Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (3): 820-830.doi: 10.13229/j.cnki.jdxbgxb20200130

Previous Articles Next Articles

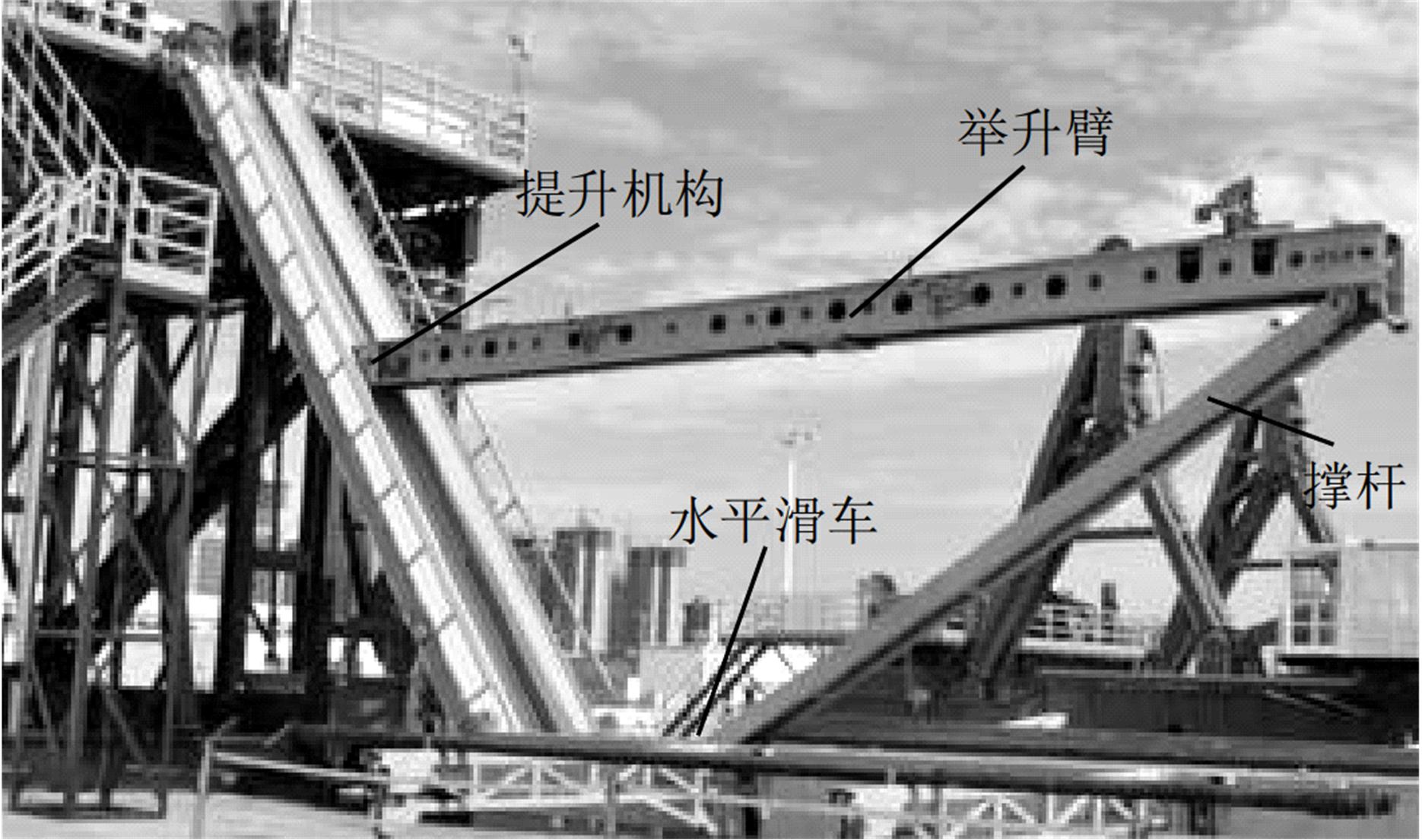

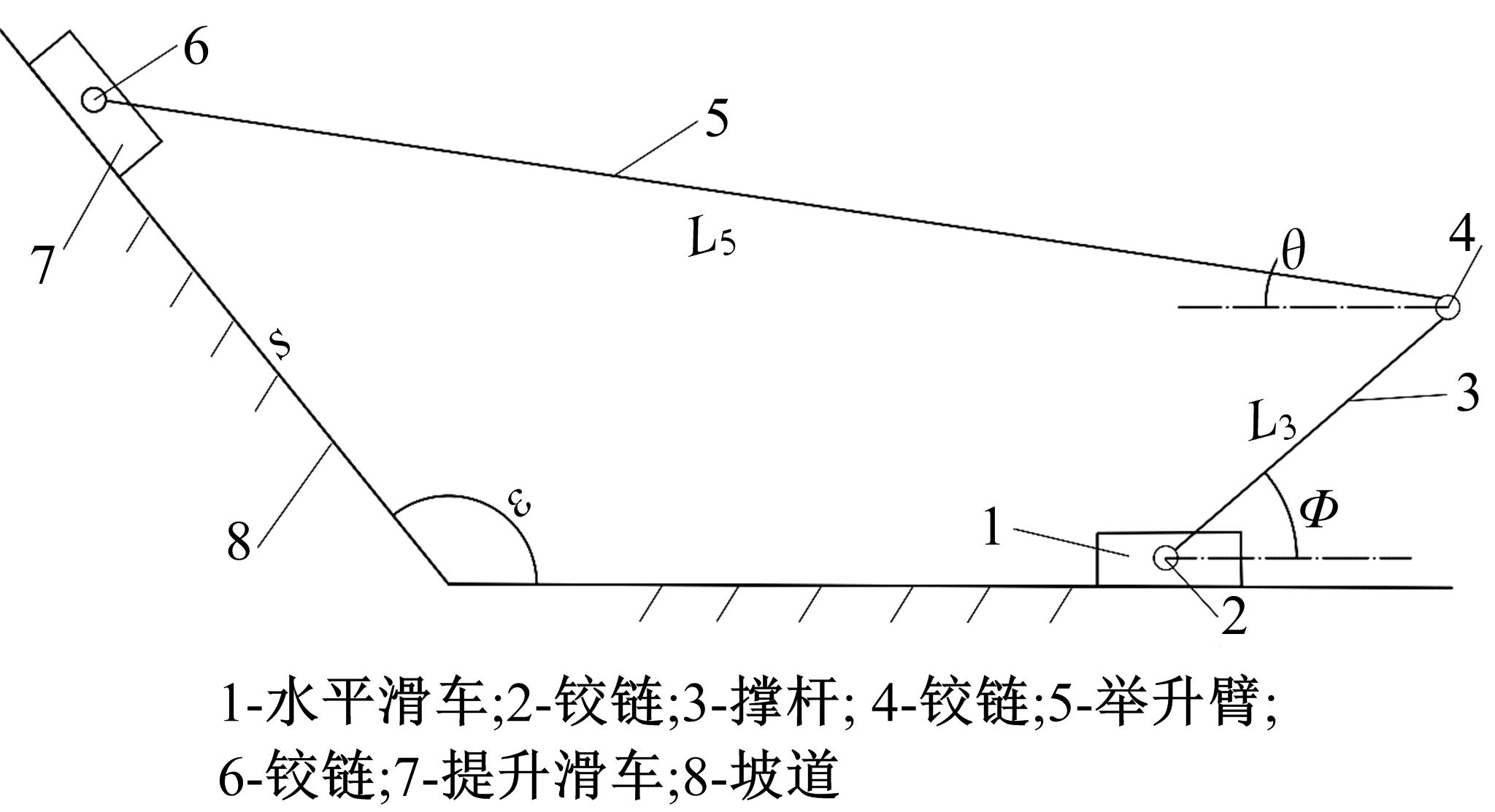

