Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (4): 1232-1240.doi: 10.13229/j.cnki.jdxbgxb.20230673

Previous Articles Next Articles

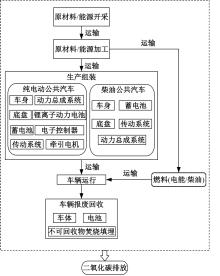

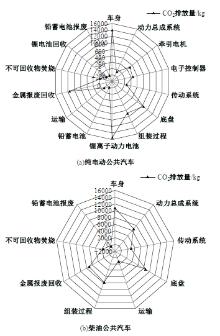

Carbon emissions calculation for urban buses throughout lifecycles

Wen-hui ZHANG( ),Bo FU,Ge ZHOU,Xiao-tian QIAO

),Bo FU,Ge ZHOU,Xiao-tian QIAO

- School of Civil Engineering and Transportation,Northeast Forestry University,Harbin 150040,China

CLC Number:

- U491

| [1] | 肖红, 邓梓浩, 任艳娟, 等. 城市交通运输碳排放预测模型及碳减排策略[J]. 重庆交通大学学报: 自然科学版, 2023, 42(9): 85-92, 98. |

| Xiao Hong, Deng Zi-hao, Ren Yan-juan, et al. Urban transportation carbon emission prediction model strategies[J]. Journal of Chongqing Jiaotong University (Natural Science), 2023, 42(9): 85-92, 98. | |

| [2] | Bieker G. A global comparison of the life-cycle greenhouse gas emissions of combustion engine and electric passenger cars[J]. Washington D.C.: Communications, 2021, 49(30): 847129-102. |

| [3] | Wong E Y C, Ho D C K, So S, et al. Life cycle assessment of electric vehicles and hydrogen fuel cell vehicles using the greet model—a comparative study[J]. Sustainability, 2021, 13(9): 4872. |

| [4] | 王雪然, 刘文峰, 张龙文, 等. 基于能源链的纯电动公交车全生命周期CO2减排效果研究[J]. 交通运输系统工程与信息, 2019, 19(1): 19-25. |

| Wang Xue-ran, Liu Wen-feng, Zhang Long-wen, et al. CO2 emission reduction effect of electric bus based on energy chain in life cycle[J]. Journal of Transportation Systems Engineering and Information Technology,2019(1): 19-25. | |

| [5] | 宋大凤, 吴西涛, 曾小华, 等. 基于理论油耗模型的轻混重卡全生命周期成本分析[J]. 吉林大学学报: 工学版, 2018, 48(5): 1313-1323. |

| Song Da-feng, Wu Xi-tao, Zeng Xiao-hua, et al. Life cycle cost analysis of mild hybrid heavy truck based on theoretical fuel consumption mode[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(5): 1313-1323. | |

| [6] | 王童, 杜轶群, 陈轶嵩, 等. 基于结构轻量化的城市客车车身生命周期评价[J]. 汽车工程, 2022, 44(5):778-788. |

| Wang Tong, Du Yi-qun, Chen Yi-song, et al. Life cycle assessment of city bus body based on structural lightweighting[J]. Automotive Engineering, 2022(5): 778-788. | |

| [7] | 田成诗, 张诗雅. 中国行业供应链碳足迹的来源分解分析——基于投入产出的生命周期评价模型[J]. 环境经济研究, 2019, 4(2): 58-75. |

| Tian Cheng-shi, Zhang Shi-ya. Source decomposition analysis of carbon footprint in China's industry supply chain: based on IO-LCA model[J]. Journal of Environmental Economics, 2019, 4(2): 58-75. | |

| [8] | Harris A, Soban D, Smyth B M, et al. Assessing life cycle impacts and the risk and uncertainty of alternative bus technologies[J]. Renewable and Sustainable Energy Reviews, 2018, 97: 569-579. |

| [9] | Chang C C, Liao Y T, Chang Y W. Life cycle assessment of alternative energy types-including hydrogen-for public city buses in Taiwan[J]. International Journal of Hydrogen Energy, 2019, 44(33): 18472-18482. |

| [10] | Ferrao P, Nhambiu J. A comparison between conventional LCA and hybrid EIO-LCA: analyzing crystal giftware contribution to global warming potential[M]∥Handbook of Input-Output Economics in Industrial Ecology,Dordrecht: Springer Netherlands, 2009: 219-230. |

| [11] | 余大立, 张洪申. 纯电动与柴油货车全生命周期能耗及排放分析[J]. 环境科学学报, 2019, 39(6): 2043-2052. |

| Yu Da-li, Zhang Hong-shen, The life cycle analysis of energy consumption and emission of pure electric van and diesel van[J]. Acta Scientiae Circumstantiae, 2019(6): 2043-2052. | |

| [12] | 丁舟波, 李彬, 牛继高, 等. 电动汽车燃料生命周期评价研究[J]. 森林工程, 2017, 33(6): 56-59, 66. |

| Ding Zhou-bo, Li Bin, Niu Ji-gao, et al. Research on life cycle assessment of electric vehicle fuel[J]. Forest Engineering, 2017, 33(6): 56-59, 66. | |

| [13] | 施羽, 张华, 于智涵. 电动汽车全生命周期节能减排效益分析及环境影响评价[J]. 资源与产业, 2021,23(2): 100-109. |

| Shi Yu, Zhang Hua, Yu Zhi-han. Energy-saving benefits and environment impacts of electric vehicles lifecycle[J]. Resources & Industries, 2021(2): 100-109. | |

