Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (4): 829-836.

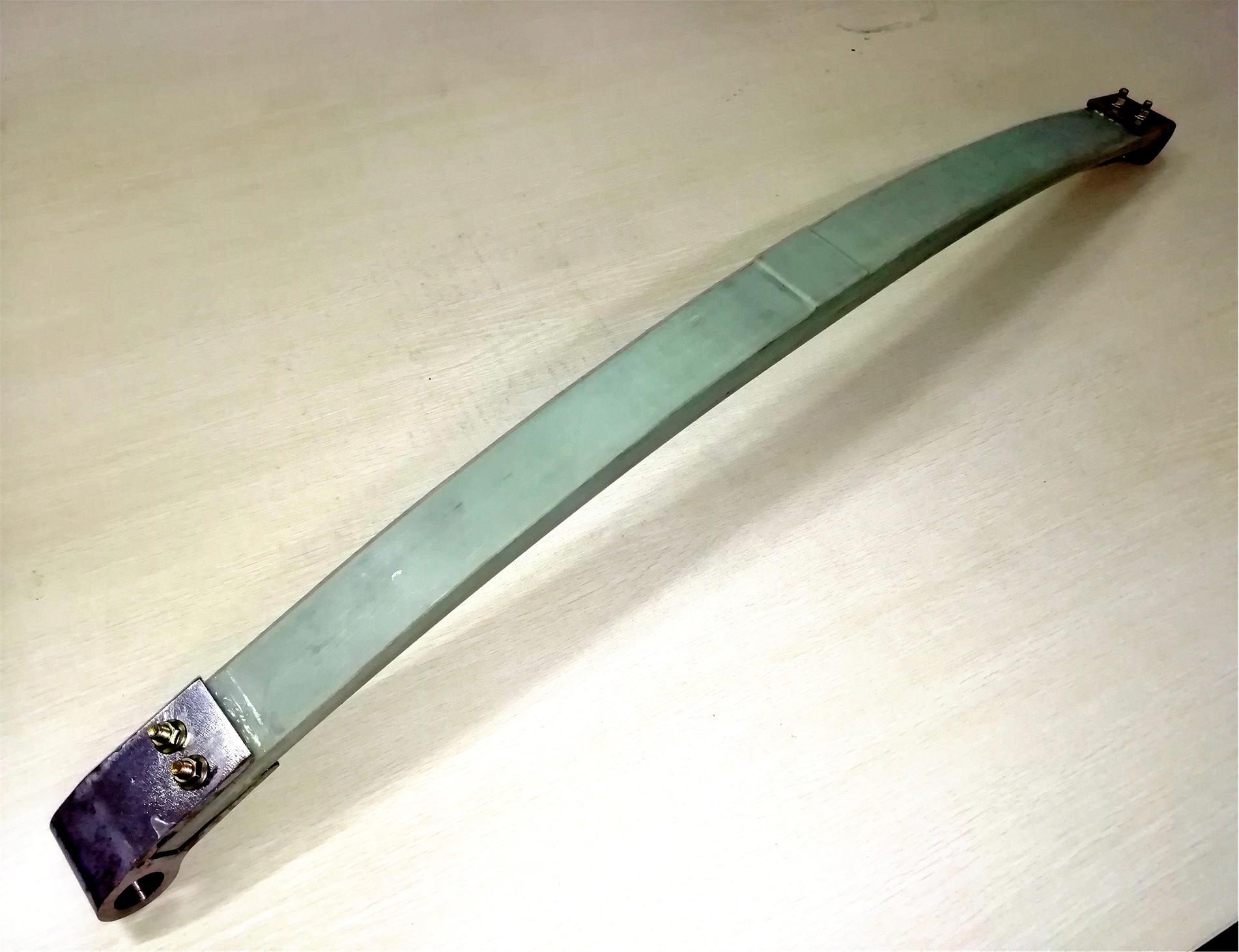

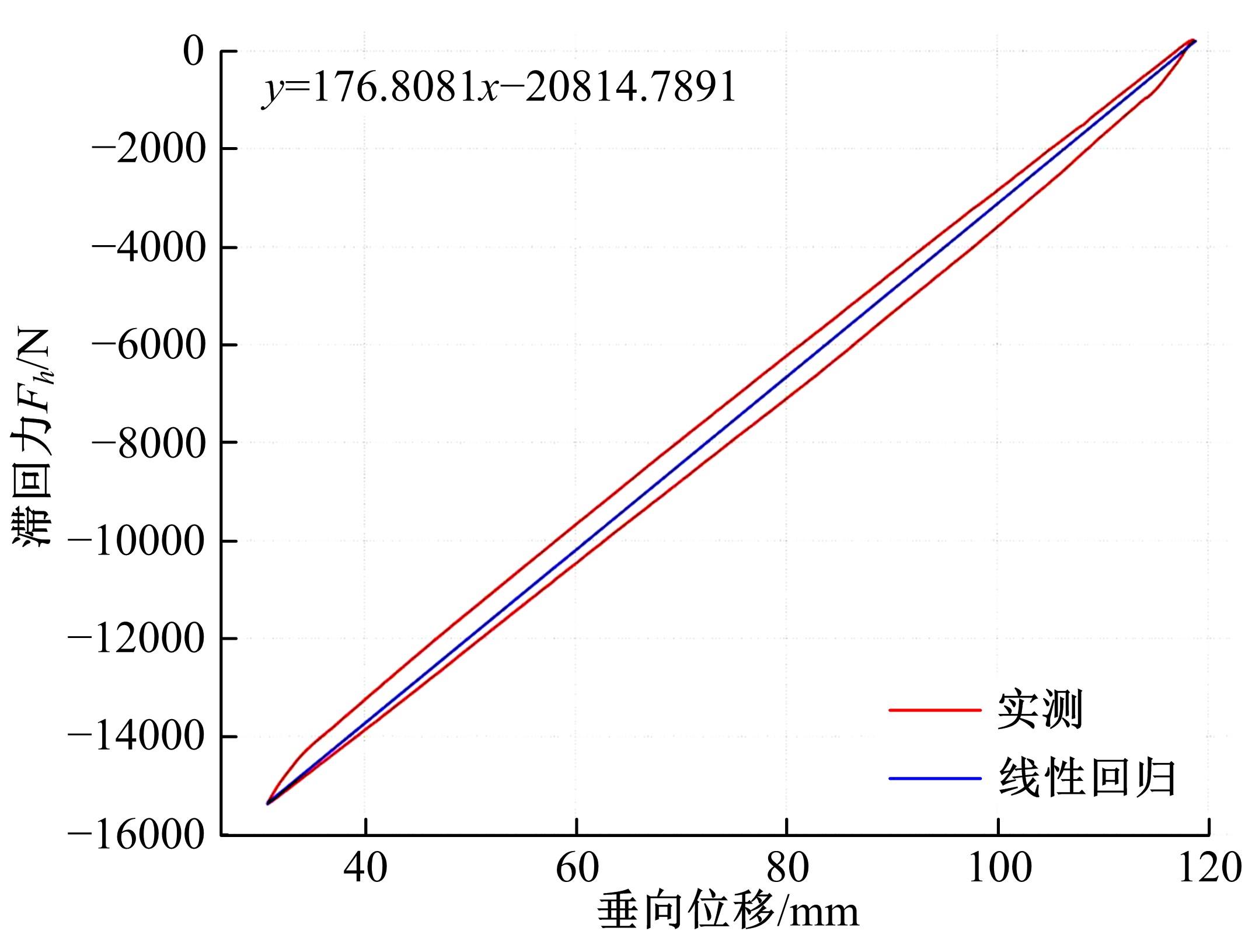

Linear identification method of hysteresis characteristic of composite leaf springs

Wei LI1( ),Hai-sheng SONG1,Hao-yu LU1,Wen-ku SHI2,Qiang WANG1,Xiao-jun WANG3(

),Hai-sheng SONG1,Hao-yu LU1,Wen-ku SHI2,Qiang WANG1,Xiao-jun WANG3( )

)

- 1.School of Automotive Engineering,Shandong Jiaotong University,Jinan 250357,China

2.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

3.School of Engineering and Machinery,Shandong Jiaotong University,Jinan 250357,China

CLC Number:

- U467.3

| 1 | 钱琛. 某轻型客车复合材料板簧关键特性建模 与性能优化 [D]. 吉林:吉林大学汽车工程学院, 2018. |

| Qian Chen. Key characteristics modeling and performance optimization of composite leaf spring for a light bus [D]. Jilin: College of Automotive Engineering, Jilin University, 2018. | |

| 2 | 王振兴,竺铝涛,沈伟.复合材料汽车板簧的应用研究进展[J].浙江理工大学学报:自然科学版, 2022,47(1):38-43. |

| Wang Zhen-xing, Zhu Lv-tao, Shen Wei. Progress in the application research of composite automobile leaf springs[J]. Journal of Zhejiang Sci-Tech University (Natural Science Edition), 2022, 47(1): 38-43. | |

| 3 | Venkatesan M, Devaraj H. Design and analysis of composite leaf spring in light vehicle[J]. International Journal of Modern Engineering Research, 2012, 2(1): 213-218. |

| 4 | Krishnamurthy K, Ravichandran P. Modeling and structural analysis of leaf spring using composite materials[J]. Materials Today: Proceedings, 2020,33: 4228-4232. |

