Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (8): 2156-2166.doi: 10.13229/j.cnki.jdxbgxb.20221339

Previous Articles Next Articles

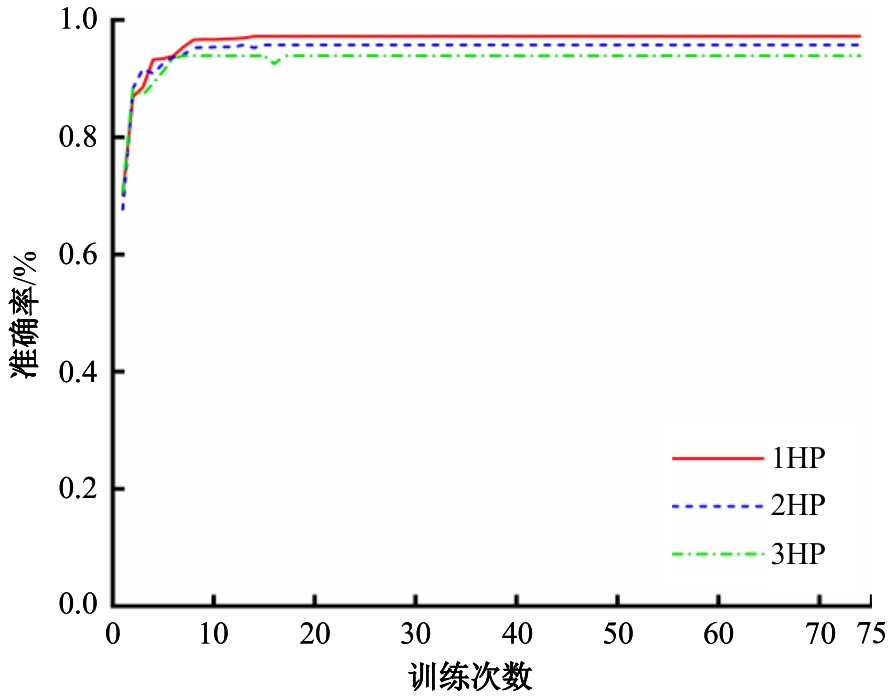

Rolling bearing fault diagnosis based on optimized A-BiLSTM

Ping YU1,2,3( ),Kang ZHAO1,Jie CAO1

),Kang ZHAO1,Jie CAO1

- 1.College of Electrical and Information Engineering,Lanzhou University of Technology,Lanzhou 730050,China

2.Key Laboratory of Gansu Advanced Control for Industrial Processes,Lanzhou University of Technology,Lanzhou 730050,China

3.National Demonstration Center for Experimental Electrical and Control Engineering Education,Lanzhou University of Technology,Lanzhou 730050,China

CLC Number:

- TH133.3

| 1 | 程军圣,于德介,杨宇.基于EMD和SVM的滚动轴承故障诊断方法[J]. 航空动力学报,2006,21(3):575-580. |

| Cheng Jun-sheng, Yu De-jie, Yang Yu. Fault diagnosis of roller bearings based on EMD and SVM[J]. Journal of Aerospace Power, 2006, 21(3): 575-580. | |

| 2 | 李红贤, 韩延, 吴敬涛, 等. 基于ICA包络增强MEMD的滚动轴承故障诊断[J]. 航空动力学报, 2021, 36(2): 405-412. |

| Li Hong-xian, Han Yan, Wu Jing-tao, et al. Rolling bearing fault diagnosis based on MEMD with ICA envelop enhancement[J]. Journal of Aerospace Power, 2021, 36(2): 405-412. | |

| 3 | 武昆, 徐元博, 杨娜. 时变滤波经验模态分解与对称差分解析能量算子在轴承故障诊断中的应用[J]. 噪声与振动控制, 2020, 40(5): 101-107. |

| Wu Kun, Xu Yuan-bo, Yang Na. Application of time-varying filtering empirical mode decomposition and symmetrical difference analytic energy operator in fault diagnosis of bearings.[J]. Noise and Vibration Control, 2020, 40(5):101-107. | |

| 4 | 刘泽锐, 邢济收, 王红军, 等. 基于VMD与快速谱峭度的滚动轴承故障诊断[J]. 电子测量与仪器学报, 2021, 35(2): 73-79. |

