Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (4): 1540-1547.doi: 10.13229/j.cnki.jdxbgxb20210304

Analysis of mechanical characteristics and recovery characteristics of bionic protective structures based on additive manufacturing

Zheng-lei YU1,2( ),Li-xin CHEN2,Ze-zhou XU2,Ren-long XIN2,Long MA3,Jing-fu JIN4(

),Li-xin CHEN2,Ze-zhou XU2,Ren-long XIN2,Long MA3,Jing-fu JIN4( ),Zhi-hui ZHANG2,Shan JIANG5

),Zhi-hui ZHANG2,Shan JIANG5

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.Key of Bionic Engineering,Ministry of Education,Jilin University,Changchun 130022,China

3.College of Combat Service,Aviation University Air Force,Changchun 130022

4.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

5.Changchun Institute of Optics,Fine Mechanics and Physics,Chinese Academy of Sciences,Changchun 130033,China

CLC Number:

- TB17

| 1 | 姚艳玲, 赵宝荣, 钟涛, 等. 铝合金板抗枪弹倾角效应试验研究[J]. 兵器材料科学与工程, 2005, 28(3): 33-36. |

| Yao Yan-lin, Zhao Bao-rong, Zhong Tao, et al. Study on obliquity effect of aluminum alloy plates against bullet[J]. Ordnance Material Science and Engineering, 2005, 28(3): 33-36. | |

| 2 | 苟瑞君, 孙丹, 张博. 陶瓷/泡沫铝/铝合金复合装甲抗射流侵彻性能[J]. 含能材料, 2017, 25(6): 451-458. |

| Gou Rui-jun, Sun Dan, Zhang Bo. Anti-jet penetration performances of the Ceramic/Aluminum Foam/Aluminum alloy composite armor[J]. Chinese Journal of Energetic Materials, 2017, 25(6): 451-458. | |

| 3 | Fan Wei, Shen Dong-jie, Zhang Zhi-yong, et al. A novel UHPFRC-based protective structure for bridge columns against vehicle collisions: experiment, simulation, and optimization[J]. Engineering Structures, 2020, 207: 110247. |

| 4 | 张媛, 郑白哲, 李妮. 蜂窝夹心板的理论研究[J]. 北京工商大学学报:自然科学版, 2001, 19(4): 47-50. |

| Zhang Yuan, Zheng Bai-zhe, Li Ni. Theoretical research of honeycomb sandwich panel[J]. Journal of Beijing Technology and Business University(Natural Science Edition), 2001, 19(4): 47-50. | |

| 5 | Liu Ping, Liu Yan, Zhang Xiong. Internal-structure model based simulation research of shielding properties of honeycomb sandwich panel subjected to high-velocity impact[J]. International Journal of Impact Engineering, 2015, 77: 120-133. |

| 6 | 王显会, 师晨光, 周云波, 等. 车辆底部防护蜂窝夹层结构抗冲击性能分析[J]. 北京理工大学学报, 2016, 36(11): 1122-1126. |

| Wang Xian-hui, Shi Chen-guang, Zhou Yun-bo, et al. Impact resistance analysis of honeycomb sandwich structure for the vehicle bottom protection[J]. Journal of Beijing Institute of Technology, 2016, 36(11): 1122-1126. | |

| 7 | 侯策, 刘天生, 王凤英, 等. 不同填充物三角孔蜂窝板抗弹性能数值模拟研究[J]. 科技通报, 2017, 33(4): 1-5. |

| Hou Ce, Liu Tian-sheng, Wang Feng-ying, et al. Numerical simulation research on ballistic performance of triangle hole honeycomb panel with different substances[J]. Bulletin of Science and Technology, 2017, 33(4): 1-5. | |

| 8 | 梅相全, 宋小宁, 董野峰. 轻量化前下防护的设计研究[J]. 汽车零部件, 2020(12): 39-44. |

| Mei Xiang-quan, Song Xiao-ning, Dong Ye-feng. Design and research of lightweight front underrun protection[J]. Automobile Parts, 2020(12): 39-44. | |

| 9 | Rakesh Kumar, Manoj Kumar, Chohan Jasgurpreet Singh. The role of additive manufacturing for biomedical applications: a critical review[J]. Journal of Manufacturing Processes, 2021, 64: 828-850. |

