Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (1): 172-180.doi: 10.13229/j.cnki.jdxbgxb20190869

Deformation behavior of shape memory alloy-metallic glass matrix composites based on finite element calculations

Fan YANG1( ),Xu-dong ZHANG1(

),Xu-dong ZHANG1( ),Meng ZHAO2,Bo SHE1,Jun-kai DENG2

),Meng ZHAO2,Bo SHE1,Jun-kai DENG2

- 1.Network Information Center,Xi'an Jiaotong University,Xi'an 710049,China

2.State Key Laboratory for Mechanical Behavior of Materials,Xi'an Jiaotong University,Xi'an 710049,China

CLC Number:

- TB331

| 1 | Pauly S, Gorantla S, Wang G, et al. Transformation-mediated ductility in CuZr-based bulk metallic glasses[J]. Nature Materials, 2010, 9(6): 473-477. |

| 2 | Hofmann D C, Suh J Y, Wiest A, et al. Designing metallic glass matrix composites with high toughness and tensile ductility[J]. Nature, 2008, 451(7182): 1085-1089. |

| 3 | Baran Sarac, Jan Schroers. Designing tensile ductility in metallic glasses[J]. Nature Communications, 2013, 4: 2158. |

| 4 | Wang Y, Li M, Xu J. Toughen and harden metallic glass through designing statistical heterogeneity[J]. Scripta Materialia, 2016, 113: 10-13. |

| 5 | Gargarella P, Pauly S, Song K K, et al. Ti-Cu-Ni shape memory bulk metallic glass composites[J]. Acta Materialia, 2013, 61 (1): 151-162. |

| 6 | Wu Y, Xiao Y, Chen G, et al. Bulk metallic glass composites with transformation-mediated work-hardening and ductility[J]. Advanced Materials, 2010, 22(25): 2770-2773. |

| 7 | Hofmann D C. Shape memory bulk metallic glass composites[J]. Science, 2010, 329(5997): 1294-1295. |

| 8 | Qiao J. In-situ dendrite/metallic glass matrix composites: a review[J]. Journal of Materials Science & Technology, 2013, 29(8): 685-701. |

| 9 | Hao S, Cui L, Jiang D, et al. A transforming metal nanocomposite with large elastic strain, low modulus, and high strength[J]. Science, 2013, 339(6124): 1191-1194. |

| 10 | Wu F F, Chan K C, Jiang S, et al. Bulk metallic glass composite with good tensile ductility, high strength and large elastic strain limit[J]. Scientific Reports, 2014, 4: 5302. |

| 11 | Wei R, Chang Y, Li Y F, et al. Effect of lateral pre-compression on the compressive behavior of a CuZr-based bulk metallic glass composite containing B2-CuZr phase[J]. Materials Science and Engineering: A, 2013, 587: 233-239. |

| 12 | Jiang Y, Shi X, Qiu K. Numerical study of shear banding evolution in bulk metallic glass composites[J]. Materials & design, 2015, 77: 32-40. |

| 13 | Sarac B, Wilmers J, Bargmann S. Property optimization of porous metallic glasses via structural design[J]. Materials Letters, 2014, 134: 306-310. |

| 14 | Jiang Y, Qiu K. Computational micromechanics analysis of toughening mechanisms of particle-reinforced bulk metallic glass composites[J]. Materials & Design, 2015, 65: 410-416. |

| 15 | Wang Y, Li M, Xu J. Mechanical properties of spinodal decomposed metallic glass composites[J]. Scripta Materialia, 2017, 135: 41-45. |

