Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (4): 819-828.doi: 10.13229/j.cnki.jdxbgxb20200939

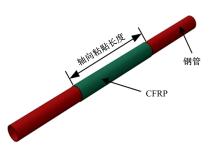

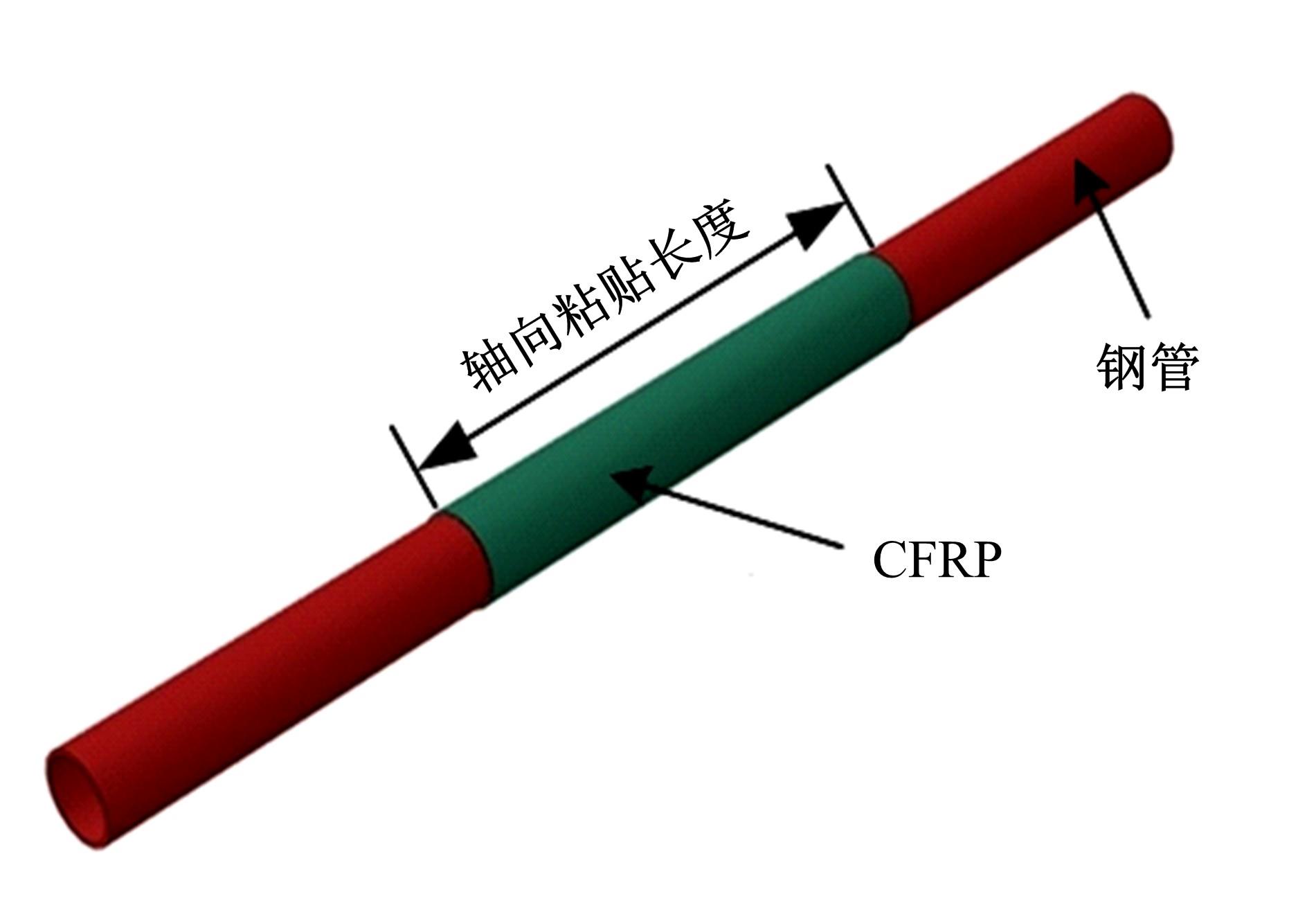

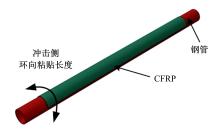

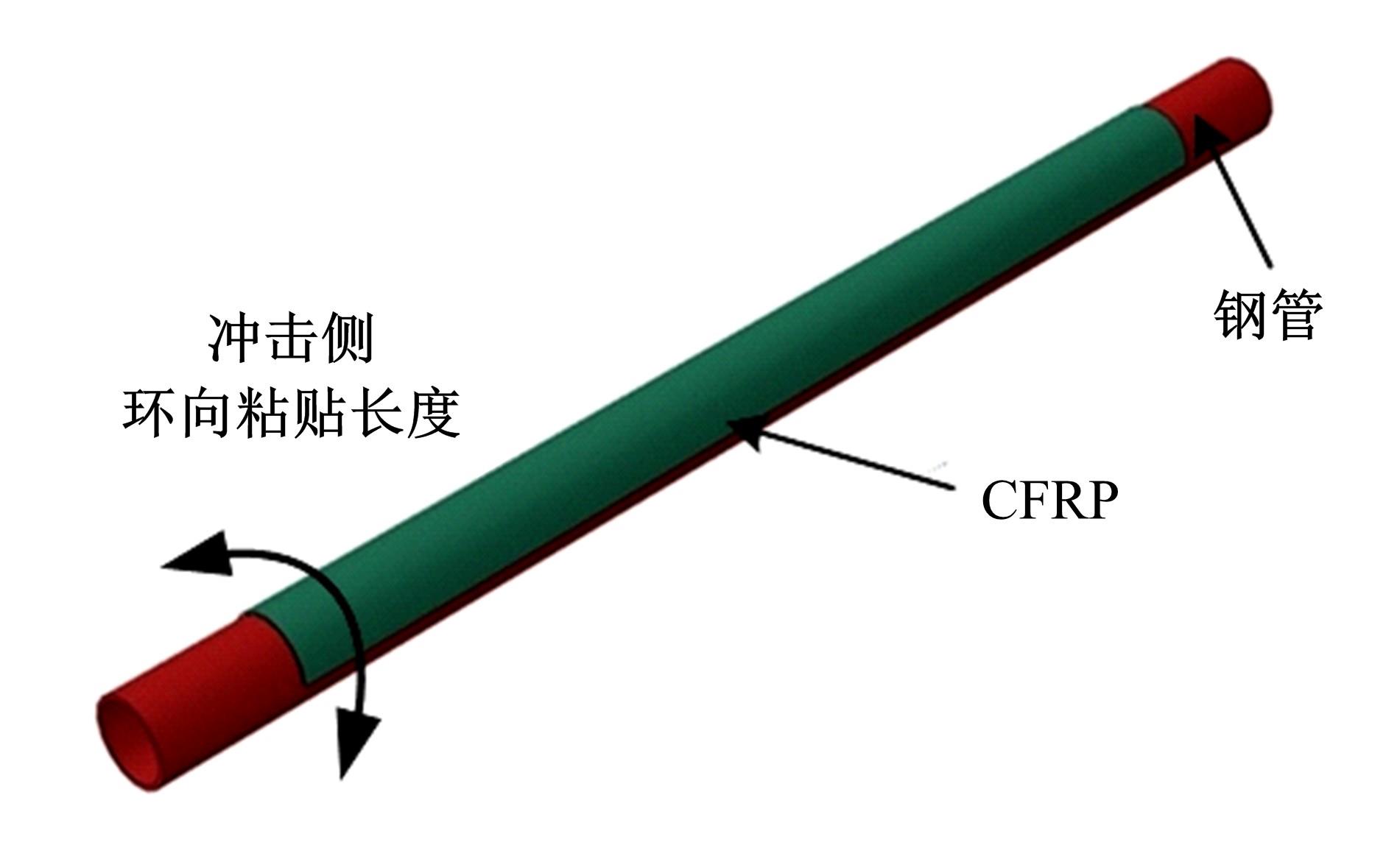

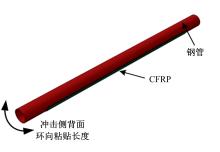

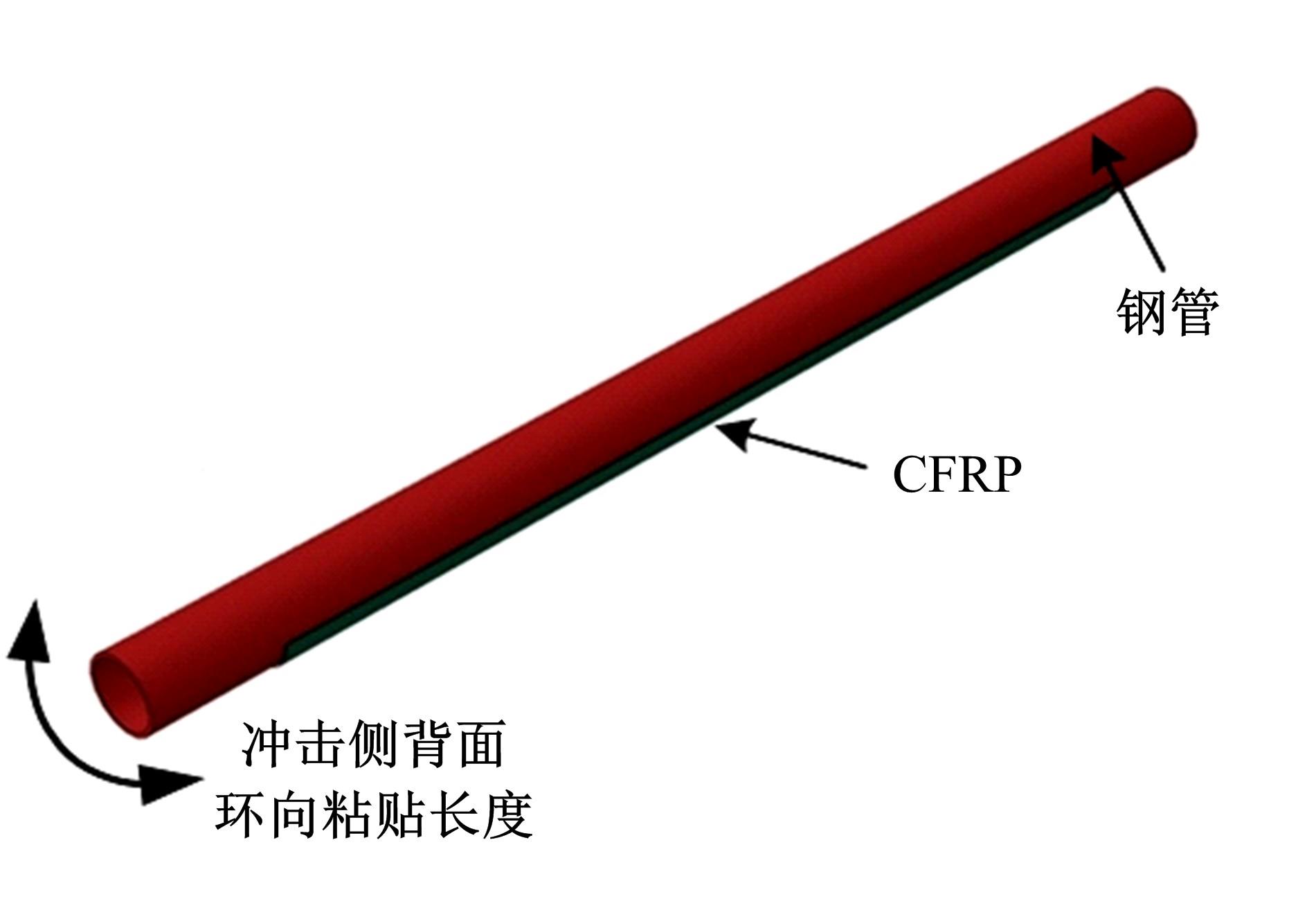

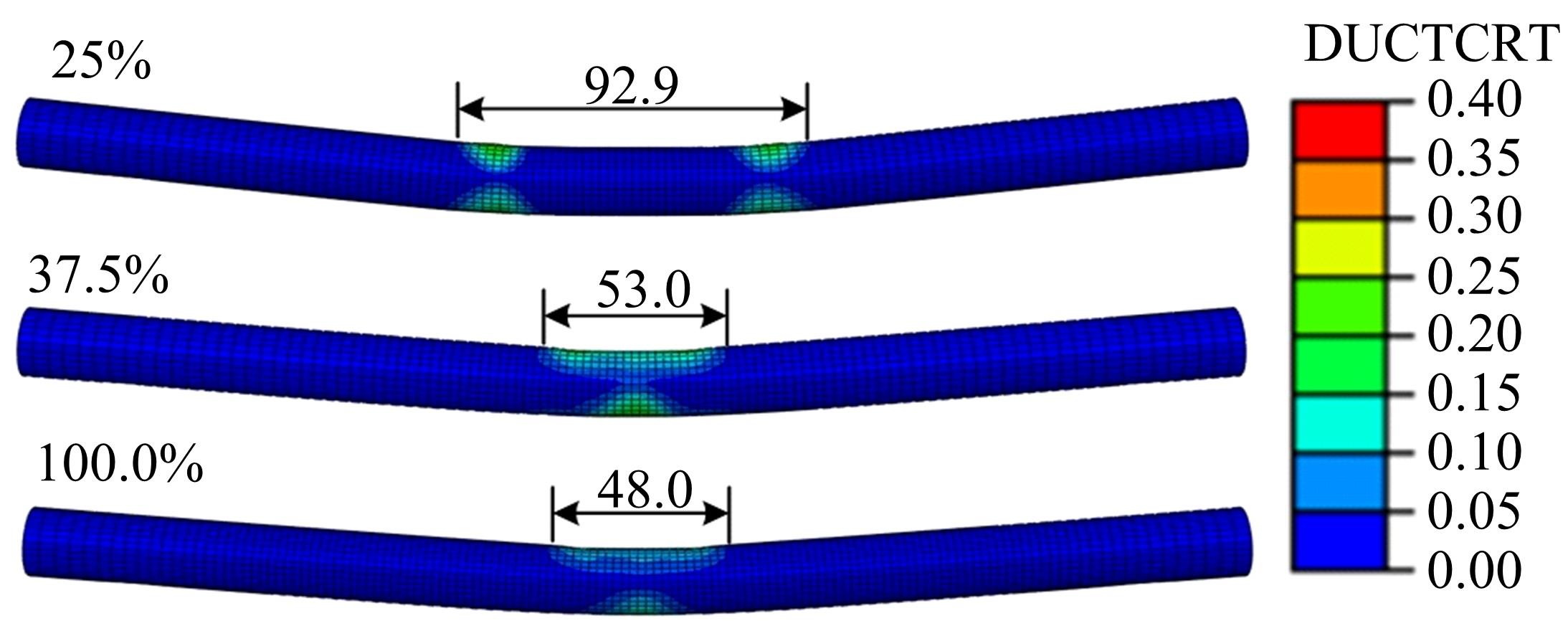

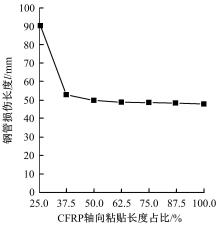

Influence of strengthening form of CFRP on transverse impact performance of steel tube

Wei-min ZHUANG( ),Shen CHEN,Di WU

