Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (9): 2581-2590.doi: 10.13229/j.cnki.jdxbgxb.20211227

Previous Articles Next Articles

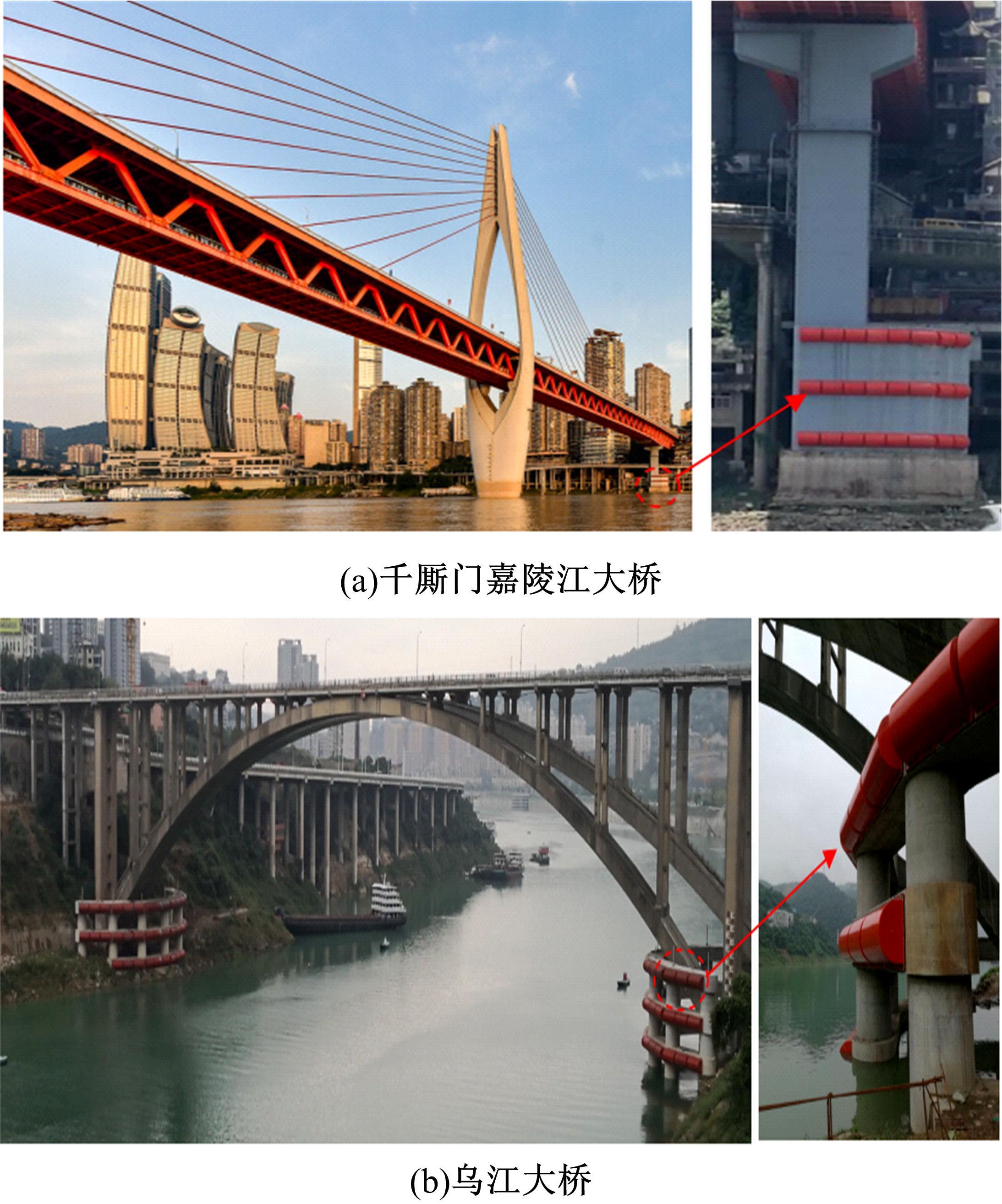

Experimental on composite flexible anti⁃collision fender of bridge pier

Zhi ZHENG1,2( ),Pei YUAN1,Xuan-hui JIN3,Si-si WEI1,Bo GENG1(

),Pei YUAN1,Xuan-hui JIN3,Si-si WEI1,Bo GENG1( )

