Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (1): 53-62.doi: 10.13229/j.cnki.jdxbgxb20200751

Previous Articles Next Articles

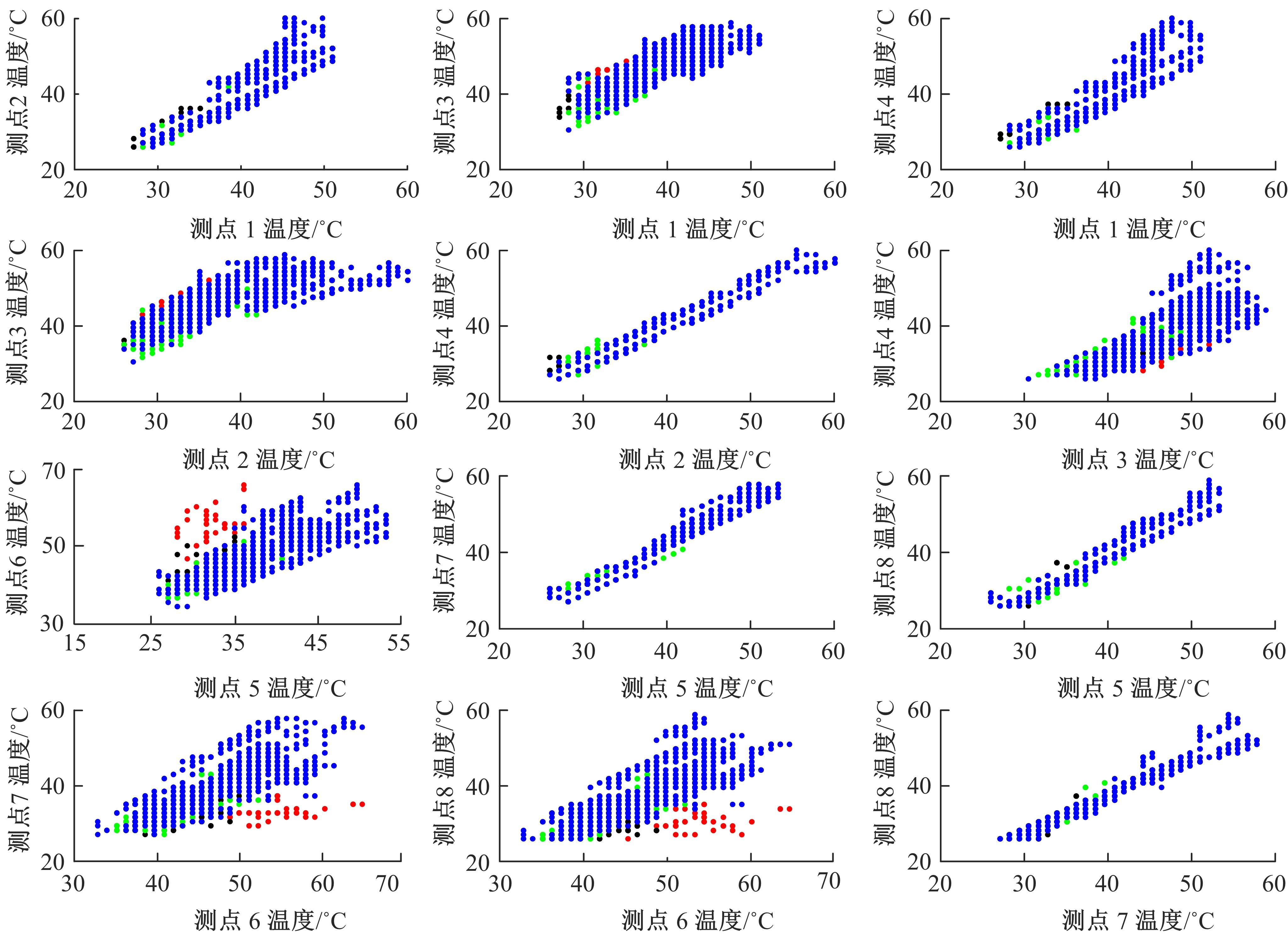

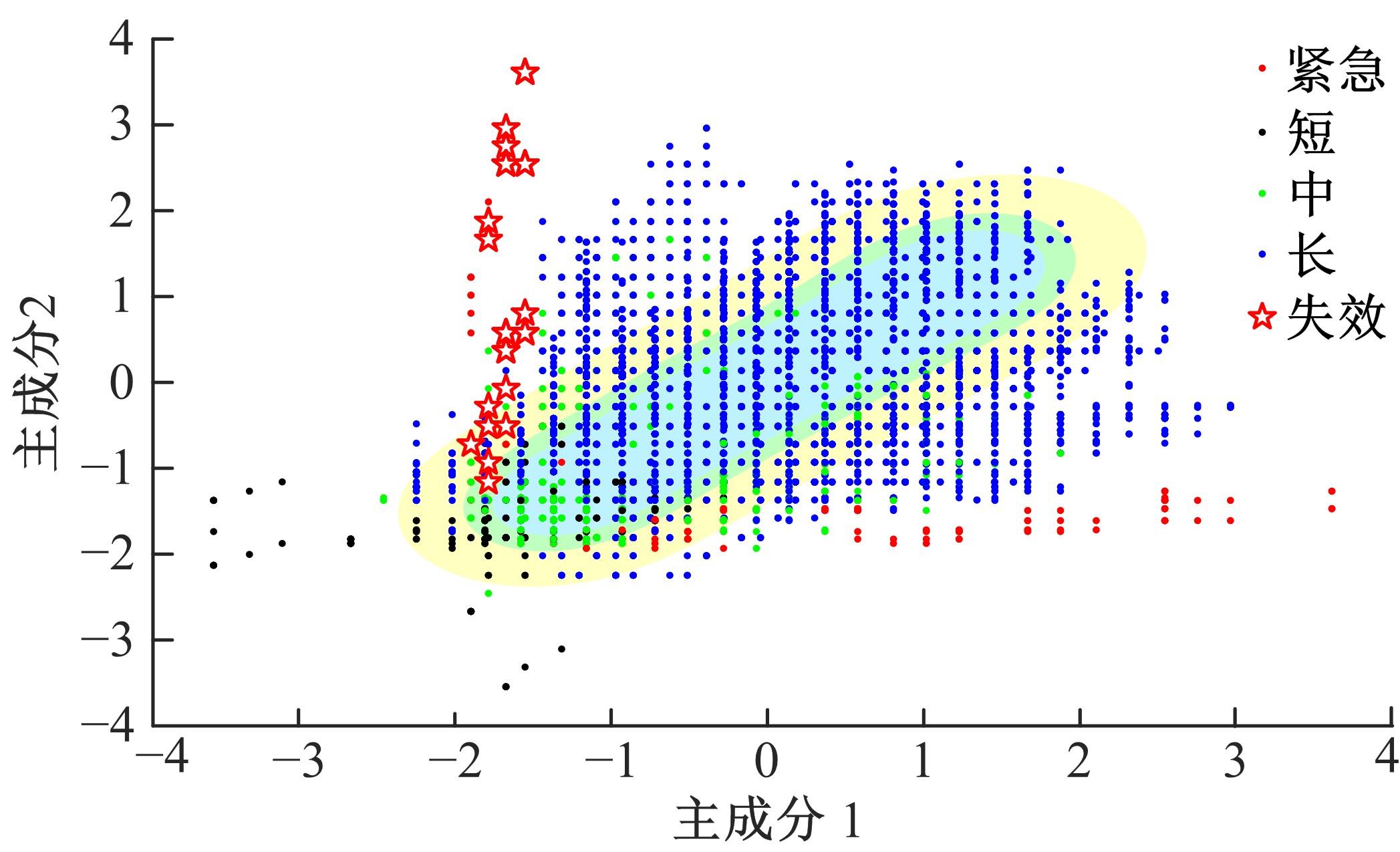

State recognition in bearing temperature of high-speed train based on machine learning algorithms

Liang DUAN( ),Chun-yuan SONG,Chao LIU,Wei WEI,Cheng-ji LYU

),Chun-yuan SONG,Chao LIU,Wei WEI,Cheng-ji LYU

- National Railway Vehicle Engineering R&D Center,CRRC Changchun Railway Vehicles Co. ,Ltd. ,Changchun 130002,China

CLC Number:

