Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (2): 772-780.doi: 10.13229/j.cnki.jdxbgxb20191177

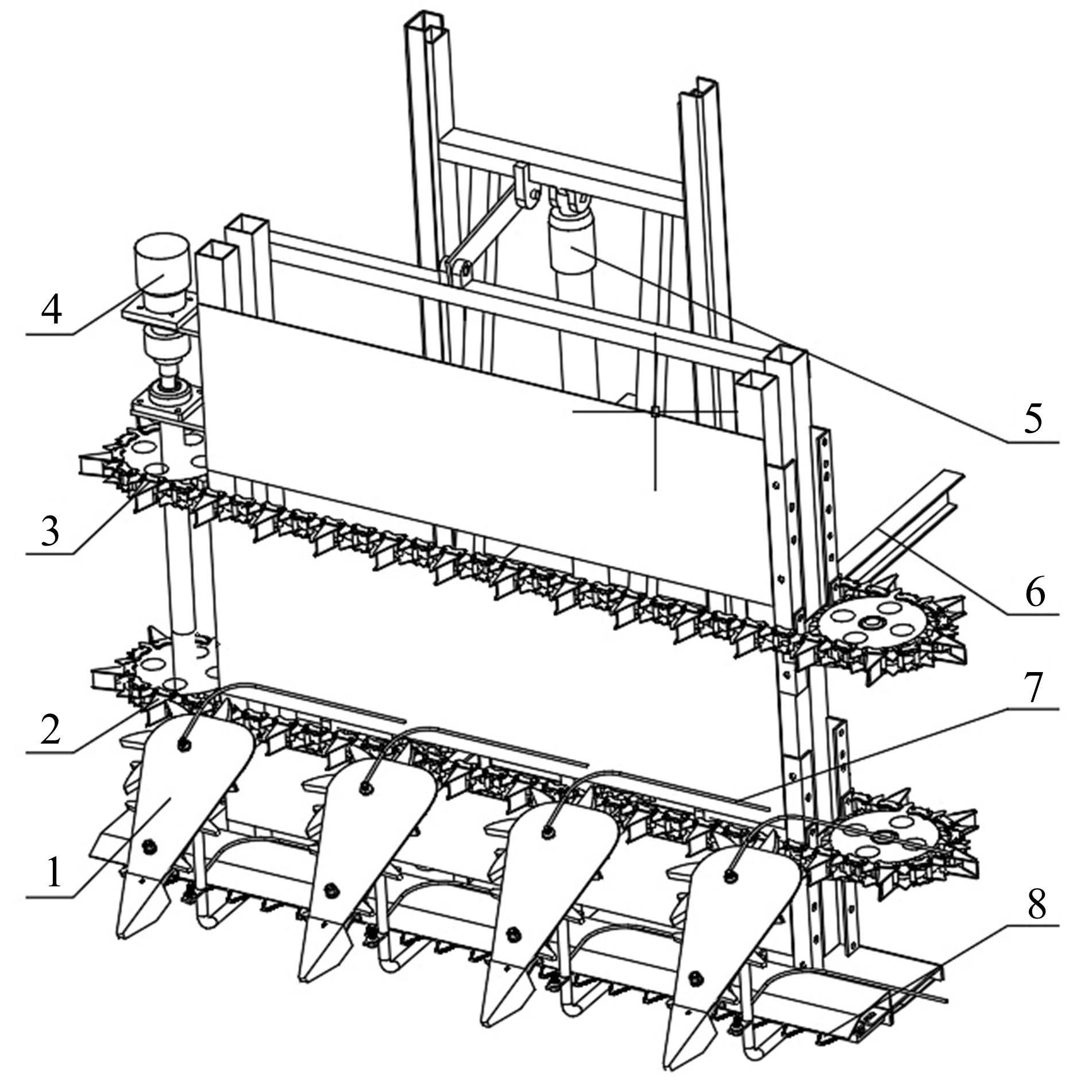

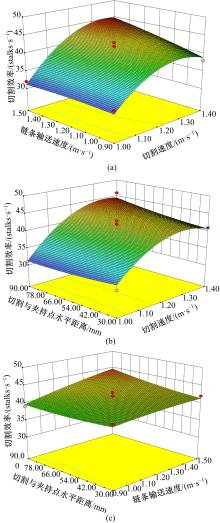

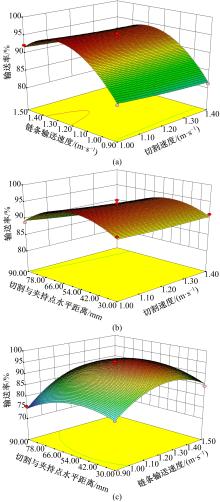

