Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (6): 1969-1976.doi: 10.13229/j.cnki.jdxbgxb20180924

Previous Articles Next Articles

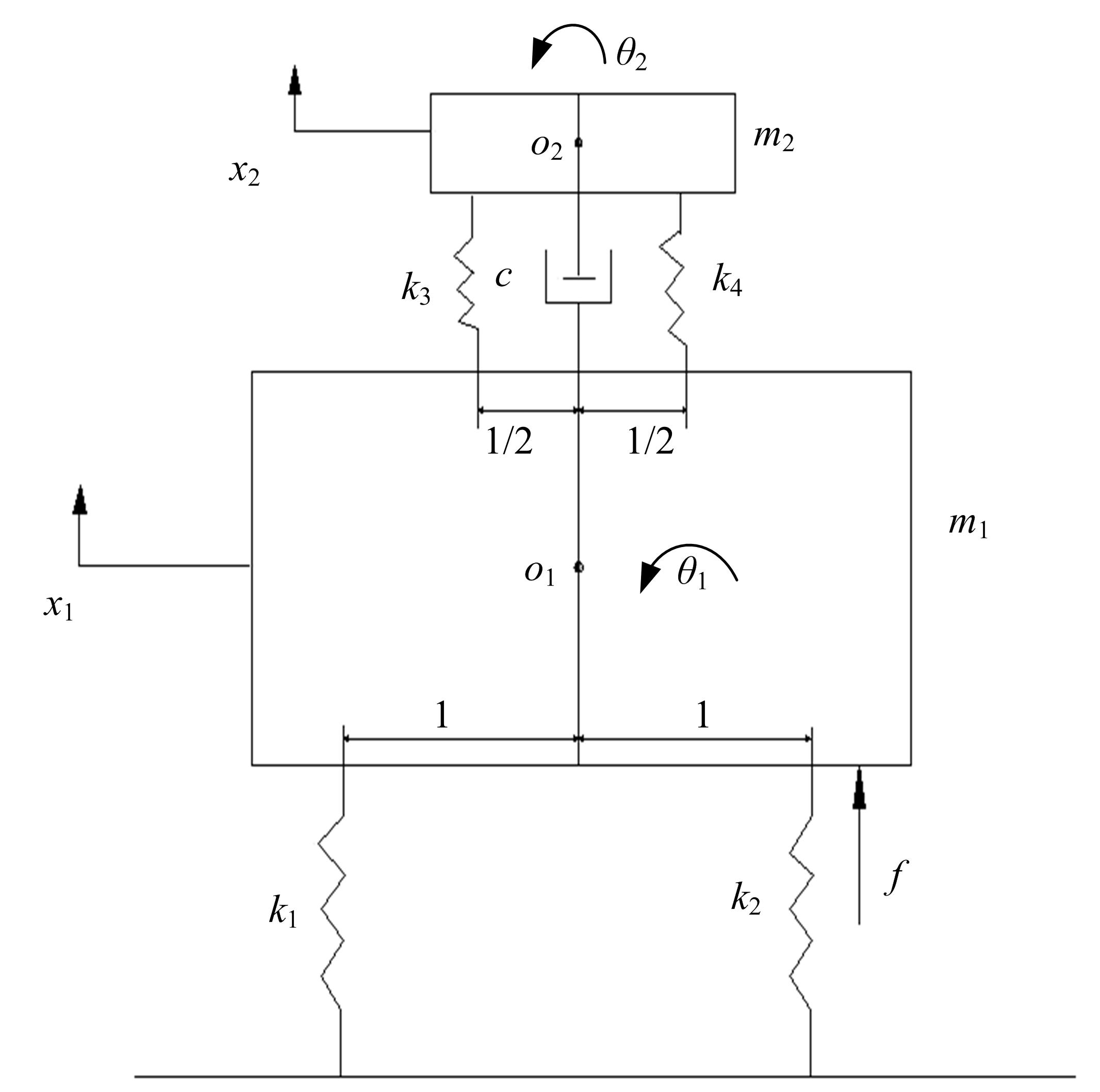

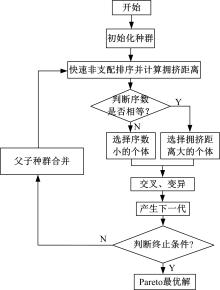