- U271

| 1 | Olver A V. The mechanism of rolling contact fatigue: an update[J]. Journal of Engineering Tribology, 2005, 219(5):313-330. |

| 2 | Sadeghi F, Jalalahmadi B, Slack T S, et al. A review of rolling contact fatigue[J]. Journal of Tribology, 2009,131 (4):1-15. |

| 3 | Harvey T J, Wood R J, Powrie H E. Electrostatic wear monitoring of rolling element bearings[J]. Wear, 2007, 263(7-12):1492-1501. |

| 4 | Tarawneh C M, Sotelo L. Temperature profilesof railroad tapered roller bearings with defective inner and outer rings[C]∥Proceedings of the ASME Joint Rail Conference, Columbia, USA,2015:12-15. |

| 5 | Kim W, Seo J, Hong D. Infrared thermographic inspection of ball bearing; condition monitoring for defects under dynamic loading stages[C]∥The 18th World Conference on Nondestructive Testing, Durban, South Africa, 2012:16-20. |

| 6 | Kim D, Yun H, Yang S, et al. Fault diagnosis of ball bearings within rotational machines using the infrared thermography method[J]. Journal of the Korean Society for Nondestructive Testing, 2010, 30(6):558-563. |

| 7 | Sciascera C, Giangrande P, Papini L, et al. Analytical thermal model for fast stator winding temperature prediction[J]. IEEE Transactions on Industrial Electronics, 2017, 64(8): 6116-6126. |

| 8 | Madonna V, Walker A, Giangrande P, et al. Improved thermal management and analysis for stator end-windings of electrical machines[J]. IEEE Transactions on Industrial Electronics, 2019, 66(7): 5057-5069. |

| 9 | Pouly F, Changenet C, Ville F, et al. Investigations on the power losses and thermal behavior of rolling element bearings[J]. Journal of Engineering Tribology, 2010, 224(9): 925-933. |

| 10 | Neurouth A, Changenet C, Ville F, et al. Thermal modeling of a grease lubricated thrust ball bearing[J]. Journal of Engineering Tribology, 2014, 228(11): 1266-1275. |

| 11 | 丁洪福, 王风涛, 景敏卿,等. 高速球轴承热稳定性研究[J]. 振动与冲击, 2017, 36(14):168-173. |

| Ding Hong-fu, Wang Feng-tao, Jing Min-qing, et al. The thermal stability of high-speed ball bearings[J]. Journal of Vibration and Shock, 2017, 36(14):168-173. | |

| 12 | 胡腾, 殷国富, 邓聪颍. 角接触球轴承热力学耦合模型与分析方法[J]. 四川大学学报:工程科学版, 2014, 46(4):189-198. |

| Hu Teng, Yin Guo-fu, Deng Cong-ying. Integrated thermo-mechanical model and analysis of angular contact ball bearing[J]. Advanced Engineering Sciences, 2014, 46(4):189-198. | |

| 13 | 何兴平, 耿远松, 郭志伟,等. 基于差分自回归移动平均模型的电气设备温度预测[J]. 自动化与仪器仪表, 2016(12):96-98. |

| He Xing-ping, Geng Yuan-song, Guo Zhi-wei, et al. The substation equipment temperature prediction based on time sequence ARIMA model[J]. Automation & Instrumentation, 2016(12):96-98. | |

| 14 | 邹永久, 张跃文, 孙培廷,等. 基于 RKGM-AR 模型的船舶主机排气温度预测[J]. 船舶工程, 2015,37(7):46-49, 58. |

| Zou Yong-jiu, Zhang Yue-wen, Sun Pei-ting, et al. Prediction of exhaust gas temperature of ship main engine based on RKGM-AR model[J]. Ship Engineering, 2015,37(7):46-49, 58. | |

| 15 | 孙建平, 朱雯. 基于小波 BP-时间序列的齿轮箱温度预警[J]. 电子测量与仪器学报, 2012, 26(3):197-201. |

| Sun Jian-ping, Zhu Wen. Gearbox temperature prewarning based on wavelets BP-time series method[J]. Journal of Electronic Measurement and Instrument, 2012, 26(3):197-201. | |

| 16 | 王新全, 孙培廷, 邹永久,等. 基于 GA-BP 模型的船舶柴油机排气温度趋势预测[J]. 大连海事大学学报, 2015, 41(3):73-76. |

| Wang Xin-quan, Sun Pei-ting, Zou Yong-jiu, et al. Prediction of marine main engine exhaust temperature changing trend based on GA-BP model[J]. Journal of Dalian Maritime University, 2015, 41(3):73-76. | |

| 17 | 梅启智. 系统可靠性工程基础[M].北京:科学出版社, 1992. |

| 18 | 刘丽娟,陈果,郝腾飞. 基于流形学习与一类支持向量机的滚动轴承早期故障识别方法[J]. 中国机械工程, 2013, 24(5):628-633. |

| Liu Li-juan, Chen Guo, Hao Teng-fei. Incipient fault recognition of rolling bearings based on manifold learning and one-class SVM[J]. China Mechanical Engineering, 2013, 24(5):628-633. | |