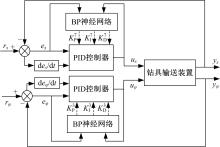

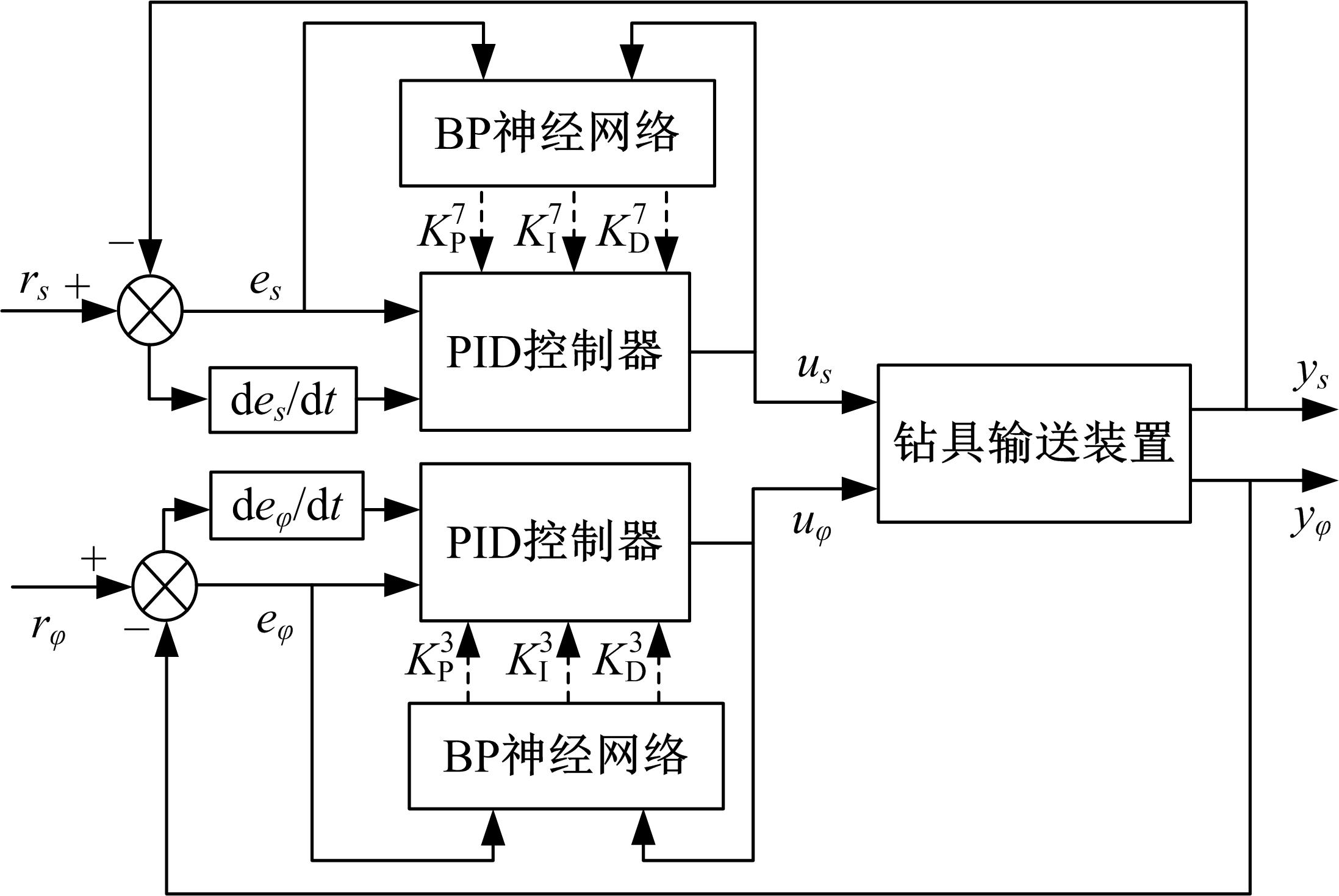

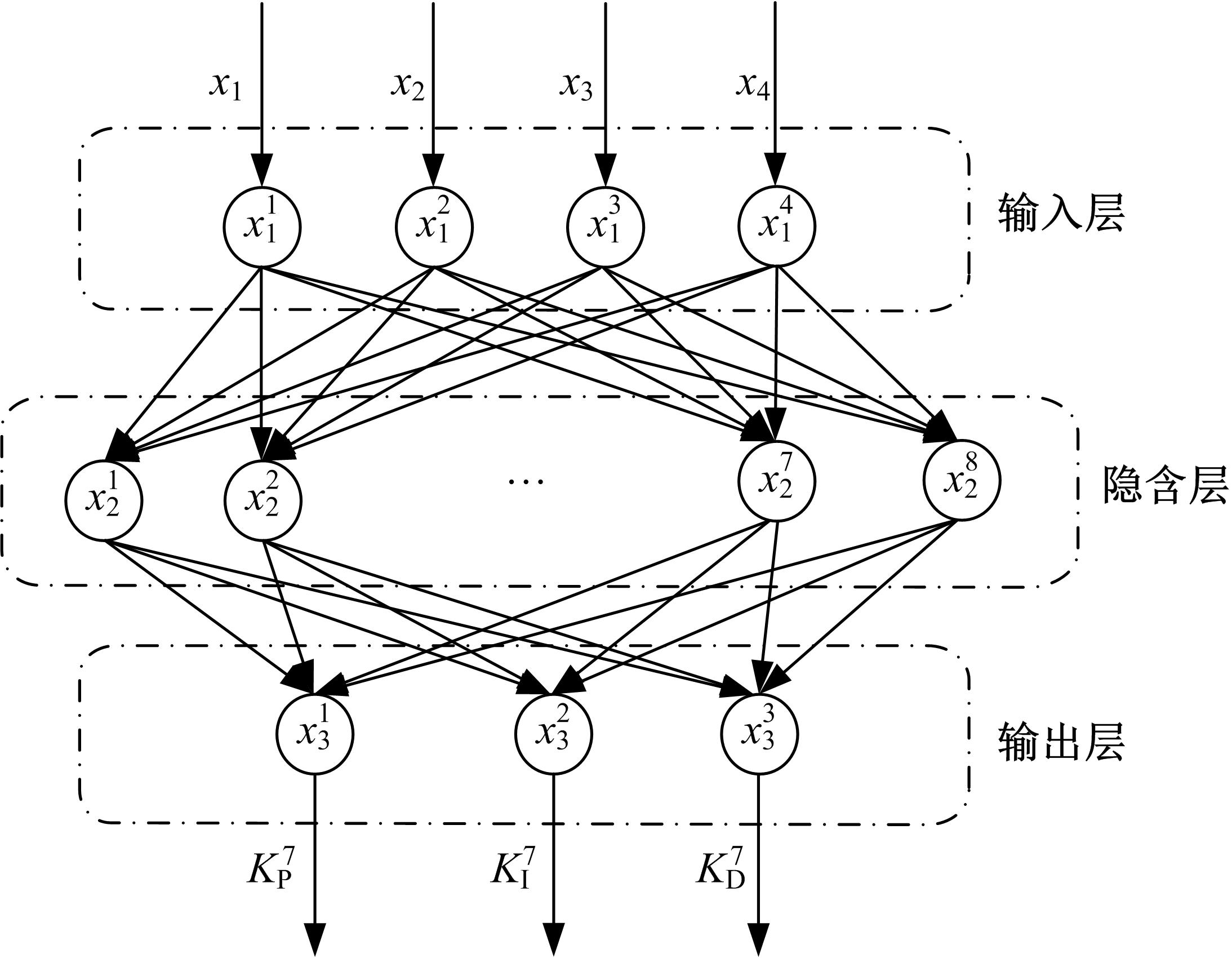

