Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (8): 2619-2629.doi: 10.13229/j.cnki.jdxbgxb.20231193

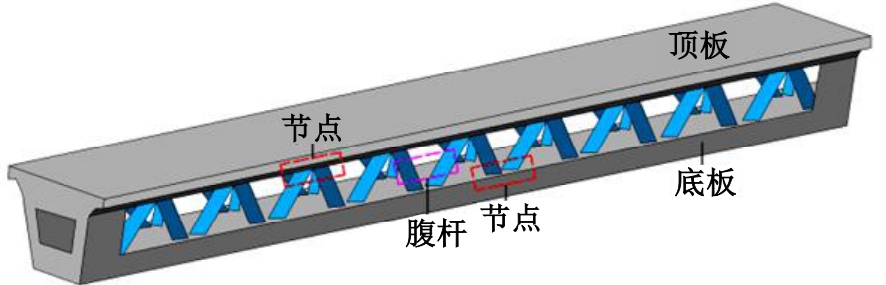

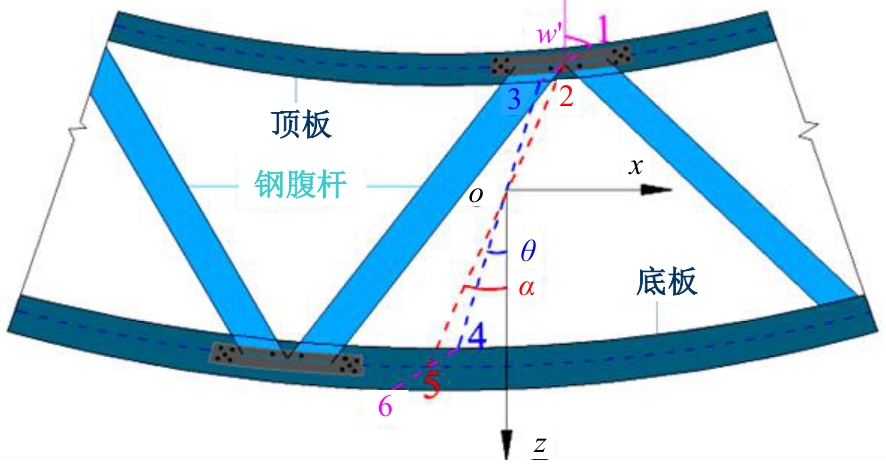

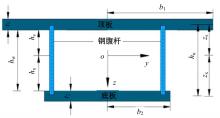

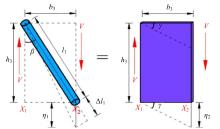

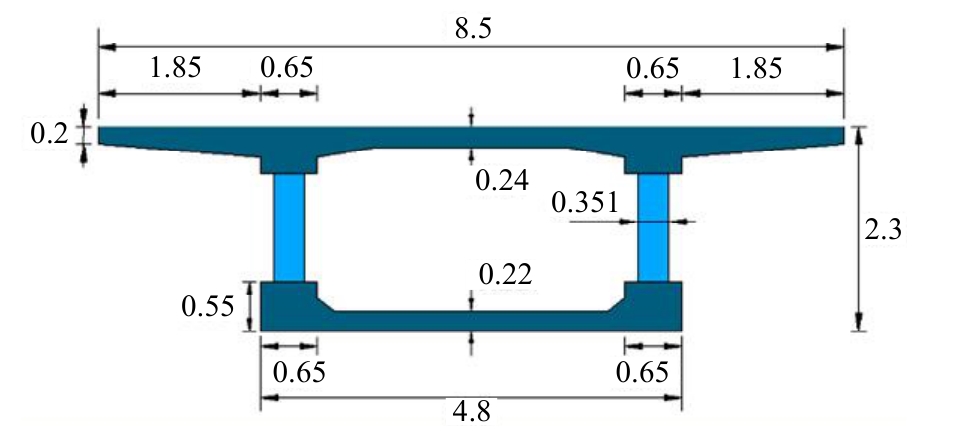

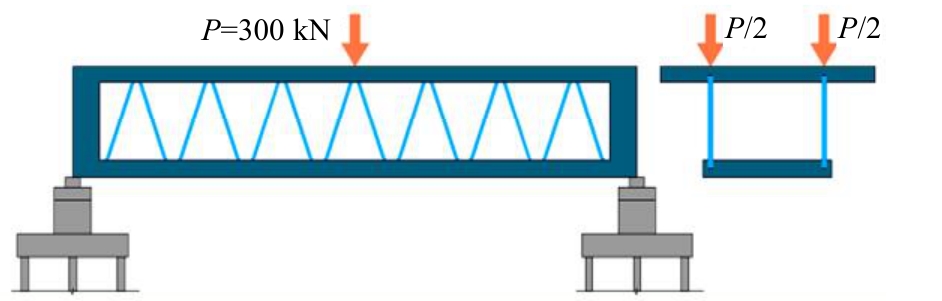

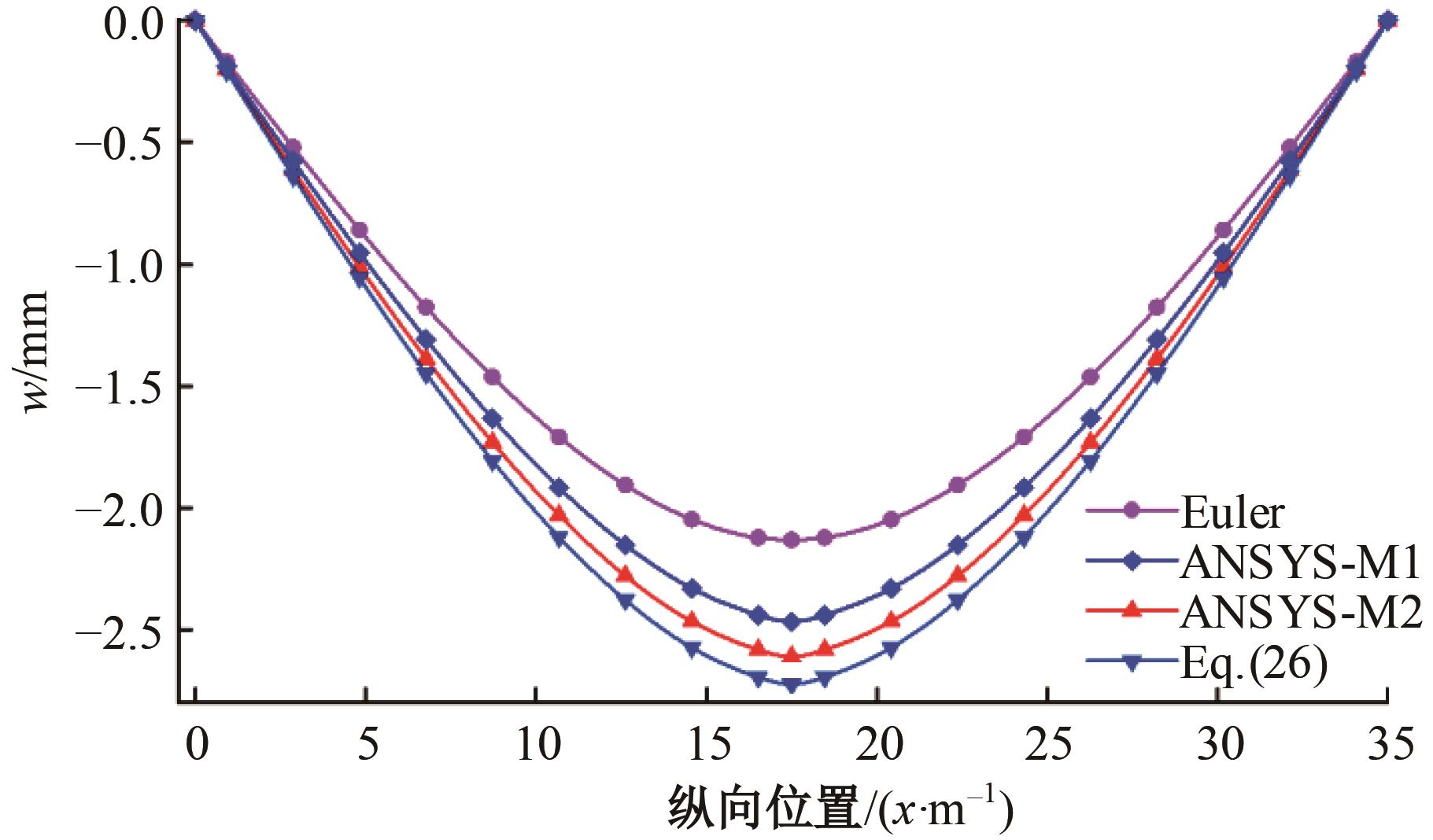

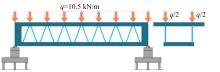

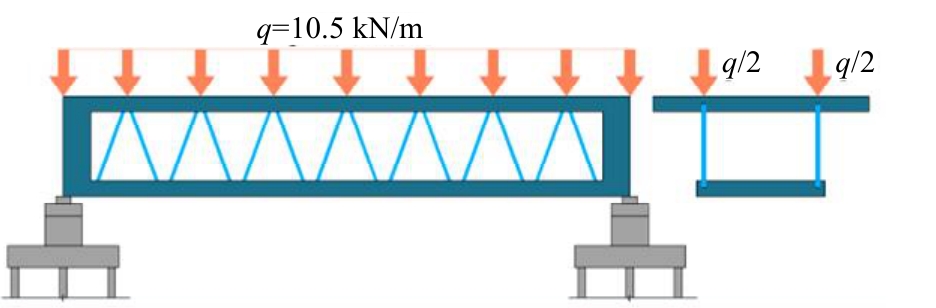

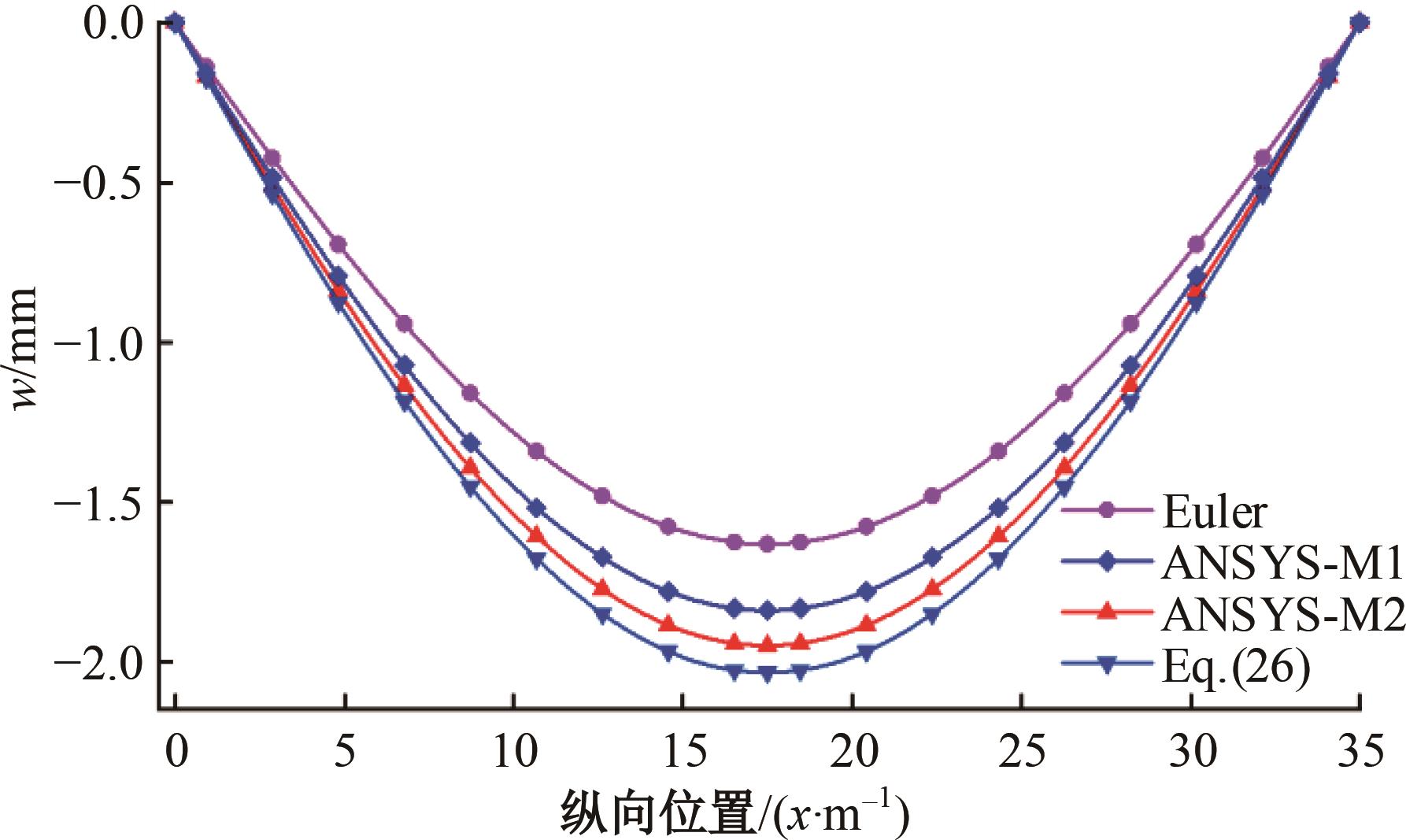

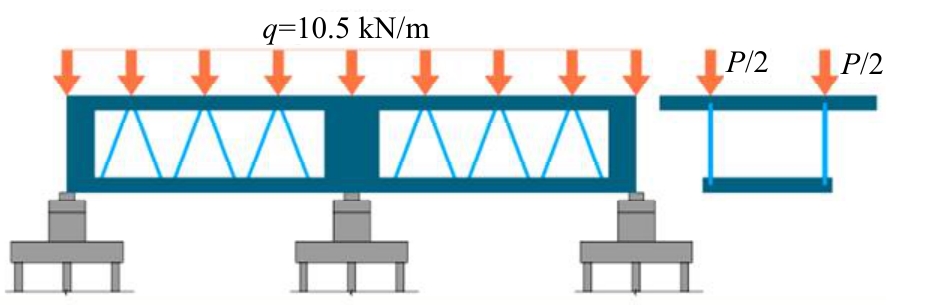