)

- 1.National Key Laboratory of Structural Dynamics of Bridge Engineering,China Merchants Chongqing Communications Technology Research and Design Institute Co. ,Ltd. ,Chongqing 400067,China

2.School of Civil Engineering,Chongqing University,Chongqing 400045,China

3.China Academy of Building Research Co. ,Ltd. ,Beijing 100029,China

CLC Number:

- U417.1

| 1 | Larsen O D.Ship Collision with Bridges: The Interaction Between Vessel Traffic and Bridge Structures[M]. Switzerland: International Association for Bridge and Structural Engineering, 1993. |

| 2 | .公路桥梁抗撞设计规范 [S]. |

| 3 | 王君杰,耿波. 桥梁船撞概率风险评估与措施[M].中国: 人民交通出版社,2010. |

| 4 | 张锡祥, 王智祥, 巫祖烈, 等. 一种新型FRP桥墩防撞浮箱结构[J].重庆交通大学学报: 自然科学版, 2011, 30(3): 388-393, 510. |

| Zhang Xi-xiang, Wang Zhi-xiang, Wu Zu-lie,et al. A late model FRP floating pontoon protection structue for bridge piers in the ship collison[J]. Journal of Chongqing Jiaotong University (Natural Science), 2011, 30(3): 388-393, 510. | |

| 5 | Fang Hai, Mao Yi-feng, Liu Wei-qing, et al. Manufacturing and evaluation of large-scale composite bumper system for bridge pier protection against ship collision[J]. Composite Structures, 2016(158): 187-198. |

| 6 | 方海, 王健, 祝露, 等. 武汉鹦鹉洲长江大桥中塔墩防船撞装置研究[J]. 桥梁建设, 2020, 50(1): 20-25. |

| Fang Hai, Wang Jian, Zhu Lu,et al.Study of collision protection devices for central pylon pier of Yingwuzhou Changjiang river bridge in Wuhan[J]. Bridge Construction, 2020, 50(1): 20-25. | |

| 7 | Wang Li-li, Yang Li-ming, Huang De-jin, et al. An impact dynamics analysis on a new crashworthy device against ship-bridge collision[J]. International Journal of Impact Engineering, 2008, 35(8): 895-904. |

| 8 | Wang J J, Song Y C, Wang W,et al. Evaluation of flexible floating anti-collision device subjected to ship impact using finite-element method[J]. Ocean Engineering, 2019, 178: 321-330. |

| 9 | Fan Wei, Guo Wei, Sun Yang, et al. Experimental and nu-merical investigations of a novel steel-UHPFRC composite fender for bridge protection in vessel collisions[J]. Ocean Engineering, 2018, 165: 1-21. |

| 10 | 周凌宇,濮星旭, 卫军. 装配式UHPC防船撞耗能装置的性能[J]. 中南大学学报: 自然科学版, 2019, 50(4): 923-930. |

| Zhou Ling-yu, Pu Xing-xu, Wei Jun. Precast UHPC protection system for bridge pier against ship collision[J]. Journal of Central South University(Science and Technology), 2019, 50(4): 923-930. | |

| 11 | 李华永, 周凌宇, 王强, 等. 新型装配式钢-UHPC防船撞装置关键参数及其性能研究[J].中南大学学报:自然科学版, 2021, 52(2): 519-528. |

| Li Hua-yong, Zhou Ling-yu, Wang Qiang, et al. Research on key parameters and performance of new fabricatedsteel-UHPC anti-ship collision device[J].Journal of CentralSouth University(Science and Technology),2021, 52(2): 519-528. | |

| 12 | LSTC. Keyword User's Manual[M]. California: Livermore Software Technology Corporation, 2006. |

| 13 | 郑植, 耿波, 袁佩, 等. 桥墩复合材料防船撞装置新型连 接试验研究[J]. 重庆交通大学学报:自然科学版,2021, 40(5): 66-73. |

| Zheng Zhi, Geng Bo, Yuan Pei, et al. Experimental study on a new connection of composite materials anti-collisiondevice for piers[J]. Journa of Chongqing Jiaotong University (Natural Science), 2021, 40(5): 66-73. | |

| 14 | Fan W, Yuan W C.Numerical simulation and analytical modeling of pile-supported structures subjected to ship collisions including soil-structure interaction[J]. Ocean Engineering, 2014, 91(15): 11-27. |

