Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (11): 3114-3124.doi: 10.13229/j.cnki.jdxbgxb.20230049

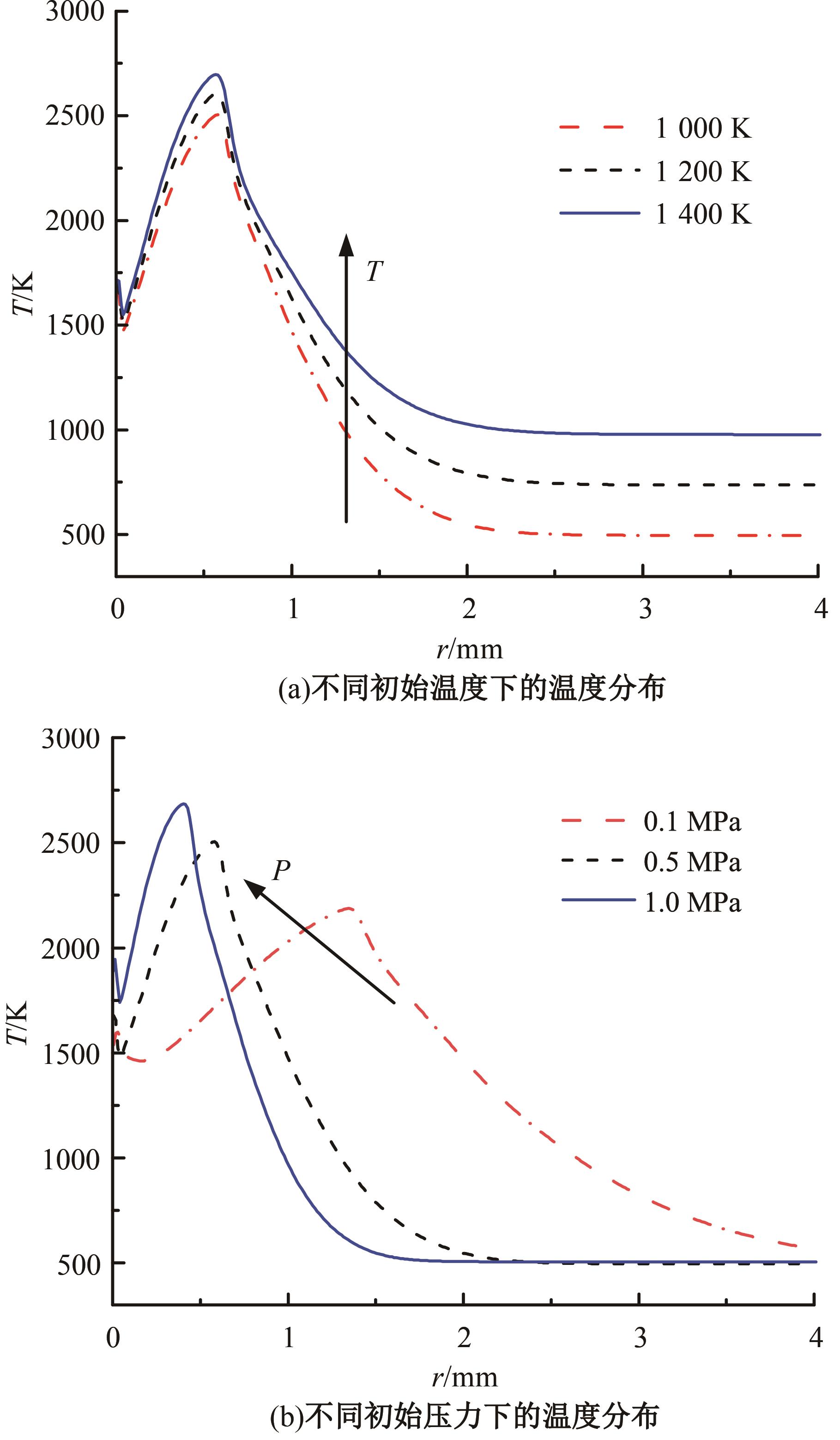

Numerical simulation of evaporation and combustion of MMH gel droplets

Fan ZHANG( ),Ning HAN,Qing DU,Jing-qi BU,Zhi-jun PENG(

),Ning HAN,Qing DU,Jing-qi BU,Zhi-jun PENG( )

)

- State Key Laboratory of Engines,Tianjin University,Tianjin 300072,China

CLC Number:

- V231

| 1 | Rapp D, Zurawski R. Characterization of aluminum/RP-1 gel propellant properties[C]∥ 24th Joint Propulsion Conference, Boston, USA, 1988: 2821. |

| 2 | Haddad A, Natan B, Arieli R. The performance of a boron-loaded gel-fuel ramjet[J]. Progress in Propulsion Physics, 2011, 2: 499-518. |

| 3 | Natan B, Rahimi S. The status of gel propellants in year 2000[J]. International Journal of Energetic Materials and Chemical Propulsion, 2002, 5: 1-6. |