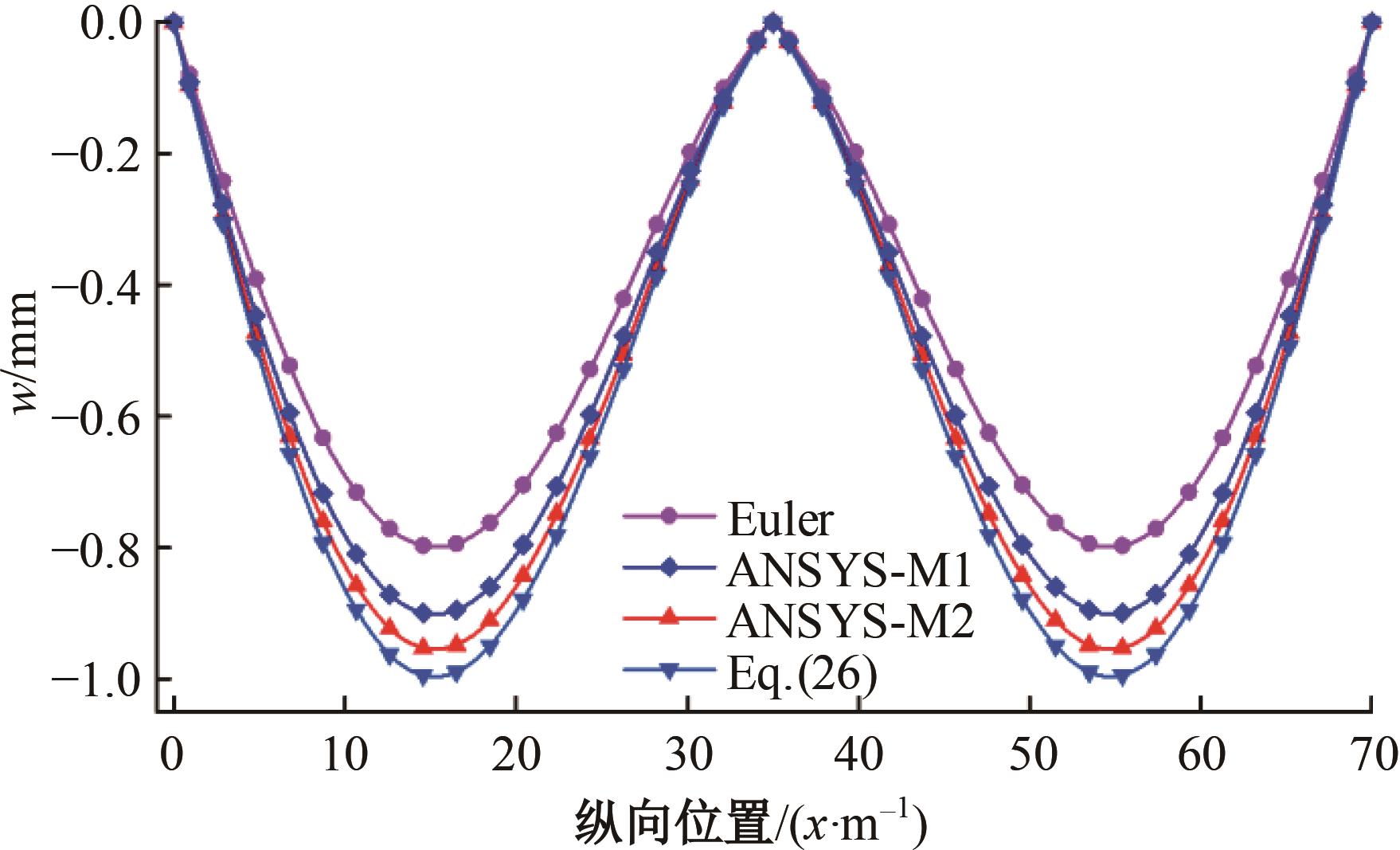

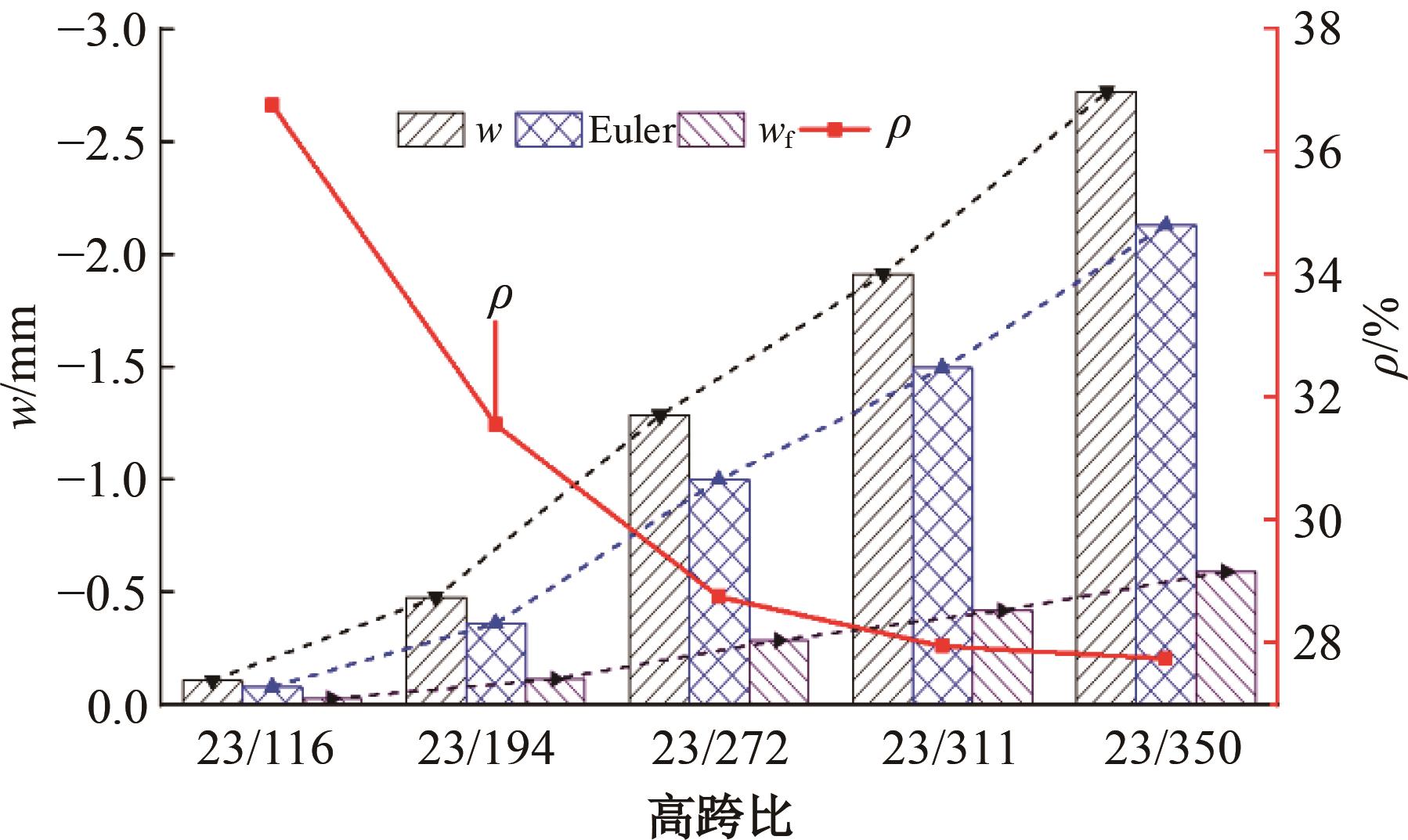

Calculation method of deflection of composite box beam with considering the deformation of the steel truss web

Fang-xu WANG( ),Shi-zhong LIU,Xia-lin YANG,Ning JIANG,Xin-yi LIU,Chi MA

),Shi-zhong LIU,Xia-lin YANG,Ning JIANG,Xin-yi LIU,Chi MA

- School of Civil Engineering,Lanzhou Jiaotong University,Lanzhou 730070,China

CLC Number:

- U443.3

| [1] | Jung K H, Kim J H J, Yi J W, et al. Development and evaluation of new connection systems for hybrid truss bridges[J]. Journal of Advanced Concrete Technology, 2013, 11(2):61-79. |

