Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (5): 1338-1344.doi: 10.13229/j.cnki.jdxbgxb.20210937

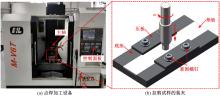

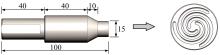

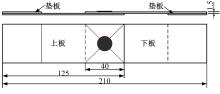

Analysis of microstructure and mechanical properties of probeless friction stir spot welding joint in AA6061⁃T6 aluminum thin plate

Gui-shen YU( ),Xin CHEN(

),Xin CHEN( ),Zi-tao WU,Yi-xiong CHEN,Guan-chen ZHANG

),Zi-tao WU,Yi-xiong CHEN,Guan-chen ZHANG

- State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

CLC Number:

- U465.2

| 1 | Paidar M, Ramalingam V V, Moharrami A, et al. Development and characterization of dissimilar joint between AA2024-T3 and AA6061-T6 by modified friction stir clinching process[J]. Vacuum, 2020, 176: 109298. |

| 2 | 聂昕, 朱伟强, 蔡洪丰, 等.基于焊点载荷的焊接工艺参数优化[J].焊接学报,2018,39(5):114-120, 134. |

| Nie Xin, Zhu Wei-qiang, Cai Hong-feng, et al. Optimization of resistance spot welding parameters based on load of welding spot[J]. Transactions of the China Welding Institution, 2018, 39(5): 114-120, 134. | |

| 3 | Zhang B, Chen X, Pan K, et al. J-integral based correlation evaluation between microstructure and mechanical strength for FSSW joints made of automotive aluminum alloys[J]. Journal of Manufacturing Processes, 2019, 44: 62-71. |

| 4 | Zhang B, Chen X, Pan K, et al. Thermo-mechanical simulation using microstructure-based modeling of friction stir spot welded AA 6061-T6[J]. Journal of Manufacturing Processes, 2019, 37: 71-81. |

| 5 | 陈鑫, 潘凯旋, 张彪, 等. 搅拌摩擦点焊瞬态输入组合热源模型[J]. 吉林大学学报: 工学版, 2020, 50(4): 1316-1323. |

| Chen Xin, Pan Kai-xuan, Zhang Biao, et al. Transient input combined heat source model of friction stir spot welding[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(4): 1316-1323. | |

| 6 | Ikumapayi O M, Akinlabi E T. Recent advances in keyhole defects repairs via refilling friction stir spot welding[J]. Materials Today-Proceedings, 2019, 18: 2201-2208. |

| 7 | Suryanarayanan R, Sridhar V. Effect of process parameters in pinless friction stir spot welding of Al 5754-Al 6061 alloys[J]. Metallography, Microstructure, Analysis, 2020, 9(2): 261-272. |

| 8 | Li W Y, Chu Q, Yang X W, et al. Microstructure and morphology evolution of probeless friction stir spot welded joints of aluminum alloy[J]. Journal of Materials Processing Technology, 2018, 252: 69-80. |

| 9 | Chu Q, Yang X W, Li W Y, et al. Impact of surface state in probeless friction stir spot welding of an Al-Li alloy[J]. Science and Technology of Welding and Joining, 2019, 24(3): 200-208. |

| 10 | Chu X, Yin M, Gao J, et al. Effects of shoulder geometry on microstructures and mechanical properties of probeless friction stir spot welded aluminum 7075-T651 sheets[J]. Metals, 2020, 10(12): 10121605. |

| 11 | Atak A. Impact of pinless stirring tools with different shoulder profile designs on friction stir spot welded joints[J]. Journal of Mechanical Science and Technology, 2020, 34(9): 3735-3743. |

| 12 | Yazdi S R, Beidokhti B, Haddad-Sabzevar M. Pinless tool for FSSW of AA 6061-T6 aluminum alloy[J]. Journal of Materials Processing Technology, 2019, 267: 44-51. |

| 13 | Zhang Z, Yu Y, Zhao H, et al. Interface behavior and impact properties of dissimilar Al/Steel keyhole-free FSSW joints[J]. Metals, 2019, 9(6): 9060691. |

| 14 | 宫文彪, 朱芮, 郄新哲, 等. 6082铝合金超厚板搅拌摩擦焊接头组织与性能[J]. 吉林大学学报: 工学版, 2020, 50(2): 512-519. |