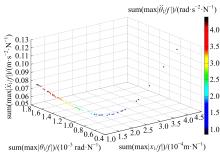

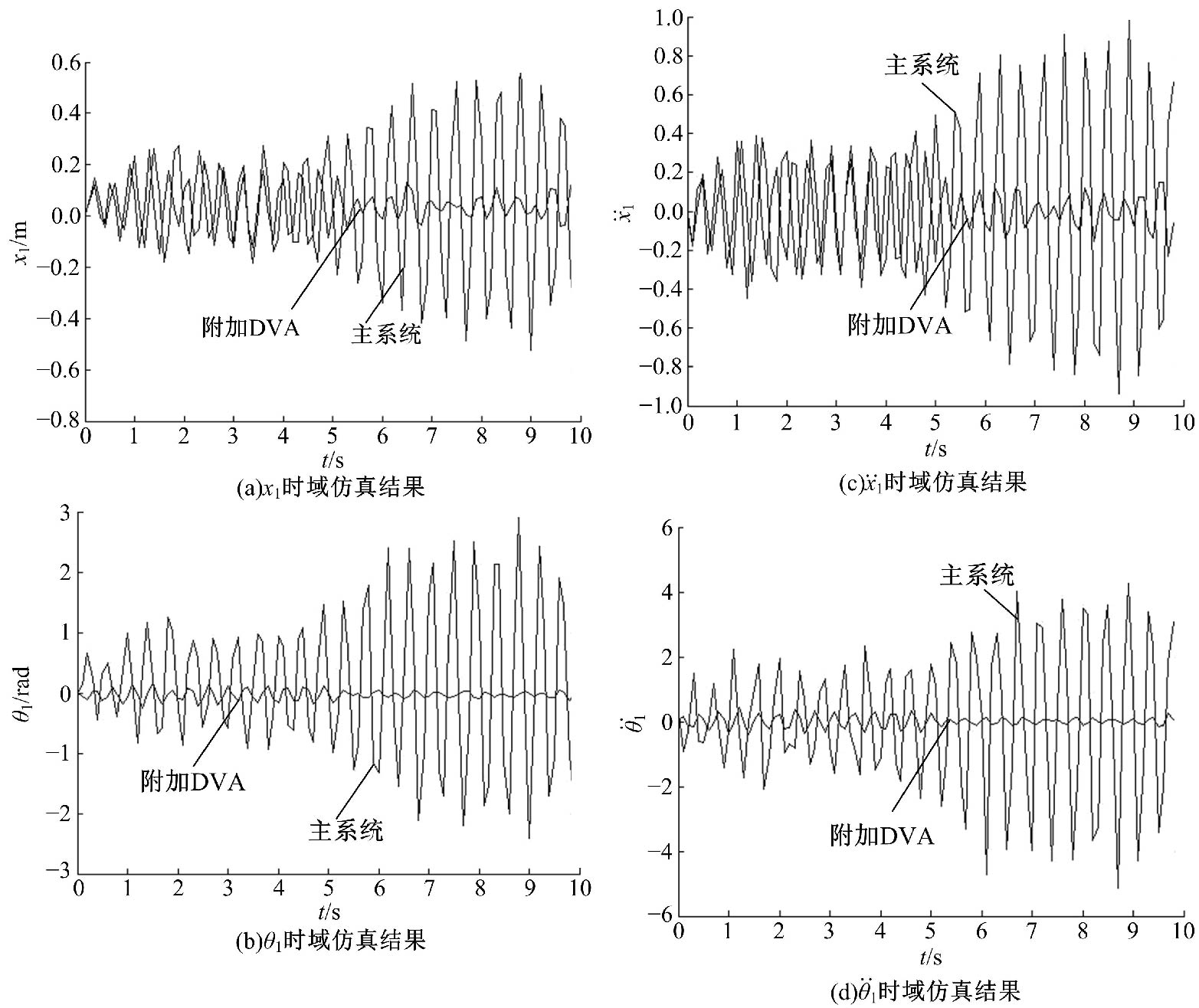

Optimal design of two degrees of freedom dynamic vibration absorber based on multi-objective genetic algorithm