| 10 | Cagri Oztan, Victoria Coverstone. Utilization of additive manufacturing in hybrid rocket technology: a review[J]. Acta Astronautica, 2021, 180: 130-140. |

| 11 | Cámara Torres Maria, Stacy Duarte, Ravi Sinha, et al. 3D additive manufactured composite scaffolds with antibiotic-loaded lamellar fillers for bone infection prevention and tissue regeneration[J]. Bioactive Materials, 2021, 6(4): 157-168. |

| 12 | Zhang Lei, Stefanie Feih, Stephen Daynes, et al. Energy absorption characteristics of metallic triply periodic minimal surface sheet structures under compressive loading[J]. Additive Manufacturing, 2018, 23: 505-515. |

| 13 | Pawel Baranowski, Pawel Płatek, Anna Antolak-Dudka, et al. Deformation of honeycomb cellular structures manufactured with laser engineered net shaping (LENS) technology under quasi-static loading: experimental testing and simulation[J]. Additive Manufacturing, 2019, 25: 307-316. |

| 14 | Zhang Xin, Ma Jun. Photothermal effect of 3D printed hydroxyapatite composite scaffolds incorporated with graphene nanoplatelets[J]. Ceramics International, 2021, 47(5): 46-53. |

| 15 | 朱雪洁, 钟诗江, 杨晓霞, 等. NiTi基形状记忆合金弹热效应及其应用研究进展[J]. 材料工程, 2021(3): 1-13. |

| Zhu Xue-jie, Zhong Shi-jiang, Yang Xiao-xia, et al. Research progress in electrocaloric effect and its application of NiTi-based shape memory alloys[J]. Journal of Materials Engineering, 2021(3): 1-13. | |

| 16 | 郭良, 张修庆. 金属基形状记忆合金研究进展[J]. 功能材料与器件学报, 2020, 26(5): 323-330. |

| Guo Liang, Zhang Xiu-qing. Research progress of metal-based shape memory alloys[J]. Journal of Functional Materials and Devices, 2020, 26(5): 323-330. | |

| 17 | 王硕, 王元昊. 形状记忆合金及其研究进展综述[J]. 科学技术创新, 2020(21): 39-40. |

| Wang Shuo, Wang Yuan-hao. Scientific and Technological Innovation[J], 2020(21): 39-40. | |

| 18 | 廖赞, 汤京龙, 袁志山, 等. 钛镍形状记忆合金医疗器械评价方法研究进展[J]. 金属功能材料, 2020, 27(4): 55-60. |

| Liao Zan, Tang Jing-long, Yuan Zhi-shan, et al. Research progress of assessment method for performance tests of NiTi shape memory alloy medical devices[J]. Metallic Functional Materials, 2020, 27(4): 55-60. | |

| 19 | Zhang Wei, Zhang Feng-hua, Lan Xin, et al. Shape memory behavior and recovery force of 4D printed textile functional composites[J]. Composites Science and Technology, 2018, 160: 224-230. |

| 20 | 孙凡越, 赵梓裕, 王文健, 等. 温度对形状记忆合金蜂窝材料动力学响应的影响[J]. 山西建筑, 2021, 47(2): 91-92. |

| Sun Fan-yue, Zhao Zi-yu, Wang Wen-jian, et al. The influence of temperature on the dynamic performance of shape memory alloy honeycombs[J]. Shanxi Architecture, 2021, 47(2): 91-92. | |

| 21 | Kim Sangbae, Elliot Hawkes, Kyujin Choy, et al. Micro artificial muscle fiber using NiTi spring for soft robotics[C]∥IROS, St.Louis, USA, 2009:2228-2234. |

| 22 | 王琳.镍钛合金复合结构保险杠性能的研究[D].哈尔滨:哈尔滨工业大学汽车工程学院,2005. |

| Wang Lin. Study on the properties of Ni-Ti alloy composite structure bumper[D] Harbin: School of Automotive Engineering,Harbin Institute of Technology, 2005. | |

| 23 | Smith M, Guan Z, Cantwell W J. Finite element modelling of the compressive response of lattice structures manufactured using the selective laser melting technique[J]. International Journal of Mechanical Sciences, 2013, 67:28-41. |