),Shen CHEN,Di WU

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

CLC Number:

- TB33

| 1 | Vermeeren C. An historic overview of the development of fibre mental laminates[J]. Applied Composite Materials, 2003, 10(4): 189-205. |

| 2 | 朱国华, 成艾国, 王振, 等. 电动车轻量化复合材料车身骨架多尺度分析[J]. 机械工程学报, 2016, 52(6): 145-152. |

| Zhu Guo-hua, Cheng Ai-guo, Wang Zhen, et al. Analysis of lightweight composite body structure for electrical vehicle using the multiscale approach[J]. Journal of Mechanical Engineering, 2016, 52(6): 145-152. | |

| 3 | 李永兵, 李亚庭, 楼铭, 等. 轿车车身轻量化及其对连接技术的挑战[J]. 机械工程学报, 2012, 48(18): 44-54. |

| Li Yong-bing, Li Ya-ting, Lou Ming, et al. Lightweighting of car body and its challenges to joining technologies[J]. Journal of Mechanical Engineering, 2012, 48(18): 44-54. | |

| 4 | Karbhari V M, Shulley S B. Use of composites for rehabilitation of steel structures-determination of bond durability[J]. Journal of Materials in Civil Engineering, 1995, 7(4): 239-245. |

| 5 | Phan V N, Yukihiro M. Experimental analytical and theoretical investigations of CFRP strengthened thin-walled steel plates under shear loads[J]. Thin-Walled Structures, 2020, 155: No. 106908. |

| 6 | Chahkand N A, Jumaat M Z, Ramli S N H, et al. Experimental and theoretical investigation on torsional behaviour of CFRP strengthened square hollow steel section[J]. Thin-Walled Structures, 2013, 68: 135-140. |

| 7 | 钮鹏, 杨刚, 金春福, 等. 几何缺陷影响下的CFRP-方钢管极限承载力解析解[J]. 工程力学, 2015, 32(): 322-326. |

| Niu Peng, Yang Gang, Jin Chun-fu, et al. Analytical solutions on ultimate bearing capacity of a square CFRP-steel tube member with initial imperfection[J]. Engineering Mechanics, 2015, 32(S1): 322-326. | |

