Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (3): 805-815.doi: 10.13229/j.cnki.jdxbgxb20171245

Previous Articles Next Articles

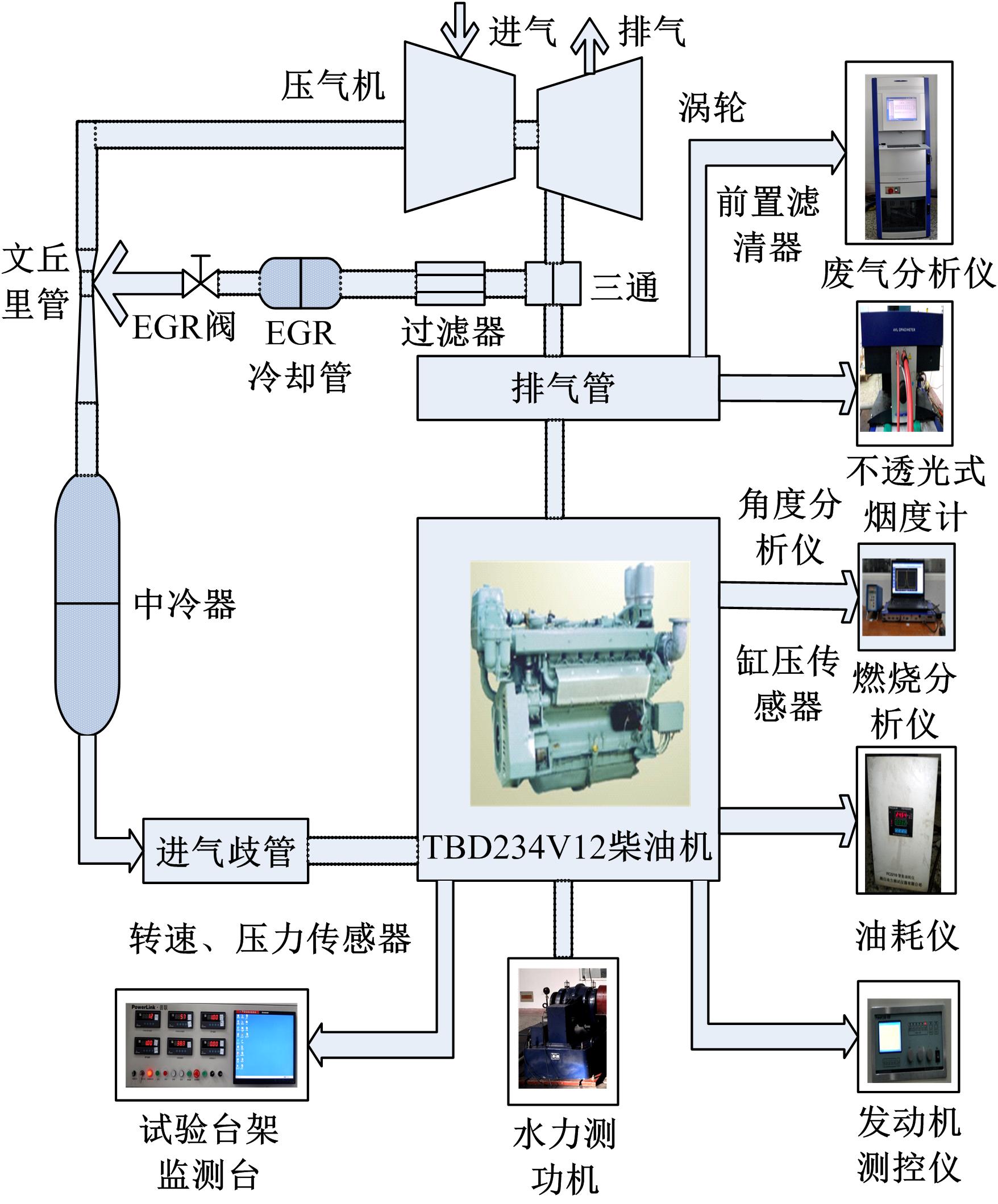

Exhaust gas recirculation performance evaluation of marine diesel engine and its application

Xiang⁃huan ZU( ),Chuan⁃lei YANG(

),Chuan⁃lei YANG( ),He⁃chun WANG,Yin⁃yan WANG

),He⁃chun WANG,Yin⁃yan WANG

- Department of Power and Energy Engineering, Harbin Engineering University, Harbin 150001, China

CLC Number:

