Journal of Jilin University(Engineering and Technology Edition) ›› 2020, Vol. 50 ›› Issue (2): 504-511.doi: 10.13229/j.cnki.jdxbgxb20181255

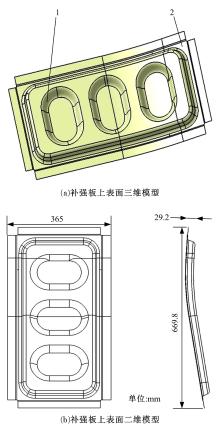

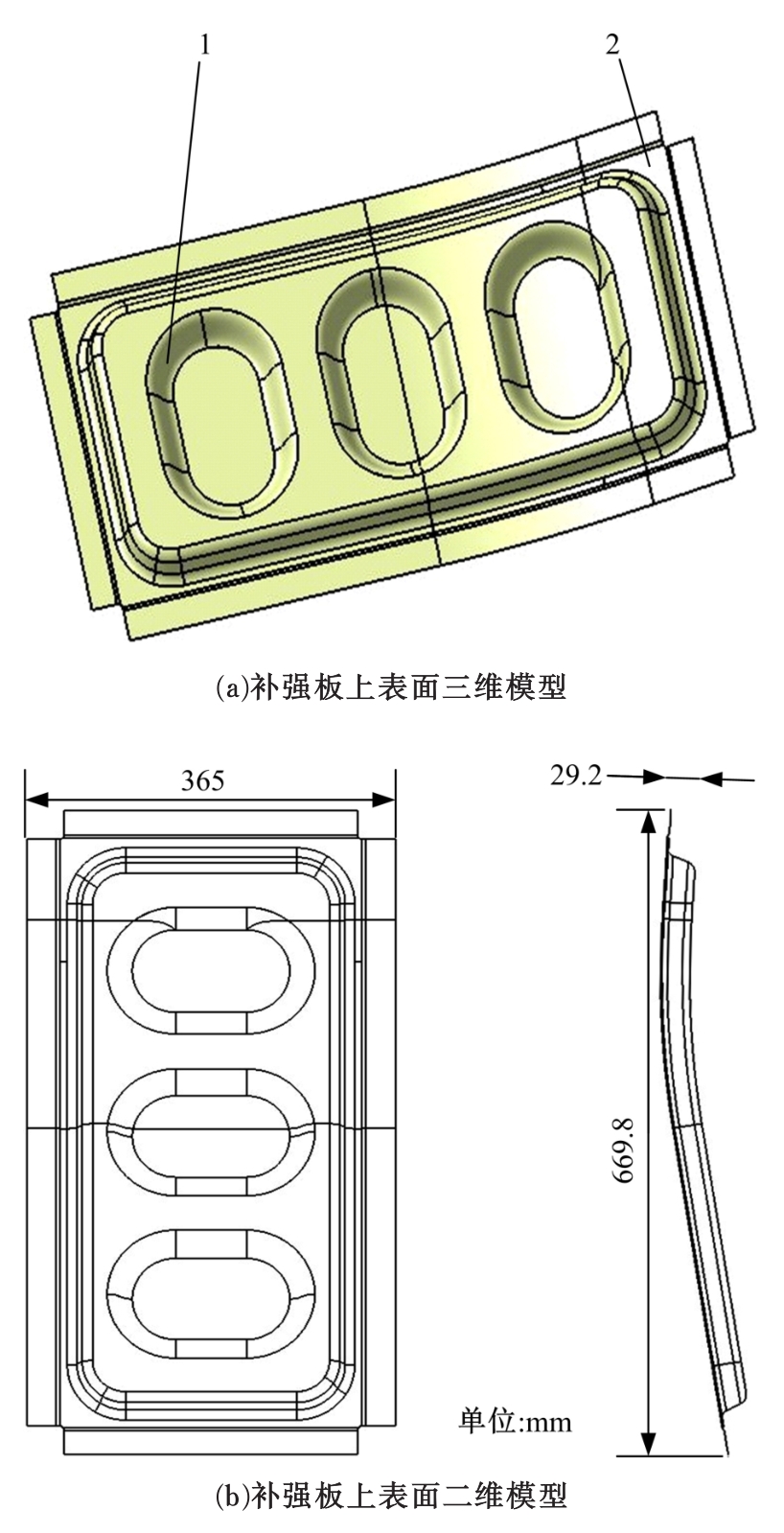

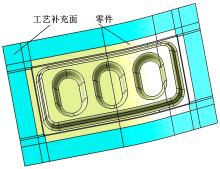

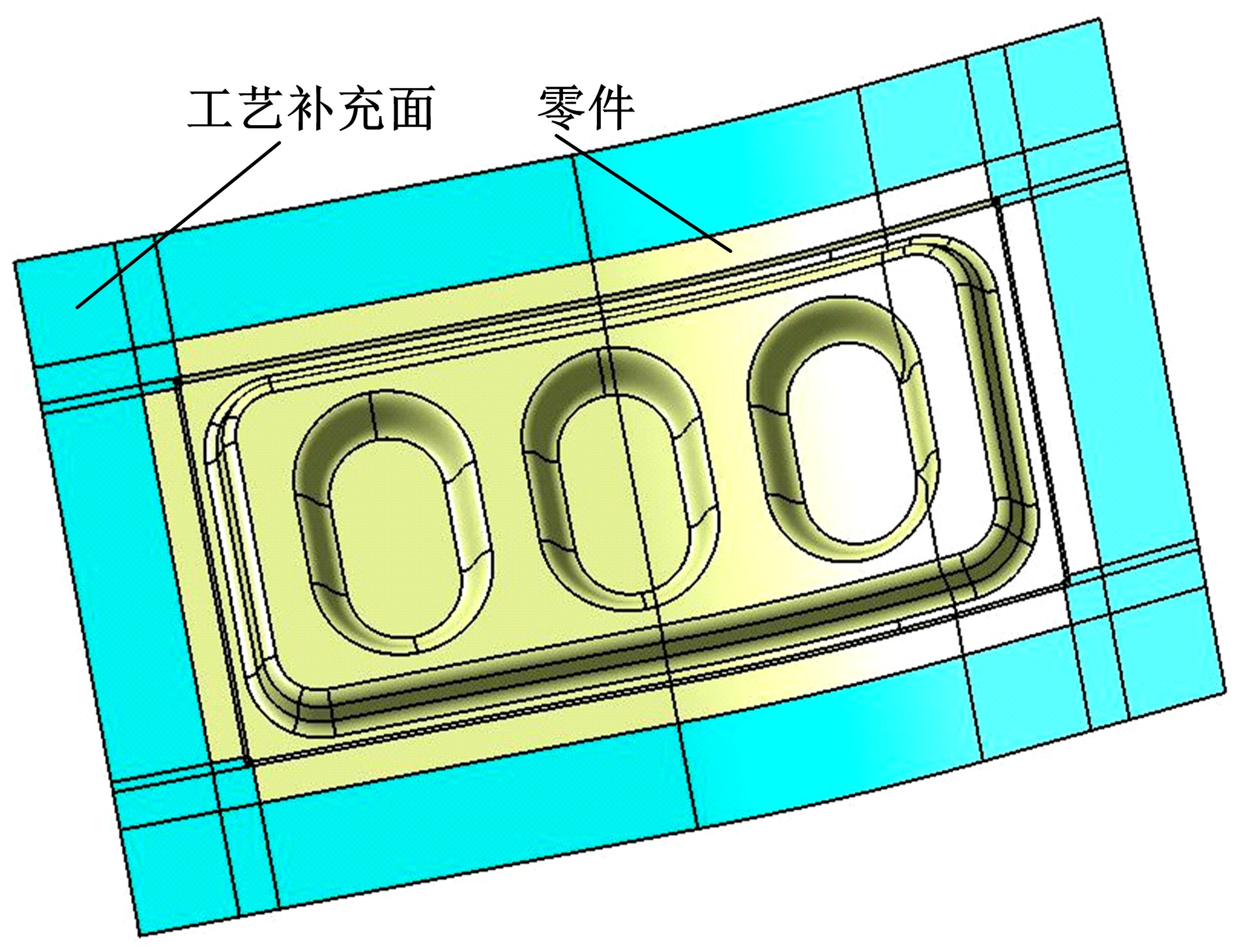

Simulation of stamping process of some reinforcement plate below windows of railway vehicles

Zheng-wei GU1( ),Lin CHEN1,Li-hui ZHAO1,Hong XU1,Xin LI1,Ge YU1,2(

),Lin CHEN1,Li-hui ZHAO1,Hong XU1,Xin LI1,Ge YU1,2( )

)

- 1.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

2.Roll Forging Institute, Jilin University, Changchun 130022,China

CLC Number:

- TG386

| 1 | 姚明哲, 杨志勇, 马秋红, 等. 不锈钢轨道车辆的特点[J]. 装备机械, 2015, 48(3): 10-13. |

| Yao Ming-zhe, Yang Zhi-yong, Ma Qiu-hong, et al. Features of railway vehicles of stainless steel[J]. The Magazine on Equipment Machine, 2015, 48(3): 10-13. | |