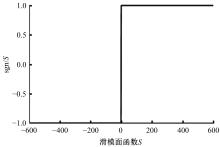

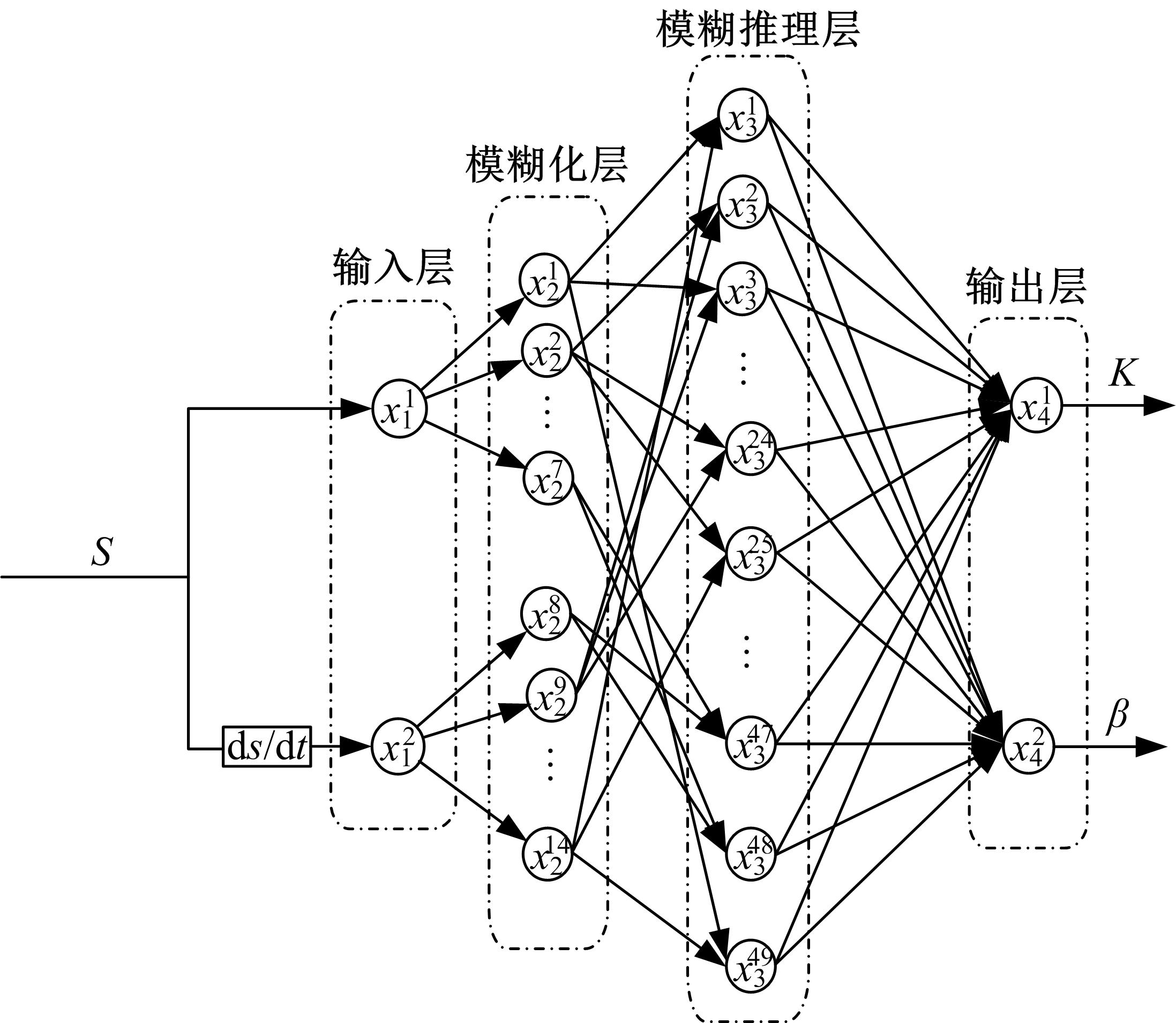

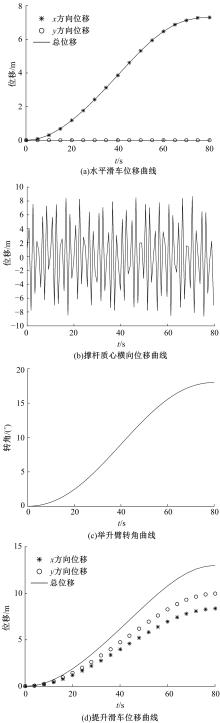

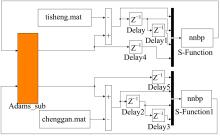

Nonlinear dynamic analysis and stability control of drilling tool conveying mechanism