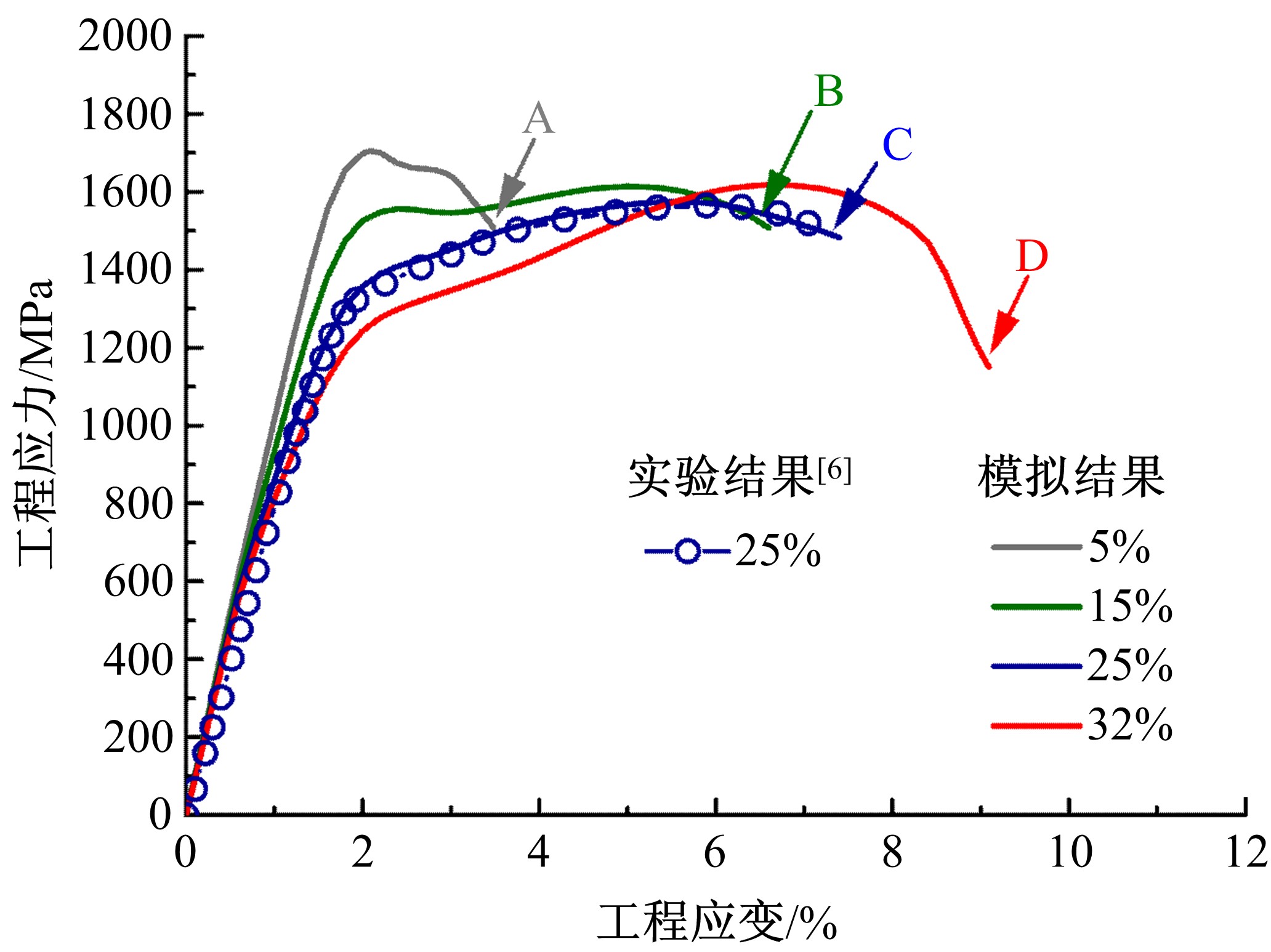

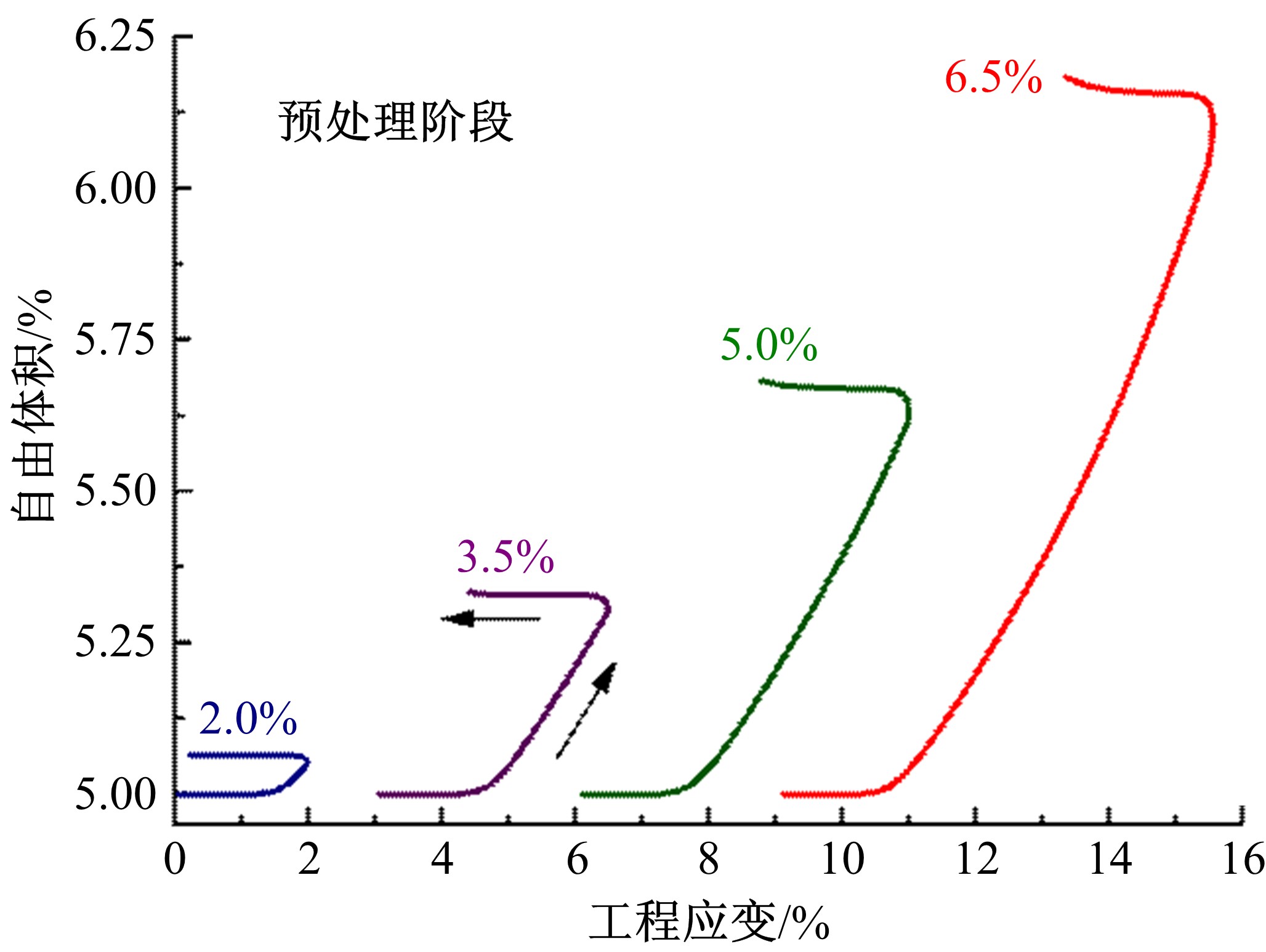

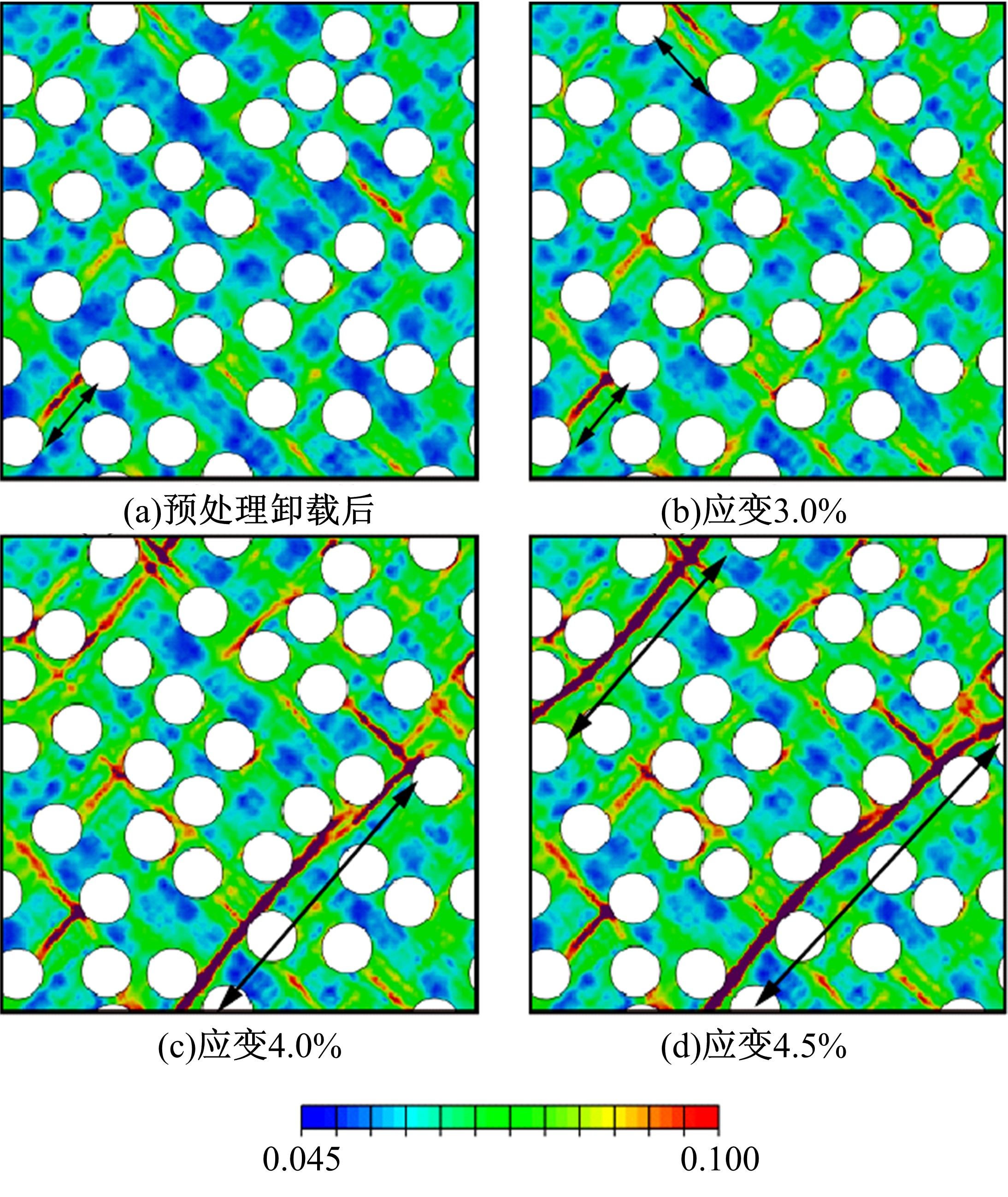

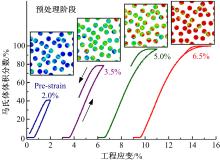

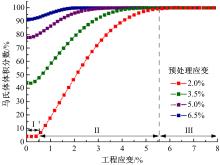

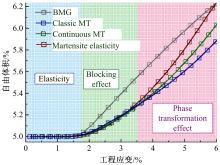

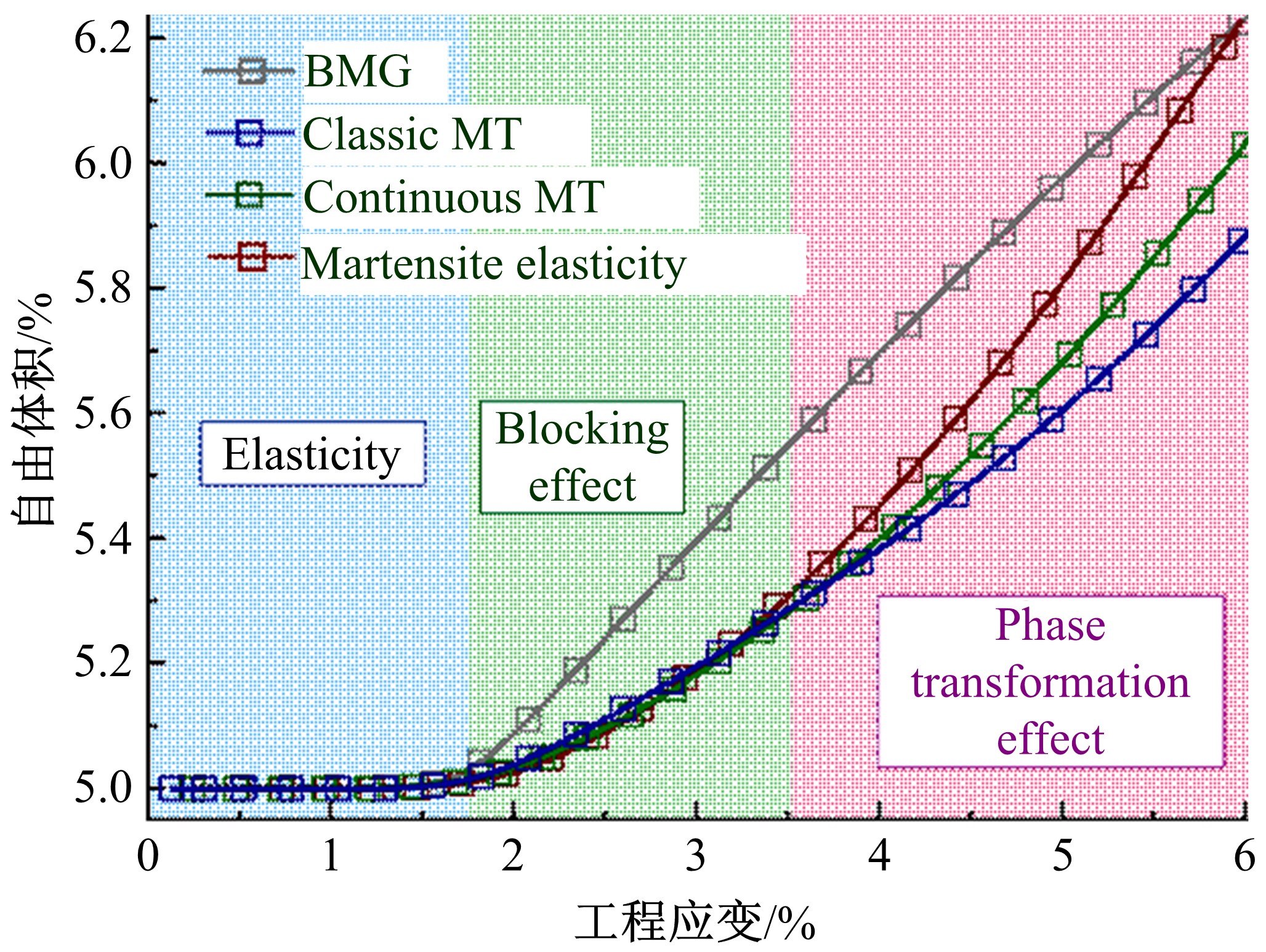

| 16 | Zhang X, Ren J, Ding X. Synergistic effects among the structure, martensite transformation and shear band in a shape memory alloy-metallic glass composite[J]. Applied Composite Materials, 2019, 26: 455-467. |