| [2] | Tian Z J, Liu Y J, Jiang L, et al. A review on application of composite truss bridges composed of hollow structural section members[J]. Journal of Traffic and Transportation Engineering, 2019, 6(1): 94-108. |

| [3] | Chen B C, Huang W J. Experimental research on ultimate load carrying capacity of truss girders made with circular tubes[J]. Journal of Building Structures, 2007, 28(3): 31-36. |

| [4] | Chen S L, Zhang H, Hou C, et al. Reliability calibration for the design of multiple-chord CFST trusses by advanced analysis[J]. Structural Safety, 2021, 89: 102051. |

| [5] | Hu B, Che R Y, Wang J F, et al. Analytical investigation into the flexural behavior of steel tubular truss-and-concrete (STTC) composite beams[J]. Structures, 2023, 50: 670-688. |

| [6] | Chen Y Y, Dong J C, Xu T H. Composite box girder with corrugated steel webs and trusses—A new type of bridge structure[J]. Engineering Structures, 2018, 166: 354-362. |

| [7] | Chen Y Y, Dong J C, Tong Z J, et al. Flexural behavior of composite box girders with corrugated steel webs and trusses[J]. Engineering Structures, 2020, 209: 110275. |

| [8] | Hu B, Wang J. Experimental investigation and analysis on flexural behavior of CFSTTC beams[J]. Thin-Walled Structures, 2017, 116:277-290. |

| [9] | Fong M, Chan S L. Advanced design for trusses of steel and concrete-filled tubular sections[J]. Engineering Structures, 2011, 33(12): 3162-3171. |

| [10] | Peng G, Nakamura S, Zhu X, et al. An experimental and numerical study on temperature gradient and thermal stress of CFST truss girders under solar radiation[J]. Computers & Concrete, 2017, 20(5): 605-616. |

| [11] | Huang W, Feng L, Chen B, et al. Experimental study on joint resistance and failure modes of concrete filled steel tubular (CFST) truss girders[J]. Journal of Constructional Steel Research, 2018, 141:241-250. |

| [12] | Chen Y, Feng R, Gao S. Experimental study of concrete-filled multiplanar circular hollow section tubular trusses[J]. Thin-Walled Structures, 2015, 94:199-213. |

| [13] | Feng R, Chen Y, Gao S, et al. Numerical investigation of concrete-filled multi-planar CHS inverse-triangular tubular truss[J]. Thin-Walled Structures, 2015, 94: 23-37. |