| 15 | Liu B, Fan W, Guo W,et al. Experimental investigate on and improved FE modeling of axially-loaded circular RC columns under lateral impact loading[J]. Engineering Structures, 2017, 152(1): 619-642. |

| 16 | Xie R, Fan W, Liu B,et al.Dynamic behavior and vulnerability analysis of bridge columns with different cross-sectional shapes under rockfall impacts[J]. Structures,2020, 26:471-486. |

| 17 | Zhu L, Liu W, Fang H, et al. Design and simulate on of innovative foam-filled lattice composite bumper system for bridge protection in ship collisions[J]. Composites Part B: Engineering, 2019, 157: 24-35. |

| 18 | Wang J J, Song Y C, Wang W,et al.Evaluation of composite crashworthy device for pier protection against barge impact[J]. Ocean Engineering,2018, 169: 144-158. |

| [1] | Guo-zhu CHENG,Lin SHENG,Hao ZHAO,Tian-jun FENG. Exclusive phase setting condition of signalized intersection based on risk analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 1962-1969. |

| [2] | Yong-ming HE,Shi-sheng CHEN,Jia FENG,Ya-nan WAN. Superhighway virtual track system based on high precision map [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 2016-2028. |

| [3] | Chun-li WU,Shi-ming HUANG,Kui LI,Zheng-wei GU,Xiao-ming HUANG,Bing-tao ZHANG,Run-chao YANG. Analysis of pier action effect under flood based on numerical simulation and statistical analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1612-1620. |

| [4] | Zheng-wei GU,Pan ZHANG,Dong-ye LYU,Chun-li WU,Zhong YANG,Guo-jin TAN,Xiao-ming HUANG. Earthquake⁃induced residual displacement analysis of simply supported beam bridge based on numerical simulation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1711-1718. |

| [5] | Feng WANG,Shuang-rui LIU,Jia-ying WANG,Jia-ling SONG,Jun WANG,Jiu-peng ZHANG,Xiao-ming HUANG. Size and shape effects of wind drag coefficients for porous structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1677-1685. |

| [6] | Zhi-jia XUE,Zhao-yang WANG,Jiu-peng ZHANG,Chang-gen YAN,Zi-kai XU,Ying-li ZHANG,Xiao-ming Huang,Tao Ma. Toughness analysis and improvement of road structure under action of debris flow [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1773-1781. |

| [7] | Hai-bin WEI,Shuan-ye HAN,Hai-peng BI,Qiong-hui LIU,Zi-peng MA. Intelligent sensing road active ice and snow removal system and experimental technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1411-1417. |

| [8] | Jing-fu JIN,Xin-ju DONG,Zhi-cheng JIA,Kang WANG,Lian-bin HE,Meng ZOU,Ying-chun QI. Optimization of the tread plate-spring structure of flexible metal wheel with plate-spring [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 964-972. |

| [9] | Rong-han YAO,Wen-tao XU,Wei-wei GUO. Drivers' takeover behavior and intention recognition based on factor and long short⁃term memory [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(3): 758-771. |

| [10] | Xue XIAO,Ke-ping LI,Bo PENG,Man-wei CHANG. Integrated lane⁃changing model of decision making and motion planning for autonomous vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(3): 746-757. |

| [11] | Min MA,Da-wei HU,Lan SHU,Zhuang-lin MA. Resilience assessment and recovery strategy on urban rail transit network [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 396-404. |

| [12] | Zhuang-zhuang LIU,You-wei ZHANG,Peng-yu JI,Abshir Ismail Yusuf,Lin LI,Ya-zhen HAO. Study on heat transfer characteristics of electric heating snow melting asphalt pavement [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 523-530. |

| [13] | Jing WANG,Feng WAN,Chun-jiao DONG,Chun-fu SHAO. Modelling on catchment area and attraction intensity of urban rail transit stations [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 439-447. |

| [14] | Xiao-hong LU,Jin-hui QIAO,Yu ZHOU,Chong MA,Guo-chuan SUI,Zhuo SUN. Research progress of temperature field in friction stir welding [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 1-17. |

| [15] | Song FANG,Jian-xiao MA,Gen LI,Ling-hong SHEN,Chu-bo XU. Traffic risk analysis of moving work zone on right lane of city expressway [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1786-1791. |

|