| 17 | Rao W, Kang G, Zhang J, et al. Numerical study on toughening mechanism of bulk metallic glass composites from martensite transformation of toughening phase[J]. Journal of Non Crystalline Solids, 2019, 506: 88-97. |

| 18 | Wu Y, Wang H, Wu H H, et al. Formation of Cu-Zr-Al bulk metallic glass composites with improved tensile properties[J]. Acta Materialia, 2011, 59: 2928-2936. |

| 19 | Jiang Y, Sun L, Wu Q, et al. Enhanced tensile ductility of metallic glass matrix composites with novel microstructure[J]. Journal of Non Crystalline Solids, 2017, 459: 26-31. |

| 20 | Jiang Y. Numerical modeling of cyclic deformation in bulk metallic glasses[J]. Metals, 2016, 6(9): 217. |

| 21 | Pauly S, Liu G, Wang G, et al. Modeling deformation behavior of Cu-Zr-Al bulk metallic glass matrix composites[J]. Applied Physics Letters, 2009, 95(10): 101906. |

| 22 | Auricchio F, Taylor R. Shape-memory alloys: modelling and numerical simulations of the finite-strain superelastic behavior[J]. Computer Methods in Applied Mechanics and Engineering, 1997, 143(1/2): 175-194. |

| 23 | Lei H, Wang Z, Zhou B, et al. Simulation and analysis of shape memory alloy fiber reinforced composite based on cohesive zone model[J]. Materials & Design, 2012, 40: 138-147. |

| 24 | Lei H, Wang Z, Tong L, et al. Experimental and numerical investigation on the macroscopic mechanical behavior of shape memory alloy hybrid composite with weak interface[J]. Composite Structures, 2013, 101: 301-312. |

| 25 | Şopu D, Soyarslan C, Sarac B, et al. Structure-property relationships in nanoporous metallic glasses[J]. Acta Materialia, 2016, 106: 199-207. |

| 26 | Kumar G, Rector D, Conner R D, et al. Embrittlement of Zr-based bulk metallic glasses[J]. Acta Materialia, 2009, 57 (12): 3572-3583. |

