Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (5): 1567-1574.doi: 10.13229/j.cnki.jdxbgxb20180623

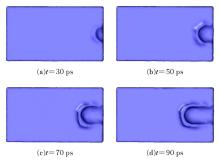

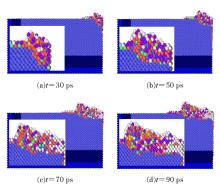

Numerical analysis of single crystal Fe with abrasive grain micro-cutting based on molecular dynamics

Jun-ye LI1,2( ),Yang LIU1,Hui LU1,Wen-qing MENG1,Zhao-jun YANG2,Xin-ming ZHANG1(

),Yang LIU1,Hui LU1,Wen-qing MENG1,Zhao-jun YANG2,Xin-ming ZHANG1( )

)

- 1. Ministry of Education Key Laboratory for Cross-Scale Micro and Nano Manufacturing, Changchun University of Science and Technology, Changchun 130022, China

2. School of Mechanical and Aerospace Engineering, Jilin University, Changchun 130022, China

CLC Number:

- TG501

| 1 | 李俊烨, 乔泽民, 杨兆军, 等. 介观尺度下磨料浓度对磨粒流加工质量的影响[J]. 吉林大学学报: 工学版, 2017, 47(3): 837-843. |

| LiJun-ye, QiaoZe-min, YangZhao-jun, et al. Influence of abrasive concentration on processing quality of abrasive flow in mesoscopic scale[J]. Journal of Jilin University (Engineering and Technology Edition), 2017, 47(3): 837-843. | |

| 2 | 焦佳能, 费群星, 白凤民, 等. 钛合金表面磨粒流加工工艺研究[J]. 金刚石与磨料磨具工程, 2010, 30(1): 42-45. |

| JiaoJia-neng, FeiQun-xing, BaiFeng-min, et al. Surface finishing of titanium alloy component by abrasive flow machining[J]. Diamond and Abrasives Engineering, 2010, 30(1): 42-45. | |

| 3 | 丁金福, 刘润之, 张克华, 等. 磨粒流精密光整加工的微切削机理[J]. 光学精密工程, 2014, 22(12): 3324-3331. |

| DingJin-fu, LiuRun-zhi, ZhangKe-hua, et al. Micro cutting mechanism of abrasive flow precision machining[J]. Optics and Precision Engineering, 2014, 22(12): 3324-3331. | |

| 4 | 李俊烨, 胡敬磊, 杨兆军, 等. 离散相磨粒粒径对磨粒流研抛共轨管质量的影响[J]. 吉林大学学报: 工学版, 2018, 48(2): 492-499. |

| LiJun-ye, HuJing-lei, YangZhao-jun, et al. Effect on the quality of abrasive flow polishing the common rail pipe in size of discrete phase abrasive particle[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(2): 492-499. | |

| 5 | VenkateshG, SharmaA K, KumarP. On ultrasonic assisted abrasive flow finishing of bevel gears[J]. International Journal of Machine Tools & Manufacture, 2015, 89: 29-38. |

| 6 | 李俊烨, 董坤, 王兴华, 等. 颗粒微切削表面创成的分子动力学仿真研究[J]. 机械工程学报, 2016, 52(17): 94-104. |

| LiJun-ye, DongKun, WangXing-hua, et al. Molecular dynamics simulation research into generative mechanism of particles micro-cutting surface[J]. Journal of Mechanical Engineering, 2016, 52(17): 94-104. | |

| 7 | GoelS, KovalchenkoA, StukowskiA, et al. Influence of microstructure on the cutting behaviour of silicon[J]. Acta Materialia, 2015, 105: 464-478. |

| 8 | LiJ Y, MengW Q, DongK, et al. Study of effect of impacting direction on abrasive nanometric cutting process with molecular dynamics[J]. Nanoscale Research Letters, 2018, 13(1): 1-14. |

| 9 | WangQ, BaiQ, ChenJ, et al. Influence of cutting parameters on the depth of subsurface deformed layer in nano-cutting process of single crystal copper[J]. Nanoscale Research Letters, 2015, 10(1): 1-8. |

| 10 | 周晓勤, 朱志伟, 罗丹, 等. 线性改变切削深度对单晶铜纳米切削的影响[J]. 吉林大学学报: 工学版, 2012, 42(1): 109-115. |

| ZhouXiao-qin, ZhuZhi-wei, LuoDan, et al. Influence of linearly varying cutting depth on nanocutting of monocrystalline copper[J]. Journal of Jilin University (Engineering and Technology Edition), 2012, 42(1): 109-115. | |