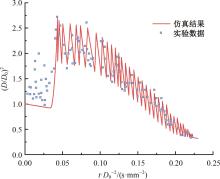

| 4 | 杨大力. 凝胶单液滴蒸发燃烧特性试验研究[D]. 长沙: 国防科学技术大学空天科学学院, 2015. |

| Yang Da-li. Experimental study on evaporative combustion characteristics of gel single droplet[D]. Changsha: School of Aerospace Science, National University of Defense Technology, 2015. | |

| 5 | Solomon Y, Natan B, Cohen Y. Combustion of gel fuels based on organic gellants[J]. Combustion and Flame, 2009, 156(1): 261-268. |

| 6 | Zhou Z F, Yin J, Chen B, et al. Liquid phase model and its coupling interaction with the ambient gas for the droplet heating and evaporation of highly volatile R134a[J]. International Journal of Heat and Mass Transfer, 2021, 166: No.120740. |

| 7 | Shen S, Che Z, Wang T, et al. A model for droplet heating and evaporation of water-in-oil emulsified fuel[J]. Fuel, 2020, 266: No.116710. |

| 8 | Abramzon B, Sirignano W A. Droplet vaporization model for spray combustion calculations[J]. International Journal of Heat and Mass Transfer, 1989, 32(9): 1605-1618. |

| 9 | 何博, 何浩波, 丰松江, 等. 液体火箭有机凝胶喷雾液滴蒸发模型及仿真研究[J]. 物理学报, 2012, 61(14): 440-450. |

| He Bo, He Hao-bo, Feng Song-jiang, et al. Droplet evaporation model and simulation of liquid rocket organogels spray[J]. Acta Physica Sinica, 2012, 61(14): 440-450. | |

| 10 | 张龙. 凝胶单液滴蒸发模型的数值研究[D]. 天津: 天津大学机械工程学院, 2014. |

| Zhang Long. Numerical study of gel single drop evaporation model[D]. Tianjin: School of Mechanical Engineering, Tianjin University, 2014. | |

| 11 | 强洪夫, 张林涛, 陈福振, 等. 基于 SPH 方法的凝胶燃料单滴微爆过程模拟[J]. 含能材料, 2017, 25(5): 372-378. |

| Qiang Hong-fu, Zhang Lin-tao, Chen Fu-zhen, et al. Simulation of single drop microdetonation process of gel fuel based on SPH method[J]. Journal of Energetic Materials, 2017, 25(5): 372-378. | |

| 12 | 何博, 聂万胜, 庄逢辰. 偏二甲肼有机凝胶液滴蒸发燃烧模型展望[J]. 化学学报, 2013, 71: 302-307. |

| He Bo, Nie Wan-sheng, Zhuang Feng-chen. Prospect of evaporative combustion model of undimethylhydrazine organic gel droplet[J]. Acta Chimica Sinica, 2013, 71: 302-307. | |

| 13 | Catoire L, Swihart M T. Thermochemistry of species produced from monomethylhydrazine in propulsion and space-related applications[J]. Journal of Propulsion and Power, 2002, 18(6): 1242-1253. |

| 14 | Catoire L, Chaumeix N, Paillard C. Chemical kinetic model for monomethylhydrazine/nitrogen tetroxide gas phase combustion and hypergolic ignition[J]. Journal of Propulsion and Power, 2004, 20(1): 87-92. |

| 15 | 巴延涛, 侯凌云, 毛晓芳, 等. 甲基肼/四氧化二氮反应化学动力学模型构建及分析[J]. 物理化学学报, 2014, 30(6): 1042-1048. |

| Ba Yan-tao, Hou Ling-yun, Mao Xiao-fang, et al. Construction and analysis of chemical kinetics model of methylhydrazine/nitrous oxide reaction[J]. Acta Physico-Chimica Sinica, 2014, 30(6): 1042-1048. | |

| 16 | Hou L, Fu P, Ba Y. Chemical mechanism of MMH/NTO and simulation in a small liquid rocket engine[J]. Combustion Science and Technology, 2019, 191(12): 2208-2225. |

| 17 | Rao P M, Raghavan V, Velusamy K, et al. Modeling of quasi-steady sodium droplet combustion in convective environment[J]. International Journal of Heat and Mass Transfer, 2012, 55(4): 734-743. |

| 18 | Chen W, Gao R, Sun J, et al. Modeling of an isolated liquid hydrogen droplet evaporation and combustion[J]. Cryogenics, 2018, 96: 151-158. |