| 2 | 张海波, 孙力伟, 温勃. 基于Autoform车顶盖板拉深成形数值模拟研究[J]. 现代制造工程, 2017(10): 85-89, 58. |

| Zhang Hai-bo, Sun Li-wei, Wen Bo. Numerical simulation research on the drawing forming of the roof cover plate based on autoform[J]. Modern Manufacturing Engineering, 2017(10): 85-89, 58. | |

| 3 | 邱晓刚, 黄跃东. 汽车顶盖零件冲压成形的数值模拟研究[J]. 锻压技术, 2009, 34(4): 148-152. |

| Qiu Xiao-gang, Huang Yue-dong. Study on numericalsimulation of automobile covering part stamping process[J]. Forging & Stamping Technology, 2009, 34(4): 148-152. | |

| 4 | Souza T, Rolfe B. Multivariate modelling of variabi-lity in sheet metal forming[J]. Journal of Materials Processing Technology, 2008, 203(1-3): 1-12. |

| 5 | Xu F, Lin Z Q, Li S H, et al. Study on the influences of geometrical parameters on the formability of stretch curved flanging by numerical simulation[J]. Journal of Materials Processing Technology, 2004, 145(1): 93-98. |

| 6 | Dezelak M, Stepisnik A, Pahole L, et al. Evaluation of twistspringback prediction after an AHSS forming process[J]. International Journal of Simulation Modelling, 2014, 13(2): 171-182. |

| 7 | 陶晨, 王双. 基于Autoform的汽车发动机罩板拉延成形仿真研究[J]. 农业装备与车辆工程, 2018, 56(2): 69-72. |

| Tao Chen, Wang Shuang. Autoform-based simulation study of automobile engine hood drawing process[J]. Agricultural Equipment & Vehicle Engineering, 2018, 56(2): 69-72. | |

| 8 | 李欣, 孙延朋, 王丹, 等. 汽车前地板成形有限元数值模拟[J]. 吉林大学学报: 工学版, 2019, 49(5): 1608-1614. |

| Li Xin, Sun Yan-peng, Wang Dan, et al. Finite element numerical simulation for automobile front floor forming[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(5): 1608-1614. | |

| 9 | 蔡中义, 李明哲, 兰英武, 等. 三维曲面零件连续成形的形状控制[J]. 吉林大学学报: 工学版, 2011, 41(4): 978-983. |

| Cai Zhong-yi, Li Ming-zhe, Lan Ying-wu, et al. Shape control of 3-dimensional curved surface part in continuous forming[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41(4): 978-983. | |