| 8 | Kim H C, Dong K S, Lee J J. Characteristics of aluminum/CFRP short square hollow section beam under transverse quasi-static loading[J]. Composites Part B: Engineering, 2013, 51: 345-358. |

| 9 | Ma Q H, Zha Y B, Dong B Y, et al. Structure design and multi-objective optimization of CFRP /aluminum hybrid crash box[J]. Polymer Composites, 2020, 41(10): 4202-4220. |

| 10 | Sha Y Y, Hao H. Laboratory tests and numerical simulations of CFRP strengthened RC pier subjected to barge impact load[J]. International Journal of Structural Stability and Dynamics, 2015, 15(2): No. 1450037. |

| 11 | Haider A Z, Riadh A M, Zhao X L. Experimental investigation of bond characteristics between CFRP fabrics and steel plate joints under impact tensile loads[J]. Composite Structures, 2011, 94(2): 510-518. |

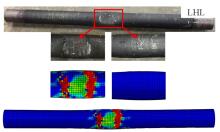

| 12 | Alam M I, Fawzia S, Zhao X L, et al. Experimental study on FRP-strengthened steel tubular members under lateral impact[J]. Journal of Composites for Construction, 2017, 21(5): No:04017022. |

| 13 | Alam M I, Fawzia S. Numerical studies on CFRP strengthened steel columns under transverse impact[J]. Composite Structures, 2015, 120: 428-441. |

| 14 | 刘斌, 赵亮, 徐红炉. 基于Hashin失效准则的复合材料螺栓连接损伤破坏研究[J]. 科学技术与工程, 2012, 12(8): 1740-1744. |

| Liu Bin, Zhao Liang, Xu Hong-lu. The research about damage of composite laminate in bolted joints based on the Hashin failure criteria[J]. Science Technology and Engineering, 2012, 12(8): 1740-1744. | |

| 15 | 吴振, 陈健. 基于Hashin准则的复合材料层合结构低速冲击研究[J]. 沈阳航空航天大学学报, 2017, 34(5): 12-20. |

| Wu Zhen, Chen Jian. Low-velocity impact damage of composite structure based on Hashin criteria[J]. Journal of Shenyang Institute of Aeronautical Engineering, 2017, 34(5): 12-20. | |

| 16 | Hashin Z. Failure criteria for unidirectional fiber composites[J]. Journal of Applied Mechanics, 1980, 47(2): 329-334. |

| 17 | Fanteria D, Lazzeri L, Panettieri E, et al. Experimental characterization of the inter laminar fracture toughness of a woven and a unidirectional carbon/epoxy composite[J]. Composites Science and Technology, 2017, 142: 20-29. |

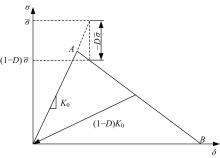

| 18 | Guo Y Q, Saanouin K, Cherouat A, et al. Two methodologies for the simulation of ductile damage in sheet metal forming processes[J]. Journal of Plasticity Engineering, 2002, 43(373): 3227-3237. |

| 19 | 孟利平, 程远征, 张伦平, 等. 应变率和应力三轴度对Q345B钢动态力学性能的影响研究[J]. 船舶力学, 2019, 23(10): 1210-1220. |

| Meng Li-ping, Cheng Yuan-zheng, Zhang Lun-ping, et al. Influence of strain rate and stress triaxiality on the dynamic mechanical behavior of Q345B steel[J]. Journal of Ship Mechanics, 2019, 23(10): 1210-1220. | |

| 20 | 杨卓云, 赵长财, 董国疆, 等. 基于Lou-2013韧性断裂准则5182铝板成形极限研究[J]. 机械工程学报, 2019, 55(16): 47-57. |

| Yang Zhuo-yun, Zhao Chang-cai, Dong Guo-jiang, et al. Forming limit research of 5182 aluminum alloy sheet based on Lou-2013 ductile fracture criterion[J]. Journal of Mechanical Engineering, 2019, 55(16): 47-57. | |

| 21 | 朱浩, 朱亮, 陈剑虹. 应力三轴度和应变率对6063铝合金力学性能的影响及材料表征[J]. 材料科学与工程学报, 2007, 25(3): 358-362. |

| Zhu Hao, Zhu Liang, Chen Jian-hong. Influence of stress triaxiality and strain rate on the mechanics behavior of 6063 aluminum alloy and material characterization[J]. Journal of Materials Science and Engineering, 2007, 25(3): 358-362. | |