| [14] | Huang Y H, Liu A R, Fu J Y, et al. Experimental investigation of the flexural behavior of CFST trusses with interfacial imperfection[J]. Journal of Constructional Steel Research, 2017, 137: 52-65. |

| [15] | Zhou W, Chen Y, Wang K, et al. Experimental research on circular concrete filled stainless steel tubular truss[J]. Thin-Walled Structures, 2017, 117:224-238. |

| [16] | Huang W, Lai Z, Chen B, et al. Concrete-filled steel tube (CFT) truss girders: Experimental tests, analysis, and design[J]. Engineering Structures, 2018, 156:118-129. |

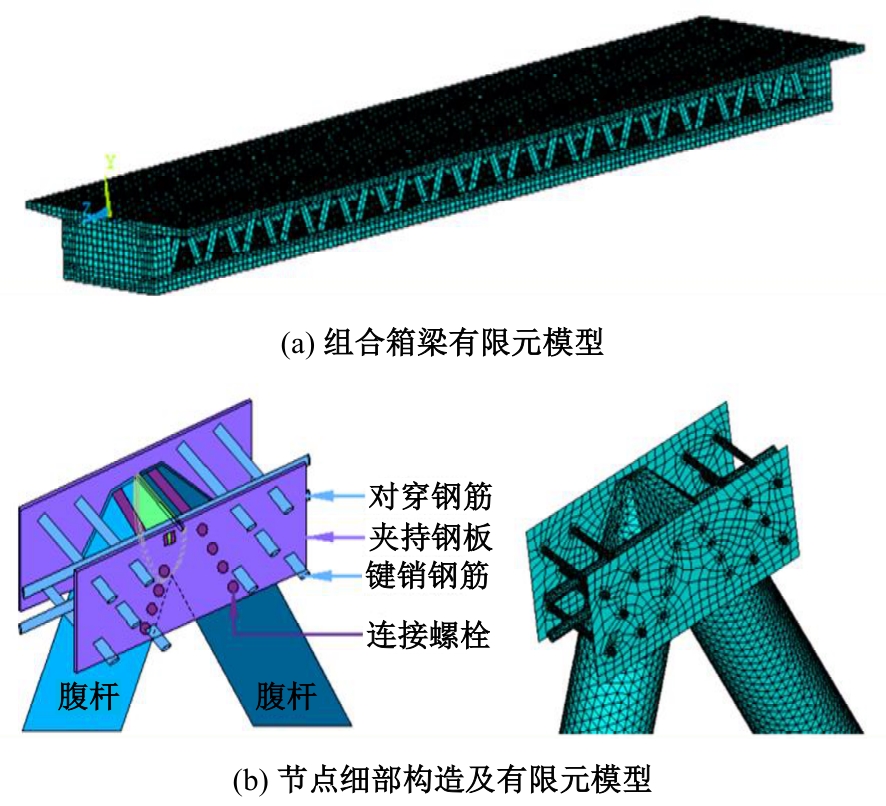

| [17] | 陈建兵, 蒋明利, 周晨, 等. 钢桁腹混凝土组合梁挠度计算方法研究[J]. 重庆交通大学学报: 自然科学版, 2022, 41(6): 66-72. |

| Chen Jian-bing, Jiang Ming-li, Zhou Chen, et al. Calculation method of deflection of steel truss web concrete composite beam[J]. Journal of Chongqing Jiaotong University (Natural Science Edition), 2022, 41 (6): 66-72. | |

| [18] | 李丽园.考虑剪切变形影响的波形钢腹板组合箱梁挠曲力学特性及其试验研究[D]. 兰州: 兰州交通大学, 土木工程学院, 2019. |

| Li Li-yuan. Vertical flexural mechanical characteristics and experimental study of composite box girder with corrugated steel web considering shear deformation[D]. Lanzhou: School of Civil Engineering, Lanzhou Jiaotong University, 2019. | |

| [19] | 王方旭, 杨霞林, 刘世忠. PBL节点初始平动刚度计算及设计参数优化[J]. 计算力学学报, 2022, 39(5): 574-581. |

| Wang Fang-xu, Yang Xia-lin, Liu Shi-zhong. Calc-ulation of initial translational stiffness of PBL nod-e and optimization of design parameters[J]. Journal of Computational Mechanics, 2022, 39(5): 574-581. | |