- TK422

| 1 | 董天普,张付军,刘波澜,等.EGR对涡轮增压柴油机瞬态特性的影响[J].内燃机学报, 2017,35(2):118⁃124. |

| DongTian⁃pu,ZhangFu⁃jun,LiuBo⁃lan,et al. Effect of EGR on transient characteristics of turbocharged diesel engine[J]. Transactions of CSICE, 2017,35(2):118⁃124. | |

| 2 | JafarmadarSamad, NematiPeyman. Analysis of exhaust gas recirculation (EGR) effects on exergy terms in an engine operating with diesel oil and hydrogen [J]. Energy, 2017,126:746⁃755. |

| 3 | ParkYoungsoo, BaeChoongsik. Experimental study on the effects of high/low pressure EGR proportion in a passenger car diesel engine[J]. Applied Energy,2014, 133:308⁃316. |

| 4 | 安晓辉,刘波澜,张付军,等. 基于氧浓度的EGR对柴油机性能影响的仿真[J].内燃机学报,2013,31(2):115⁃119. |

| AnXiao⁃hui, LiuBo⁃lan, ZhangFu⁃jun, et al. Simulation of the effect of intake charge oxygen concentration based EGR on diesel engine performance[J]. Transactions of CSICE, 2013, 31(2) :115⁃119. | |

| 5 | 于秀敏,商震,张岳韬,等.废气再循环对直喷汽油机燃烧及排放影响的仿真[J].吉林大学学报:工学版,2016,46(4):1109⁃1117. |

| YuXiu⁃min, ShangZhen, ZhangYue⁃tao, et al. Simulation of EGR on combustion and emission of gasoline direct⁃injection engine[J]. Journal of Jilin University (Engineering and Technology Edition),2016, 46(4):1109⁃1117. | |

| 6 | ShenKai, LiFang⁃bo, ZhangZhen⁃dong, et al. Effects of LP and HP cooled EGR on performance and emissions in turbocharged GDI engine[J]. Applied Thermal Engineering, 2017, 125: 746⁃755. |

| 7 | JafarmadarSamad, NematiPeyman. Analysis of Exhaust Gas Recirculation (EGR) effects on exergy terms in an engine operating with diesel oil and hydrogen [J]. Energy, 2017,126: 746⁃755. |

| 8 | 赵昌普,朱云尧,李艳丽,等.增压中冷柴油机EGR系统文丘里管的设计与试验[J].农业工程学报, 2013,29(15): 49⁃56. |

| ZhaoChang⁃pu, ZhuYun⁃yao,LiYan⁃li, et al. Design and experimental of venturi in EGR system of turbocharged intercooled diesel engine[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(15): 49⁃56. | |

| 9 | ShiXiao⁃chen, LiuBo⁃lan, ZhangChao, et al. A study on combined effect of high EGR rate and biodiesel on combustion and emission performance of a diesel engine[J].Applied Thermal Engineering,2017,125: 1272⁃1279. |

| 10 | 郭亮,杨文昭,王云开,等.废气再循环对丁醇/柴油混合燃料发动机的影响[J].吉林大学学报:工学版,2017,47(6):1767⁃1774. |

| GuoLiang, YangWen⁃zhao, WangYun⁃kai, et al. Effect of exhaust recirculation on internal combustion engine fueled with butanol/diesel blend[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(6):1767⁃1774. | |

| 11 | 韩林沛, 洪伟, 苏岩, 解方喜, 陈静, 杜文畅. 直喷汽油机排气门二次开启对回流废气分层和燃烧特性的影响[J]. 吉林大学学报:工学版, 2017, 47(1): 113⁃121. |

| HanLin⁃pei, HongWei, SuYan,et al. Effect of GDI engine exhaust valve secondary open on refluent EGR stratification and combustion characteristics[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(1): 113⁃121. | |

| 12 | 鹿盈盈,于文斌,裴毅强,等. EGR与喷油定时对柴油机预混燃烧颗粒排放的影响[J]. 内燃机学报,2017,35(3):193⁃199. |

| LuYing⁃ying, YuWen⁃bin, PeiYi⁃qiang, et al. Effects of EGR and injection timing on PM emissions of PCCI combustion in a diesel engine[J]. Transactions of CSICE, 2017,35(3):193⁃199. | |

| 13 | 赵靖华,洪伟,冯枫,等.基于EGR策略的重型柴油机瞬态空燃比优化控制[J].吉林大学学报:工学版,2012,42(增刊1):151⁃155. |

| ZhaoJing⁃hua, HongWei, FengFeng, et al. Transient air⁃to⁃fuel ratio control on heavy duty diesel engine based on EGR technology[J]. Journal of Jilin University (Engineering and Technology Edition),2012,42(Sup.1): 151⁃155. | |

