Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (8): 2167-2173.doi: 10.13229/j.cnki.jdxbgxb.20221332

Previous Articles Next Articles

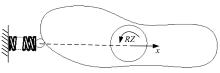

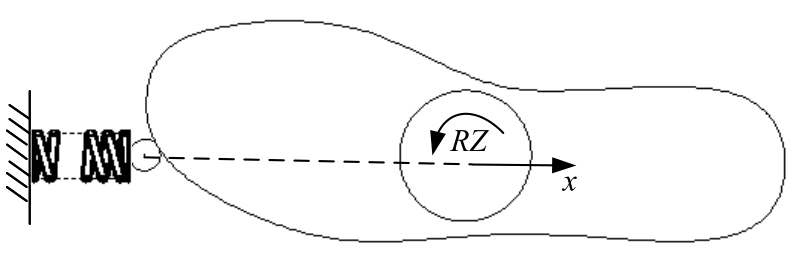

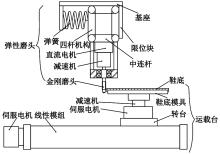

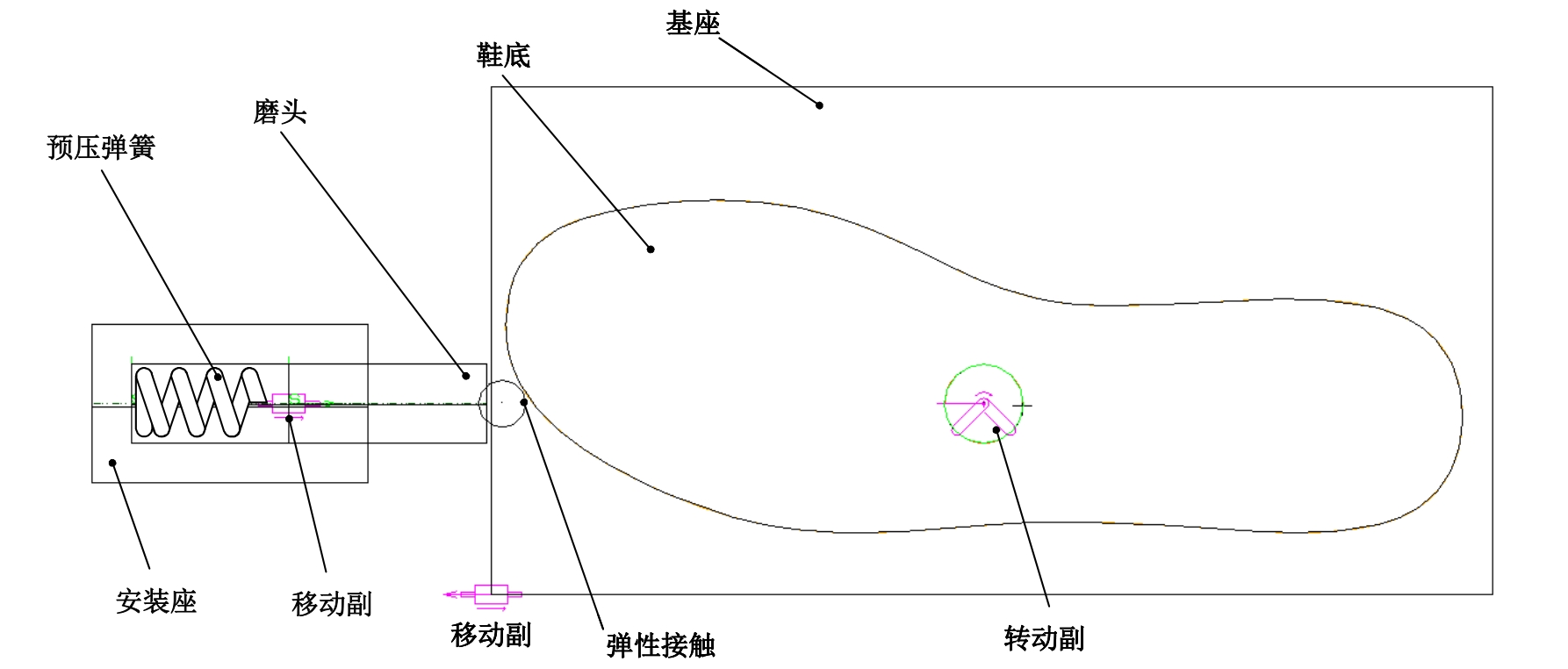

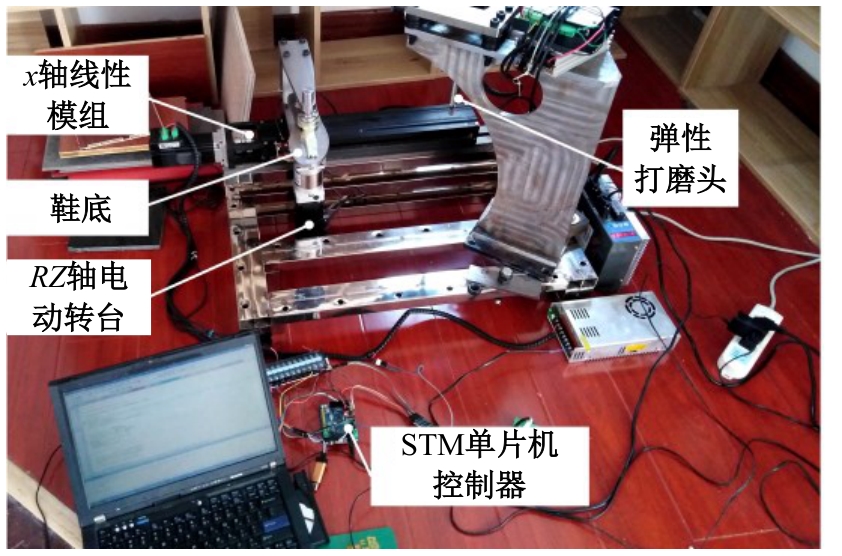

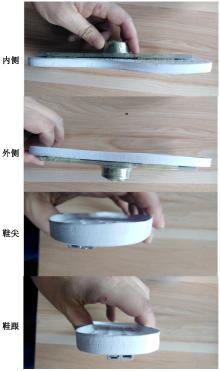

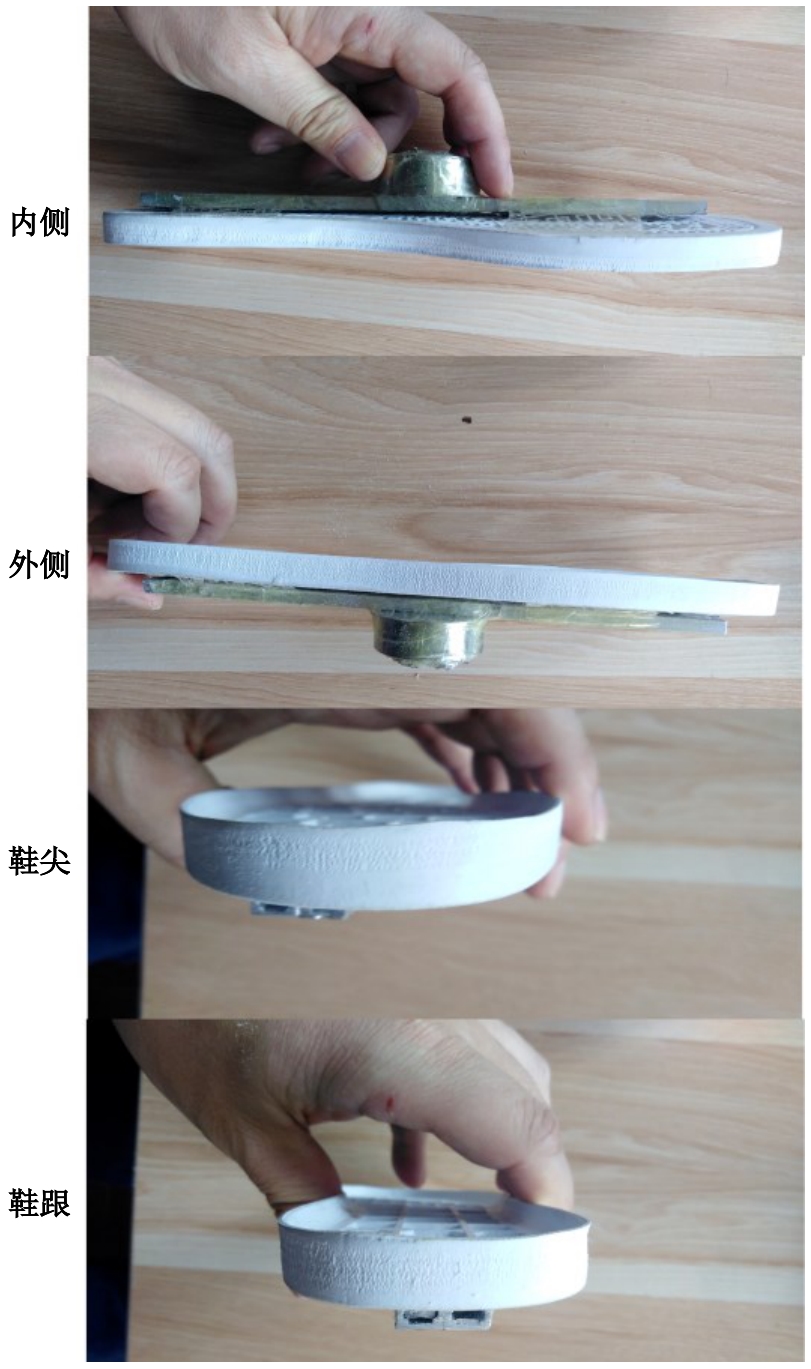

Simulation and experiment of elastic roughing for rubber shoe

- College of Engineering and Design,Hunan Normal University,Changsha 410081,China

CLC Number:

- TP242.3

| 1 | 李恒, 沈辉, 吕明明, 等. 全自动鞋底磨边机研制[J]. 机械制造与自动化, 2013, 42(3): 175-177. |