| 11 | DawM S, BaskesM I. Embedded-atom method: derivation and application to impurities, surfaces, and other defects in metals[J]. Physical Review B, 1984, 29(12): 6443-6453. |

| 12 | GirifalcoL A, WeizerV G. Application of the morse potential function to cubic metals[J]. Physical Review, 1959, 114(3): 687-690. |

| 13 | TersoffJ. Modeling solid-state chemistry: interatomic potentials for multicomponent systems[J]. Physical Review B, 1989, 39(8): 5566-5568. |

| [1] | En-guo CAO,Kun LIU,Shuo JI,Zhen-yuan SUN,Hong-wei XU,Xing-ji LUO. Mechanical structure design and optimization of weight-support STS rehabilitation training system [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1558-1566. |

| [2] | Cheng YANG,Yong⁃sheng ZHAO,Zhi⁃feng LIU,Li⁃gang CAI. Stiffness model of bolted joint based on multi⁃scale theory [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1212-1220. |

| [3] | Kun LIU,Shuo JI,Zhen⁃yuan SUN,Hong⁃wei XU,Yong LIU,Jing⁃xia ZHAO. Mechanical structure design and optimization of multifunctional auxiliary toilet wheelchair [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 872-880. |

| [4] | Xing⁃ye WANG,Jin⁃qiu ZHANG,Guo⁃qiang LI,Zhi⁃zhao PENG. Influence of inertial mass on rack and pinion actuator′s damping characteristic [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 881-887. |

| [5] | Jia⁃xu WANG,Xiao⁃kang NI,Yan⁃feng HAN,Guo XIANG,Ke XIAO. Numerical model of mixed lubrication for microgroove bearing considering axial reciprocating motion [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 888-896. |

| [6] | BI Qiu-shi,WANG Guo-qiang,HUANG Ting-ting,MAO Rui,LU Yan-peng. Tooth strength analysis of mineral sizer by coupling discrete element method and finite element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1770-1776. |

| [7] | ZHU Wei,WANG Chuan-wei,GU Kai-rong,SHEN Hui-ping,XU Ke,WANG Yuan. Stiffness and dynamics analysis of a new type of tensegrity parallel mechanism [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1777-1786. |

| [8] | LIU Jian-fang, WANG Ji-bo, LIU Guo-jun, LI Xin-bo, LIANG Shi-hai, YANG Zhi-gang. PMMA micromixer embedded with 3D channel based on piezoelectric actuation [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1500-1507. |

| [9] | WANG Tao, SAN Xiao-gang, GAO Shi-jie, WANG Hui-xian, WANG Jing, NI Ying-xue. Dynamic characteristics of vertical shaft system of photoelectric turntable [J]. 吉林大学学报(工学版), 2018, 48(4): 1099-1105. |

| [10] | LIU Kun, LIU Yong, YAN Jian-chao, JI Shuo, SUN Zhen-yuan, XU Hong-wei. Dynamic analysis of sit-to-stand human motion based on in vitro-sensor detection [J]. 吉林大学学报(工学版), 2018, 48(4): 1140-1146. |

| [11] | YOSHINO Tatsuo, FAN Lu-lu, YAN Lei, XU Tao, LIN Ye, GUO Gui-kai. Multiobjective optimization design for dummy chest structure based on MBNWS algorithm [J]. 吉林大学学报(工学版), 2018, 48(4): 1133-1139. |

| [12] | HE Ji-lin, CHEN Yi-long, WU Kang, ZHAO Yu-ming, WANG Zhi-jie, CHEN Zhi-wei. Energy flow analysis of crane hoisting system and experiment of potential energy recovery system [J]. 吉林大学学报(工学版), 2018, 48(4): 1106-1113. |

| [13] | XIE Chuan-liu, TANG Fang-ping, SUN Dan-dan, ZHANG Wen-peng, XIA Ye, DUAN Xiao-hui. Model experimental analysis of pressure pulsation in vertical mixed-flow pump system [J]. 吉林大学学报(工学版), 2018, 48(4): 1114-1123. |

| [14] | SUN Xiu-rong, DONG Shi-min, WANG Hong-bo, LI Wei-cheng, SUN Liang. Comparison of multistage simulation models of entire sucker rod with spatial buckling in tubing [J]. 吉林大学学报(工学版), 2018, 48(4): 1124-1132. |

| [15] | LIU Zhi-feng, ZHAO Dai-hong, WANG Yu-mo, HUN Lian-ming, ZHAO Yong-sheng, DONG Xiang-min. Relationship between bearing capacity of heavy machine hydrostatic rotary table and temperature field distribution of oil pad [J]. 吉林大学学报(工学版), 2018, 48(3): 773-780. |

|

||