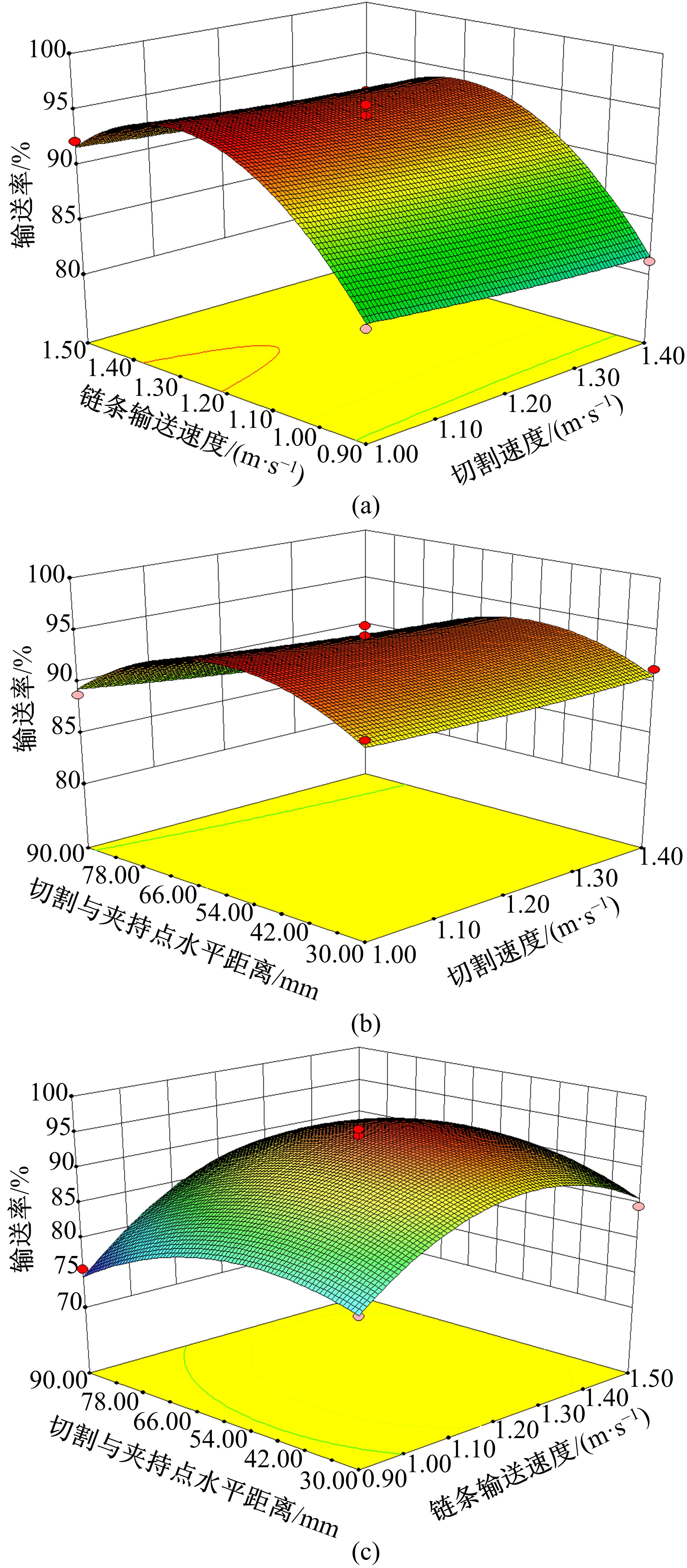

Optimization of cutting⁃conveying key working parameters of hemp harvester

Ji-cheng HUANG1,2( ),Cheng SHEN2,3,Ai-min JI1(

),Cheng SHEN2,3,Ai-min JI1( ),Xian-wang LI2,Bin ZHANG2,3,Kun-peng TIAN2,Hao-lu LIU2