Ping YU( ),Te MU,Li-hui ZHU,Zi-ye ZHOU,Jie SONG

),Te MU,Li-hui ZHU,Zi-ye ZHOU,Jie SONG

- College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

CLC Number:

- TE928

| 1 | Sun Y H, Zhang F Y, Wang Q Y, et al. Application of "Crust 1" 10k ultra-deep scientific drilling rig in Songliao Basin Drilling Project (CCSD-SKII)[J]. Journal of Petroleum Science and Engineering,2016,145: 222-229. |

| 2 | 柴汇,荣学文,唐兴鹏,等. 基于能量规划的崎岖地面四足机器人平面跳跃控制[J]. 吉林大学学报:工学版,2017,47(2):557-566. |

| Chai Hui,Rong Xue-wen,Tang Xing-peng.Telescoping path optimization of a single-cylinder pin-type multi-section boom based on Hopfield neural network[J]. Journal of Jilin University(Engineering and Technology Edition),2017,47(2):557-566. | |

| 3 | Wang F, Chao Z Q, Huang L B, et al. Trajectory tracking control of robot manipulator based on RBF neural network and fuzzy sliding mode[J]. Cluster Computing, 2019,22:5799-5809. |

| 4 | Cao F F, Liu J K. Optimal trajectory control for a two-link rigid-flexible manipulator with ODE-PDE model[J]. Optimal Control Applications and Methods, 2018, 39(4): 1515-1529. |

| 5 | 朱伟,王传伟,顾开荣,等. 一种新型张拉整体并联机构刚度及动力学分析[J]. 吉林大学学报:工学版,2018,48(6):1777-1786. |

| Zhu Wei,Wang Chuan-wei,Gu Kai-rong. Stiffness and dynamics analysis of a new type of tensegrity parallel mechanism[J]. Journal of Jilin University(Engineering and Technology Edition),2018,48(6):1777-1786. | |

| 6 | Chiang C J, Chen Y C. Neural network fuzzy sliding mode control of pneumatic muscle actuators[J]. Engineering Applications of Artificial Intelligence, 2017, 65: 68-86. |

| 7 | 毛艳,成凯. 基于Hopfield神经网络的单缸插销式伸缩臂伸缩路径优化[J].吉林大学学报:工学版,2020,50(1):53-65. |

| Mao Yan,Cheng Kai. Telescoping path optimization of a single-cylinder pin-type multi-section boom based on Hopfield neural network[J]. Journal of Jilin University(Engineering and Technology Edition), 2020,50(1):53-65. | |

| 8 | Qiu Zhi-cheng, Wang Xian-feng, Zhang Xian-min, et al. A novel vibration measurement and active control method for a hinged flexible two-connected piezoelectric plate[J]. Mechanical Systems and Signal Processing, 2018,107:357-395. |

| 9 | 王杰,钱利勤,陈新龙,等. 自动猫道起升系统动力学模型与分析[J]. 工程设计学报, 2016,23(5):437-443, 460. |

| Wang Jie,Qian Li-qin,Chen Xin-long, et al. Dynamics model and analysis of the lifting system of automatic catwalk[J]. Journal of Engineering Design,2016,23(5):437-443, 460. | |

| 10 | 于萍,宋杰,赵楠. 自动猫道翻转机构失效研究[J]. 机械设计与制造,2019(10):257-261. |

| Yu Ping,Song Jie,Zhao Nan. Failure analysis of turnover mechanism in automatic catwalk[J]. Machinery Design & Manufacture,2019(10):257-261. | |

| 11 | Pawlus W, Choux M, Hansen M R, et al. Load torque estimation method to design electric drivetrains for offshore pipe handling equipment[J]. Journal of Offshore Mechanics and Arctic Engineering, 2016, 138(4):041304. |

| 12 | 黄悦华,赵亮亮,李峰,等. 基于ADAMS的动力猫道扶持臂变幅机构优化设计[J]. 石油矿场机械,2016,44(7):36-38. |

| Huang Yue-hua,Zhao Liang-liang,Li Feng. Optimization design of the amplitude variation mechanism of supportive arm of power catwalk based on ADAMS[J]. Oil Field Equipment, 2016,44(7):36-38. | |