| 10 | 刘志卫, 李明哲, 韩奇钢. 具有防皱功能的多点成形工艺数值模拟[J]. 吉林大学学报: 工学版, 2012, 42(5): 1208-1213. |

| Liu Zhi-wei, Li Ming-zhe, Han Qi-gang. Numerical simulation on multi-point sheet metal forming with wrinkle resistance function[J]. Journal of Jinlin University (Engineering and Technology Edition), 2012, 42(5): 1208-1213. |

| [1] | Xin CHEN,Ning WANG,Chuan-liang SHEN,Xiao FENG,Chang-hai YANG. Effect of rearview mirror modeling on aerodynamic noise of front window [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 426-436. |

| [2] | Zhou SHI,Shu-qing KOU. Performance analysis and lightweight design of 36MnVS4 fracture⁃splitting connecting rod [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1992-2001. |

| [3] | Wei-ping SHI,Xu ZHAO,Xing-jun HU,Tian-ming YU,Bo-wen LIU,Yan DUAN. Design and numerical simulation of water restriction device AICD for natural gas exploitation [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1986-1991. |

| [4] | Ya-feng GONG,Bo WANG,Guo-jin TAN,Li-min ZHANG,Wen-ding WU,Hai-peng BI. Comparative analysis of mechanical characteristics of two typical fabricated culverts in Jilin [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1865-1870. |

| [5] | Yong PENG,Hua GAO,Lei WAN,Gui-ying LIU. Numerical simulation of influence factors of splitting strength of asphalt mixtures [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1521-1530. |

| [6] | Zhuo YI,Wen-zhi FU,Ming-zhe LI. Numerical simulation and experiment on double⁃layered split ultrahigh pressure die [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1593-1599. |

| [7] | Xin LI,Yan-peng SUN,Dan WANG,Jun-xu CHEN,Zheng-wei GU,Hong XU. Finite element numerical simulation for automobile front floor forming [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1608-1614. |

| [8] | Hua ZHOU,Zhi⁃gang YANG,Hui ZHU. Aerodynamic calculation of MIRA model correlated with wind tunnel test [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1043-1053. |

| [9] | Xin LI,Dan WANG,Jun⁃xu CHEN,Yan⁃peng SUN,Zheng⁃wei GU,Hong XU. Numerical simulation for handbrake fixed plate forming [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1258-1265. |

| [10] | Xue⁃guang ZHANG,Ming⁃meng JIA,Chun⁃guo LIU,Guang⁃zhong HE. Trajectory design and FE simulation for profile stretch bending based on incremental control method [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1272-1279. |

| [11] | Zhao⁃wei QU,Zhao⁃tian PAN,Yong⁃heng CHEN,Peng⁃fei TAO,Di SUN. Car⁃following model with improving safety distance based on optimal velocity model [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1092-1099. |

| [12] | GUO Hao-tian,XU Tao,LIANG Xiao,YU Zheng-lei,LIU Huan,MA Long. Optimization on thermal surface with rib turbulator inspired by turbulence of alopias' gill in simplified gas turbine transition piece [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1793-1798. |

| [13] | GONG Ya-feng, WANG Bo, WEI Hai-bin, HE Zi-heng, HE Yu-long, SHEN Yang-fan. Surface subsidence law of double-line shield tunnel based on Peck formula [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1411-1417. |

| [14] | KOU Shu-qing, SHI Zhou. Three-dimensional reconstruction of fracture-split connecting rod joint surface and its strength and stiffness [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1515-1523. |

| [15] | QIU Yan-kai, LI Bao-ren, YANG Gang, CAO Bo, LIU Zhen. Characteristics and mechanism reducing pressure ripple of hydraulic system with novel hydraulic muffler [J]. 吉林大学学报(工学版), 2018, 48(4): 1085-1091. |

|

||