| Li Heng, Shen Hui, Ming-ming Lyu, et al. Development of full-automatic sole edge grinding machine[J]. Machine Building & Automation, 2013, 42(3): 175-177. | |

| 2 | Zhao L X, Zhang J, Gao L M. Path optimization for uniform removal pre-polishing of optical glass with industrial robots[J]. Optical Engineering, 2022, 61(4):045104. |

| 3 | Zhang C, Tang Z, Li K L, et al. A polishing robot force control system based on time series data in industrial internet of things[J]. Acm Transactions on Internet Technology, 2021, 21(2): 1-22. |

| 4 | 赵扬, 赵继, 张雷, 等. 基于逆向工程的机器人磨削叶片[J]. 吉林大学学报: 工学版, 2009, 39(5): 1176-1180. |

| Zhao Yang, Zhao Ji, Zhang Lei, et al. Robotic blade grinding based on reverse engineering[J]. Journal of Jilin University (Engieering and Technology Edition), 2009, 39(5): 1176-1180. | |

| 5 | 张立彬, 周邦达, 沈遥, 等. 基于工业机器人的鞋帮打磨系统设计[J]. 高技术通讯, 2020, 30(8): 822-830. |

| Zhang Li-bin, Zhou Bang-da, Shen Yao, et al. Design of upper grinding system based on industrial robot[J]. High Technology Letters, 2020, 30(8): 822-830. | |

| 6 | Kim M G, Kim J, Chung S Y, et al. Robot-based automation for upper and sole manufacturing in shoe production[J]. Machines, 2022, 10(4): 1004255. |

| 7 | . 普通运动鞋 [S]. |

| 8 | Luh Y P, Huang L C, Lu H J, et al. A smart manufacturing solution for multi-axis dispenser motion planning in mixed production of shoe soles[J]. International Journal of Precision Engineering and Manufacturing-Green Technology, 2020, 7: 769-779. |