| 5 | 柯俊,史文库,钱琛,等.复合材料板簧刚度的预测及匹配设计方法[J].浙江大学学报:工学版,2015,11(49):2103-2110. |

| Ke Jun, Shi Wen-ku, Qian Chen, et al. Prediction and matching design method for stiffness of composite leaf spring[J]. Journal of Zhejiang University (Engineering Science), 2015,11(49):2103-2110. | |

| 6 | 周孔亢,陆建辉,侯永涛,等. 基于RecurDyn的钢板弹簧动力学模型的建立与参数辨识[J]. 机械工程学报,2014,50(4):128-134. |

| Zhou Kong-kang, Lu Jian-hui, Hou Yong-tao, et al. Dynamics modeling and parameter identification of leaf spring based on RecurDyn[J]. Journal of Mechanical Engineering,2014,50(4):128-134. | |

| 7 | Rajesh S, Bhaskar B. Response of composite leaf springs to low velocity impact loading[J]. Applied Mechanics and Materials,2014,591:47-50. |

| 8 | Guillaume Puel, Béatrice Bourgeteau, Denis Aubry, et al. Parameter identification of nonlinear time-dependent rubber bushings models towards their integration in multibody simulations of a vehicle chassis [J]. Mechanical Systems and Signal Processing,2013,36(2):354-369. |

| 9 | 周金龙,董凌华,杨卫东. 直升机后缘襟翼驱动器迟滞现象仿真与抑制[J]. 航空学报,2020,41(4):144-154. |

| Zhou Jin-long, Dong Ling-hua, Yang Wei-dong. Hysteresis modeling and suppression of piezoelectric actuator for helicopter trailing edge flaps[J]. Acta Aeronautica et Astronautica Sinica,2020,41(4):144-154. | |

| 10 | 章杰,吴茵,张邦基, 等. 板簧Bouc‐Wen迟滞模型的仿真与试验研究 [J]. 汽车工程,2017,39(12):1402-1408, 1443. |

| Zhang Jie, Wu Yin, Zhang Bang-ji, et al. Simulation and experimental study on Bouc‐Wen hysteresis model of leaf spring [J]. Automotive Engineering,2017,39(12):1402-1408, 1443. | |

| 11 | 李玲,蔡安江,蔡力钢,等. 基于Bouc-Wen模型辨识结合面动态特性研究[J]. 振动与冲击,2013,32(20):139-144. |

| Li Ling, Cai An-jiang, Cai Li-gang, et al. Dynamic characteristics identification of joint interfaces based on a Bouc‐Wen model[J]. Journal of Vibration and Shock,2013,32(20):139-144. | |

| 12 | Charalampakis E, Dimou K. Identification of Bouc-Wen hysteretic systems using particle swarm optimization [J]. Computers & Structures,2010,88 (21):1197-1205. |

| 13 | 史文库,张曙光,张友坤,等. 基于改进海鸥算法的磁流变减振器模型辨识[J/OL]. [2021-11-29].. |

| 14 | 卢荡,董益量,秦民,等.钢板弹簧动态力建模[J].吉林大学学报:工学版,2011,41():12-16. |

| Lu Dang, Dong Yi-liang, Qin Min, et al. Modeling of dynamic load for leaf spring [J]. Journal of Jilin University (Engineering and Technology Edition), 2011,41(S1):12-16. | |