| Gong Wen-biao, Zhu Rui, Xin-zhe Qie, et al. Microstructure and properties of 6082 aluminum alloy ultra-thick plate preparated by friction stir weld[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 512-519. | |

| 15 | Zhou L, Luo L Y, Zhang T P, et al. Effect of rotation speed on microstructure and mechanical properties of refill friction stir spot welded 6061-T6 aluminum alloy[J]. International Journal of Advanced Manufacturing Technology, 2017, 92(9-12): 3425-3433. |

| 16 | 邹阳帆, 王非凡, 李文亚, 等. 不等厚2219铝合金板回填式搅拌摩擦点焊接头组织及性能研究[J]. 机械工程学报, 2020, 56(6): 176-183. |

| Zou Yang-fan, Wang Fei-fan, Li Wen-ya, et al. Study on microstructure and properties of refill friction stir spot welding joints of 2219 aluminum alloy with different thickness[J]. Journal of Mechanical Engineering, 2020, 56(6): 176-183. |

| [1] | Lei CHEN,Yang WANG,Zhi-sheng DONG,Ya-qi SONG. A vehicle agility control strategy based on steering intent [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1257-1263. |

| [2] | Xin CHEN,Guan-chen ZHANG,Kang-ming ZHAO,Jia-ning WANG,Li-fei YANG,De-rong SITU. Influence of lap welds on the lightweight design of welded aluminum structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1282-1288. |

| [3] | Yong ZHANG,Feng-zhao MAO,Shui-chang LIU,Qing-yu WANG,Shen-gong PAN,Guang-sheng ZENG. Optimization on distortion grid of vehicle external flow field based on Laplacian Algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1289-1296. |

| [4] | Shao-hua WANG,Kun CHU,De-hua SHI,Chun-fang YIN,Chun LI. Robust compound coordinated control of HEV based on finite⁃time extended state observation [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1272-1281. |

| [5] | Chao XIE,Qi-cai WANG,Ben-tian YU,Sheng LI,Xiao-xu LIN,Zhi-ming LU. Determination of elastic modulus by atomic force microscopy and microstructure analysis for polyurethane coating film [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1322-1330. |

| [6] | Di WU,Wen-hua GENG,Hong-mei LI,Da-qian SUN. Electron backscattered diffraction analysis on interface of aluminum/steel joints produced by plasma arc welding⁃brazing [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1331-1337. |

| [7] | Xiao-bo CHEN,Ling CHEN. Variational Bayesian cooperative target tracking with unknown localization noise statistics [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1030-1039. |

| [8] | Rui ZHAO,Yun LI,Hong-yu HU,Zhen-hai GAO. Vehicle collision warning method at intersection based on V2I communication [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1019-1029. |

| [9] | Hong-bo YANG,Wen-ku SHI,Zhi-yong CHEN,Nian-cheng GUO,Yan-yan ZHAO. Multi⁃objective optimization of macro parameters of helical gear based on NSGA⁃Ⅱ [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(4): 1007-1018. |

| [10] | Ke HE,Hai-tao DING,Nan XU,Kong-hui GUO. Enhanced localization system based on camera and lane markings [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(3): 663-673. |

| [11] | Bing ZHU,Tian-xin FAN,Jian ZHAO,Pei-xing ZHANG,Yu-hang SUN. Accelerate test method of automated driving system based on hazardous boundary search [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(3): 704-712. |

| [12] | Yan-tao TIAN,Yan-shi JI,Huan CHANG,Bo XIE. Deep reinforcement learning augmented decision⁃making model for intelligent driving vehicles [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(3): 682-692. |

| [13] | Jian ZHANG,Jin-bo LIU,Yuan GAO,Meng-ke LIU,Zhen-hai GAO,Bin YANG. Localization algorithm of vehicular sensor based on multi⁃mode interaction [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(3): 772-780. |

| [14] | Ke HE,Hai-tao DING,Xuan-qi LAI,Nan XU,Kong-hui GUO. Wheel odometry error prediction model based on transformer [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(3): 653-662. |

| [15] | Yan-ran LIU,Qing-yu MENG,Hong-yan GUO,Jia-lin LI. Vehicle trajectory prediction combined with high definition map in graph attention mode [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(3): 792-801. |

|

||