| [14] | 李娟, 杨沿平, 陈轶嵩. 铝合金与铸铁缸盖的生命周期评价对比分析[J]. 环境工程学报, 2015, 9(11):5642-5648. |

| Li Juan, Yang Yan-ping, Chen Yi-song. Comparative analysis on life cycle assessment between aluminum alloy and cast iron cylinder cover[J]. Chinese Journal of Environmental Engineering, 2015(11): 5642-5648. | |

| [15] | 张雷, 刘志峰, 王进京. 电动与内燃机汽车的动力系统生命周期环境影响对比分析[J]. 环境科学学报,2013, 33(3): 931-940. |

| Zhang Lei, Liu Zhi-feng, Wang Jin-jing. Comparative analysis of life cycle environmental impact between power system of electric and internal combustion engine vehicles[J]. Acta Scientiae Circumstantiae. 2013(3): 931-940. | |

| [16] | 程冬茹. 汽柴油全生命周期碳排放计算[D]. 北京: 中国石油大学化学工程与环境学院, 2016. |

| Cheng Dong-ru. Carbon emissions calculation of gasoline and diesel fuel based on life cycle assessment[D]. Beijing: College of Chemical Engineering and Environment, China University of Petroleum, 2016. | |

| [17] | 欧训民, 张希良. 中国终端能源的全生命周期化石能耗及碳强度分析[J]. 中国软科学, 2009(): 208-214. |

| Xun-min Ou, Zhang Xi-liang. Fossil energy consumption and GHG emissions of final energy by LCA in China[J]. China Soft Science,2009(Sup.2): 208-214. | |

| [18] | Ou X M, Yan X Y, Zhang X L. Life-cycle energy consumption and greenhouse gas emissions for electricity generation and supply in China[J]. Applied Energy, 2011, 88(1): 289-297. |

| [19] | 井晓燕. 天然气净化系统能耗分析及其节能优化研究[D]. 西安: 西安石油大学化学化工学院, 2019. |

| Jing Xiao-yan. Research on energy consumption analysis and energy saving optimization of natural gas purification system[D]. Xi´an: College of Chemistry and Chemical Engineering, Xi´an Shiyou University,2019. |

| [1] | Hui-zhao TU,Chang LU,Miao-jia LU,Hao LI. Risk factors for autonomous vehicle road testing based on risk-avoiding disengagement [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1935-1943. |

| [2] | Zhao-zheng HU,Xun-pei SUN,Jia-nan ZHANG,Ge HUANG,Yu-ting LIU. Vehicle-infrastructure-map cooperative localization method based on spatial-temporal graph model [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1246-1257. |

| [3] | Qing-jin XU,Rui FU,Ying-shi GUO,Fu-wei WU. Roadside prediction method for truck rollover on the curve [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1302-1310. |

| [4] | Can-can SONG,Di-fei JING,Jun-feng XIE,Ke-xin KANG. Analysis on driving behaviors on flat curved sections of highways with advertising signs [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(5): 1345-1354. |

| [5] | Jin LI,Yu-tong SUN,Xiao-zhong WEI,Yu-ling JIAO. Design of bus priority signal considering flexible lane setting [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 448-456. |

| [6] | Wen-yong LI,Cong-ruo MA,Qing-wei HU,Cheng-kun LIU,Guan LIAN,Guo-bin GU,Dan ZHOU. Bus speed guidance model based on station capacity limit and section green wave control [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(11): 3088-3103. |

| [7] | SONG Da-feng, WU Xi-tao, ZENG Xiao-hua, YANG Nan-nan, LI Wen-yuan. Life cycle cost analysis of mild hybrid heavy truck based on theoretical fuel consumption model [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1313-1323. |

| [8] | XU Hong-feng, GAO Shuang-shuang, ZHENG Qi-ming, ZHANG Kun. Hybrid dynamic lane operation at signalized intersection [J]. 吉林大学学报(工学版), 2018, 48(2): 430-439. |

| [9] | WANG Hai-wei, WEN Hui-ying, LIU Min. Experimental evaluation of nighttime driver's physiological characteristics in driving simulator [J]. 吉林大学学报(工学版), 2017, 47(2): 420-428. |

| [10] | JIANG Gui-yan, LIU Bin, SUI Xiao-yan, MA Ming-fang. Real time information collection of passenger flow in public transportation based on bus IC card charging system [J]. 吉林大学学报(工学版), 2016, 46(4): 1076-1082. |

| [11] | LI Shi-wu, XU Yi, SUN Wen-cai, WANG Lin-hong, GUO Meng-zhu, CHAI Meng. Pupil diameter based construction conflict self-feedback discrimination method [J]. 吉林大学学报(工学版), 2016, 46(2): 418-425. |

| [12] | ZHAO Shu-zhi, LIANG Shi-dong, MA Ming-hui, LIU Hua-sheng, ZHU Yong-gang. Real-time queue length estimation at signalized intersection [J]. 吉林大学学报(工学版), 2016, 46(1): 85-91. |

| [13] | ZHU Jin-cheng, XIAO Feng, SHUAI Bin, LIU Xiao-bo. Impact and feasibility of charging taxis in pricing zone [J]. 吉林大学学报(工学版), 2015, 45(1): 89-96. |

| [14] | ZHAO Shu-zhi, TIAN Qing-fei, CAO Yang. Transit efficiency network design model based on the restriction of station capacity [J]. 吉林大学学报(工学版), 2011, 41(增刊1): 81-84. |

| [15] | HU Hong-yu, WANG Qing-nian, QU Zhao-wei, LI Zhi-hui. Spatial pattern recognition and abnormal traffic behavior detection of moving object [J]. 吉林大学学报(工学版), 2011, 41(6): 1598-1602. |

|