| 24 | 张凯雯. 3D打印膝关节假体多孔结构对骨组织应力遮挡影响的数值仿真研究[D].长春:吉林大学机械与航空航天工程学院,2019. |

| Zhang Kai-wen. Numberical simulation on the effect of 3D printed knee joint prosthesis on stress shielding of bone tissue[D]. Changchun:Shool of Mechnical and Aerospace,Jilin University, 2019. | |

| 25 | Ali M H, Sagidolla B, Dulat K. Material minimization in 3D printing with novel hybrid cellular structures[J]. Materials Today: Proceedings, 2021,,42(5):1800-1809. |

| 26 | Wang Xie-bin, Yu Jing-ya, Liu Jiang-wei, et al. Effect of process parameters on the phase transformation behavior and tensile properties of NiTi shape memory alloys fabricated by selective laser melting[J]. Additive Manufacturing, 2020, 36: No.101545. |

| 27 | Sa Edi S, Moghaddam N S, Amerinatanzi A, et al. On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi[J].Acta Materialia, 2018, 144: 552-560. |

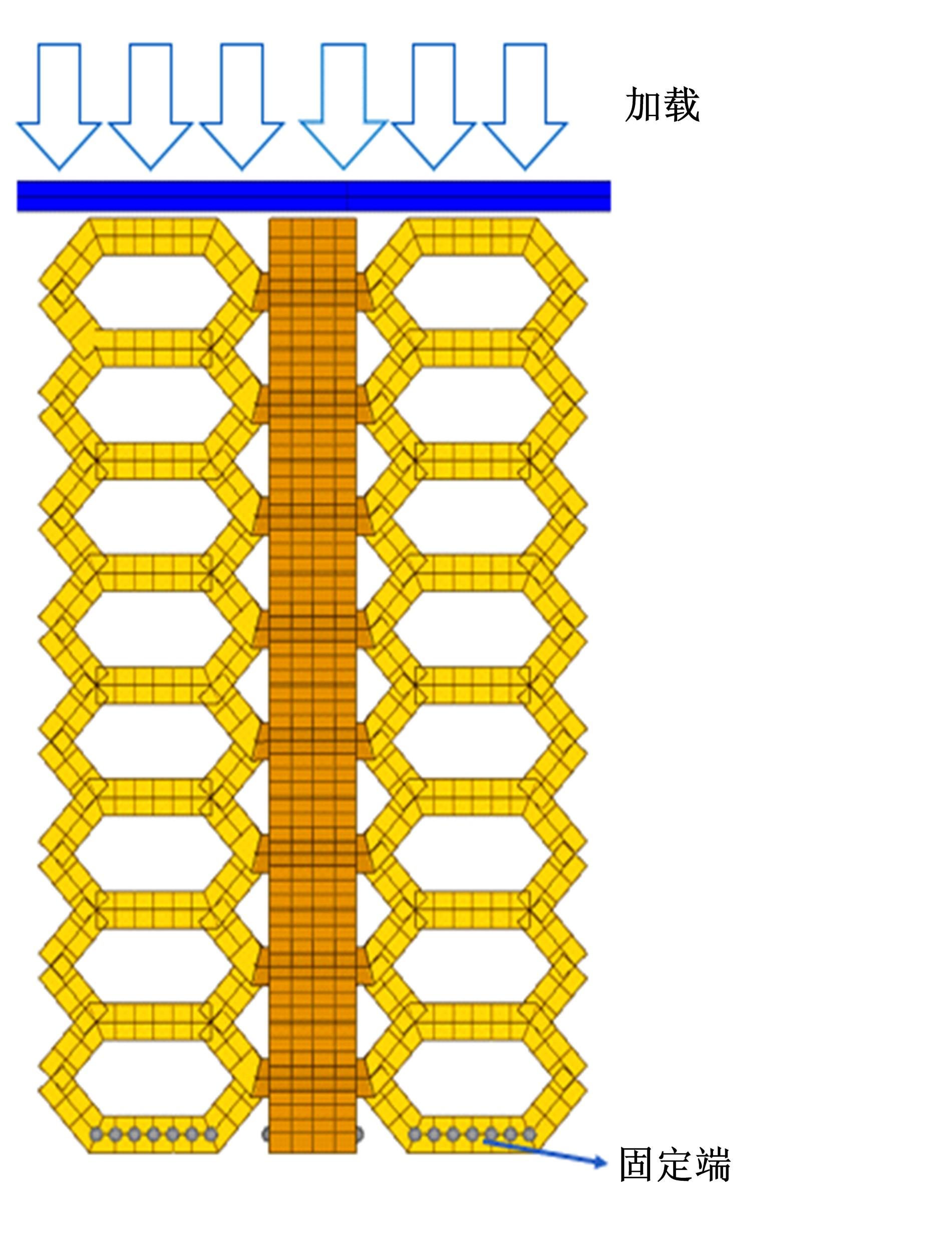

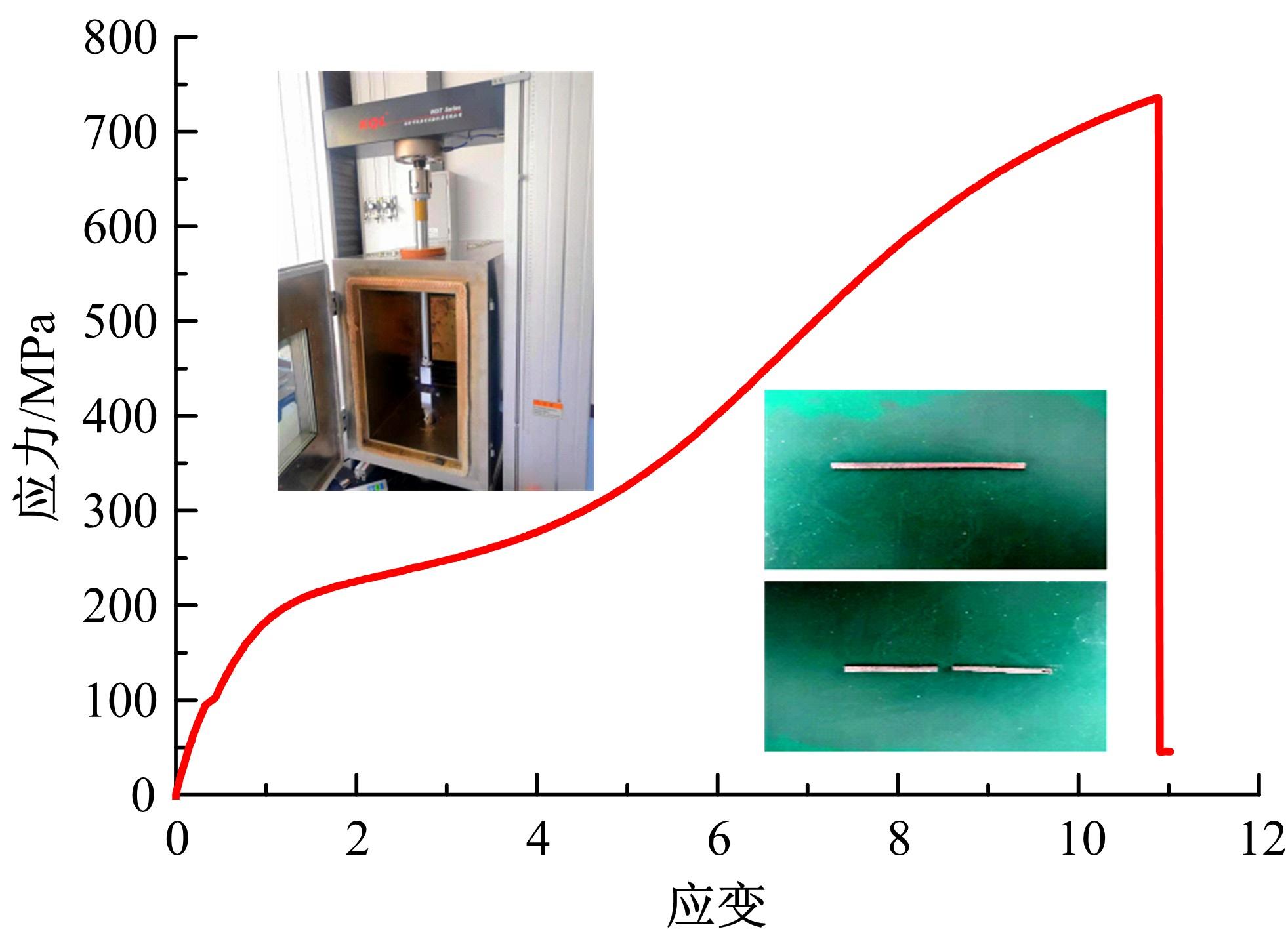

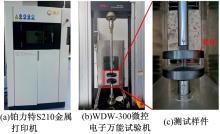

| 28 | Yu Zheng-lei, Xu Ze-zhou, Guo Yun-ting, et al. Study on properties of SLM-NiTi shape memory alloy under the same energy density[J]. Journal of Materials Research and Technology, 2021, 13: 241-250. |