| 19 | Arlot S,Celisse A. A survey of cross-validation procedures for model selection[J]. Statistics Surveys,2010,4:40-79. |

| 20 | 龚丁禧,曹长荣.基于卷积神经网络的植物叶片分类[J].计算机与现代化, 2014(4):12-15, 19. |

| Gong Ding-xi, Cao Chang-rong. Plant leaf classification based on cnn[J]. Computer and Modernization, 2014 (4):12-15, 19. | |

| 21 | 董峻妃,郑伯川,杨泽静.基于卷积神经网络的车牌字符识别[J].计算机应用,2017,37(7):2014-2018. |

| Dong Jun-fei, Zheng Bo-chuan, Yang Ze-jing. Character recognition of license plate based on convolution neural network[J]. Journal of Computer Applications, 2017, 37(7):2014-2018. | |

| 22 | Krizhevsky A, Sutskever I, Hinton G E. ImageNet classification with deep convolutional neural networks[C]∥The Twenty-sixth Annual Conference on Neural Information Processing System, Lake Tahoe,USA,2012:1097-1105. |

| [1] | Xing-jun HU,Jing-long ZHANG,Yu-fei LUO,Li XIN,Sheng LI,Jin-rui HU,Wei LAN. Influence investigation of cooling tube structure and airflow direction on thermal⁃hydraulic performance of air⁃cooled charge air cooler [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1933-1942. |

| [2] | Jian-bin CHEN,Song-ze ZHOU,Feng-yong FEI,Yong-long CHEN,Guo-ping LING. Influences of interference fit and knurling connection type on press fitting failure of assembled camshaft [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1959-1966. |

| [3] | Hui ZHONG,Heng KANG,Ying-da LYU,Zhen-jian LI,Hong LI,Ruo-chuan OUYANG. Image manipulation localization algorithm based on channel attention convolutional neural networks [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1838-1844. |

| [4] | Yong LUO,Yong-heng WEI,Huan HUANG,Ren-jie XIAO,Lin REN,Huan-yu CUI. Starting control of P2.5 plug⁃in hybrid configuration dual⁃clutch based on driver's intention recognition [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1575-1582. |

| [5] | Xiao-hua ZENG,Mei-jie SONG,Da-feng SONG,Yue WANG. Data processing method of bus driving cycle based on vehicular network information [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1692-1699. |

| [6] | Chao MA,Yun-kai GAO,Zhe LIU,Yue-xing DUAN,Lin-li TIAN. Optimization of multi⁃material and beam cross⁃sectional shape and dimension of skeleton⁃type body [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1583-1592. |

| [7] | Feng-chong LAN,Ji-wen LI,Ji-qing CHEN. DG-SLAM algorithm for dynamic scene compound deep learning and parallel computing [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1437-1446. |

| [8] | Jian YANG,Qi XIA,Hai-chao ZHOU,Guo-lin WANG. Noise reduction mechanism of truck radial tire based on modified carcass string contour design [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1198-1203. |

| [9] | Jiang-qi LONG,Jin-tao XIANG,Ping YU,Jun-cheng WANG. Linear disturbance observer suitable for sliding mode control of nonlinear active suspension [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1230-1240. |

| [10] | De-xing WANG,Ruo-you WU,Hong-chun YUAN,Peng GONG,Yue WANG. Underwater image restoration based on multi-scale attention fusion and convolutional neural network [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1396-1404. |

| [11] | Xin CHEN,Gui-shen YU,Biao ZHANG,Kai-xuan PAN,Li-fei YANG. Equivalent modeling of tensile-shear behavior for friction stir spot welding joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1190-1197. |

| [12] | Guang-song LI,Wen-qing LI,Qing LI. Encrypted and compressed traffic classification based on random feature set [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1375-1386. |

| [13] | Hou⁃jie LI,Fa⁃sheng WANG,Jian⁃jun HE,Yu ZHOU,Wei LI,Yu⁃xuan DOU. Pseudo sample regularization Faster R⁃CNN for traffic sign detection [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1251-1260. |

| [14] | Xiao-long ZHU,Zhong XIE. Geospatial data extraction algorithm based on machine learning [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1011-1016. |

| [15] | Jia-xu ZHANG,Xin-zhi WANG,Jian ZHAO,Zheng-tang SHI. Path planning and discrete sliding mode tracking control for high⁃speed lane changing collision avoidance of vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1081-1090. |

|

||