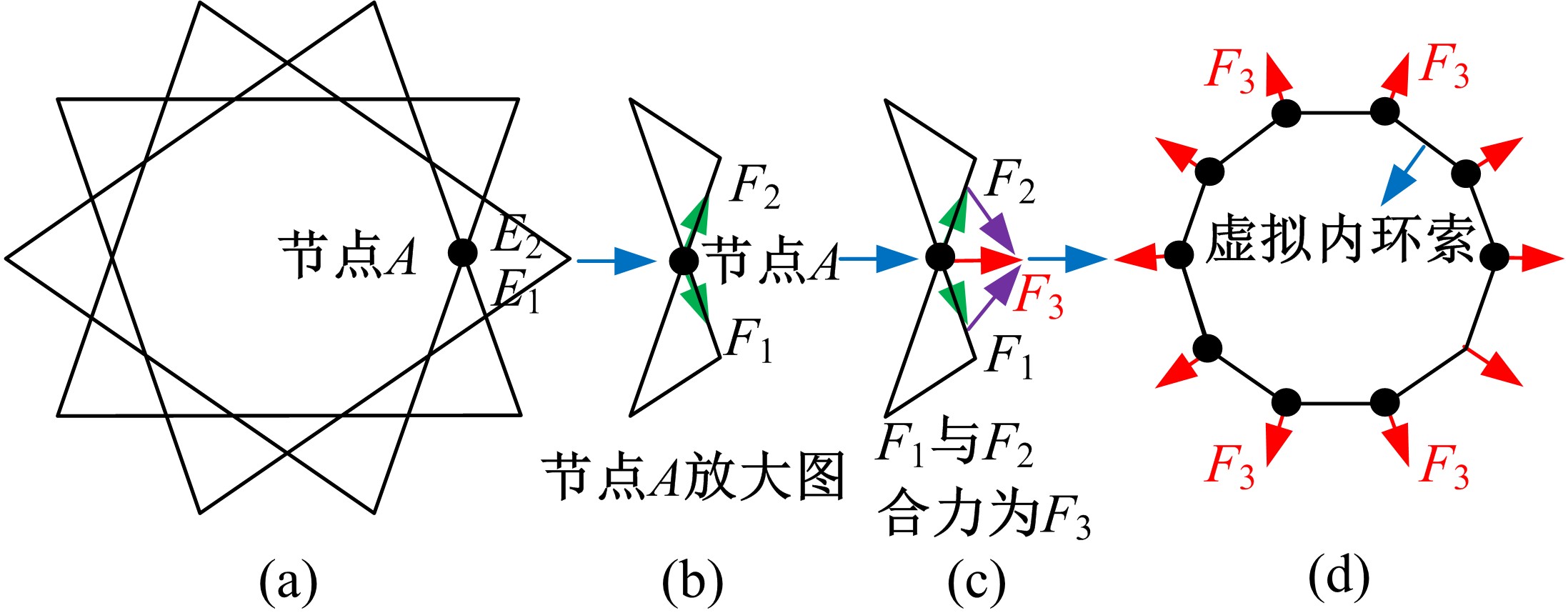

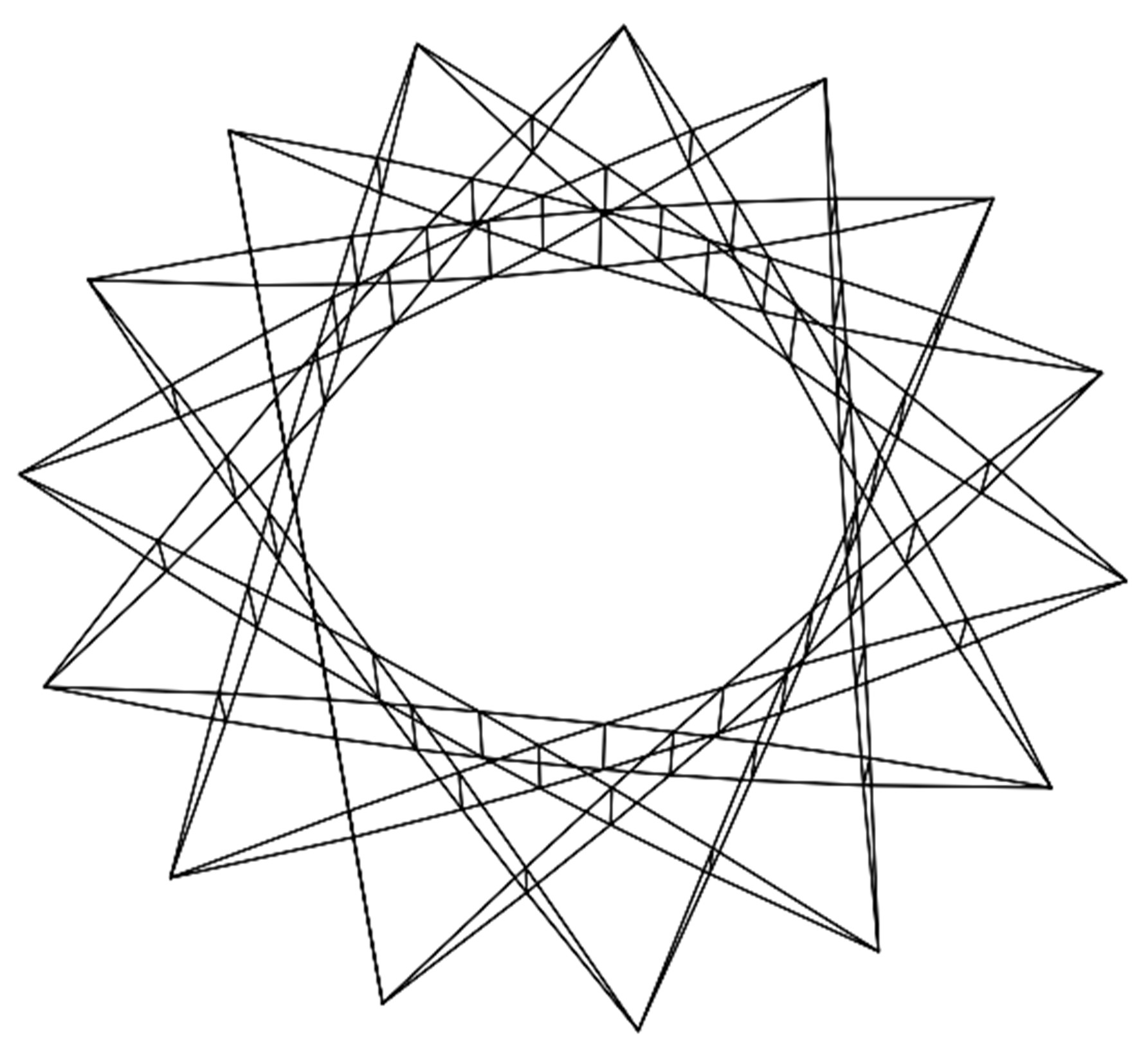

Influence of grid⁃jumping arrangement on static and dynamic performance of annular crossed cable⁃truss structure

Su-duo XUE1( ),Jian LU1,Xiong-yan LI1,Ren-jie LIU2

),Jian LU1,Xiong-yan LI1,Ren-jie LIU2

- 1.College of Architecture and Civil Engineering, Beijing University of Technology, Beijing 100124, China

2.School of Civil Engineering, Yantai University, Yantai 264000, China

CLC Number:

- TU394

| 1 | 田广宇. 车辐式张拉结构设计理论与施工控制关键技术研究[D]. 北京: 清华大学土木工程系, 2012. |

| Tian Guang-yu. Research on key technology of design theory and construction control in spoke tension structures[D]. Beijing: Department of Civil Engineering, Tsinghua University, 2012. | |

| 2 | 梁笑天. 索杆张力结构优化与控制研究[D]. 杭州: 浙江大学建筑工程学院, 2017. |

| Liang Xiao-tian. Optimization and control research of cable-strut tensile structures[D]. Hangzhou: School of Architecture and Engineering, Zhejiang University, 2017. | |

| 3 | Wang Z H, Yuan X F, Dong S L, et al. Simple approach for force finding analysis of circular Geiger domes with consideration of self-weight[J]. Journal of Constructional Steel Research, 2010, 66(2): 317-322. |