| [20] | 中交公路规划设计院有限公司. 公路桥涵设计通用规范: JTG D60—2015[M]. 北京: 人民交通出版社股份有限公司, 2015. |

| [21] | 张岩. 钢桁腹式混凝土组合箱梁的力学性能研究[D]. 兰州: 兰州交通大学 土木工程学院, 2019. |

| Zhang Yan. Research on mechanical properties of concrete composite box girder with steel truss webs[D]. Lanzhou: School of Civil Engineering, Lanzhou Jiaotong University, 2019. |

| [1] | Yu-xin XUE,Yong-jun ZHOU,Ye-lu WANG,Kai-xiang FAN,Yu ZHAO. Application of dynamic load allowance test method of simply supported girder bridge based on suspension hammer system [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(9): 2557-2567. |

| [2] | Guo-hui CHEN,Ye-yin XU,Ying-hou JIAO. Meshing stiffness calculation and vibration analysis of helical gear considering deflection [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(7): 1902-1910. |

| [3] | Ya-na MAO,Shi-zhong LIU,Jian XING,Hua YANG,Yu-bo JIAO. Bond⁃slip characterization between ultra⁃high performance glass sand concrete and high⁃strength reinforcement based on acoustic emission parameters [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1686-1694. |

| [4] | Jian-qing BU,Zhi-bo GUO,Ji-ren ZHANG,Jing-chuan XUN,Xiao-ming HUANG. Finite element analysis method for mechanical properties of steel⁃concrete composite beam bridges with multiple damages [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(6): 1621-1637. |

| [5] | Zhi-qiang HAN,Gang XIE,Yong-jun ZHOU,Shi-zhong LIU,Min-jie JIN. Numerical analysis method of vehicle⁃bridge coupling vibration of curved bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 515-522. |

| [6] | Jin-song ZHU,Ya-ting QIN,Zhou-qiang LIU. Section optimization design of prestressed UHPC-NC composite beams [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(11): 3151-3159. |

| [7] | Guo-jun YANG,Qi-wei TIAN,Ming-hang LYU,Yong-feng DU,Guang-wu TANG,Zong-jian HAN,Yi-duo FU. Review of mechanic characteristics of tunnel⁃type anchorage of long⁃span suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1245-1263. |

| [8] | Zhi-yuan YUANZHOU,Bo-hai JI,Jun-yuan XIA,Tong SUN. Pneumatic impact test on rib⁃to⁃diaphragm fatigue crack of steel box girder [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 2883-2891. |

| [9] | Chun-liang LI,Zhi-hao LIN,Luo-luo ZHAO. Effect of damaged hinge joint and damaged slab on transverse force of hollow slab bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 611-619. |

| [10] | Lun-hua BAI,Rui-li SHEN,Xing-biao ZHANG,Lu WANG. In-plane stability of self-anchored suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1500-1508. |

| [11] | WANG Tao, SAN Xiao-gang, GAO Shi-jie, WANG Hui-xian, WANG Jing, NI Ying-xue. Dynamic characteristics of vertical shaft system of photoelectric turntable [J]. 吉林大学学报(工学版), 2018, 48(4): 1099-1105. |

| [12] | ZANG Guo-shuai, SUN Li-jun. Method based on inertial point for setting depth to rigid layer [J]. 吉林大学学报(工学版), 2018, 48(4): 1037-1044. |

| [13] | JI Wen-yu, LI Wang-wang, GUO Min-long, WANG Jue. Experimentation and calculation methods of prestressed RPC-NC composite beam deflection [J]. 吉林大学学报(工学版), 2018, 48(1): 129-136. |

| [14] | ZHUANG Ye, CHEN Yu-hang, YANG Ye-hai, XU Shu-fang. Twin-tube hydraulic shock absorber F-V modeling based on structure parameters [J]. 吉林大学学报(工学版), 2016, 46(3): 732-736. |

| [15] | WEI Hai-bin, ZHANG Yang-peng, JIAO Yu-bo, LIU Han-bing. Neural network-based calculation of deflection increasing coefficient of steel-concrete composite beam [J]. 吉林大学学报(工学版), 2014, 44(4): 963-967. |

|

||