| 19 | Higham D J, Higham N J. MATLAB Guide[M]. Philadelphia: Society for Industrial and Applied Mathematics, 2016. |

| 20 | Goodwin D G, Moffat H K, Speth R L. Cantera: an object-oriented software toolkit for chemical kinetics, thermodynamics, and transport processes[J]. Cantera, 2023, 3: No.8137090. |

| 21 | Stephen R T. 燃烧学导论:概念与应用[M]. 姚强,李水清,王宇,译.3版.北京: 清华大学出版社, 2015. |

| 22 | 聂万胜, 何博, 苏凌宇, 等. 有机凝胶偏二甲肼液滴着火燃烧特性及影响因素实验研究[J]. 实验流体力学, 2013, 27(4): 23-31. |

| Nie Wan-sheng, He Bo, Su Ling-yu, et al. Experimental study on combustion characteristics and influencing factors of droplet of undimethylhydrazine organic gel[J]. Experimental Fluid Mechanics, 2013, 27(4): 23-31. | |

| 23 | Kee R J, Miller J A, Jefferson T H. Chemkin: a general-purpose, problem-independent, transportable, fortran chemical kinetics code package[R]. Albuquerque: Sandia National Laboratories, 1980. |

| [1] | Yu FANG,De-qing MEI,Hui-long ZHENG,Xiao-fang YANG,Hai-long WU,Xiao-wu ZHANG. Ground⁃based experiments of measuring flame speed for combustion science rack aboard china space station [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2460-2468. |

| [2] | Gui-sheng CHEN,Guo-yan LUO,Liang-xue LI,Zhen HUANG,Yi LI. Analysis of diesel particulate filter channel flow field and its noise characteristics in plateau environment [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 1892-1901. |

| [3] | Yan ZHANG,Wei LIU,Shu-yong ZHANG,Yi-qiang PEI,Meng-meng DONG,Jing QIN. Optimization on thermal load of combustion chamber on two/four⁃stroke switchable diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 504-514. |

| [4] | Zhong-hua GU,Pei-gang YAN,Pan-hong LIU,Xiang-feng WANG. Applying data driven algorithm to promote prediction accuracy of separation boundary simulation with eddy viscosity model [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2532-2541. |

| [5] | Dong TANG,Yu-bin HAN,Lun HUA,Jin-chong PAN,Sheng LIU. Effect of lubricating oil ash on performance of gasoline particle filter in direct injection gasoline engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(11): 2501-2507. |

| [6] | Wen-bo ZHAO,Yu-jie LI,Jun DENG,Li-guang LI,Zhi-jun WU. Needle motion and its influence on in-nozzle flow and spray jet characteristics [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2234-2243. |

| [7] | Zhi-jun LI,Hao LIU,Li-peng ZHANG,Zhen-guo LI,Yuan-kai SHAO,Zhi-yang LI. Simulation on influence of microstructure of the wall on deep bed filtration of particulate filter [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 422-434. |

| [8] | Jian WANG,Xin XU,Han GU,Duo-jun ZHANG,Sheng-ji LIU. Heating characteristics of DOC based on exhaust thermal management of diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 408-416. |

| [9] | Chang-qing SONG,Wen-miao CHEN,Jun LI,Da-wei QU,Hao CUI. Effects of single and dual ignition on combustion characteristics of natural gas under different equivalence ratios [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1929-1935. |

| [10] | Yi-xiao ZHU,Xiao-min HE,Yi JIN. Effects of radial strut width on flow structure ofsingle⁃cavity trapped vortex combustor [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1936-1944. |

| [11] | Qiao WANG,Wan-chen SUN,Liang GUO,Peng CHENG,Lu-yan FAN,Guo-liang LI. Effects of butanol/diesel blends on combustion and particulate emission characteristics of compression ignition engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1920-1928. |

| [12] | Chang-cheng LIU,Zhong-chang LIU,Jing TIAN,Yun XU,Ze-yu YANG. In⁃cylinder exergy destruction during combustion process ofheavy⁃duty turbocharged diesel engine [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1911-1919. |

| [13] | Xiao-yu HU,Guo-xiang LI,Shu-zhan BAI,Ke SUN,Si-yuan LI. Modified boiling heat transfer model considering roughness and material of heating surface [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1945-1950. |

| [14] | De⁃jun WANG,Zhi⁃chao LYU,Qi⁃ming WANG,Jian⁃rui ZHANG,Jian⁃nan DING. Cylinder pressure identification based on EKF and frequency⁃amplitude modulation Fourier series [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1174-1185. |

| [15] | Peng⁃fei ZANG,Zhe WANG,Yang GAO,Chen⁃le SUN. Investigation of integrated control strategy for stable operation of linear generator/engine system [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 798-804. |

|

||