Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (1): 122-133.doi: 10.13229/j.cnki.jdxbgxb20190948

Building and application of metal cutting knowledge graph

Yang DUAN( ),Li HOU(

),Li HOU( ),Song LENG

),Song LENG

- School of Mechanical Engineering,Sichuan University,Chengdu 610065,China

CLC Number:

- TH166

| 1 | 刘战强, 黄传真, 万熠, 等. 切削数据库的研究现状与发展[J]. 计算机集成制造系统, 2003, 9(11): 937-943. |

| Liu Zhan-qiang, Huang Chuan-zhen, Wan Yi, et al. Research state and development directions of cutting database[J]. Computer Integrated Manufacturing Systems, 2003, 9(11): 937-943. | |

| 2 | Walter GPS.[EB/OL]. [2019-10-08].. |

| 3 | ToolLibrary CoroPlus.[EB/OL]. [2019-10-08].. |

| 4 | 谭方浩. 基于特征的智能型车削数据库系统研究与开发[D]. 北京: 北京理工大学机械与车辆学院, 2015. |

| Tan Fang-hao. Research and development of intelligent turning database system based on machining features[D]. Beijing: School of Machinery and Vehicle, Beijing University of Technology, 2015. | |

| 5 | 任莹晖, 纪会敏, 杜勇, 等. 切削刀具综合管理系统的数据采集和存储设计研究[J].计算机应用研究, 2016, 33(10): 3031-3035. |

| Ren Ying-hui,Ji Hui-min,Du Yong,et al. Study on design of data acquisition and storage for comprehensive tool management system[J]. Application Research of Computers, 2016, 33(10): 3031-3035. | |

| 6 | 海源, 张松, 李剑峰, 等. 基于射频识别技术的车间级刀具管理系统[J]. 计算机集成制造系统, 2016, 22(8): 1907-1918. |

| Hai Yuan, Zhang Song, Li Jian-feng, et al. Workshop-level tool management system based on radio frequency identification technology[J]. Computer Integrated Manufacturing Systems, 2016, 22(8): 1907-1918. | |

| 7 | 廖生辉, 王建军, 卓勇, 等. 在线智能刀具管理系统的开发与研究[J]. 锻压技术, 2018, 43(9): 189-195. |

| Liao Sheng-hui,Wang Jian-jun,Zhuo Yong, et al. Development and research on online intelligent tool management system[J]. Forging & Stamping Technology, 2018, 43(9): 189-195. | |

| 8 | 白雪, 鄢萍. 齿轮加工数字化车间刀夹具管理系统的设计[J]. 计算机集成制造系统, 2020, 26(5): 1233-1245. |

| Bai Xue, Yan Ping. Design of cutting tools and fixtures management system for digital workshop of gear machining[J]. Computer Integrated Manufacturing Systems, 2020, 26(5): 1233-1245. | |

| 9 | Peng C, Du H, Warren Liao T. A research on the cutting database system based on machining features and TOPSIS[J]. Robotics and Computer-Integrated Manufacturing, 2017, 43: 96-104. |

| 10 | 张丹丹. 基于特征的航空结构件工艺知识库建立和数据挖掘研究[D]. 山东:山东大学机械工程学院, 2018. |

| Zhang Dan-dan. Feature-based knowledge base building and data mining for aeronautical structural parts[D]. Shandong: School of Mechanical Engineering, Shandong University, 2018. | |

| 11 | Zhang Y Z, Luo X F, Zhang H. A knowledge representation for unit manufacturing processes[J]. International Journal of Advanced Manufacturing Technology, 2014, 73: 1011-1031. |

| 12 | 王晶, 张定华, 吴宝海, 等. 基于临界约束的四轴数控加工刀轴优化方法[J]. 机械工程学报, 2012, 48(17): 114-120. |

| Wang Jing, Zhang Ding-hua, Wu Bao-hai, et al. Tool orientation optimization method in four-axis CNC machining based on critical constraints[J]. Journal of Mechanical Engineering, 2012, 48(17): 114-120. | |

| 13 | 吴宝海, 梁满仓, 张莹, 等. 复杂曲面通道多轴加工的刀具选择方法[J]. 机械工程学报, 2018, 54(3): 117-124. |

| Wu Bao-hai, Liang Man-cang, Zhang Ying, et al. Tool selection of multi-axis machining for channel parts with sculptured surface[J]. Journal of Mechanical Engineering, 2018, 54(3): 117-124. | |

| 14 | 陈行政, 李聪波, 吴磊, 等. 面向能耗的多刀具孔加工刀具直径及工艺参数集成优化模型[J]. 机械工程学报, 2018, 54(15): 221-231. |

| Chen Xing-zheng, Li Cong-bo, Wu Lei, et al. Integrating optimization of cutter diameter and cutting parameters for energy-aware multi-tool hole machining[J]. Journal of Mechanical Engineering, 2018, 54(15): 221-231. | |

| 15 | An Q, Chen J, Tao Z, et al. Experimental investigation on tool wear characteristics of PVD and CVD coatings during face milling of Ti-6242S and Ti-555 titanium alloys[J]. International Journal of Refractory Metals and Hard Materials, 2020, 86: 105091. |

| 16 | Sun J, Huang S, Ding H, et al. Cutting performance and wear mechanism of Sialon ceramic tools in highspeed face milling GH4099[J]. Ceramics International, 2020, 46(2): 1621-1630. |

| 17 | 黄恒琪, 于娟, 廖晓, 等. 知识图谱研究综述[J]. 计算机系统应用, 2019, 28(6): 1-12. |

| Huang Heng-qi, Yu Juan, Liao Xiao, et al. Review on knowledge graphs[J]. Computer Systems & Applications, 2019, 28(6): 1-12. | |