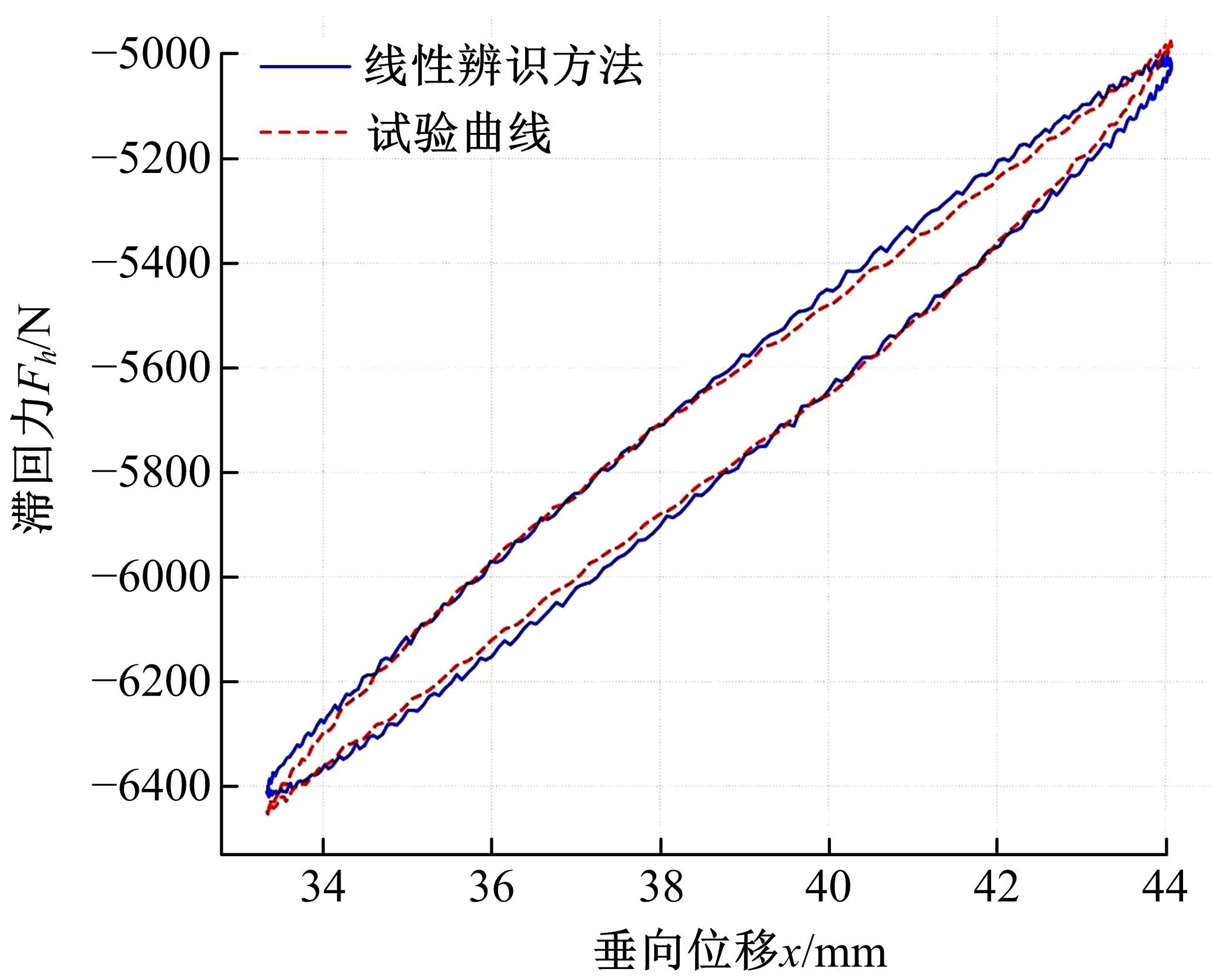

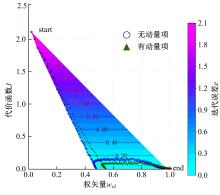

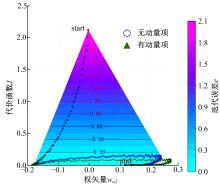

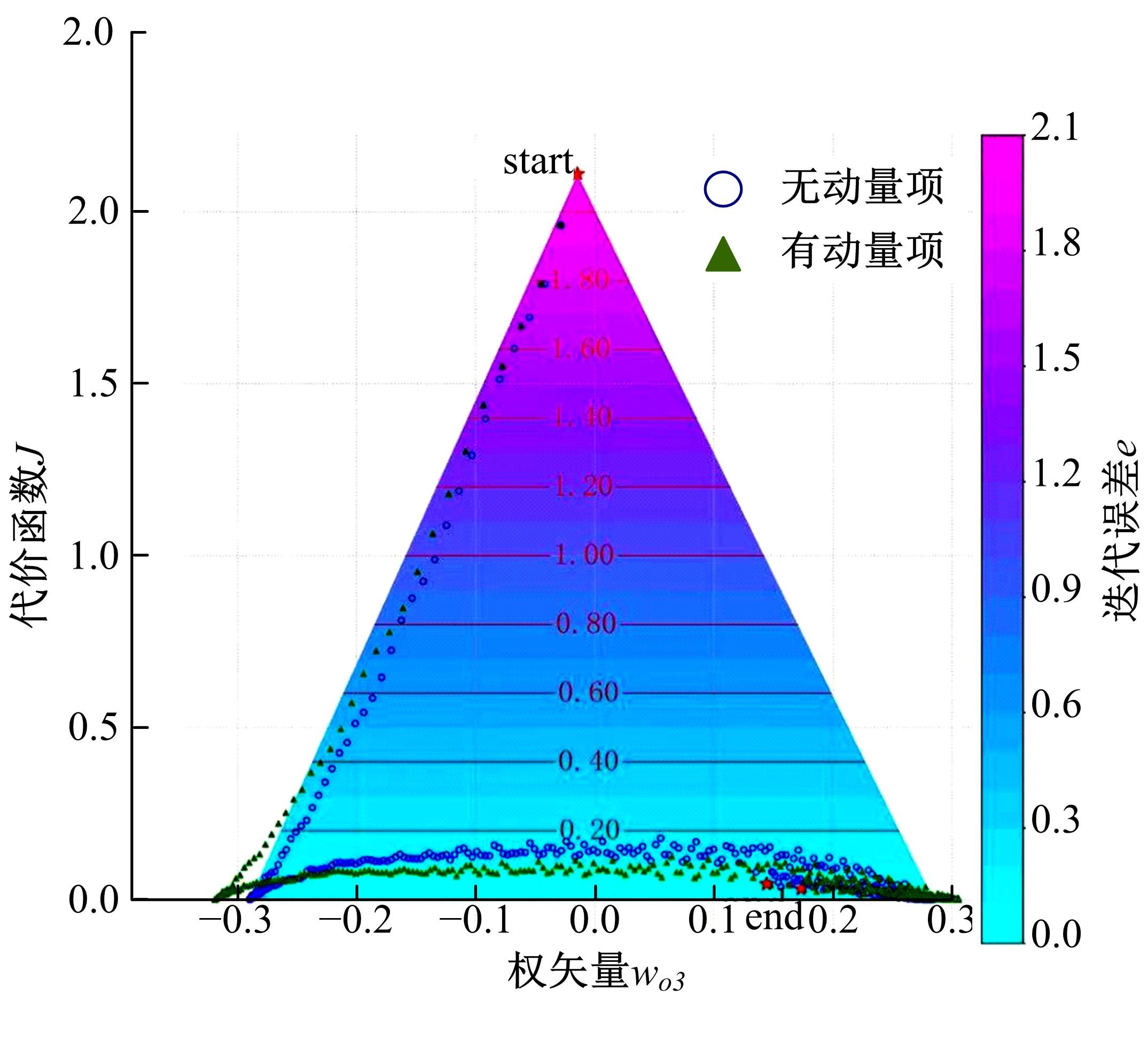

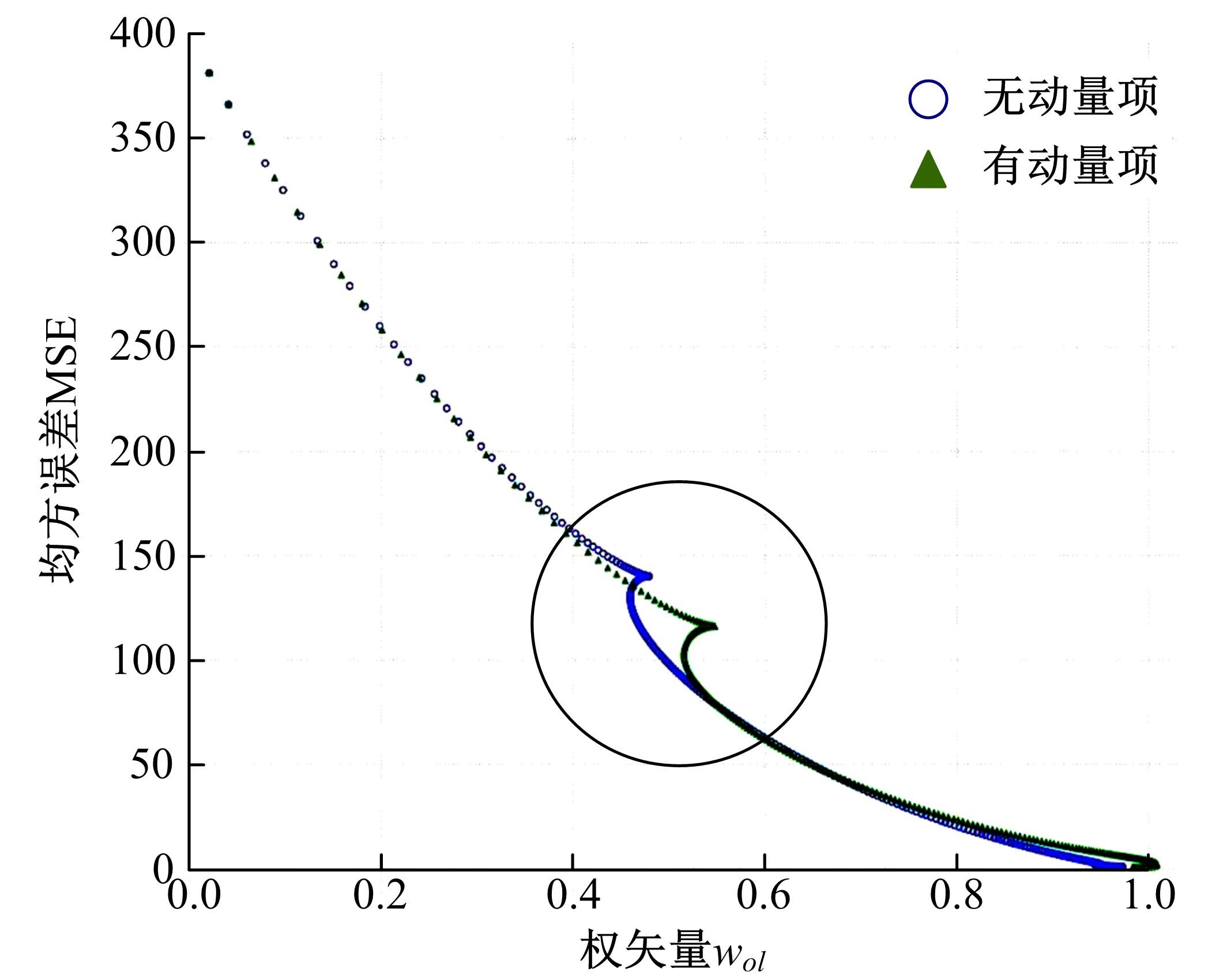

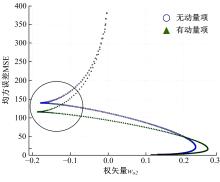

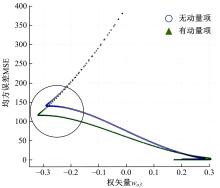