| 27 | Chen L Y, Fu Z D, Zhang G Q, et al. New class of plastic bulk metallic glass[J]. Physical Review Letters, 2008, 100 (7): 075501. |

| 28 | Gao Y F. An implicit finite element method for simulating inhomogeneous deformation and shear bands of amorphous alloys based on the free-volume model[J]. Modelling and Simulation in Materials Science and Engineering, 2006, 14(8): 1329-1345. |

| [1] | Xin LI,Yan-peng SUN,Dan WANG,Jun-xu CHEN,Zheng-wei GU,Hong XU. Finite element numerical simulation for automobile front floor forming [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1608-1614. |

| [2] | Chun-zheng DUAN,Fang-yuan ZHANG,Wen-neng KOU,Bin WEI. Martensitic transformation of surface white layer in high speed hard cutting [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1575-1583. |

| [3] | Xiao⁃qin ZHOU,Lu YANG,Lei ZHANG,Li⁃jun CHEN. Finite element analysis of hinging octahedron structure withnegative compressibility [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 865-871. |

| [4] | BI Qiu-shi,WANG Guo-qiang,HUANG Ting-ting,MAO Rui,LU Yan-peng. Tooth strength analysis of mineral sizer by coupling discrete element method and finite element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1770-1776. |

| [5] | HU Zhi-qing, ZHENG Hui-hui, XU Ya-nan, ZHANG Chun-ling, DANG Ting-ting. Effect of Al surface with micro/macro grooves on Al/CFRP adhesive-bonded joints [J]. 吉林大学学报(工学版), 2018, 48(1): 229-235. |

| [6] | WANG Jing-yu, YU Xu-tao, HU Xing-jun, GUO Peng, XIN Li, GUO Feng, ZHANG Yang-hui. Fluid-induced vibration and flow mechanism of automotive external rearview mirror [J]. 吉林大学学报(工学版), 2017, 47(6): 1669-1676. |

| [7] | SUN Rong-jun, GU Shuan-cheng, JU Pei, GAO Ke. Optimal design of new arc angle PDC drill bit for coal mining based on finite element method [J]. 吉林大学学报(工学版), 2017, 47(6): 1991-1998. |

| [8] | LIU Yu, LI Peng-fei, ZHANG Yi-min. Analysis and prediction of micro milling deformation of copper thin-wall parts [J]. 吉林大学学报(工学版), 2017, 47(3): 844-849. |

| [9] | ZHANG Yun-long, LIU Zhan-ying, WU Chun-li, WANG Jing. Static and dynamic responses of steel-concrete composite beams [J]. 吉林大学学报(工学版), 2017, 47(3): 789-795. |

| [10] | LIU Cheng, SHI Wen-ku, CHEN Zhi-yong, HE Wei, RONG Ru-song, SONG Huai-lan. Experiment on tooth root bending stress of driving axle hypoid gear of automobile [J]. 吉林大学学报(工学版), 2017, 47(2): 344-352. |

| [11] | YAN Guang, ZHUANG Wei, LIU Feng, ZHU Lian-qing. Preload package and characteristics of a sensitizing effect sensor based Fiber Bragg Grating (FBG) [J]. 吉林大学学报(工学版), 2016, 46(5): 1739-1745. |

| [12] | LIU Li-ping, LIU Yong-bing, JI Lian-feng, CAO Zhan-yi, YANG Xiao-hong. Flow stress behavior of in situ particulate reinforced titanium atrix composite at elevated temperature [J]. 吉林大学学报(工学版), 2016, 46(4): 1197-1201. |

| [13] | LIU Han-bing, SHI Cheng-lin, TAN Guo-jin. Finite element solution of composite beam with effect of shear slip [J]. 吉林大学学报(工学版), 2016, 46(3): 792-797. |

| [14] | ZHUANG Ye, CHEN Yu-hang, YANG Ye-hai, XU Shu-fang. Twin-tube hydraulic shock absorber F-V modeling based on structure parameters [J]. 吉林大学学报(工学版), 2016, 46(3): 732-736. |

| [15] | XIAO Xiang, HUANG En-hou, NI Ying-sheng. Theoretical analysis and experiment of the effect of flange width on beam-plates system of prestressed concrete [J]. 吉林大学学报(工学版), 2015, 45(6): 1784-1790. |

|

||