| 13 | 康思杰. 基于刚柔耦合模型的钻具自动输送装置动态特性研究[D]. 长春: 吉林大学机械与航空航天工程学院,2017. |

| Kang Si-jie. Study on the dynamic characteristics of drilling tool automatic conveying mechanism based on rigid-flexible coupling model[D]. Changchun:College of Mechanical and Aerospace Engineering, Jilin University, 2017. | |

| 14 | Rong Bao, Rui Xiao-ting, Wang Guo-ping, et al. Erratum: new efficient method for dynamic modeling and simulation of flexible multibody systems moving in plane[J]. Multibody System Dynamics, 2010, 24(2):201-202. |

| 15 | Rong Bao, Rui Xiao-ting, Tao Ling. Dynamics and genetic fuzzy neural network vibration control design of a smart flexible four-bar linkage mechanism[J]. Multibody System Dynamics, 2012, 38(4):291-311. |

| [1] | Qiang SONG,Dan-ting SUN,Wei ZHANG. Shift nonlinear modeling and control of automated mechanical transmission in pure electric vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 810-819. |

| [2] | Guo-ying CHEN,Jun YAO,Peng WANG,Qi-kun XIA. Stability control strategy for rear in⁃wheel motor drive vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 397-405. |

| [3] | Ming-wei HU,Hong-guang WANG,Xin-an PAN. Global structural optimization design of collaborative robots using orthogonal design [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 370-378. |

| [4] | ZHAO Wei-qiang, GAO Ke, WANG Wen-bin. Prevention of instability control of commercial vehicle based on electric-hydraulic coupling steering system [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1305-1312. |

| [5] | WANG De-jun, WEI Wei-li, BAO Ya-xin. Actuator fault diagnosis of ESC system considering crosswind interference [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1548-1555. |

| [6] | LI Ling, SHI Shu-ming, WANG Xian-bin, YU Zhuang. Stability of high-speed and turning vehicle influenced by engine braking [J]. 吉林大学学报(工学版), 2017, 47(1): 64-70. |

| [7] | JIN Li-qiang, LIU Gang, CHEN Peng-fei. Hierarchical control for vehicle electronic stability control system [J]. 吉林大学学报(工学版), 2016, 46(6): 1765-1771. |

| [8] | GAO Lin-lin, JIN Li-sheng, ZHENG Yi, LI Ke-yong. Design of radial basis function neural network compound controller for four wheel steering vehicle [J]. 吉林大学学报(工学版), 2016, 46(2): 366-372. |

| [9] | HE Lei, MA Bo-xiang, ZHENG Hong-yu, WANG Xiang. Stability control of steering-by-wire vehicle based on passive theory [J]. 吉林大学学报(工学版), 2015, 45(6): 1737-1742. |

| [10] | WU Dong-mei, DING Hai-tao, GUO Kong-hui. Sideslip angle estimation based on linear estimation model for electric vehicle [J]. 吉林大学学报(工学版), 2014, 44(4): 901-906. |

| [11] | LI Jing, YU Chun-xian, LU Hui, GAO Yue-lei. Vehicle stability control based on model prediction [J]. 吉林大学学报(工学版), 2013, 43(增刊1): 504-508. |

| [12] | LIU Wei, DING Hai-tao, GUO Kong-hui. Open-loop pressure estimation for hydraulic control unit of vehicle electronic stability control system [J]. , 2012, 42(05): 1095-1099. |

| [13] | TIAN Cheng-Wei, ZONG Chang-Fu, HE Lei, YU Zhi-Xin, WANG Xiang. Control strategy of 4W steerbywire system [J]. 吉林大学学报(工学版), 2010, 40(05): 1177-1182. |

| [14] | DING Hai-tao,GUO Kong-hui,CHEN Hong. LQR method for vehicle yaw moment decision in vehicle stability control [J]. 吉林大学学报(工学版), 2010, 40(03): 597-0601. |

| [15] | MAI Li,ZHANG Ji-hong,ZONG Chang-fu,ZHENG Hong-yu,GUO Li-shu. Vehicle stability control based on electronic hydraulic brake system [J]. 吉林大学学报(工学版), 2010, 40(03): 607-0613. |

|

||