| 22 | Ranz D, Cuartero J, Castejon L, et al. A cohesive zone model approach to interlaminar behavior of carbon/epoxy laminated curved beams[J]. Composite Structures, 2020, 238: No. 111983. |

| 23 | Deng J, Li J, Wang Y, et al. Numerical study on notched steel beams strengthened by CFRP plates[J]. Construction and Building Materials, 2018, 163: 622-633. |

| 24 | 寇剑锋, 徐绯, 郭家平. 黏聚力模型破坏准则及其参数选取[J]. 机械强度, 2011, 33(5): 714-718. |

| Kou Jian-feng, Xu Fei, Guo Jia-ping. Damage laws of Cohesive zone model and selection of the parameters[J]. Journal of Mechanical Strength, 2011, 033(5): 14-718. | |

| 25 | Adams C, Bös J, Slomski E M., et al. Scaling laws obtained from a sensitivity analysis and applied to thin vibrating structures[J]. Mechanical Systems and Signal Processing, 2018, 110: 590-610. |

| [1] | Jie LI,Tao CHEN,Wen-cui GUO,Qi ZHAO. Pseudo excitation method of vehicle non-stationary random vibration in space domain and its application [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 738-744. |

| [2] | Wen-ku SHI,Shu-guang ZHANG,You-kun ZHANG,Zhi-yong CHEN,Yi-fei JIANG,Bin-bin LIN. Parameter identification of magnetorheological damper model with modified seagull optimization algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 764-772. |

| [3] | Ying-chao ZHANG,Yun-hang LI,Zi-yu GUO,Guo-hua WANG,Zhe ZHANG,Chang SU. Optimization of the aerodynamic drag reduction of a cab behind engine vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 745-753. |

| [4] | Wei-min ZHUANG,Shen CHEN,Nan WANG. Influence on thermal stress of autobody steel-aluminum clinch-adhesive connection structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 70-78. |

| [5] | Liang DUAN,Chun-yuan SONG,Chao LIU,Wei WEI,Cheng-ji LYU. State recognition in bearing temperature of high-speed train based on machine learning algorithms [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 53-62. |

| [6] | Xing-jun HU,Jing-long ZHANG,Yu-fei LUO,Li XIN,Sheng LI,Jin-rui HU,Wei LAN. Influence investigation of cooling tube structure and airflow direction on thermal⁃hydraulic performance of air⁃cooled charge air cooler [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1933-1942. |

| [7] | Jian-bin CHEN,Song-ze ZHOU,Feng-yong FEI,Yong-long CHEN,Guo-ping LING. Influences of interference fit and knurling connection type on press fitting failure of assembled camshaft [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1959-1966. |

| [8] | Yong LUO,Yong-heng WEI,Huan HUANG,Ren-jie XIAO,Lin REN,Huan-yu CUI. Starting control of P2.5 plug⁃in hybrid configuration dual⁃clutch based on driver's intention recognition [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1575-1582. |

| [9] | Xiao-hua ZENG,Mei-jie SONG,Da-feng SONG,Yue WANG. Data processing method of bus driving cycle based on vehicular network information [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1692-1699. |

| [10] | Chao MA,Yun-kai GAO,Zhe LIU,Yue-xing DUAN,Lin-li TIAN. Optimization of multi⁃material and beam cross⁃sectional shape and dimension of skeleton⁃type body [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1583-1592. |

| [11] | Feng-chong LAN,Ji-wen LI,Ji-qing CHEN. DG-SLAM algorithm for dynamic scene compound deep learning and parallel computing [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1437-1446. |

| [12] | Jian YANG,Qi XIA,Hai-chao ZHOU,Guo-lin WANG. Noise reduction mechanism of truck radial tire based on modified carcass string contour design [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1198-1203. |

| [13] | Jiang-qi LONG,Jin-tao XIANG,Ping YU,Jun-cheng WANG. Linear disturbance observer suitable for sliding mode control of nonlinear active suspension [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1230-1240. |

| [14] | Xin CHEN,Gui-shen YU,Biao ZHANG,Kai-xuan PAN,Li-fei YANG. Equivalent modeling of tensile-shear behavior for friction stir spot welding joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1190-1197. |

| [15] | Da-feng SONG,Li-li YANG,Xiao-hua ZENG,Xing-qi WANG,Wei-zhi LIANG,Nan-nan YANG. Battery life optimization of hybrid electric vehicle based on driving cycle construction [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 781-791. |

|

||