| 14 | NishiMina, KaneharaMasato, IidaNorimasa. Assessment for innovative combustion on HCCI engine by controlling EGR ratio and engine speed[J]. Applied Thermal Engineering,2016,99(25):42⁃60. |

| 15 | Kræn Vodder Nielsen, BlankeMogens, ErikssonLars, et al. Adaptive feedforward control of exhaust recirculation in large diesel engines[J]. Control Engineering Practice, 2017,65: 26⁃35. |

| 16 | XuMin, GuiYong, DengKang⁃yao.Fuel injection and EGR control strategy on smooth switching of CI/HCCI mode in a diesel engine[J].Journal of the Energy Institute,2015, 88(2):157⁃168. |

| 17 | 王迎迎. 大功率柴油机EGR模拟研究[D].成都:西南交通大学机械工程学院,2012. |

| WangYing⁃ying. Simulation the effect of exhaust gas recirculation on the high⁃power diesel engine[D]. Chengdu:College of Mechanical Engineering of Southwest Jiaotong University,2012. | |

| 18 | 张振东,方毅博,陈振天.增压直喷式柴油机EGR率测试及优化研究[J].内燃机工程,2006,27(2):81⁃84. |

| ZhangZhen⁃dong, FangYi⁃bo, ChenZhen⁃tian. Research and experiments of EGR rates effect on a turbocharged diesel engine[J]. Chinese Internal Combustion Engine Engineering, 2006,27(2):81⁃84. | |

| 19 | 郑清平,黎苏,郎晓姣,等.增压中冷柴油机EGR数值模拟与试验研究[J]. 内燃机工程,2012,33(2):33⁃37. |

| ZhengQing⁃ping, LiSu, LangXiao⁃jiao, et al. Simulation and Experimental Study on Turbocharged Inter⁃Cooled Diesel Engine with Exhaust Gas Recirculation[J]. Chinese Internal Combustion Engine Engineering, 2012,33 (2):33⁃37. | |

| 20 | 张振坤. EGR技术降低某船用柴油机NOx排放的研究[D].大连:大连海事大学轮机工程学院,2015. |

| ZhangZhen⁃kun. Study on NOx displacement of marine diesel engine with EGR[D].Dalian: College of Marine Engineering,Dalian Maritime University, 2015. | |

| 21 | 杜俊.V型柴油机采用EGR系统的计算与试验研究[D].哈尔滨:哈尔滨工程大学动力与能源工程学院,2013. |

| DuJun. Calculation and experimental research with EGR system for V type diesel engine[D]. Harbin:College of Power and Energy Engineering,Harbin Engineering University,2013. | |

| 22 | 温永美. EGR率对柴油机燃烧排放性能影响仿真分析 [D]. 重庆:重庆交通大学交通运输学院,2012. |

| WenYong⁃mei. The simulation analysis of EGR on the combustion and emission characteristics of diesel Engine[D]. Chongqing:College of Traffic and Transportation,Chongqing Jiaotong University, 2012. | |

| 23 | WangLi⁃zhen, QianWu⁃yong. Grey target decisionmaking model of interval grey number based on cone volume[J]. Grey Systems: Theory and Application, 2017,7(2): 247⁃258. |

| 24 | GolinskaPaulina, KosackaMonika, MierzwiakRafal, et al. Grey decision making as a tool for the classification of the sustainability level of remanufacturing companies[J].Journal of Cleaner Production,2015,105(15): 28⁃40. |

| 25 | 王渡,龚淼,陈德珍. 基于灰色决策的太阳能发电系统在垃圾填埋场应用[J].太阳能学报,2013,34(3):471⁃476. |

| WangDu, GongMiao, ChenDe⁃zhen. Application of solar power system on landfill based on grey relational method[J]. Acta Energiae Solaris Sinica, 2013, 34(3):471⁃476. | |

| 26 | 罗周全,徐海,谭浪浪,等. 矿山产能灰色局势决策优化[J]. 中南大学学报:自然科学版,2013,44(1):289⁃293. |

| LuoZhou⁃quan, XuHai, TanLang⁃lang, et al. Optimization of mine productivity based on grey situation decision[J]. Journal of Central South University (Science and Technology), 2013,44(1):289⁃293. | |

| 27 | LiuS F, LinY. Grey Information: Theory and Practical Applications[M]. London: Springer⁃Verlag, 2006. |