| Liu Ze-rui, Xing Ji-shou, Wang Hong-jun, et al. Fault diagnosis of rolling bearings based on VMD and fast spectral kurtosis[J]. Journal of Electronic Measurement and Instrumentation, 2021, 35(2): 73-79. | |

| 5 | Li Z, Wang Y, Ma J. Fault diagnosis of motor bearings based on a convolutional long short-term memory network of bayesian optimization[J]. IEEE Access, 2021, 9: 97546-97556. |

| 6 | 邓飞跃, 吕浩洋, 顾晓辉, 等. 基于轻量化神经网络Shuffle⁃SENet的高速动车组轴箱轴承故障诊断方法[J]. 吉林大学学报: 工学版, 2022, 52(2): 474-482. |

| Deng Fei-yue, Hao-yang Lyu, Gu Xiao-hui, et al. Fault diagnosis of high⁃speed train axle bearing based on a lightweight neural network Shuffle⁃SENet[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 474-482. | |

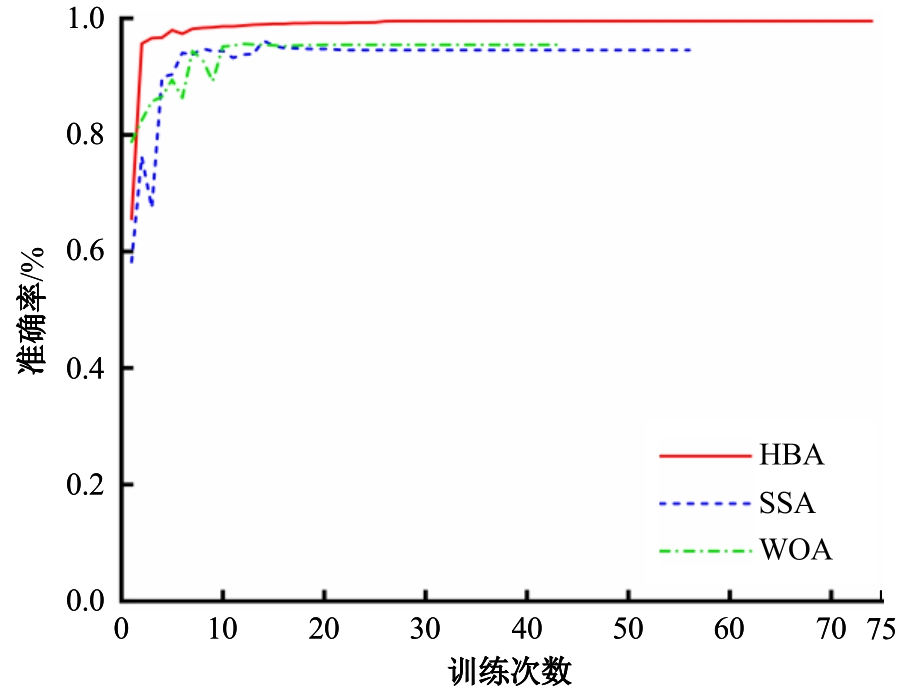

| 7 | Tuerxun W, Chang X, Guo H Y, et al. Fault diagnosis of wind turbines based on a support vector machine optimized by the sparrow search algorithm[J]. IEEE Access, 2021, 9: 69307-69315. |

| 8 | 董绍江, 朱朋, 裴雪武, 等. 基于子领域自适应的变工况下滚动轴承故障诊断[J]. 吉林大学学报: 工学版, 2022, 52(2): 288-295. |

| Dong Shao-jiang, Zhu Peng, Pei Xue-wu, et al. Fault diagnosis of rolling bearing under variable operating conditions based on subdomain adaptation[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 288-295. | |

| 9 | Yin A, Yan Y, Zhang Z, et al. Fault diagnosis of wind turbine gearbox based on the optimized LSTM neural network with cosine loss[J]. Sensors, 2020, 20(8): No.20082339. |

| 10 | Chen X, Zhang B, Gao D. Bearing fault diagnosis base on multi-scale CNN and LSTM model[J]. Journal of Intelligent Manufacturing, 2021, 32: 971-987. |

| 11 | 杨振波, 贾民平. GA-1DLCNN 方法及其在轴承故障诊断中的应用[J]. 东南大学学报: 英文版, 2019, 2019 (1): 36-42. |

| Yang Zhen-bo, Jia Min-ping. GA-1DLCNN method and its application in bearing fault diagnosis[J]. Journal of Southeast University(English Edition), 2019, 2019(1): 36-42. | |