| 18 | YAGO. [EB/OL]. [2019-10-08]. . |

| 19 | GeoNames.[EB/OL]. [2019-10-08]. . |

| 20 | 中国中医科学院中医药信息研究所. 中医药知识图谱[EB/OL]. [2019-10-08]. . |

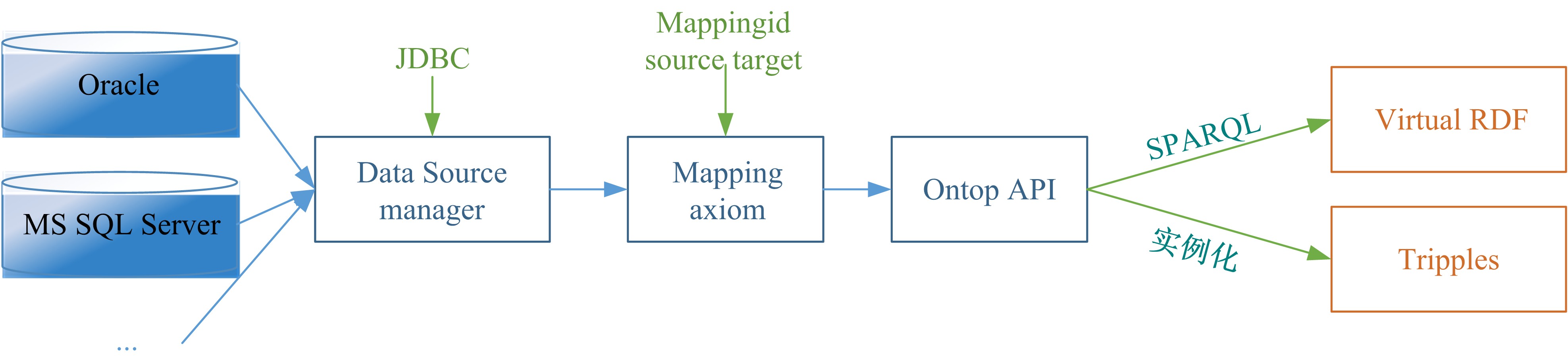

| 21 | Calvanese D, Cogrel B, Komla-Ebri S, et al. Ontop: answering SPARQL queries over relational databases[J]. Semantic Web, 2016, 8(3): 471-487. |

| 22 | Barrasa Jesús.[EB/OL]. [2019-10-08]. . |

| [1] | Dan-tong OUYANG,Cong MA,Jing-pei LEI,Sha-sha FENG. Knowledge graph embedding with adaptive sampling [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 685-691. |

| [2] | Lei CHEN,Jiang⁃feng WANG,Yuan⁃li GU,Xue⁃dong YAN. Multi⁃source traffic data fusion algorithm based onmind evolutionary algorithm optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 705-713. |

| [3] | YANG Zhao-sheng, MO Xiang-lun, YU Yao, ZHANG Biao. Estimation of travel time under abnormal state [J]. 吉林大学学报(工学版), 2013, 43(06): 1459-1464. |

| [4] | YANG Xiao-jun, SONG Qing-song, MA Xiang, LI Dong-hai. Fault-tolerance target tracking based on multi-model information filtering [J]. 吉林大学学报(工学版), 2013, 43(05): 1381-1385. |

| [5] | ZHOU Jing, GAO Yin-han, CHEN Xiao-lin, LIU Chang-ying, LIU Jing. Networked data fusion based on visual measure system with single camera [J]. 吉林大学学报(工学版), 2013, 43(01): 92-97. |

| [6] | YANG Zhao-sheng, GAO Xue-ying, SUN Di, ZHANG Mao-lei. Estimation of travel time based on SCATS /GPS data [J]. 吉林大学学报(工学版), 2011, 41(增刊2): 137-143. |

| [7] | JIAO Zhu-Jing, XIONG Wei-Li, XU Bao-Guo. Dissimilarsensor data fusion based on weighted least square [J]. 吉林大学学报(工学版), 2010, 40(03): 816-0820. |

| [8] | YANG Chi-Fu, ZHENG Chu-Chao, JIANG Hong-Zhou, HAN Dun-Wei. Construction of navigation database for the systems of flight simulator prototype [J]. 吉林大学学报(工学版), 2010, 40(03): 863-0867. |

| [9] |

ZHAO Yi-bing,WANG Rong-ben,LI Lin-hui,Guo Lie .

Obstacle identification based on dempstershafer theory of evidence [J]. 吉林大学学报(工学版), 2008, 38(06): 1295-1299. |

| [10] | Yang Zhao-sheng;Wang Wei;Dong Sheng;Zhu Wei-quan;Shen Jian-hui . nformation fusion technology of GPS/DR integrated positioning system [J]. 吉林大学学报(工学版), 2008, 38(03): 508-0513. |

| [11] | Yang Zhao-sheng,Feng Jin-qiao,Zhang Lin . Kalman filtering based traffic information fusion method [J]. 吉林大学学报(工学版), 2007, 37(05): 1039-1042. |

| [12] |

Feng Zhi-gang, Wang Qi .

Health evaluation of liquid hydrogen providing system based on fuzzy data fusion method [J]. 吉林大学学报(工学版), 2006, 36(05): 751-0756. |

| [13] | ZHOU Jie-min, HAN Jing, XIAO Ji-li . Fusion Algorithm of Target Identification [J]. 吉林大学学报(工学版), 2001, (4): 69-72. |

|

||