Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (1): 198-208.doi: 10.13229/j.cnki.jdxbgxb.20220268

Numerical simulation of residual stress field of stud girth weld in low temperature environment

Xing WEI( ),Ya-jie GAO,Zhi-rui KANG,Yu-chen LIU,Jun-ming ZHAO,Lin XIAO(

),Ya-jie GAO,Zhi-rui KANG,Yu-chen LIU,Jun-ming ZHAO,Lin XIAO( )

)

- School of Civil Engineering,Southwest Jiaotong University,Chengdu 610031,China

CLC Number:

- TU398.9

| 1 | 卫星, 肖林, 温宗意, 等. 钢混组合结构桥梁2020年度研究进展[J]. 土木与环境工程学报, 2021, 43(): 107-119. |

| Wei Xing, Xiao Lin, Wen Zong-yi, et al. Research progress of steel-concrete composite bridges in 2020[J]. Journal of Civil and Environmental Engineering, 2021, 43(Sup.1): 107-119. | |

| 2 | 王天鹏, 张建仁, 肖宏彬. 低温环境下桥梁用结构钢疲劳寿命估算方法[J]. 自然灾害学报, 2020, 29(1): 64-71. |

| Wang Tian-peng, Zhang Jian-ren, Xiao Hong-bin. Estimation method of fatigue life of bridge struct-ural steel in low temperature environment[J]. Journal of Natural Disasters, 2020, 29(1): 64-71. | |

| 3 | 王元清, 廖小伟, 贾单锋, 等. 钢结构的低温疲劳性能研究进展综述[J]. 建筑钢结构进展, 2018, 20(1): 1-11. |

| Wang Yuan-qing, Liao Xiao-wei, Jia Shan-feng, et al. A review of research progress on low temperature fatigue properties of steel structures [J]. Progress in Building Steel Structures, 2018, 20(1): 1-11. | |

| 4 | 张玉玲. 低温环境下铁路钢桥疲劳断裂性能研究[J]. 中国铁道科学, 2008(1): 22-25. |

| Zhang Yu-ling. Research on fatigue fracture performance of railway steel bridge under low temperature environment[J]. China Railway Science, 2008(1): 22-25. | |

| 5 | 刘昱含. 钢板混凝土组合结构中栓钉焊接残余应力测定与影响分析[D]. 上海:上海交通大学船舶海洋与建筑工程学院, 2019. |

| Liu Yu-han. Determination and influence analysis of stud welding residual stress in steel plate-concrete composite structure[D]. Shanghai: School of Ship, Ocean and Architectural Engineerring, Shanghai Jiaotong University, 2019. | |

| 6 | 焦晋峰, 贾朋朋, 贾玥, 等. 钢管-焊接空心球节点焊接残余应力数值模拟及试验研究[J]. 广西大学学报:自然科学版, 2020, 45(6): 1259-1266. |

| Jiao Jin-feng, Jia Peng-peng, Jia Yue, et al. Numerical simulation and experimental research on welding residual stress of steel pipe-welded hollow sphere joints[J]. Journal of Guangxi University(Natural Science Edition), 2020, 45(6): 1259-1266. | |

| 7 | Barsoum Z, Barsoum I. Residual stress effects on fatigue life of welded structures using LEFM[J]. Engineering Failure Analysis, 2009, 16: 449-467. |

| 8 | Barsoum Zuheir. Residual stress analysis and fatigue assessment of welded steel structures[D]. Stockholm,Sweden: KungligaTekniska Högskolan, 2008. |

| 9 | Obeid O, Alfano G, Bahai H, et al. Numerical simulation of thermal and residual stress fields induced by lined pipe welding[J]. Thermal Science and Engineering Progress, 2018, 5: 1-14. |

| 10 | 廖小伟. 低温环境下桥梁钢材与焊接细节的疲劳性能研究[D]. 北京: 清华大学土木工程学院, 2018. |

| Liao Xiao-wei. Research on fatigue properties of bridge steel and welding details in low temperature environment[D]. Beijing: School of Civil Engineering, Tsinghua University, 2018. | |

| 11 | 卫星, 刘茂坤, 肖林, 等. 斜十字接头三维焊接残余应力的数值模拟[J]. 焊接学报, 2019, 40(5): 48-53,78, 163. |

| Wei Xing, Liu Mao-kun, Xiao Lin, et al. Numerical simulation of three-dimensional welding residual stress of inclined cross joints [J]. Chinese Journal of Welding, 2019, 40(5): 48-53, 78,163. | |

| 12 | 王瑞. 钢箱梁制造焊接过程温度场及应力场的数值分析[D]. 成都: 西南交通大学机械工程学院, 2016. |

| Wang Rui. Numerical analysis of temperature field and stress field during welding of steel box girder[D]. Chengdu: School of Mechanical Engineering, Southwest Jiaotong University, 2016. | |