Fu-chun JIA1( ),Xian-jie MENG2,Yu-long LEI1(

),Xian-jie MENG2,Yu-long LEI1( )

)

- 1. State Key Laboratory of Automotive Simulation and Control, Jinlin University, Changchun 130022, China

2. School of Transportation and Vehicle Engineering, Shandong University of Technology, Zibo 255000, China

CLC Number:

- TH113.1

|

| [1] | Zhi-jiang XIE,Kun WANG,Yang-jun PI,Xiao-yong WU,Ying-wei GUO. Novel method for forward kinematics of 6⁃PSSparallel manipulator [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1977-1985. |

| [2] | Chang-you MA, Hai-bo GAO, Liang DING, Hai-tao YU, Hong-jun XING, Zong-quan DENG. Mechanism design and docking strategy forend⁃effectors exchange of robot [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 2027-2037. |

| [3] | Fang-wu MA,Lu HAN,Yang ZHOU,Shi-ying WANG,Yong-feng PU. Multi material optimal design of vehicle product using polylactic acid composites [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1385-1391. |

| [4] | En-guo CAO,Kun LIU,Shuo JI,Zhen-yuan SUN,Hong-wei XU,Xing-ji LUO. Mechanical structure design and optimization of weight-support STS rehabilitation training system [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1558-1566. |

| [5] | Jun-ye LI,Yang LIU,Hui LU,Wen-qing MENG,Zhao-jun YANG,Xin-ming ZHANG. Numerical analysis of single crystal Fe with abrasive grain micro-cutting based on molecular dynamics [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1567-1574. |

| [6] | Hong⁃zhi WANG,Fang⁃da JIANG,Ming⁃yue ZHOU. Power allocation of cognitive radio system based on genetic particle swarm optimization [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1363-1368. |

| [7] | Cheng YANG,Yong⁃sheng ZHAO,Zhi⁃feng LIU,Li⁃gang CAI. Stiffness model of bolted joint based on multi⁃scale theory [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1212-1220. |

| [8] | Kun LIU,Shuo JI,Zhen⁃yuan SUN,Hong⁃wei XU,Yong LIU,Jing⁃xia ZHAO. Mechanical structure design and optimization of multifunctional auxiliary toilet wheelchair [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 872-880. |

| [9] | Xing⁃ye WANG,Jin⁃qiu ZHANG,Guo⁃qiang LI,Zhi⁃zhao PENG. Influence of inertial mass on rack and pinion actuator′s damping characteristic [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 881-887. |

| [10] | Jia⁃xu WANG,Xiao⁃kang NI,Yan⁃feng HAN,Guo XIANG,Ke XIAO. Numerical model of mixed lubrication for microgroove bearing considering axial reciprocating motion [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 888-896. |

| [11] | BI Qiu-shi,WANG Guo-qiang,HUANG Ting-ting,MAO Rui,LU Yan-peng. Tooth strength analysis of mineral sizer by coupling discrete element method and finite element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1770-1776. |

| [12] | ZHU Wei,WANG Chuan-wei,GU Kai-rong,SHEN Hui-ping,XU Ke,WANG Yuan. Stiffness and dynamics analysis of a new type of tensegrity parallel mechanism [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1777-1786. |

| [13] | WU Wei-nan,CUI Nai-gang,GUO Ji-feng,ZHAO Yang-yang. Distributed integrated method for mission planning of heterogeneous unmanned aerial vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1827-1837. |

| [14] | JIAO Yu-ling, ZHANG Peng, TIAN Guang-dong, XING Xiao-cui, ZOU Lian-hui. Slotting optimization of automated warehouse based on multi-population GA [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1398-1404. |

| [15] | LIU Jian-fang, WANG Ji-bo, LIU Guo-jun, LI Xin-bo, LIANG Shi-hai, YANG Zhi-gang. PMMA micromixer embedded with 3D channel based on piezoelectric actuation [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1500-1507. |

|