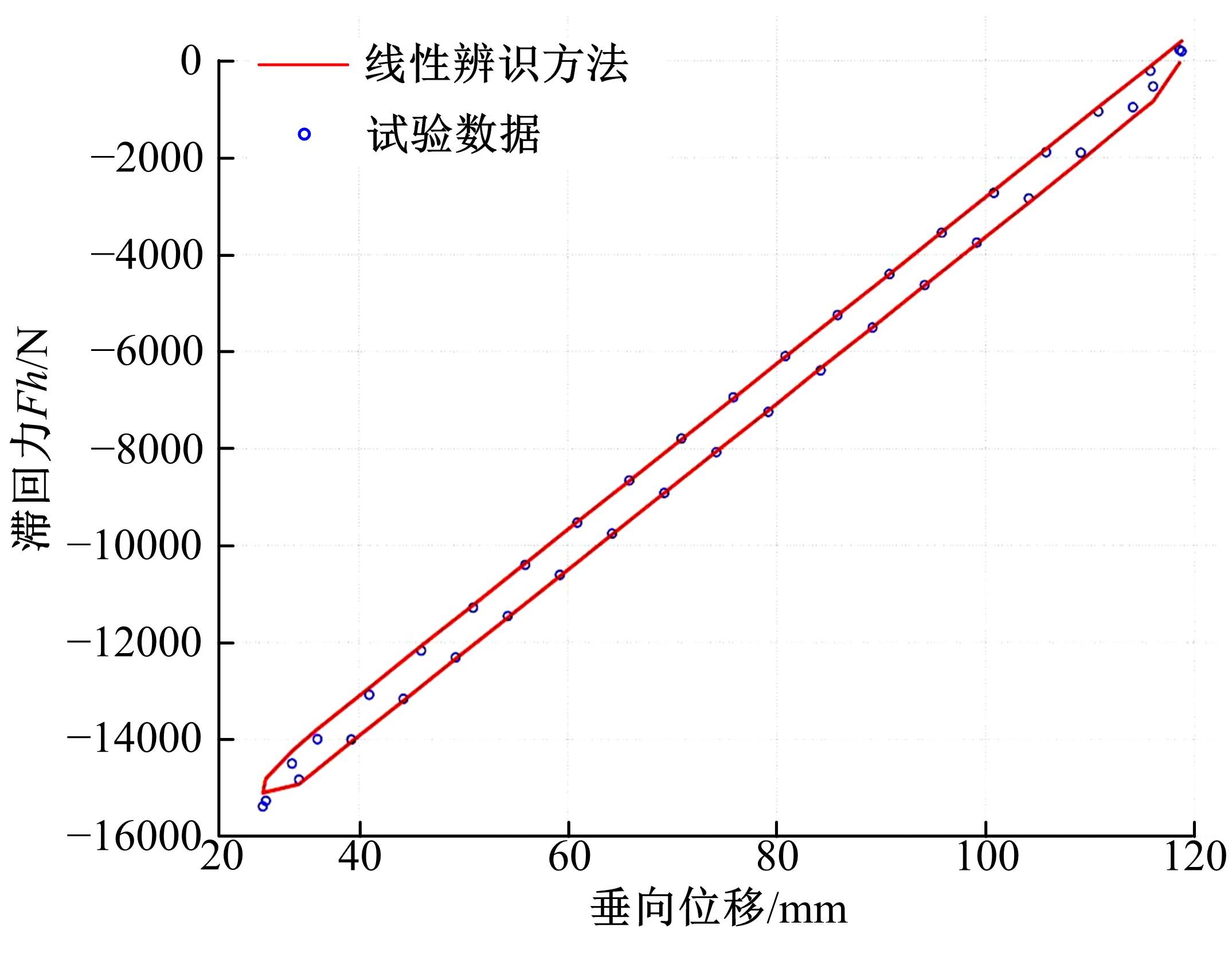

| 15 | 刘鹤龙,史文库,高蕊,等. 复合材料板簧的迟滞特性建模与试验研究[J]. 汽车工程,2021, 43(6):934-942. |

| Liu He-long, Shi Wen-ku, Gao Rui, et al. Modeling and experimental study on hysteresis characteristic of composite leaf springs [J]. Automotive Engineering, 2021, 43(6):934-942. | |

| 16 | 何荣,郭睿,管欣, 等. 钢板弹簧Fancher模型物理机理及参数辨识[J].吉林大学学报:工学版,2013,43(1):12-16. |

| He Rong, Guo Rui, Guan Xin, et al. Physical mechanism and parameter identification of Fancher leaf spring model [J]. Journal of Jilin University (Engineering and Technology Edition), 2013,43(1):12-16. | |

| 17 | 史文库,刘鹤龙,刘巧斌, 等.复合材料板簧非线性迟滞建模和参数识别[J].振动工程学报,2019,32(6):1050-1059. |

| Shi Wen-ku, Liu He-long, Liu Qiao-bin, et, al. Hysteresis characteristic modelling and parameter identification for composite leaf spring [J]. Journal of Vibration Engineering, 2019,32(6):1050-1059. | |