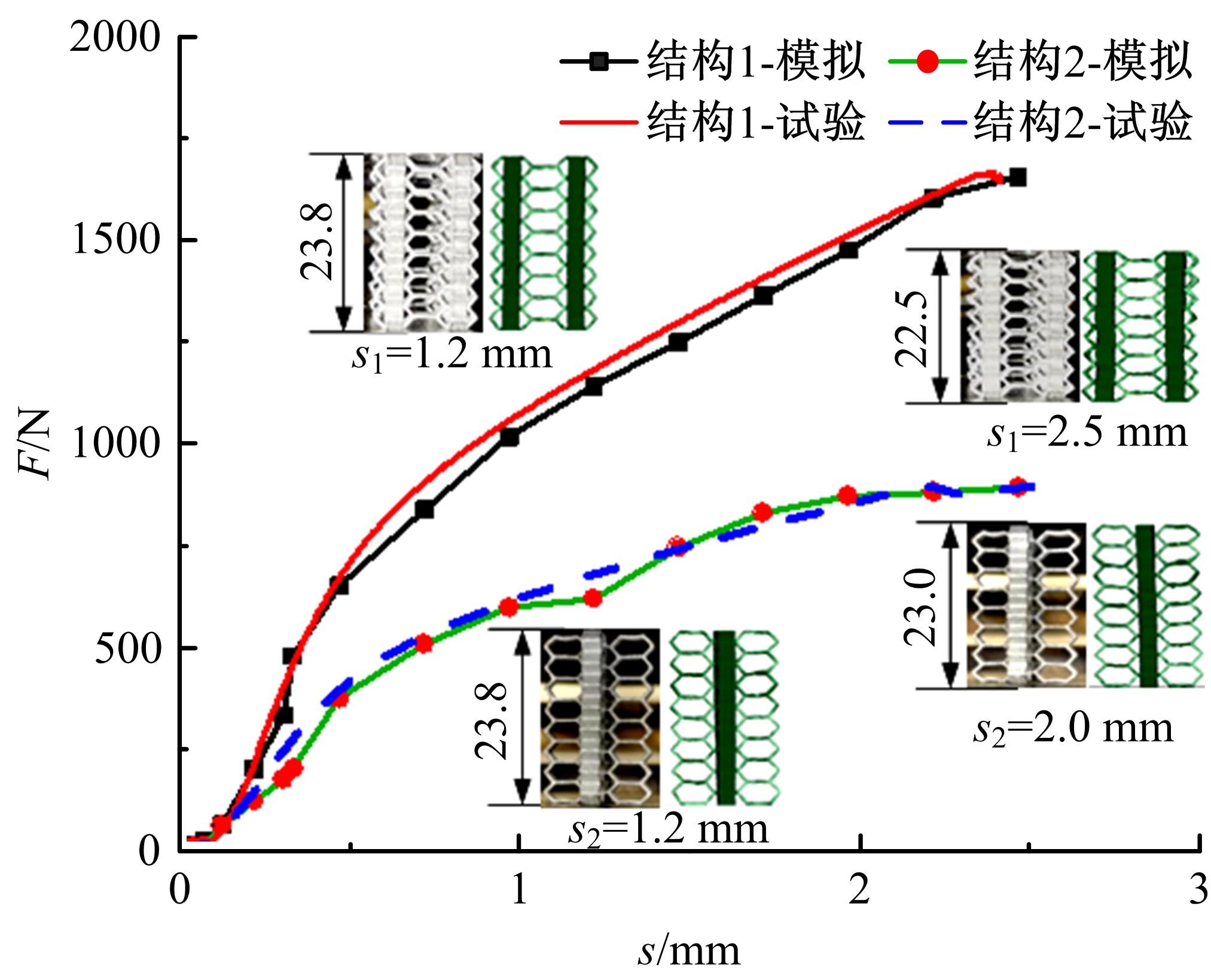

| [1] | Zheng-lei YU,Ren-long XIN,Li-xin CHEN,Yi-ning ZHU,Zhi-hui ZHANG,Qing CAO,Jing-fu JIN,Jie-liang ZHAO. Load bearing characteristics of honeycomb protection structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1140-1145. |

| [2] | Ya-feng GONG,Yun-ze PANG,Bo WANG,Guo-jin TAN,Hai-peng BI. Mechanical properties of new prefabricated box culvert structure based on road conditions in Jilin Province [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 917-924. |

| [3] | Chang SU,Ying HAN,Ying-chao ZHANG,Zhen-hua MIAO. Influence performance with wheel spoke design parameters of vehicle aerodynamic [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 107-113. |

| [4] | Zheng-wei GU,Lin CHEN,Li-hui ZHAO,Hong XU,Xin LI,Ge YU. Simulation of stamping process of some reinforcement plate below windows of railway vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 504-511. |

| [5] | Xin CHEN,Ning WANG,Chuan-liang SHEN,Xiao FENG,Chang-hai YANG. Effect of rearview mirror modeling on aerodynamic noise of front window [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 426-436. |

| [6] | Chun-bao LIU,Shan-shi CHEN,Chuang SHENG,Zhi-hui QIAN,Lu-quan REN,Lei REN. Bionic hydraulic driving mechanism of spider and its bio⁃inspiration [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 375-381. |

| [7] | Wei-ping SHI,Xu ZHAO,Xing-jun HU,Tian-ming YU,Bo-wen LIU,Yan DUAN. Design and numerical simulation of water restriction device AICD for natural gas exploitation [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1986-1991. |