| 28 | 王正新,党耀国,宋传平. 基于区间数的多目标灰色局势决策模型[J]. 控制与决策,2009,24(3):388⁃392. |

| WangZheng⁃xin, DangYao⁃guo, SongChuan⁃ping. Multi⁃objective decision model of grey situation based on interval number[J]. Control and Decision, 2009,24(3): 388⁃392. | |

| 29 | 祖象欢,杨传雷,王银燕.基于GM(1,1)模型和MATLAB GUI的相继增压柴油机性能预测[J].哈尔滨工程大学学报,2015,36(11):1454⁃1458. |

| ZuXiang⁃huan, YangChuan⁃lei, WangYin⁃yan. Performance prediction of a sequential turbocharging diesel engine based on GM(1,1)model and MATLAB GUI[J]. Journal of Harbin Engineering University, 2015,36(11):1454⁃1458. | |

| 30 | GigonBae,GreggRothermel,Doo⁃HwanBae. Comparing model⁃based and dynamic event⁃extraction based GUI testing techniques: an empirical study[J]. Journal of Systems and Software,2014,97:15⁃46. |

| 31 | Raj Jean Rossario, RahmanS M K, Sneh.Anand . Microcontroller USB interfacing with MATLAB GUI for low cost medical ultrasound scanners[J]. Engineering Science and Technology, an International Journal, 2016,19(2):964⁃969. |

| [1] | GUO Liang, YANG Wen-zhao, WANG Yun-kai, SUN Wan-chen, CHENG Peng, LI Guo-liang. Effect of exhaust gas recirculation on internal combustion engine fueled with butanol/diesel blend [J]. 吉林大学学报(工学版), 2017, 47(6): 1767-1774. |

| [2] | XU Jin-kai, WANG Yu-tian, ZHANG Shi-zhong. Dynamic characteristics of a heavy duty parallel mechanism with actuation redundancy [J]. 吉林大学学报(工学版), 2017, 47(4): 1138-1143. |

| [3] | LI Xiao-ping, HONG Wei, XIE Fang-xi, LI Xiang-yu, YANG Wen-hai, DAI Zhi-yao. NOx emission reduction of a lean-burn methanol engine by retarding ignition timing, exhaust gas recirculation and leaner air/fuel mixture [J]. 吉林大学学报(工学版), 2016, 46(5): 1478-1483. |

| [4] | YU Xiu-min, SHANG Zheng, ZHANG Yue-tao, DU Yao-dong. Simulation of EGR on combustion and emission of gasoline direct-injection engine [J]. 吉林大学学报(工学版), 2016, 46(4): 1109-1117. |

| [5] | ZHENG Xin, PENG Zhen-ming, XING Yan. Novel method of evaluating image segmentation algorithms based on activity degree [J]. 吉林大学学报(工学版), 2016, 46(1): 311-317. |

| [6] | QI Xing-da, LI Xian-jun, LIU Si-yu, MENG Dong-hui. Differentiation research on industrial technology innovation ability by DEA and PCA [J]. 吉林大学学报(工学版), 2015, 45(3): 1017-1023. |

| [7] | ZHAO Jing-hua, HONG Wei, FENG Feng, XIE Fang-xi. Transient air-to-fuel ratio control on heavy duty diesel engine based on EGR technology [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 151-155. |

| [8] | LI Jun, LI Xiong-fei, DONG Yuan-fang, ZHAO Hai-ying. New performance evaluation method for classifier [J]. 吉林大学学报(工学版), 2012, 42(02): 463-468. |

| [9] | YANG Li-ping,MA Xiu-zhen,LI Jun,WANG Li-yuan. Application of EGR |and excess air ratio combined NOx emission control strategy on natural gas engine [J]. 吉林大学学报(工学版), 2010, 40(04): 942-0946. |

| [10] | CHEN Li-jun,YANG Shan-rang,WANG Sheng-long,MI Li-jun. Thermodynamic anslysis of combined power and refrigerating cycle for power plant air cooling system [J]. 吉林大学学报(工学版), 2009, 39(增刊2): 283-0286. |

| [11] |

Yang Li-ping,Guo Ying-nan,Li Jun,Liu Jin-shan,Wang Li-yuan .

Influence of mixture quality on HCCI combustion characteristics of ethanol engine [J]. 吉林大学学报(工学版), 2008, 38(02): 273-0277. |

| [12] | SI Yu-juan . The Research on an Analysis Method for Input Buffer Limitation [J]. 吉林大学学报(工学版), 2001, (3): 31-35. |

|