| 4 | Guo J M, Jiang J Q. An algorithm for calculating the feasible pre-stress of cable-struts structure[J]. Engineering Structures, 2016, 118: 228-239. |

| 5 | 郭彦林, 王昆, 田广宇, 等. 车辐式张拉结构体型研究与设计[J]. 建筑结构学报, 2013, 34(5): 1-10. |

| Guo Yan-lin, Wang Kun, Tian Guang-yu, et al. Research and design of structural form of spoke structure[J]. Journal of Building Structures, 2013, 34(5): 1-10. | |

| 6 | Liu R J, Xue S D, Li X Y, et al. Preventing disproportionate displacements in an annular crossed cable-truss structure[J]. International Journal of Space Structures, 2017, 32(1): 3-10. |

| 7 | 冯远, 向新岸, 王恒, 等. 大开口车辐式索承网格结构构建及其受力机制和找形研究[J]. 建筑结构学报, 2019, 40(3): 69-80. |

| Feng Yuan, Xiang Xin-an, Wang Heng, et al. Mechanical behavior and form-finding research on large opening spoke-wheel-type cable supported grid structure[J]. Journal of Building Structures, 2019, 40(3): 69-80. | |

| 8 | 张爱林, 孙超, 姜子欣. 联方型双撑杆索穹顶考虑自重的预应力计算方法[J]. 工程力学, 2017, 34(3): 211-218. |

| Zhang Ai-lin, Sun Chao, Jiang Zi-qin. Calculation method of prestress distribution for levy cable dome with double struts considering self-weight[J]. Engineering Mechanics, 2017, 34 (3): 211-218. | |