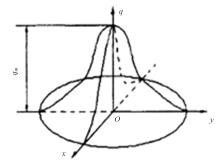

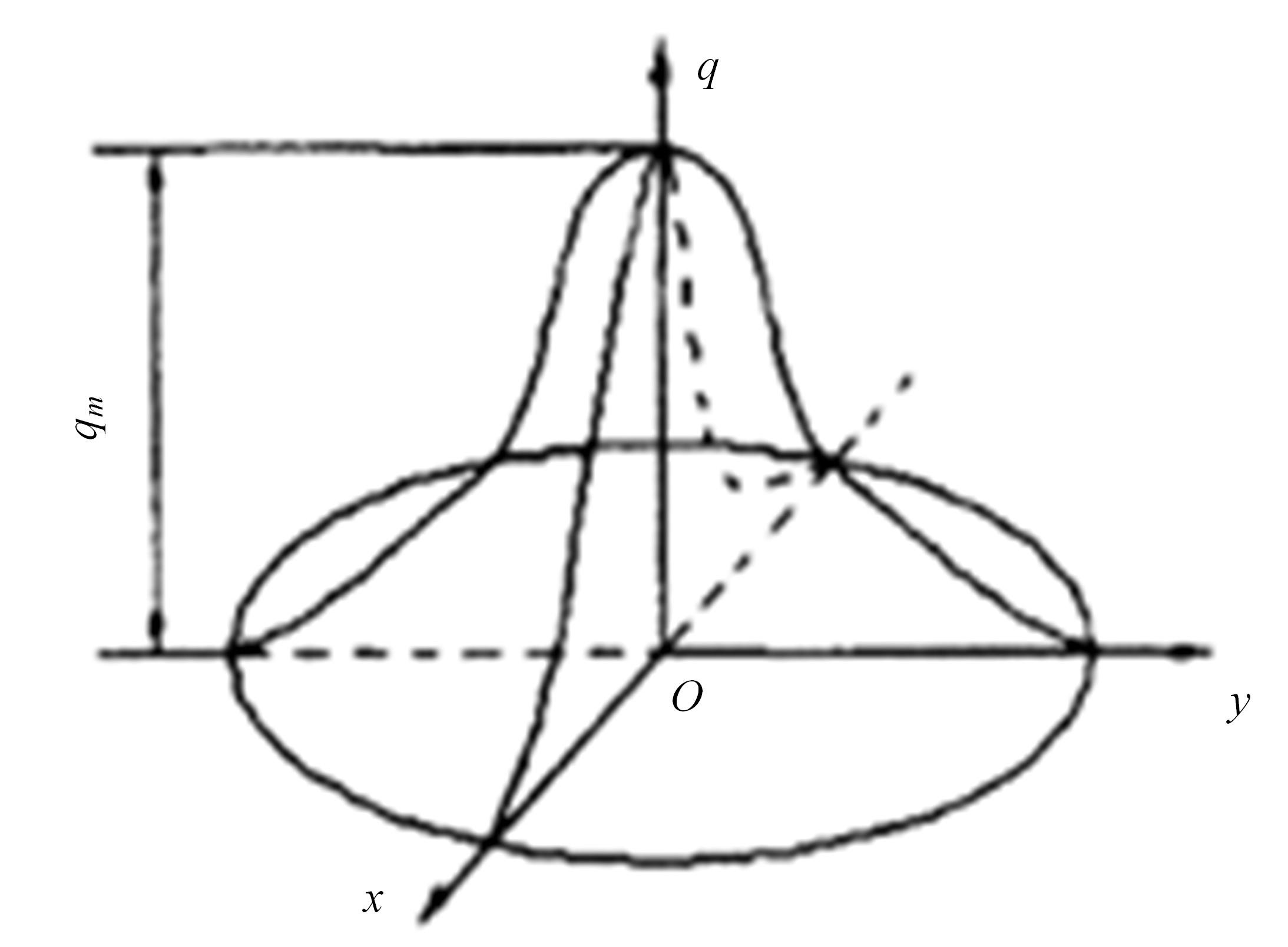

| 13 | Eagar T W, Tsai N S. Temperature fields produced by traveling distributed heat sources[J]. Weld Res Suppl, 1983, 62(12): 346-355. |