),Xian-wang LI2,Bin ZHANG2,3,Kun-peng TIAN2,Hao-lu LIU2

- 1.College of Mechanical and Electrical Engineering,Hohai University,Changzhou 213022,China

2.Nanjing Research Institute for Agricultural Mechanization,Ministry of Agriculture,Nanjing 210014,China

3.School of Mechanical Engineering,Southeast University,Nanjing 211189,China

CLC Number:

- S225.5

| 1 | 张晓艳, 孙宇峰, 韩承伟, 等. 我国工业大麻产业发展现状及策略分析[J]. 特种经济动植物, 2019, 22(8): 26-28. |

| 2 | 郭丽, 王明泽, 王殿奎, 等. 工业大麻综合利用研究进展与前景展望[J]. 黑龙江农业科学, 2014(8): 132-134. |

| Guo Li, Wang Ming-ze, Wang Dian-kui, et al. Research progress and prospect of comprehensive utilization of industrial hemp[J]. Heilongjiang Agricultural Sciences, 2014(8): 132-134. | |

| 3 | Cassano R, Trombino S, Ferrarelli T, et al. Hemp fiber(cannabis sativa L.)derivatives with antibacterial and chelating properties[J]. Cellulose, 2013, 20(1): 547-557. |

| 4 | Kumar N, Singh T, Grewal J S, et al. Experimental investigation on the physical,mechanical and tribological properties of hemp fiber-based non-asbestos organic brake friction composites[J/OL]. [2019-03-29] 91/ab2399#references |

| 5 | Musio S, Mussig J, Amaducci S. Optimizing hemp fiber production for high performance composite applications[J]. Frontiers in Plant Science, 2018, 9: 1-14. |

| 6 | Malomo S A, Aluko R E. Kinetics of acetylcholinesterase inhibition by hemp seed protein-derived peptides[J/OL]. [2019-03-15] |

| 7 | Rodriguez-Martin N M, Toscano R, Villanueva A, et al. Neuroprotective protein hydrolysates from hemp (cannabis sativa L.) seeds[J]. Food & Function, 2019, 10: 6732-6739. |

| 8 | 唐斌, 李显旺, 袁建宁, 等. 工业大麻微型收获机械的技术与发展分析[J]. 中国农机化学报, 2018, 39(2): 17-21. |

| Tang Bin, Li Xian-wang, Yuan Jian-ning, et al. Analysis of technology and development for hemp micro-harvesting machinery[J]. Journal of Chinese Agricultural Mechanization, 2018, 39(2): 17-21. | |

| 9 | 黄继承, 李显旺, 张彬, 等. 4LMZ160型履带式苎麻联合收割机的研究[J]. 农机化研究, 2015(9): 155-158, 163. |

| Huang Ji-cheng, Li Xian-wang, Zhang Bin, et al. Research on the 4LMZ160 crawler ramie combine harvester[J]. Journal of Agricultural Mechanization Research, 2015(9): 155-158, 163. | |

| 10 | 吕江南, 马兰, 刘佳杰, 等. 黑龙江省工业大麻产业发展及收获加工机械情况调研[J]. 中国麻业科学, 2017, 39(2): 94-102. |

| Lv Jiang-nan, Ma Lan, Liu Jia-jie, et al. The investigation on the development of industrial hemp and its harvesting machinery of Heilongjiang province[J], Plant Fiber Sciences in China, 2017, 39(2): 94-102. | |

| 11 | 朱浩, 张治国, 于革. 汉麻割晒机研制与试验[J]. 农业工程, 2018, 8(2): 95-98. |

| Zhu Hao, Zhang Zhi-guo, Yu Ge. Development and test of hemp swather[J]. Agricultural Engineering, 2018, 8(2): 95-98. | |