| 12 | 蔡赛男, 宋卫星, 班利明, 等. 基于鲸鱼算法优化 LSSVM 的滚动轴承故障诊断[J]. 控制与决策, 2022, 37(1): 230-236. |

| Cai Sai-nan, Song Wei-xing, Ban Li-ming, et al. Fault diagnosis method of rolling bearing based on LSSVM optimized by whale optimization algorithm[J]. Control and Decision, 2022, 37(1): 230-236. | |

| 13 | Zheng J, Gu M, Pan H, et al. A fault classification method for rolling bearing based on multisynchrosque-ezing transform and WOA-SMM[J]. IEEE Access, 2020, 8: 215355-215364. |

| 14 | Li J, Chen W, Han K, et al. Fault diagnosis of rolling bearing based on GA-VMD and improved WOALSSVM[J]. IEEE Access, 2020, 8: 166753-166767. |

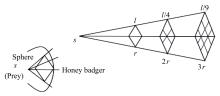

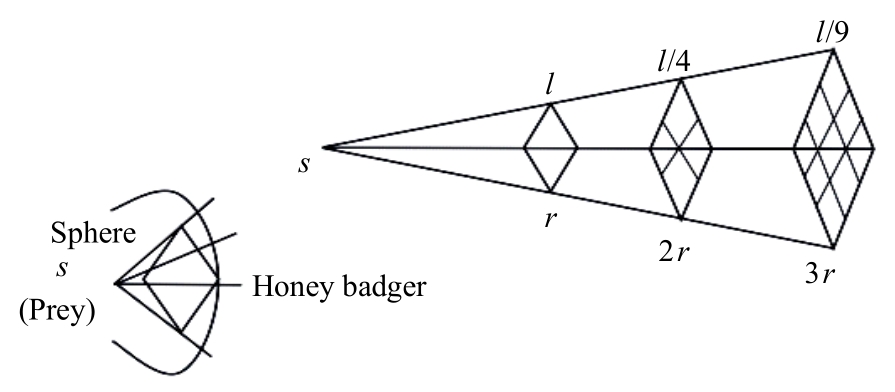

| 15 | Hashim F A, Houssein E H, Hussain K, et al. Honey badger algorithm: new metaheuristic algorithm for solving optimization problems[J]. Mathematics and Computers in Simulation, 2022, 192: 84-110. |

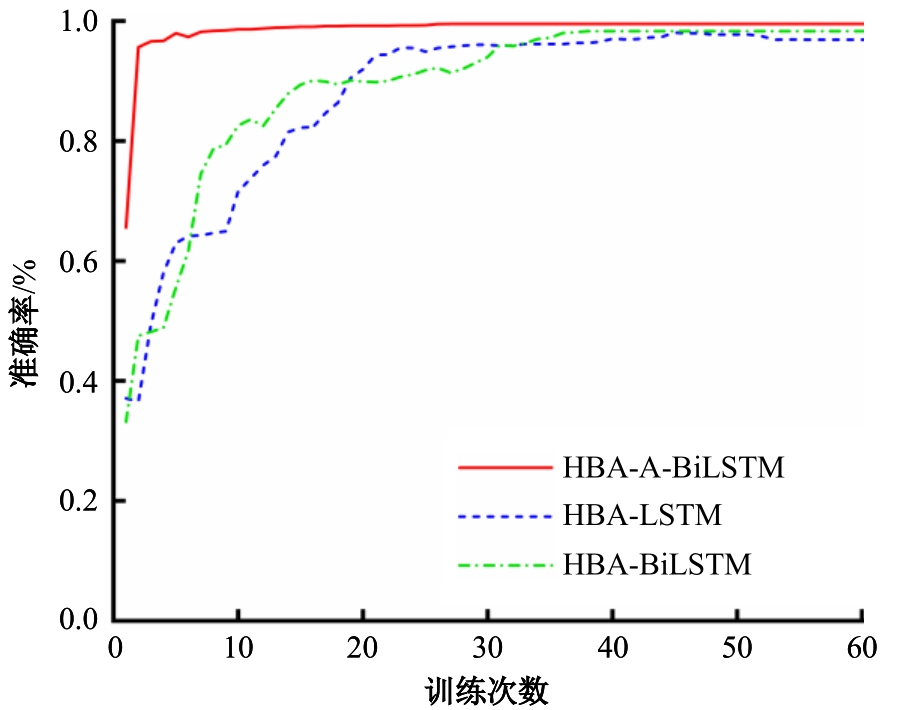

| 16 | Chadha G S, Panambilly A, Schwung A, et al. Bidirectional deep recurrent neural networks for process fault classification[J]. ISA Transactions, 2020, 106: 330-342. |