| [8] | Ya-feng GONG,Bo WANG,Guo-jin TAN,Li-min ZHANG,Wen-ding WU,Hai-peng BI. Comparative analysis of mechanical characteristics of two typical fabricated culverts in Jilin [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1865-1870. |

| [9] | Zhuo YI,Wen-zhi FU,Ming-zhe LI. Numerical simulation and experiment on double⁃layered split ultrahigh pressure die [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1593-1599. |

| [10] | Xin LI,Yan-peng SUN,Dan WANG,Jun-xu CHEN,Zheng-wei GU,Hong XU. Finite element numerical simulation for automobile front floor forming [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1608-1614. |

| [11] | Hua ZHOU,Zhi⁃gang YANG,Hui ZHU. Aerodynamic calculation of MIRA model correlated with wind tunnel test [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1043-1053. |

| [12] | Dong⁃liang CHEN,Rui ZANG,Peng DUAN,Wei⁃peng ZHAO,Xu⁃tao WENG,Yang SUN,Yi⁃peng TANG. Biomimetic design of multi⁃link fishbone based on crescent′s fishtail propulsion theory [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1246-1257. |

| [13] | Xin LI,Dan WANG,Jun⁃xu CHEN,Yan⁃peng SUN,Zheng⁃wei GU,Hong XU. Numerical simulation for handbrake fixed plate forming [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1258-1265. |

| [14] | Xue⁃guang ZHANG,Ming⁃meng JIA,Chun⁃guo LIU,Guang⁃zhong HE. Trajectory design and FE simulation for profile stretch bending based on incremental control method [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1272-1279. |

| [15] | Zhao⁃wei QU,Zhao⁃tian PAN,Yong⁃heng CHEN,Peng⁃fei TAO,Di SUN. Car⁃following model with improving safety distance based on optimal velocity model [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1092-1099. |

|

||