| 12 | 熊和平. 2016-2017国家麻类产业技术发展报告[M]. 北京: 中国农业科学技术出版社, 2019. |

| 13 | Zhou Y, Li X W, Shen C, et al. Experimental analysis on mechanical model of industrial hemp stalk[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(9): 22-29. |

| 14 | Shen C, Zhang B, Li X W, et al. Bench cutting tests and analysis for harvesting hemp stalk[J]. International Journal of Agricultural and Biological Engineering, 2017, 10(6): 56-67. |

| 15 | Kakitis A, Berzins U, Berzins R, et al. Cutting properties of hemp fibre[J]. Engineering for Rural Development, 2012, 11: 245-250. |

| 16 | Adamovics A, Kakitis A. Productivity and tensile endurance determination of hemp fiber[J]. Chemical Engineering Transactions, 2013, 35: 805-810. |

| 17 | 马兰, 刘佳杰, 周韦, 等. 工业大麻干茎秆轴向压缩力学特性试验研究[J]. 中国农机化学报, 2018, 39(11): 34-40, 50. |

| Ma Lan, Liu Jia-jie, Zhou Wei, et al. Test of axial mechanical compressive properties for industial hemp dry stalk[J]. Journal of Chinese Agricultural Mechanization, 2018, 39(11): 34-40, 50. | |

| 18 | Huang J C, Shen C, Li X W, et al. Design and tests of hemp harvester[J]. International Agricultural Engineering Journal, 2017, 26(2): 117-127. |

| 19 | Pari L, Alfano V, Scarfone A. An innovative harvesting system for multipurpose hemp[C]∥24th International European Biomass Conference on Setting the Course for a Biobased Economy. Florence: Amsterdam, 2016: 356-358. |

| 20 | Kaniewski R, Mankowski J, Rynduch W, et al. Modemized hemp mower[C]∥Natural Fiber Wokna Naturalne. Flax and Other Bast Plants Symposium, Poznon, Poland, 1997: 25-27. |

| 21 | Chen Y, Liu J, Gratton J L. Engineering perspectives of the hemp plant, harvesting and processing[J]. Journal of Industrial Hemp, 2004, 9(2): 23-39. |

| 22 | 周杨. 工业大麻圆盘切割装置的设计与试验研究[D]. 北京: 中国农业科学院研究生院, 2017. |

| Zhou Yang. Design and expeirmental research of hemp disc cutter[D]. Beijing: Graduate School, Chinese Academy of Agricultural Sciences, 2017. | |

| 23 | 王法昌, 周学建, 师清翔, 等. 新型玉米收获机横向输送装置的参数研究[J]. 农机化研究, 2010, 32(5): 152-155. |

| Wang Fa-chang, Zhou Xue-jian, Shi Qing-xiang, et al. Parameters study on transverse transport of new corn combine[J]. Journal of Agricultural Mechanization Research, 2010, 32(5): 152-155. | |

| 24 | 张宗玲, 韩增德, 李树君, 等. 玉米穗茎兼收收割台切割夹持输送装置仿真与试验[J]. 农业机械学报, 2016, 47(): 215-221. |

| Zhang Zong-ling, Han Zeng-de, Li Shu-jun, et al. Simulation and test on straw cutting and clamping device of corn combine harvester for stalk and ears[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(Sup.1): 215-221. | |

| 25 | 徐向宏, 何明珠. 试验设计与Design-Expert SPSS应用[M]. 北京: 科学出版社责任有限公司, 2016. |

| 26 | 王利民, 肖志刚, 刘宇欣, 等. 响应面法优化板栗基营养米挤压加工参数[J]. 吉林大学学报: 工学版, 2013, 43(2): 550-556. |

| Wang Li-min, Xiao Zhi-gang, Liu Yu-xin, et al. Optimization of extrusion process parameters of nutritious rice rich in chestnut by response surface method[J]. Journal of Jilin University (Engineering and Technology Edition), 2013, 43(2): 550-556. | |

| 27 | 王建楠, 刘敏基, 曹明珠, 等. 薏苡脱壳机关键部件作业参数优化与试验[J]. 农业工程学报, 2018, 34(13): 288-295. |

| Wang Jian-nan, Liu Min-ji, Cao Ming-zhu, et al. Working parameter optimization and experiment of key components of coix lacryma-jobi sheller[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(13): 288-295. | |