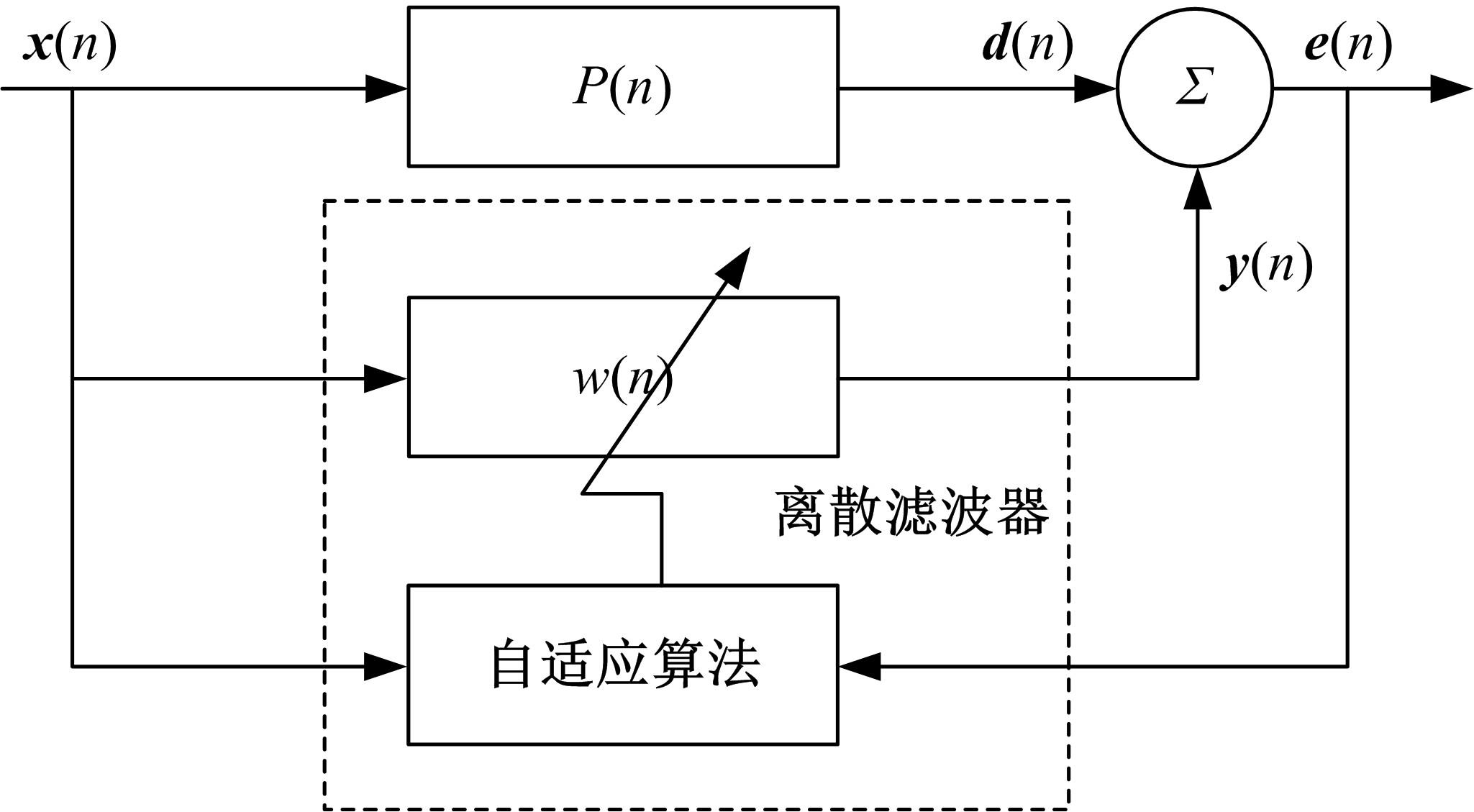

| 18 | 沈福民. 自适应信号处理 [M]. 西安:西安电子科技大学出版社,2001. |

| 19 | 陈克安. 有源噪声控制[M]. 2版.北京:国防工业出版社,2014. |

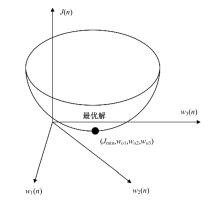

| 20 | 李士勇. 智能优化算法与涌现计算[M]. 北京:清华大学出版社,2019. |

| [1] | Jie LI,Tao CHEN,Wen-cui GUO,Qi ZHAO. Pseudo excitation method of vehicle non-stationary random vibration in space domain and its application [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 738-744. |

| [2] | Wei-min ZHUANG,Shen CHEN,Di WU. Influence of strengthening form of CFRP on transverse impact performance of steel tube [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 819-828. |

| [3] | Wen-ku SHI,Shu-guang ZHANG,You-kun ZHANG,Zhi-yong CHEN,Yi-fei JIANG,Bin-bin LIN. Parameter identification of magnetorheological damper model with modified seagull optimization algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 764-772. |

| [4] | Ying-chao ZHANG,Yun-hang LI,Zi-yu GUO,Guo-hua WANG,Zhe ZHANG,Chang SU. Optimization of the aerodynamic drag reduction of a cab behind engine vehicle [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(4): 745-753. |

| [5] | Wei-min ZHUANG,Shen CHEN,Nan WANG. Influence on thermal stress of autobody steel-aluminum clinch-adhesive connection structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 70-78. |

| [6] | Liang DUAN,Chun-yuan SONG,Chao LIU,Wei WEI,Cheng-ji LYU. State recognition in bearing temperature of high-speed train based on machine learning algorithms [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 53-62. |

| [7] | Yu-xuan WEI,Ming ZHANG,Jia LIU,Shuo LIU,Ming-yu LU,Hong-yu WANG. Buckling performance of variable stiffness composite cylindrical shells based on mode imperfections [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 91-100. |

| [8] | Xing-jun HU,Jing-long ZHANG,Yu-fei LUO,Li XIN,Sheng LI,Jin-rui HU,Wei LAN. Influence investigation of cooling tube structure and airflow direction on thermal⁃hydraulic performance of air⁃cooled charge air cooler [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1933-1942. |

| [9] | Jian-bin CHEN,Song-ze ZHOU,Feng-yong FEI,Yong-long CHEN,Guo-ping LING. Influences of interference fit and knurling connection type on press fitting failure of assembled camshaft [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(6): 1959-1966. |

| [10] | Yong LUO,Yong-heng WEI,Huan HUANG,Ren-jie XIAO,Lin REN,Huan-yu CUI. Starting control of P2.5 plug⁃in hybrid configuration dual⁃clutch based on driver's intention recognition [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1575-1582. |

| [11] | Xiao-hua ZENG,Mei-jie SONG,Da-feng SONG,Yue WANG. Data processing method of bus driving cycle based on vehicular network information [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1692-1699. |

| [12] | Chao MA,Yun-kai GAO,Zhe LIU,Yue-xing DUAN,Lin-li TIAN. Optimization of multi⁃material and beam cross⁃sectional shape and dimension of skeleton⁃type body [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1583-1592. |

| [13] | Feng-chong LAN,Ji-wen LI,Ji-qing CHEN. DG-SLAM algorithm for dynamic scene compound deep learning and parallel computing [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1437-1446. |

| [14] | Jian YANG,Qi XIA,Hai-chao ZHOU,Guo-lin WANG. Noise reduction mechanism of truck radial tire based on modified carcass string contour design [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1198-1203. |

| [15] | Jiang-qi LONG,Jin-tao XIANG,Ping YU,Jun-cheng WANG. Linear disturbance observer suitable for sliding mode control of nonlinear active suspension [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(4): 1230-1240. |

|

||