| 9 | 薛素铎, 高占远, 张超, 等. 劲性支撑穹顶结构的施工方法与试验研究[J]. 中南大学学报: 自然科学版, 2016, 47 (4): 1219-1226. |

| Xue Su-duo, Gao Zhan-yuan, Zhang Chao, et al. Research on construction method and model test of rigid bracing dome[J]. Journal of Central South University(Science and Technology), 2016, 47(4): 1219-1226. | |

| 10 | 邓华, 祖义祯, 沈嘉嘉, 等. 月牙形索桁罩棚结构的施工成形分析和试验[J]. 浙江大学学报: 工学版, 2013, 47(3): 488-494, 527. |

| Deng Hua, Zu Yi-zhen, Shen Jia-jia, et al. Analysis and experiment on erection process of a crescent-shaped cable-truss canopy structure[J]. Journal of Zhejiang University(Engineering Science), 2013, 47(3): 488-494, 527. | |

| 11 | Liu R J, Li X Y, Xue S D, et al. Numerical and experimental research on annular crossed cable-truss structure under cable rupture[J]. Earthquake Engineering and Engineering Vibration, 2017, 16(3): 557-569. |

| 12 | JGJ257—2012. 索结构技术规程[S]. |

| 13 | 李娟. 设内拉环的肋环型索穹顶的静动力特性分析[D]. 成都: 西南交通大学土木工程学院, 2014. |

| Li Juan. Study of the static and dynamic characteristics of ribbed cable dome[D]. Chengdu: School of Civil Engineering, Southwest Jiaotong University, 2014. |

| [1] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Experimental of loading-bearing capacity of one-way laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 654-667. |

| [2] | Peng-hui WANG,Hong-xia QIAO,Qiong FENG,Hui CAO,Shao-yong WEN. Durability model of magnesium oxychloride-coated reinforced concrete under the two coupling factors [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 191-201. |

| [3] | Ming LI,Hao-ran WANG,Wei-jian ZHAO. Mechanical properties of laminated slab with shear keys [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1509-1520. |

| [4] | Jun ZHANG,Cheng QIAN,Chun⁃yan GUO,Yu⁃jun QIAN. Dynamic design of building livability based on multi⁃source spatiotemporal data [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1169-1173. |

| [5] | Ning⁃hui LIANG,Qing⁃xu MIAO,Xin⁃rong LIU,Ji⁃fei DAI,Zu⁃liang ZHONG. Determination of fracture toughness and softening traction⁃separation law of polypropylene fiber reinforced concrete [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1144-1152. |

| [6] | Lei ZHANG,Bao⁃guo LIU,Zhao⁃fei CHU. Model test of the influence on shield shaft owing to water loss settlement of deep sandstone aquifer layer [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 788-797. |

| [7] | ZHENG Yi-feng, ZHAO Qun, BAO Wei, LI Zhuang, YU Xiao-fei. Wind resistance performance of long-span continuous rigid-frame bridge in cantilever construction stage [J]. 吉林大学学报(工学版), 2018, 48(2): 466-472. |

| [8] | NI Ying-sheng, SUN Qi-xin, MA Ye, XU Dong. Calculation of capacity reinforcement about composite box girder with corrugated steel webs based on tensile stress region theory [J]. 吉林大学学报(工学版), 2018, 48(1): 148-158. |

| [9] | WANG Teng, ZHOU Ming-ru, MA Lian-sheng, QIAO Hong-xia. Fracture grouting crack growth of collapsible loess based on fracture theory [J]. 吉林大学学报(工学版), 2017, 47(5): 1472-1481. |

| [10] | ZHENG Yi-feng, MAO Jian, LIANG Shi-zhong, ZHENG Chuan-feng. Negative skin friction of pile foundation considering soil consolidation in high fill site [J]. 吉林大学学报(工学版), 2017, 47(4): 1075-1081. |

| [11] | LI Jing, WANG Zhe. Mechanical characteristics of concrete under true triaxial loading condition [J]. 吉林大学学报(工学版), 2017, 47(3): 771-777. |

| [12] | GUO Nan, ZHANG Ping-yang, ZUO Yu, ZUO Hong-liang. Bending performance of glue-lumber beam reinforced by bamboo plyboard [J]. 吉林大学学报(工学版), 2017, 47(3): 778-788. |

| [13] | ZHANG Jing, LIU Xiang-dong. Prediction of concrete strength based on least square support vector machine optimized by chaotic particle swarm optimization [J]. 吉林大学学报(工学版), 2016, 46(4): 1097-1102. |

| [14] | GUO Xue-dong, MA Li-jun, ZHANG Yun-long. Analytical solution of the double joint layer composite beam with shear-slip under vertical concentrated load [J]. 吉林大学学报(工学版), 2016, 46(2): 432-438. |

| [15] | HOU Zhong-ming, WANG Yuan-qing, XIA He, ZHANG Tian-shen. Simply-supported steel-concrete composite beams under moving load [J]. 吉林大学学报(工学版), 2015, 45(5): 1420-1427. |

|

||