| 28 | 薛钊, 付君, 陈志, 等. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报: 工学版, 2020, 50(2): 739-748. |

| Xue Zhao, Fu Jun, Chen Zhi, et al. Optimization experiment on parameters of chopping device of forage maize harvester[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(2): 739-748. | |

| 29 | 陈魁. 试验设计与分析[M]. 北京: 清华大学出版社, 2005. |

| 30 | 杨德. 试验设计与分析[M]. 北京: 中国农业出版社, 2002. |

| [1] | Bing-hai ZHOU,Qiong WU. Balancing and bi⁃objective optimization of robotic assemble lines [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 720-727. |

| [2] | Chao CHENG,Jun FU,Zhi CHEN,Lu-quan REN. Sieve blocking laws and stripping test of corn grain harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 761-771. |

| [3] | Fang-wu MA,Li HAN,Liang WU,Jin-hang LI,Long-fan YANG. Damping optimization of heavy⁃loaded anti⁃vibration platform based on genetic algorithm and particle swarm algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1608-1616. |

| [4] | Xue-shen CHEN,Tao CHEN,Tao WU,Xu MA,Ling-chao ZENG,Lin-tao CHEN. Design and experiment on harvester for winter planting potato of straw coverage [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 749-757. |

| [5] | Yin-ping LI,Tian-xu JIN,Li LIU. Design and dynamic characteristic simulation of pantograph⁃catenary continuous energy system for pure electric LHD [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 454-463. |

| [6] | Zhao XUE,Jun FU,Zhi CHEN,Feng-de WANG,Shao-ping HAN,Lu-quan REN. Optimization experiment on parameters of chopping device of forage maize harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 739-748. |

| [7] | Fang-wu MA,Hong-yu LIANG,Ying ZHAO,Meng YANG,Yong-feng PU. Multi⁃objective crashworthiness optimization design of concave triangles cell structure with negative Poisson′s ratio [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 29-35. |

| [8] | Zhong-yi CAI,Fan-xiang MENG,Qing-min CHEN,Xuan ZHAO. Preform optimization for near-net-shape forming process of complex knuckle forging [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 84-90. |

| [9] | Fu-chun JIA,Xian-jie MENG,Yu-long LEI. Optimal design of two degrees of freedom dynamic vibration absorber based on multi-objective genetic algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1969-1976. |

| [10] | Fang-wu MA,Lu HAN,Yang ZHOU,Shi-ying WANG,Yong-feng PU. Multi material optimal design of vehicle product using polylactic acid composites [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1385-1391. |

| [11] | QIU Xiao-ming, WANG Yin-xue, YAO Han-wei, FANG Xue-qing, XING Fei. Multi-objective optimization of resistance spot welding parameters for DP1180/DP590 using grey relational analysis based Taguchi [J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [12] | SUN Xiao-ying, WANG Zhen, YANG Jin-peng, HU Ze-zheng, CHEN Jian. Electromagnetic susceptibility assessment of electronic throttle based on Bayesian network [J]. 吉林大学学报(工学版), 2018, 48(1): 281-289. |

| [13] | WANG Deng-feng, ZHANG Shuai, WANG Yong, CHEN Hui. Optimization design of assembled wheel based on performance of fatigue and 13° impact [J]. 吉林大学学报(工学版), 2018, 48(1): 44-56. |

| [14] | YU Fan-hua, LIU Ren-yun, ZHANG Yi-min, ZHANG Xiao-li, SUN Qiu-cheng. Swarm intelligence algorithm of dynamic reliability-based robust optimization design of mechanic components [J]. 吉林大学学报(工学版), 2017, 47(6): 1903-1908. |

| [15] | ZHOU Fang, SONG Chuan-xue, LIANG Tian-wei, XIAO Feng. Parameter matching of on-board hybrid energy storage system using NSGA-II algorithm [J]. 吉林大学学报(工学版), 2017, 47(5): 1336-1343. |

|

||