| 17 | Zhang Z Y, Yin A J, Tan J. Improved DBN method with attention mechanism for the fault diagnosis of gearboxes under varying working condition[J]. Journal of Vibration and Shock, 2021, 40(14): 47-52. |

| 18 | 梁海涛, 王立纲, 王亮, 等. 基于ARCN模型的轴承故障诊断[J]. 航空动力学报, 2021, 36(9): 1793-1803. |

| Liang Hai-tao, Wang Li-gang, Wang Liang, et al. Bearing fault diagnosis based on ARCN model[J]. Journal of Aerospace Power, 2021, 36(9): 1793-1803. |

| [1] | Yun-zuo ZHANG,Yu-xin ZHENG,Cun-yu WU,Tian ZHANG. Accurate lane detection of complex environment based on double feature extraction network [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1894-1902. |

| [2] | Chang-jian WANG,Jiu-ming LIU,Jin-zhou ZHANG,Bin LI. Laser sequence pulse diagnosis method of planetary reducer fault based on high-speed photography technology [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1869-1875. |

| [3] | Ming-hui SUN,Hao XUE,Yu-bo JIN,Wei-dong QU,Gui-he QIN. Video saliency prediction with collective spatio-temporal attention [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1767-1776. |

| [4] | Yun-long GAO,Ming REN,Chuan WU,Wen GAO. An improved anchor-free model based on attention mechanism for ship detection [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1407-1416. |

| [5] | Xiao-xu LI,Wen-juan AN,Ji-jie WU,Zhen LI,Ke ZHANG,Zhan-yu MA. Channel attention bilinear metric network [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 524-532. |

| [6] | Guang HUO,Da-wei LIN,Yuan-ning LIU,Xiao-dong ZHU,Meng YUAN,Di GAI. Lightweight iris segmentation model based on multiscale feature and attention mechanism [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2591-2600. |

| [7] | Xiao-xin GUO,Jia-hui LI,Bao-liang ZHANG. Joint segmentation of optic cup and disc based on high resolution network [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(8): 2350-2357. |

| [8] | Fei-fei TANG,Hai-lian ZHOU,Tian-jun TANG,Hong-zhou ZHU,Yong WEN. Multi⁃step prediction method of landslide displacement based on fusion dynamic and static variables [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1833-1841. |

| [9] | Yan-tao TIAN,Xing HUANG,Hui-qiu LU,Kai-ge WANG,Fu-qiang XU. Multi⁃mode behavior trajectory prediction of surrounding vehicle based on attention and depth interaction [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1474-1480. |

| [10] | Gui-shen YU,Xin CHEN,Zi-tao WU,Yi-xiong CHEN,Guan-chen ZHANG. Analysis of microstructure and mechanical properties of probeless friction stir spot welding joint in AA6061⁃T6 aluminum thin plate [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1338-1344. |

| [11] | Wei LYU,Jia-ze HAN,Jing-hui CHU,Pei-guang JING. Multi⁃modal self⁃attention network for video memorability prediction [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1211-1219. |

| [12] | Dan-tong OUYANG,Rui SUN,Xin-liang TIAN,Li-ming ZHANG,Ping-ping LIU. Approach for generating minimal fault detectability and isolability set in dynamic system based on partial maximum satisfiability problem [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1163-1173. |

| [13] | Yan-tao TIAN,Fu-qiang XU,Kai-ge WANG,Zi-xu HAO. Expected trajectory prediction of vehicle considering surrounding vehicle information [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(3): 674-681. |

| [14] | Dan-tong OU-YANG,Rui SUN,Xin-liang TIAN,Bo-han GAO. Set blocking⁃based approach to sensor selection in uncertain systems [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 547-554. |

| [15] | Sheng JIANG,Peng-lang WANG,Zhi-ji DENG,Yi-ming BIE. Image fusion algorithm for traffic accident rescue based on deep learning [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(12): 3472-3480. |

|