| 14 | 贾单锋, 王元清, 崔佳, 等. 桥梁钢Q345qD低温力学性能及冲击韧性试验研究[J]. 钢结构, 2017, 32(5): 41-45. |

| Jia Shan-feng, Wang Yuan-qing, Cui Jia, et al. Experimental study on low temperature mechanical properties and impact toughness of bridge steel Q345qD[J]. Steel Structure, 2017, 32(5): 41-45. |

| [1] | Guan-xu LONG,Xiu-shi ZHANG,Gong-feng XIN,Tao WANG,Gan YANG. Bridge weigh-in-motion combined with machine version [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 188-197. |

| [2] | Guo-jin TAN,Ji OU,Yong-ming AI,Run-chao YANG. Bridge crack image segmentation method based on improved DeepLabv3+ model [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(1): 173-179. |

| [3] | Liang FAN,Ying-ming XU,Yang TAN. Interface slip calculation of prefabricated steel⁃concrete composite beams with clustering studs [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2533-2541. |

| [4] | Xin-dai ZUO,Jin-quan ZHANG,Shang-chuan ZHAO. Fatigue stiffness degradation and life prediction method of in⁃service concrete T⁃beams [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2563-2572. |

| [5] | Zhi ZHENG,Pei YUAN,Xuan-hui JIN,Si-si WEI,Bo GENG. Experimental on composite flexible anti⁃collision fender of bridge pier [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2581-2590. |

| [6] | Ran AN,You-zhi WANG. Shear properties of shear stud connectors under combined tension and shear loading [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2554-2562. |

| [7] | Ya-feng GONG,Shu-zheng WU,Hai-peng BI,Guo-jin TAN. Temperature field and frost heaving analysis of prefabricated box culvert based on field monitoring [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2321-2331. |

| [8] | Jun WANG,Jia-wu LI,Feng WANG,Jiu-peng ZHANG,Xiao-ming HUANG. Wind speed distribution in simplified U⁃shaped valley and its effect on buffeting response of long⁃span suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1658-1668. |

| [9] | Feng WANG,Shuang-rui LIU,Jia-ying WANG,Jia-ling SONG,Jun WANG,Jiu-peng ZHANG,Xiao-ming HUANG. Size and shape effects of wind drag coefficients for porous structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1677-1685. |

| [10] | Yu FENG,Jian-ming HAO,Feng WANF,Jiu-peng ZHANG,Xiao-ming HUANG. Analysis of transient wind⁃induced response of long⁃span bridge under nonstationary wind field [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1638-1649. |

| [11] | Hua WANG,Long-lin WANG,Zi-mo ZHANG,Xin HE. Safety early warning technology of continuous rigid frame bridges based on crack width variation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1650-1657. |

| [12] | Chun-li WU,Shi-ming HUANG,Kui LI,Zheng-wei GU,Xiao-ming HUANG,Bing-tao ZHANG,Run-chao YANG. Analysis of pier action effect under flood based on numerical simulation and statistical analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1612-1620. |

| [13] | Zheng-wei GU,Pan ZHANG,Dong-ye LYU,Chun-li WU,Zhong YANG,Guo-jin TAN,Xiao-ming HUANG. Earthquake⁃induced residual displacement analysis of simply supported beam bridge based on numerical simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1711-1718. |

| [14] | Hui JIANG,Xin LI,Xiao-yu BAI. Review on development of bridge seismic structural systems: from ductility to resilience [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1550-1565. |

| [15] | Guo-jin TAN,Qing-wen KONG,Xin HE,Pan ZHANG,Run-chao YANG,Yang-jun CHAO,Zhong YANG. Bridge scour depth identification based on dynamic characteristics and improved particle swarm optimization algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1592-1600. |

|

||