| 9 | 武传宇, 贺磊盈, 李秦川, 等. 鞋底曲面数据提取与喷胶轨迹的自动生成方法[J]. 机械工程学报, 2008, 44(8): 85-89. |

| Wu Chuan-yu, He Lei-ying, Li Qin-chuan, et al. Method for extraction of information of shoe upper and for automatic generation of spraying trajectory[J]. Chinese Journal of Mechanical Engineering, 2008, 44(8): 85-89. | |

| 10 | Wang A G, Shen W P, Wu C Y. Research on a new extraction method of laser light stripes center based on soles information scanned[J]. Journal of Mechanical & Electrical Engineering, 2010, 27(2): 21-23. |

| 11 | 赵国如, 任露泉, 田丽梅, 等. 利用逆向制造系统集成技术开发仿生防粘鞋底[J]. 吉林大学学报: 工学版, 2005, 35(6): 87-91. |

| Zhao Guo-ru, Ren Lu-quan, Tian Li-mei, et al. Exploiting biomimetic anti-adhesive shoe soles using reverse manufacturing system integration technology[J]. Journal of Jilin University (Engieering and Technology Edition), 2005, 35(6): 87-91. | |

| 12 | 袁海兵. 一种自适应鞋底打磨机构[P].中国专利:CN201821020354.2, 2019-05-24. |

| 13 | Pedrocchi N, Villagrossi E, Cenati C, et al. Design of fuzzy logic controller of industrial robot for roughing the uppers of fashion shoes[J]. The International Journal of Advanced Manufacturing Technology. 2015, 77: 939-953. |

| 14 | Corporation MSC. ADAMS / Solver online help version[EB /OL]. [2022-10-13]. |

| [1] | Chen WANG,Te LUO,Qian-qian HUI,Zhong-hao WANG,Fang-fang WANG. Design and verification of electromechanical system for docking and locking of modular flying vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2130-2140. |

| [2] | Yang LIU,Tao JIANG. Interference calculation model of Hooke joint of 6-DOF platform considering installation angle [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1519-1527. |

| [3] | Xiao-dan TAN,Yong-peng WANG,Robert Hall,Tian-shuang XU,Qing-xue HUANG. Haul truck dump body optimization for autonomous shovel loading [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1227-1236. |

| [4] | Wei SUN,Jun YANG. Finite element modeling and vibration reduction analysis of cylindrical shell structures with equal⁃angle attachment of piezoelectric shunt patches [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 365-374. |

| [5] | Bin HU,Yi-quan CAI,Xin LUO,Zi-bin MAO,Jun-wei LI,Meng-yu GUO,Jian WANG. Theory and experiment of high⁃speed seed filling in limited gear⁃shaped side space based on seeds group stress [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(2): 574-588. |

| [6] | Yang LIU. Calculation method of anti-backward-tilting buffer force of luffing jib tower crane [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(10): 2785-2794. |

| [7] | Yang ZHAO,Yang XIAO,Hao SUN,Wen-hao HUO,Song FENG,Yong LIAO. Numerical simulation of micro pitting damage characteristics of lubricated contact gears based on contour integral [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 799-810. |

| [8] | Wei ZHENG,Jian-jun SUN,Chen-bo MA,Qiu-ping YU,Yu-yan ZHANG,Tao NIU. Research status and prospect of automobile wheel hub machining fixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 25-36. |

| [9] | Wei CHEN,Yu-long LEI,Xing-zhong LI,Yao FU,Jian-long HU,Li-guo HOU. Calculation of adhesive wear of involute cylindrical spur gear under low⁃speed conditions [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1628-1634. |

| [10] | Zhen GUO,Hong-ying YU,Zhong-xin HUA,Di ZHAO. Kinematic analysis and simulation of folding process for rigid origami mechanisms [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 66-76. |

| [11] | ZHU Wei,WANG Chuan-wei,GU Kai-rong,SHEN Hui-ping,XU Ke,WANG Yuan. Stiffness and dynamics analysis of a new type of tensegrity parallel mechanism [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1777-1786. |

|